Unmatched dynamic performance envelope and versatility for applications that require up to 3 kN.

ElectroForce 3300 Series III instruments are well-suited for a variety of tests that include ASTM and ISO standards for materials and biomaterials characterization and long-term durability tests of materials, components and devices.

The ElectroForce 3300 family includes two models; the ElectroForce 3310 provides 1000 N of maximum force while the ElectroForce 3330 provides 3000 N. Both models are available with either table-top or floor-standing frames. The floor-standing frame enables the expansion of capabilities by either adding torsion or extended stroke motors. All configurations can perform tests that range from one cycle per day (or static tests) up to 100 Hz. Select the force capacity and frame configuration that is appropriate for your testing needs.

Key Features

- High resolution and high accuracy displacement measurement for both the dynamic axial motor and the optional torsional motor

- Static to 100 Hz dynamic performance for a variety of applications

- Integrated System Status Indicator (SSI) Light for highly visible color-coded display of instrument status

- Electric motor driven test space adjustment with convenient locks, plus the added convenience of the lower Micro-adjust for precision alignment of grips.

- Optional 14 Nm and 25 Nm torsional motor are available for multi-axial test applications

- Optional 150 mm stroke extension motor to increase the instrument versatility for slower longer-travel tests

- Accommodates a variety of environmental chambers including temperature-controlled saline baths and hot/cold chambers

3300 Series III Specifications Table

| Product Specifications | ElectroForce 3310 | ElectroForce 3330 |

| Force – Peak/Max Sine | ± 1000 N | ± 3000 N |

| Force – Static or RMS (continuous) | ± 700 N | ± 2100 N |

| Displacement | 25 mm | 25 mm |

| Linear Velocity | 0.013 μm/s – 1.5 m/s | 0.013 μm/s – 2.0 m/s |

| Frequency | 0.00001 Hz – 100 Hz | 0.00001 Hz – 100 Hz |

| Torsional Motor Option | ||

| Torque – Peak/Max | ± 14 N-m | ± 25 N-m |

| Torque – Static or RMS (continuous) | ± 14 N-m | ± 25 N-m |

| Rotation | Multi-Turn (62 Revolutions) | Multi-Turn (62 Revolutions) |

| Extended Stroke (ES) Option | ||

| Displacement | 150 mm | 150 mm |

Motor Technology Benefits

Reliable testing

Reliable testing

- 10-year ElectroForce® motor warranty

- ElectroForce motor designed, developed and manufactured by TA Electroforce to exacting standards

- Frictionless design ensures optimal control and long-life for a variety of durability testing applications

- Integrated Air-bearing preserves frictionless benefits even in the presence of moderate side loads

High-fidelity, responsive control

High-fidelity, responsive control

- Accurate control and high-resolution performance provides more precise material properties

- Very low motor moving-mass provides industry leading frequency response

Low-force control applications

Low-force control applications

- No motor friction or stiction provides accurate, low-force testing

- Model 3330 delivers a wide range of controlled forces, from below 1 N forces to 3000 N, providing versatility for a variety of tests.

- Model 3310 features a high precision amplifier package to deliver even better low-force control, from below 0.1N to 1000N

Clean, electromagnetic technology

Clean, electromagnetic technology

- Standard ElectroForce® systems can be used in clean rooms or incubators for exceptional versatility

- Efficient electromagnetic power conversion is well-suited for a variety of test environments

Energy-efficient technology

Energy-efficient technology

- Efficient power utilization reduces operating costs

- Lab-friendly instruments and easy installation allows testing to start immediately

- No expensive infrastructure or contamination – saves upfront costs and operating expense

Software Technology Benefits

Easy-to-use, flexible software

Easy-to-use, flexible software

- Test setup and status window to guide users

- Customizable windows and views

- Intuitive and configurable test setup

- Multiple test monitoring sources

Direct control over your data

Direct control over your data

- Customizable and flexible data collection

- Control of data acquisition before and during the test

- Data is stored even if test stops unexpectedly

Real-time test parameter control

Real-time test parameter control

- Adjust waveforms in real-time

- No need to stop test to reconfigure major test parameters

Security and history tracking

Security and history tracking

- User login for added security

- Secure workspace with audit trail traceability

- File system security to protect test files

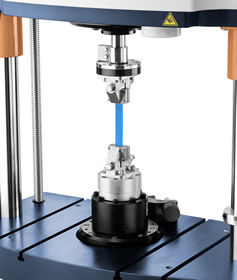

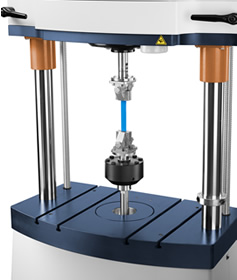

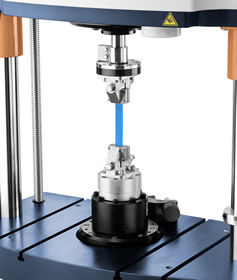

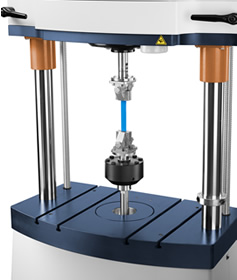

3300 Series III Axial Torsion

3300 Series III Axial Torsion

3300 Series III Axial Torsion

Combined axial and torsion loading that offers rotation and torque control

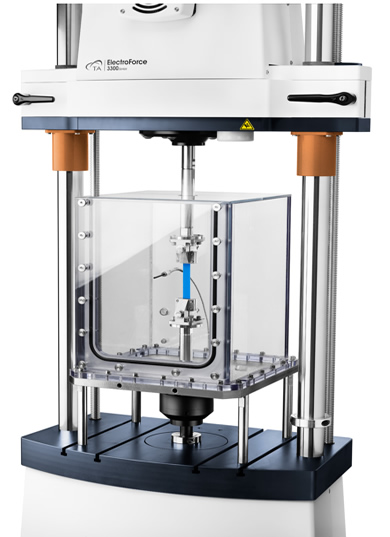

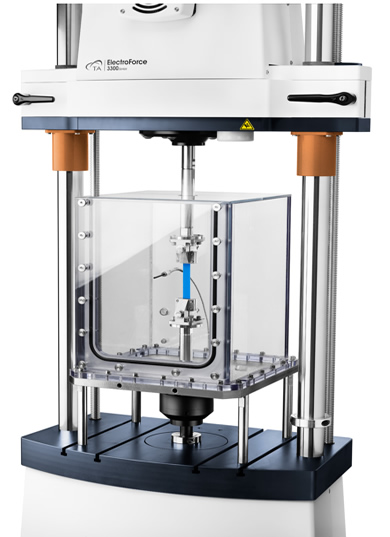

3300 Series III Extended Stroke

3300 Series III Extended Stroke

3300 Series III Extended Stroke

150 mm of additional stroke that complements the 25 mm of dynamic stroke for long-travel applications.

3300 Series III Axial Floor-standing

3300 Series III Axial Floor-standing

3300 Series III Axial Floor-standing

A floor standing configuration with a Micro-adjust in the midplate for convenient adjustment of the lower fixture. This configuration is upgradable to Axial Torsion or Extended Stroke for adding capability in the future.

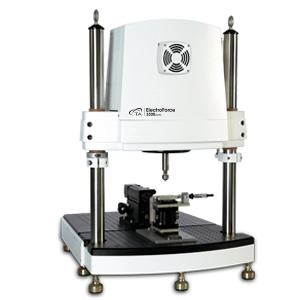

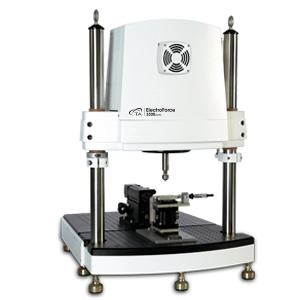

3300 Series III Multi-Specimen Fatigue

3300 Series III Multi-Specimen Fatigue

3300 Series III Multi-Specimen Fatigue

The ElectroForce 3300 MSF is ideally suited for characterizing the fatigue life of materials, components and devices by offering 16 specimens of simultaneous displacement at up to 100 Hz.

Multi-Specimen Fatigue Instrument

3300 Series III Dental Wear

3300 Series III Dental Wear

3300 Series III Dental Wear

The ElectroForce 3300 Dental Wear configuration integrates a horizontal mover to simulate two-body wear that occurs during chewing.

- Description

-

ElectroForce 3300 Series III instruments are well-suited for a variety of tests that include ASTM and ISO standards for materials and biomaterials characterization and long-term durability tests of materials, components and devices.

The ElectroForce 3300 family includes two models; the ElectroForce 3310 provides 1000 N of maximum force while the ElectroForce 3330 provides 3000 N. Both models are available with either table-top or floor-standing frames. The floor-standing frame enables the expansion of capabilities by either adding torsion or extended stroke motors. All configurations can perform tests that range from one cycle per day (or static tests) up to 100 Hz. Select the force capacity and frame configuration that is appropriate for your testing needs.

Key Features

- High resolution and high accuracy displacement measurement for both the dynamic axial motor and the optional torsional motor

- Static to 100 Hz dynamic performance for a variety of applications

- Integrated System Status Indicator (SSI) Light for highly visible color-coded display of instrument status

- Electric motor driven test space adjustment with convenient locks, plus the added convenience of the lower Micro-adjust for precision alignment of grips.

- Optional 14 Nm and 25 Nm torsional motor are available for multi-axial test applications

- Optional 150 mm stroke extension motor to increase the instrument versatility for slower longer-travel tests

- Accommodates a variety of environmental chambers including temperature-controlled saline baths and hot/cold chambers

- Specifications

-

3300 Series III Specifications Table

Product Specifications ElectroForce 3310 ElectroForce 3330 Force – Peak/Max Sine ± 1000 N ± 3000 N Force – Static or RMS (continuous) ± 700 N ± 2100 N Displacement 25 mm 25 mm Linear Velocity 0.013 μm/s – 1.5 m/s 0.013 μm/s – 2.0 m/s Frequency 0.00001 Hz – 100 Hz 0.00001 Hz – 100 Hz Torsional Motor Option Torque – Peak/Max ± 14 N-m ± 25 N-m Torque – Static or RMS (continuous) ± 14 N-m ± 25 N-m Rotation Multi-Turn (62 Revolutions) Multi-Turn (62 Revolutions) Extended Stroke (ES) Option Displacement 150 mm 150 mm - Technology Benefits

-

Motor Technology Benefits

Reliable testing

Reliable testing

- 10-year ElectroForce® motor warranty

- ElectroForce motor designed, developed and manufactured by TA Electroforce to exacting standards

- Frictionless design ensures optimal control and long-life for a variety of durability testing applications

- Integrated Air-bearing preserves frictionless benefits even in the presence of moderate side loads

High-fidelity, responsive control

High-fidelity, responsive control

- Accurate control and high-resolution performance provides more precise material properties

- Very low motor moving-mass provides industry leading frequency response

Low-force control applications

Low-force control applications

- No motor friction or stiction provides accurate, low-force testing

- Model 3330 delivers a wide range of controlled forces, from below 1 N forces to 3000 N, providing versatility for a variety of tests.

- Model 3310 features a high precision amplifier package to deliver even better low-force control, from below 0.1N to 1000N

Clean, electromagnetic technology

Clean, electromagnetic technology

- Standard ElectroForce® systems can be used in clean rooms or incubators for exceptional versatility

- Efficient electromagnetic power conversion is well-suited for a variety of test environments

Energy-efficient technology

Energy-efficient technology

- Efficient power utilization reduces operating costs

- Lab-friendly instruments and easy installation allows testing to start immediately

- No expensive infrastructure or contamination – saves upfront costs and operating expense

Software Technology Benefits

Easy-to-use, flexible software

Easy-to-use, flexible software

- Test setup and status window to guide users

- Customizable windows and views

- Intuitive and configurable test setup

- Multiple test monitoring sources

Direct control over your data

Direct control over your data

- Customizable and flexible data collection

- Control of data acquisition before and during the test

- Data is stored even if test stops unexpectedly

Real-time test parameter control

Real-time test parameter control

- Adjust waveforms in real-time

- No need to stop test to reconfigure major test parameters

Security and history tracking

Security and history tracking

- User login for added security

- Secure workspace with audit trail traceability

- File system security to protect test files

- Instrument Config.

-

3300 Series III Axial Torsion

3300 Series III Axial Torsion

3300 Series III Axial TorsionCombined axial and torsion loading that offers rotation and torque control

3300 Series III Extended Stroke

3300 Series III Extended Stroke

3300 Series III Extended Stroke150 mm of additional stroke that complements the 25 mm of dynamic stroke for long-travel applications.

3300 Series III Axial Floor-standing

3300 Series III Axial Floor-standing

3300 Series III Axial Floor-standingA floor standing configuration with a Micro-adjust in the midplate for convenient adjustment of the lower fixture. This configuration is upgradable to Axial Torsion or Extended Stroke for adding capability in the future.

3300 Series III Multi-Specimen Fatigue

3300 Series III Multi-Specimen Fatigue

3300 Series III Multi-Specimen FatigueThe ElectroForce 3300 MSF is ideally suited for characterizing the fatigue life of materials, components and devices by offering 16 specimens of simultaneous displacement at up to 100 Hz.

Multi-Specimen Fatigue Instrument

3300 Series III Dental Wear

3300 Series III Dental Wear

3300 Series III Dental WearThe ElectroForce 3300 Dental Wear configuration integrates a horizontal mover to simulate two-body wear that occurs during chewing.

- Resources

- Video

-