4 Polymer Insights from Dynamic Mechanical Analysis

How DMA can make your fatigue testing more efficient

Morgan Ulrich | Andy Simon

December 12, 2023

From material selection and failure analysis to end-use application, Dynamic Mechanical Analysis (DMA) offers crucial polymer insights. Polymer scientists and design engineers pair DMA with fatigue testing to gain a complete view of their material’s properties and performance attributes.

What is Dynamic Mechanical Analysis?

Dynamic Mechanical Analysis (DMA) measures a material’s modulus, damping, and glass transition as the material is deformed under a periodic stress. DMA is particularly useful for evaluating polymeric materials that exhibit time, frequency, and temperature effects on mechanical properties because of their viscoelastic nature.1

DMA measures two kinds of modulus: Storage modulus is a material’s stored energy or elasticity; when you pull the material, it returns the energy and moves back into shape. Loss modulus is a material’s energy that is lost to heat; this is also known as viscous or damping properties.

DMA also measures glass transition (Tg), the temperature range in which a polymer changes from a hard “glassy” material to a softer, rubbery material with more viscous properties.2 This is useful information for designing processing conditions, predicting product performance, and ensuring quality control.

Four Polymer Insights from DMA

Difference in Modulus

DMA efficiently and accurately measures the modulus of a polymer, offering quick comparisons of different samples’ stiffness. While modulus is usually included in a material’s data sheet, running DMA tests allows polymer labs to verify their material’s modulus under specific conditions and draw accurate comparisons between samples.

Change in Modulus

DMA can measure how your material’s stiffness changes as a sample is heated or cooled from room temperature to the temperature of interest. Tracking changes in modulus is especially useful for quickly evaluating the influence of temperature on your materials, especially in a temperature range of interest which can help identify where to focus other mechanical tests such as fatigue studies.

Approaching Transitions

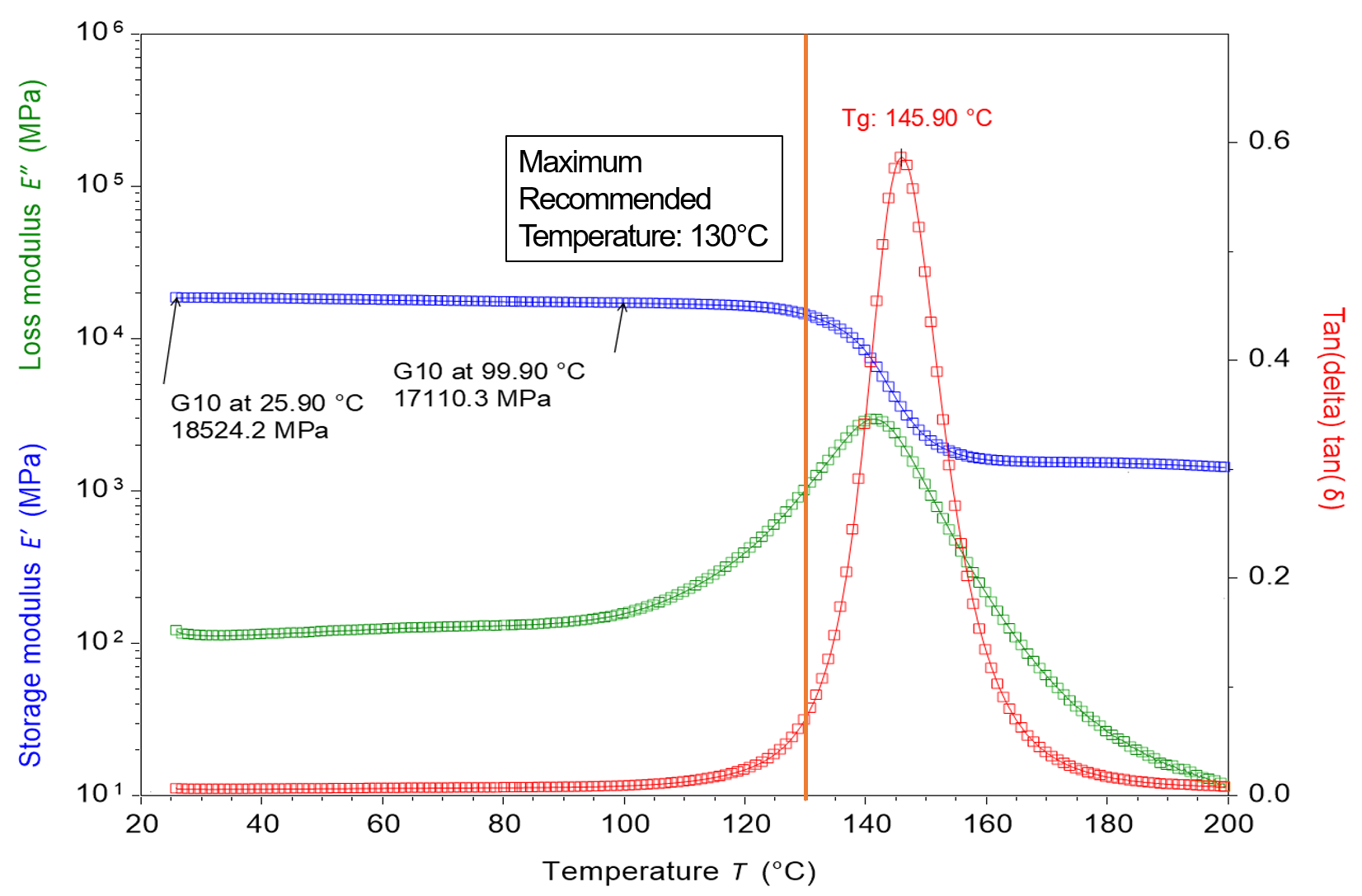

DMA is useful for tracking overall material properties as you approach a temperature of interest, such as an application-specific temperature range or potential failure temperatures. Even if you know that a material’s glass transition is at 145° C, how does it change up until that transition? Mapping the temperatures that impact your material beyond simple failure or transition temperatures offers a much more accurate and complete picture of material behavior.

Deeper Insights than Manufacturer’s Operating Ratings

While manufacturers offer suggested temperature ranges for use, those ranges often overlook more subtle changes that take place in the material. In the example below, the manufacturer’s operating rating is 130°. However, the material is clearly changing well below that temperature rating, meaning significant effects on strength and fatigue life are likely, but the exact effect is not possible to predict from DMA data alone.

Upon seeing the change in loss modulus well below the temperature rating, researchers were able to zero in on a temperature range where the material is changing and focus their effort in that range. They decided to perform a fatigue test at 100° C to evaluate the effect of the increased temperature on the fatigue life. Their fatigue testing data revealed that at 100° C, the material had a 90% reduction in fatigue life. DMA highlighted that the manufacturer’s rating was incomplete, and fatigue data completed the picture with a more accurate understanding of the material at “approved” temperatures.

Combining DMA and Fatigue for the Complete Picture

As the example above illustrates, DMA data can effectively inform fatigue testing to offer the complete picture of polymer performance. DMA offers deeper insights into material behavior that may be oversimplified in operating ratings and on data sheets. Learn more about fatigue testing and see the rest of the fatigue data for this sample in the TA application note “Flexural Fatigue Behavior of Woven Fiberglass Composites at Elevated Temperature.”

References:

- Introduction to Dynamic Mechanical Analysis and its Application to Testing of Polymer Solids – TA Instruments. https://www.tainstruments.com/applications-notes/introduction-to-dynamic-mechanical-analysis-and-its-application-to-testing-of-polymer-solids/

- Measurement of Glass Transition Temperatures by Dynamic Mechanical Analysis and Rheology – TA Instruments. https://www.tainstruments.com/applications-notes/measurement-of-glass-transition-temperatures-by-dynamic-mechanical-analysis-and-rheology/

Other Resources

- Blog – What is Dynamic Mechanical Analysis?

- Blog – How Sustainable Polymer Development is Supported by Dynamic Mechanical Analysis

- Blog – 3 Time-Saving Techniques for Your Polymer Research

- Webinar – Fingerprinting recycled thermoplastic resins for process optimisation

- Webinar – Connecting Polymer Processing and Product Performance through Rheology & DMA on the New DHR

- Application Note – Evaluation Of The Loss Of Polymer Strength And Durability Due To Fatigue Loading And Manufacturing Artifacts

- Application Note – Tensile and Fatigue Properties of Additively Manufactured Polyamides

- Application Note – Flexural Fatigue Behavior of Woven Fiberglass Composites at Elevated Temperature

- Application Note – Characterization of Bio-Derived Polymer Under Controlled Humidity