Rheology Theory and Applications

Sarah Cotts | Kimberly Dennis

June 24, 2024

Will my paint coat the wall or drip off? Will my topical pharmaceutical spread on skin or form clumps? Rheology answers vital questions to inform how we create and interact with materials on a daily basis.

What is rheology?

Rheology is the study of the deformation and flow of matter and can provide a foundational understanding of material behavior. The relationship between stress and deformation is a property of the material, so rheology helps link the properties of a sample to its overall performance. A rheometer applies stress or strain to a sample and the resulting deformation or stress is measured.

Rheology investigates materials in terms of deformation and flow. Deformation is how much a material moves when a force is applied. For example, a stress ball temporarily changes shape when you squeeze it.

Flow is the measurement of a fluid’s movement from one point to another. The opposition to flow in a material is called viscosity, with highly viscous materials having lower degrees of flow. Honey is more viscous than water and thus flows slower at room temperature.

Viscous and Elastic Material Behaviors

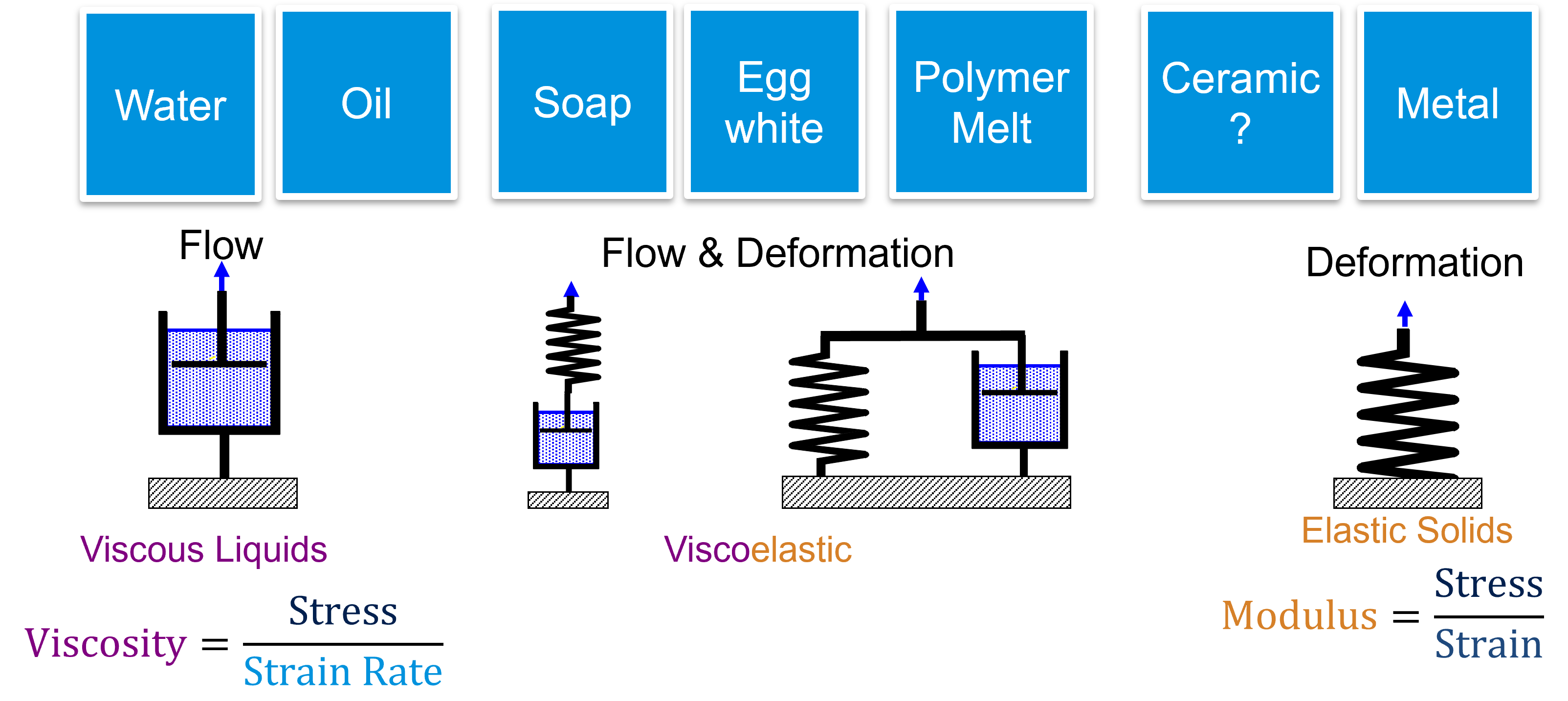

All materials exist on a spectrum between two bounds: viscous liquids, like water, and elastic solids, like metal. Most materials fall somewhere in the middle and are viscoelastic, exhibiting both viscous and elastic properties. For example, silly putty can be rolled into a ball and bounced over short times, but over long times, it flows and flattens out.

Viscous liquids are used in dashpots, which are a kind of damper that uses the viscous liquid to dissipate a plunger’s energy into heat. Elastic solids are like springs that recover from deformation. Viscoelastic materials fall somewhere in the middle, illustrated by a combination of both models.

Importance of Rheological Measurements

Since a material’s molecular structure affects its rheological properties, rheology is often used for quantitative and qualitative molecular analysis. This rheological data can provide material insights and inform structural design changes.

Rheology is frequently used to evaluate processing conditions and product performance since it can be used to link final properties back to the material’s underlying structure. For example, how do additives affect processing a polymer melt? And will that same polymer maintain its shape when it is molded into a car component? Rheology thus supports successful material design and quality control testing.

Newtonian and Non-Newtonian Fluids

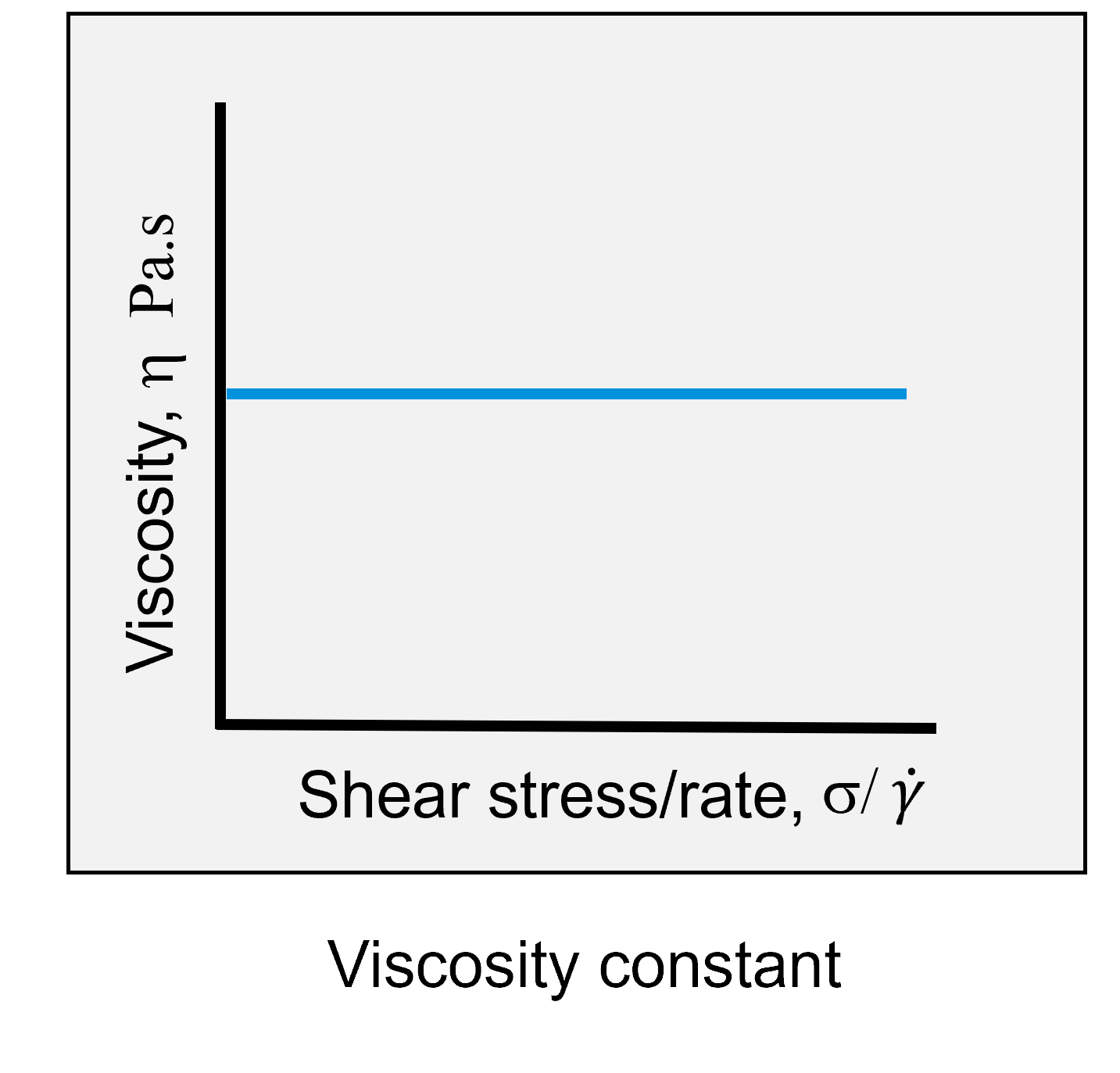

Within viscous fluids, there is an important distinction based on their viscosity. A Newtonian fluid’s viscosity is independent of shear rate or shear stress. Viscosity measurements as a function of shear rate or shear stress show a flat line like in the figure below, meaning their viscosity is constant. Examples of Newtonian fluids include water, ethanol, and cooking oil.

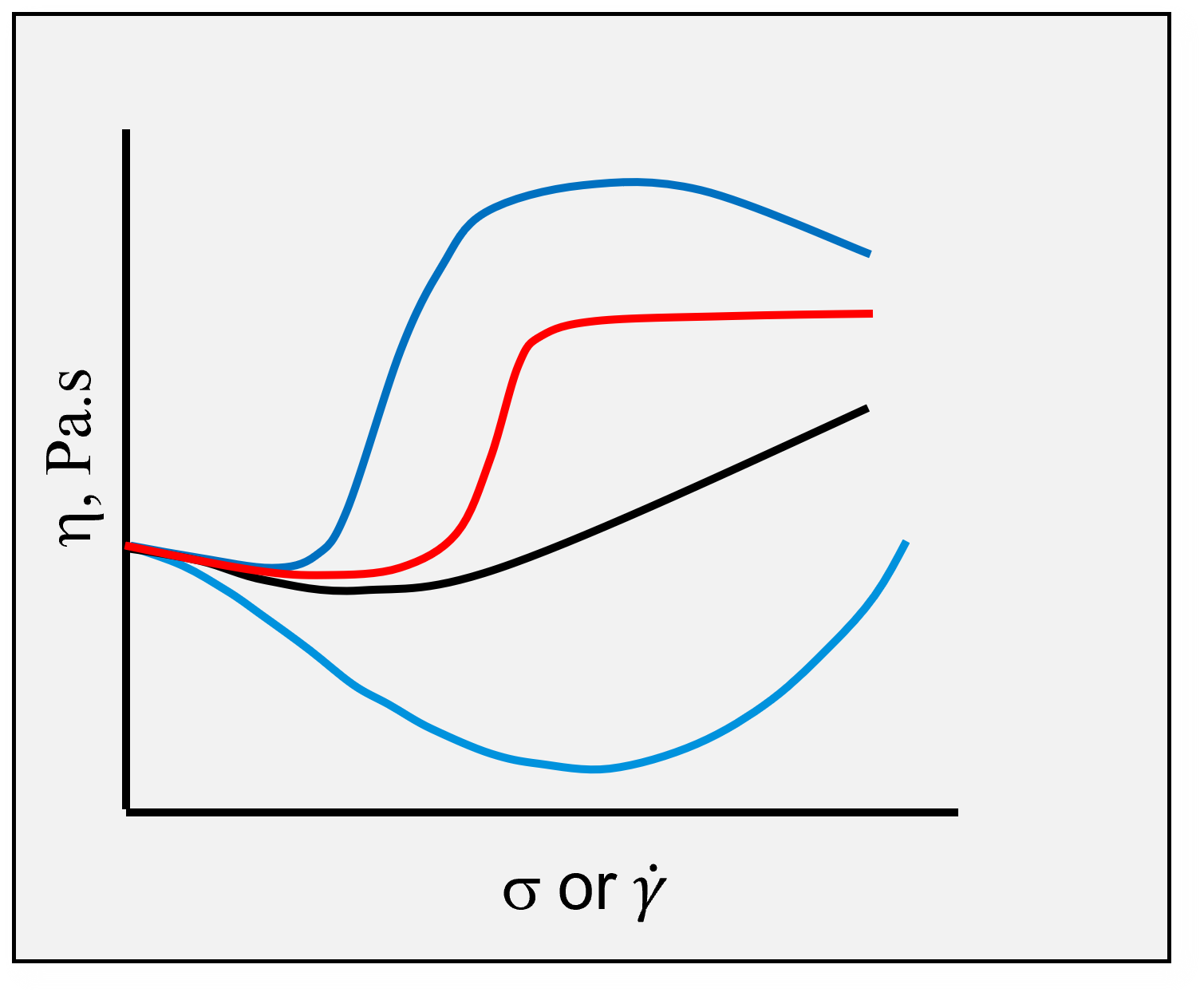

Non-Newtonian fluids exhibit a viscosity change with shear rate and shear stress. If viscosity increases, the fluid is shear thickening, like the materials measured on the plot below. For example, a highly concentrated cornstarch slurry is shear thickening and becomes more viscous as you stir it.

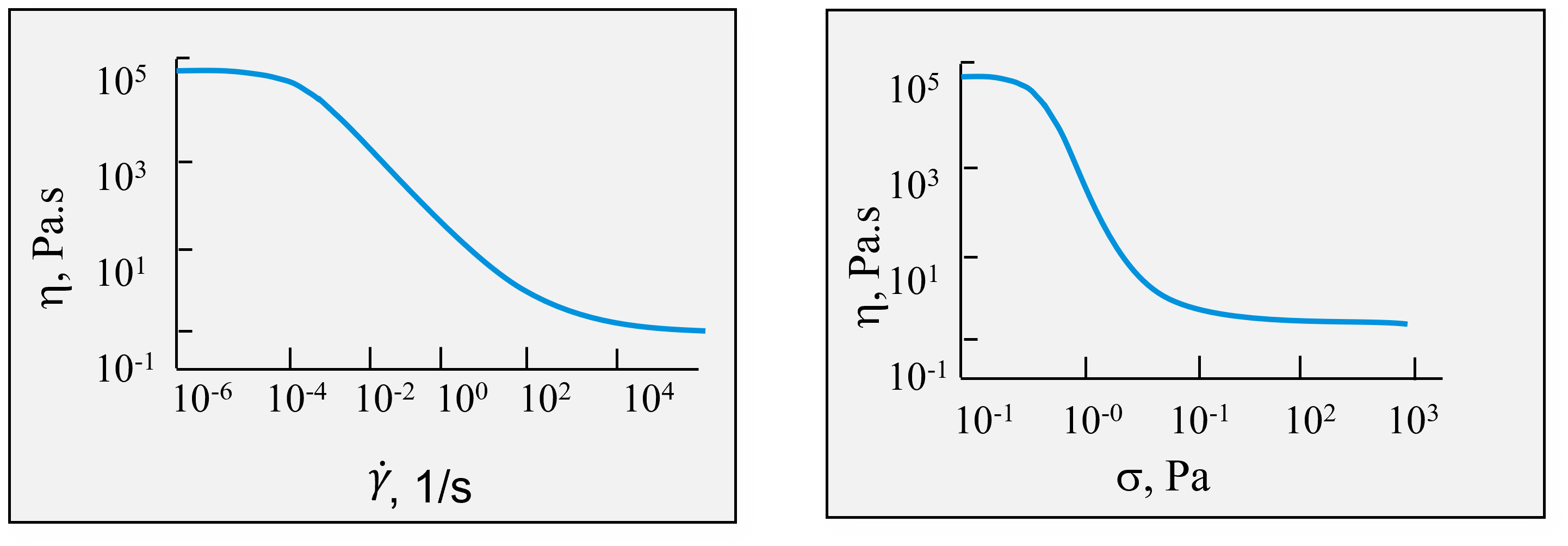

If viscosity decreases with shear rate and shear stress, the fluid is shear thinning, shown in the plots below. Hand soap is shear thinning – it becomes less viscous as you apply stress by rubbing it between your hands.

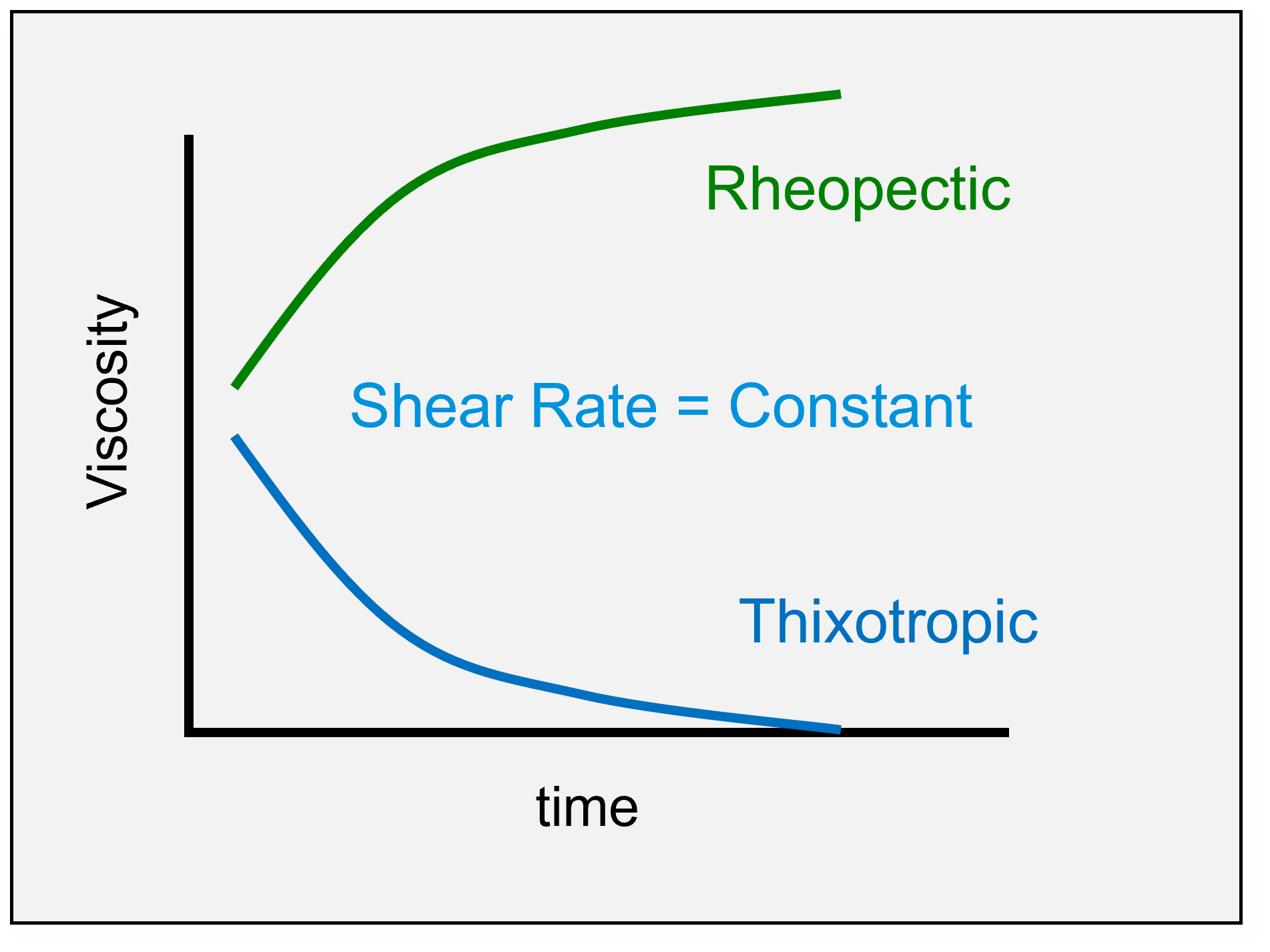

Non-Newtonian fluids often have viscosity properties that are time-dependent. In these cases, the shear rate or stress is kept constant and time is the variable instead. If the viscosity increases over time, the material is known as rheopectic, like the green line below. If it decreases with time, the material is known as thixotropic, like the blue line below. Printer ink is rheopectic, and shaving cream is thixotropic.

Overall, rheology provides a way to characterize material deformation and flow based on its response to applied stress. Rheometers apply and measure wide ranges of stress, strain, and strain rate, while simultaneously controlling the material’s environment. Rheology thus offers important information for successful material processing and optimal end-use performance.

Contact TA Instruments for an expert opinion on how rheology can facilitate your material design, analysis, and manufacturing.

Other Resources

- Blog – What are Rheometry and Rheology?

- Application Note – Polymer Flow and Mechanical Characterization for Material Development, Processing, and Performance

- Application Note – Effect of Moisture and Substrate Material on Wall Friction Angle of Carboxymethyl Cellulose Powder

- Application Note – Polymer Melt Rheology Workflow Automation: Auto-Trim Accessory for Discovery Hybrid Rheometers

- Application Note – Rheological Analysis of Hydrogel Materials