DuraPulse™ Stent/Graft Test

(SGT) Instrument

DuraPulse™ SGTs provide unrivaled dynamic performance & proven reliability over billions of maintenance-free cycles for accelerated pulsatile stent testing.

The NEW DuraPulse™ Stent/Graft test (SGT) instrument extends the performance and reliability that ElectroForce SGTs have become known for over the past 20 years. Still utilizing proprietary high-bandwidth, low-distortion ElectroForce actuator technology to provide best-in-class performance, the DuraPulse SGT incorporates a modular manifold design that allows the user to easily change out manifold and tube sets to optimize sample throughput for various stented device sizes. An enhanced software user interface is easier to use and includes inner diameter (ID) and outer diameter (OD) radial strain calculations, improved strain control modes, and simplified data acquisition.

Key Benefits:

- Achieve highest strain and frequency combinations with closed-loop, symmetric dual-sided pulse

- Single test instrument can be optimized for device geometry and sample number with interchangeable manifold sets – 12, 8, 6, and 4 (bifurcated) mock vessel options

- Accommodates wide range of device diameters – 2 mm to 50 mm

- Conveniently measure tube strain across all tubes with optical micrometer positioning slide and 360° manifold rotation, and a tube scanning function that holds command levels and allows the laser to be repositioned during testing

- Select from 3 ID/OD Strain Calculation modes including Zero Strain or Zero Stress Conditions (as defined by ISO 25539-2)

- Automate test pressure control with optional Pressure Control Accessory (PCA)

- Clearly identify system operation state with System Status Indicator (SSI) lights

- Instrument reliability for years of use supported by industry leading 10 year actuator warranty

- Meets or exceeds international testing standards such as ISO 25539-2 and ASTM F2477

Motor Technology Benefits

Reliable testing

Reliable testing

- 10-year ElectroForce® motor warranty

- ElectroForce motor designed, developed and manufactured by TA Electroforce to exacting standards

- Frictionless design ensures optimal control and long-life for a variety of durability testing applications

High-fidelity, responsive control

High-fidelity, responsive control

- Accurate control and high-resolution performance provides more precise material properties

- Very low motor moving-mass provides industry leading frequency response

Low-force control applications

Low-force control applications

- No motor friction or stiction provides accurate, low-force testing

- Excellent control from gram-force loads to 200N, providing versatility for a variety of tests

Clean, electromagnetic technology

Clean, electromagnetic technology

- Standard ElectroForce® systems can be used in clean rooms or incubators for exceptional versatility

- Efficient electromagnetic power conversion is well-suited for a variety of test environments

Energy-efficient technology

Energy-efficient technology

- Efficient power utilization reduces operating costs

- Lab-friendly instruments and easy installation allows testing to start immediately

- No expensive infrastructure or contamination – saves upfront costs and operating expense

Software Technology Benefits

Easy-to-use, flexible software

Easy-to-use, flexible software

- Test setup and status window to guide users

- Customizable windows and views

- Intuitive and configurable test setup

- Multiple test monitoring sources

Direct control over your data

Direct control over your data

- Customizable and flexible data collection

- Control of data acquisition before and during the test

- Data is stored even if test stops unexpectedly

Real-time test parameter control

Real-time test parameter control

- Adjust waveforms in real-time

- No need to stop test to reconfigure major test parameters

Security and history tracking

Security and history tracking

- User login for added security

- Secure workspace with audit trail traceability

- File system security to protect test files

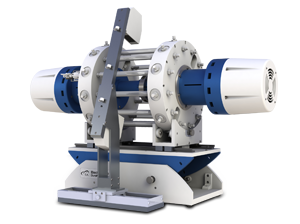

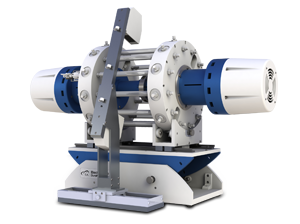

12 Tube DuraPulse SGT

12 Tube DuraPulse SGT

12 Tube DuraPulse SGT

Twelve tube configuration for pulsatile fatigue of coronary or neural stents (device diameter range of 2 mm to 10 mm) with optical strain measurement accessory.

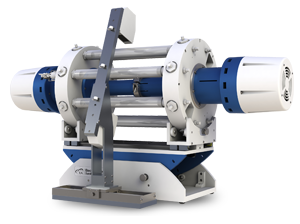

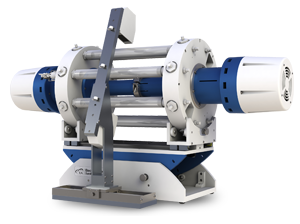

8 Tube DuraPulse SGT

8 Tube DuraPulse SGT

8 Tube DuraPulse SGT

Eight tube configuration for pulsatile fatigue of stents (mean stent diameter range of 2.5 to 32 mm) with optical radial strain measurement

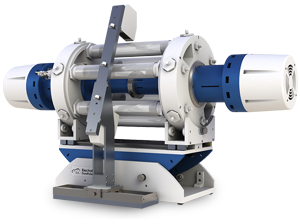

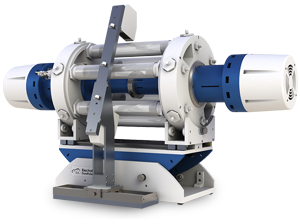

6 Tube DuraPulse SGT

6 Tube DuraPulse SGT

6 Tube DuraPulse SGT

Six tube configuration for pulsatile fatigue of thoracic stents, filters and other devices including larger stented heart valve frames (device diameter range of 25 mm to 50 mm) with optical strain measurement accessory.

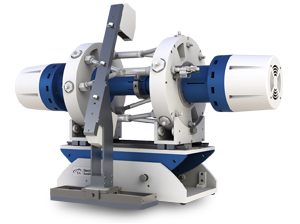

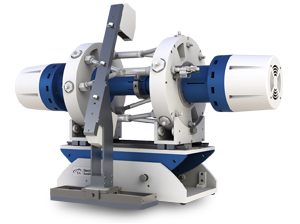

4 Tube DuraPulse SGT

4 Tube DuraPulse SGT

4 Tube DuraPulse SGT

Four bifurcated tube configuration for pulsatile fatigue of AAA branched stents (stent diameter range of: 10 mm to 18 mm for iliacs; 18 mm to 30 mm for aorta) with optical strain measurement accessory.

- Description

-

The NEW DuraPulse™ Stent/Graft test (SGT) instrument extends the performance and reliability that ElectroForce SGTs have become known for over the past 20 years. Still utilizing proprietary high-bandwidth, low-distortion ElectroForce actuator technology to provide best-in-class performance, the DuraPulse SGT incorporates a modular manifold design that allows the user to easily change out manifold and tube sets to optimize sample throughput for various stented device sizes. An enhanced software user interface is easier to use and includes inner diameter (ID) and outer diameter (OD) radial strain calculations, improved strain control modes, and simplified data acquisition.

Key Benefits:

- Achieve highest strain and frequency combinations with closed-loop, symmetric dual-sided pulse

- Single test instrument can be optimized for device geometry and sample number with interchangeable manifold sets – 12, 8, 6, and 4 (bifurcated) mock vessel options

- Accommodates wide range of device diameters – 2 mm to 50 mm

- Conveniently measure tube strain across all tubes with optical micrometer positioning slide and 360° manifold rotation, and a tube scanning function that holds command levels and allows the laser to be repositioned during testing

- Select from 3 ID/OD Strain Calculation modes including Zero Strain or Zero Stress Conditions (as defined by ISO 25539-2)

- Automate test pressure control with optional Pressure Control Accessory (PCA)

- Clearly identify system operation state with System Status Indicator (SSI) lights

- Instrument reliability for years of use supported by industry leading 10 year actuator warranty

- Meets or exceeds international testing standards such as ISO 25539-2 and ASTM F2477

- Technology Benefits

-

Motor Technology Benefits

Reliable testing

Reliable testing

- 10-year ElectroForce® motor warranty

- ElectroForce motor designed, developed and manufactured by TA Electroforce to exacting standards

- Frictionless design ensures optimal control and long-life for a variety of durability testing applications

High-fidelity, responsive control

High-fidelity, responsive control

- Accurate control and high-resolution performance provides more precise material properties

- Very low motor moving-mass provides industry leading frequency response

Low-force control applications

Low-force control applications

- No motor friction or stiction provides accurate, low-force testing

- Excellent control from gram-force loads to 200N, providing versatility for a variety of tests

Clean, electromagnetic technology

Clean, electromagnetic technology

- Standard ElectroForce® systems can be used in clean rooms or incubators for exceptional versatility

- Efficient electromagnetic power conversion is well-suited for a variety of test environments

Energy-efficient technology

Energy-efficient technology

- Efficient power utilization reduces operating costs

- Lab-friendly instruments and easy installation allows testing to start immediately

- No expensive infrastructure or contamination – saves upfront costs and operating expense

Software Technology Benefits

Easy-to-use, flexible software

Easy-to-use, flexible software

- Test setup and status window to guide users

- Customizable windows and views

- Intuitive and configurable test setup

- Multiple test monitoring sources

Direct control over your data

Direct control over your data

- Customizable and flexible data collection

- Control of data acquisition before and during the test

- Data is stored even if test stops unexpectedly

Real-time test parameter control

Real-time test parameter control

- Adjust waveforms in real-time

- No need to stop test to reconfigure major test parameters

Security and history tracking

Security and history tracking

- User login for added security

- Secure workspace with audit trail traceability

- File system security to protect test files

- Instrument Configurations

-

12 Tube DuraPulse SGT

12 Tube DuraPulse SGT

12 Tube DuraPulse SGT

Twelve tube configuration for pulsatile fatigue of coronary or neural stents (device diameter range of 2 mm to 10 mm) with optical strain measurement accessory.

8 Tube DuraPulse SGT

8 Tube DuraPulse SGT

8 Tube DuraPulse SGT

Eight tube configuration for pulsatile fatigue of stents (mean stent diameter range of 2.5 to 32 mm) with optical radial strain measurement

6 Tube DuraPulse SGT

6 Tube DuraPulse SGT

6 Tube DuraPulse SGT

Six tube configuration for pulsatile fatigue of thoracic stents, filters and other devices including larger stented heart valve frames (device diameter range of 25 mm to 50 mm) with optical strain measurement accessory.

4 Tube DuraPulse SGT

4 Tube DuraPulse SGT

4 Tube DuraPulse SGT

Four bifurcated tube configuration for pulsatile fatigue of AAA branched stents (stent diameter range of: 10 mm to 18 mm for iliacs; 18 mm to 30 mm for aorta) with optical strain measurement accessory.

- Resources

- Video

-