Combining industry-leading performance with a modular, user-configurable platform results in a flexible test instrument that can adapt to changing test requirements.

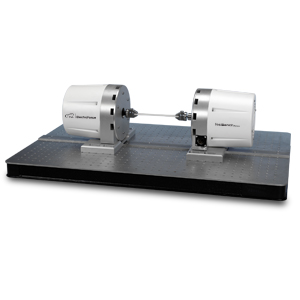

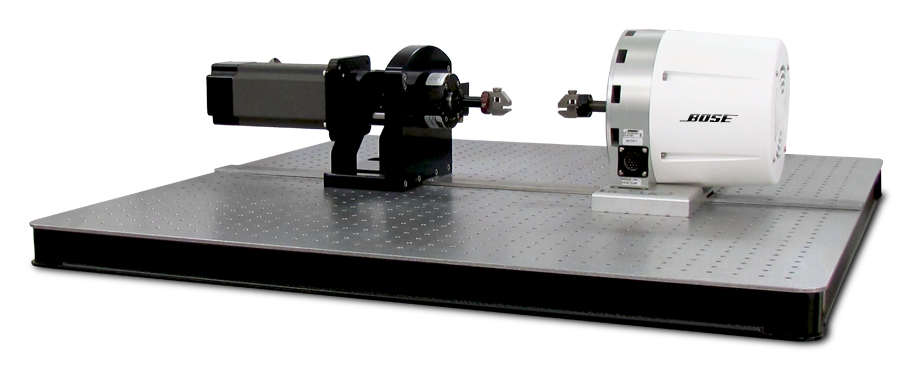

Sales PromotionsElectroForce TestBench configurations were designed with component testing in mind, and thanks to their modular approach, a wide array of configurations and performance capabilities are possible. These instruments can be configured with 200N or 400N ElectroForce linear motors mounted on a horizontal baseplate and include multi-channel and multi-axis options.

Reaction brackets are pre-designed to allow attachment of components or the test specimen to the mounting baseplate. In addition, a saline bath can be provided as an environmental option. By selecting the proper baseplate and ElectroForce® motor packages, a variety of testing needs can be addressed.

Key Features

- Superior performance: choose parameters for your test protocol without compromising accuracy, including force, displacement, frequency, and wave shape (loading profile)

- Controllability: precisely characterize different materials by controlling specific experimental parameters, including load, displacement, and strain control (with the Digital Video Extensometer (DVE))

- Tailored for specific research needs: optional configurations for horizontal or vertical mounting, accessories such as saline baths, and multi-axis loading, including additional ElectroForce linear motors, extended stroke actuators, and rotary motors

ElectroForce Linear Motors

ElectroForce Linear Motors

ElectroForce linear actuators can be chosen for 200N or 400N force capacity with a 13mm displacement range. Additional actuators can be mounted to the base plate and operated independently or simultaneously.

Extended Stroke Actuators

Extended Stroke Actuators

The Extended Stroke Actuator significantly extends the range of testing capability, delivering high frequency, dynamic testing with more than 160 mm of displacement for creep/pull-to-failure test protocols in one instrument. The extra displacement is beneficial for biomaterials and tissue testing applications, including tendons, ligaments and skin in which high strain is often expected. In addition, there are many traditional material testing applications involving polymers, elastomers, and thin films for which this long-stroke capability is also required.

The ES test instruments, combining high-frequency dynamic testing and creep/pull-to-failure capabilities in a single test instrument, are available in a variety of configurations. In addition, customers using earlier versions of the ElectroForce 3200 and LM1 TestBench instruments can upgrade to the new range of displacement.

Rotary Motors

Rotary Motors

A 5.6Nm rotary brushless motor is an option for the 200N/400N TestBench instruments. It is useful for fine control, low torque applications with or without axial loading. It can be configured for continuous rotation for applications such as screw insertion simulation.

Motor Technology Benefits

Reliable testing

Reliable testing

- 10-year ElectroForce® motor warranty

- ElectroForce motor designed, developed and manufactured by TA Electroforce to exacting standards

- Frictionless design ensures optimal control and long-life for a variety of durability testing applications

High-fidelity, responsive control

High-fidelity, responsive control

- Accurate control and high-resolution performance provides more precise material properties

- Very low motor moving-mass provides industry leading frequency response

Low-force control applications

Low-force control applications

- No motor friction or stiction provides accurate, low-force testing

- Excellent control from gram-force loads to 200N, providing versatility for a variety of tests

Clean, electromagnetic technology

Clean, electromagnetic technology

- Standard ElectroForce® systems can be used in clean rooms or incubators for exceptional versatility

- Efficient electromagnetic power conversion is well-suited for a variety of test environments

Energy-efficient technology

Energy-efficient technology

- Efficient power utilization reduces operating costs

- Lab-friendly instruments and easy installation allows testing to start immediately

- No expensive infrastructure or contamination – saves upfront costs and operating expense

Software Technology Benefits

Easy-to-use, flexible software

Easy-to-use, flexible software

- Test setup and status window to guide users

- Customizable windows and views

- Intuitive and configurable test setup

- Multiple test monitoring sources

Direct control over your data

Direct control over your data

- Customizable and flexible data collection

- Control of data acquisition before and during the test

- Data is stored even if test stops unexpectedly

Real-time test parameter control

Real-time test parameter control

- Adjust waveforms in real-time

- No need to stop test to reconfigure major test parameters

Security and history tracking

Security and history tracking

- User login for added security

- Secure workspace with audit trail traceability

- File system security to protect test files

- Description

-

ElectroForce TestBench configurations were designed with component testing in mind, and thanks to their modular approach, a wide array of configurations and performance capabilities are possible. These instruments can be configured with 200N or 400N ElectroForce linear motors mounted on a horizontal baseplate and include multi-channel and multi-axis options.

Reaction brackets are pre-designed to allow attachment of components or the test specimen to the mounting baseplate. In addition, a saline bath can be provided as an environmental option. By selecting the proper baseplate and ElectroForce® motor packages, a variety of testing needs can be addressed.

Key Features

- Superior performance: choose parameters for your test protocol without compromising accuracy, including force, displacement, frequency, and wave shape (loading profile)

- Controllability: precisely characterize different materials by controlling specific experimental parameters, including load, displacement, and strain control (with the Digital Video Extensometer (DVE))

- Tailored for specific research needs: optional configurations for horizontal or vertical mounting, accessories such as saline baths, and multi-axis loading, including additional ElectroForce linear motors, extended stroke actuators, and rotary motors

- Instrument Configurations

-

ElectroForce Linear Motors

ElectroForce Linear Motors

ElectroForce linear actuators can be chosen for 200N or 400N force capacity with a 13mm displacement range. Additional actuators can be mounted to the base plate and operated independently or simultaneously.

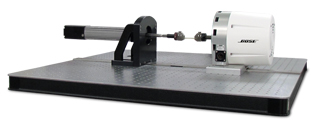

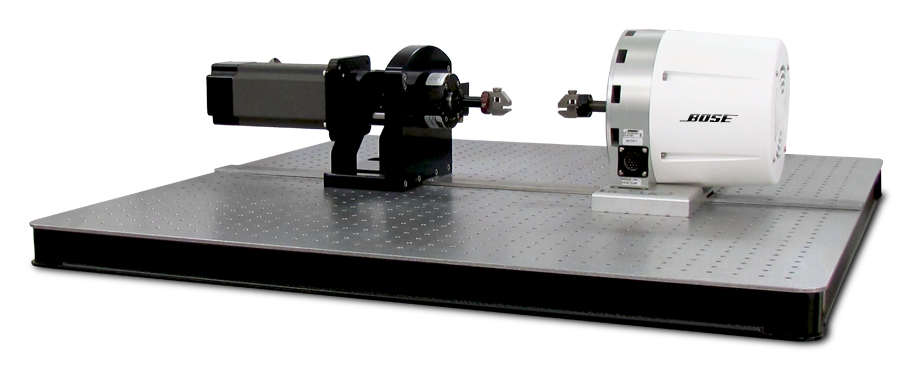

Extended Stroke Actuators

Extended Stroke Actuators

The Extended Stroke Actuator significantly extends the range of testing capability, delivering high frequency, dynamic testing with more than 160 mm of displacement for creep/pull-to-failure test protocols in one instrument. The extra displacement is beneficial for biomaterials and tissue testing applications, including tendons, ligaments and skin in which high strain is often expected. In addition, there are many traditional material testing applications involving polymers, elastomers, and thin films for which this long-stroke capability is also required.

The ES test instruments, combining high-frequency dynamic testing and creep/pull-to-failure capabilities in a single test instrument, are available in a variety of configurations. In addition, customers using earlier versions of the ElectroForce 3200 and LM1 TestBench instruments can upgrade to the new range of displacement.

Rotary Motors

Rotary Motors

A 5.6Nm rotary brushless motor is an option for the 200N/400N TestBench instruments. It is useful for fine control, low torque applications with or without axial loading. It can be configured for continuous rotation for applications such as screw insertion simulation.

- Technology Benefits

-

Motor Technology Benefits

Reliable testing

Reliable testing

- 10-year ElectroForce® motor warranty

- ElectroForce motor designed, developed and manufactured by TA Electroforce to exacting standards

- Frictionless design ensures optimal control and long-life for a variety of durability testing applications

High-fidelity, responsive control

High-fidelity, responsive control

- Accurate control and high-resolution performance provides more precise material properties

- Very low motor moving-mass provides industry leading frequency response

Low-force control applications

Low-force control applications

- No motor friction or stiction provides accurate, low-force testing

- Excellent control from gram-force loads to 200N, providing versatility for a variety of tests

Clean, electromagnetic technology

Clean, electromagnetic technology

- Standard ElectroForce® systems can be used in clean rooms or incubators for exceptional versatility

- Efficient electromagnetic power conversion is well-suited for a variety of test environments

Energy-efficient technology

Energy-efficient technology

- Efficient power utilization reduces operating costs

- Lab-friendly instruments and easy installation allows testing to start immediately

- No expensive infrastructure or contamination – saves upfront costs and operating expense

Software Technology Benefits

Easy-to-use, flexible software

Easy-to-use, flexible software

- Test setup and status window to guide users

- Customizable windows and views

- Intuitive and configurable test setup

- Multiple test monitoring sources

Direct control over your data

Direct control over your data

- Customizable and flexible data collection

- Control of data acquisition before and during the test

- Data is stored even if test stops unexpectedly

Real-time test parameter control

Real-time test parameter control

- Adjust waveforms in real-time

- No need to stop test to reconfigure major test parameters

Security and history tracking

Security and history tracking

- User login for added security

- Secure workspace with audit trail traceability

- File system security to protect test files

- Resources