Viscometer vs Rheometer: Discover Why a Rheometer Offers More Than Just Viscosity Measurement

Philippa Cranwell | Sarah Cotts

September 30, 2024

If you’re working with materials that can be flowed, for example within pharmaceutical, food, cosmetics, or petrochemical industries, it’s likely that there is a viscometer in the laboratory that is the go-to instrument for formulation testing or QA purposes. However, does this viscometer give you the whole picture and fully meet all your needs? Like an iceberg only shows 10% of its volume above the waterline, a viscometer only gives a small snapshot of a material’s properties. Sometimes this is enough, but there are instances where a rheometer will provide significant advantage, saving time, money and effort in the long run.

This short blog will outline key advantages that can be gained through use of a rheometer over a viscometer, with the differences between each instrument outlined and examples showcasing where a rheometer provided crucial data that a viscometer could not.

Viscometer vs rheometer: what’s the difference?

Before considering the operational differences between a viscometer and a rheometer, it is crucial to understand what each measures. A viscometer characterizes the viscosity of a fluid at a single shear rate, and, as such, reports one viscosity value. This is a key drawback: often the shear rate used to report a particular viscosity is not reported and when working with non-Newtonian materials (such as creams or emulsions), where the viscosity is dependent upon shear rate, the values provided may not be accurate or reproducible.

A rheometer, by contrast, measures the way that a liquid flows in response to an applied stress and can reliably achieve a wide range of shear rates, usually between 0.001 and 1000 s–1. In fact, the low shear rates accessible allow us to understand how materials behave when they are at rest, a property that can significantly impact upon the stability of heterogenous materials, the perception of consumer products (for example in food and personal care), and, most importantly, provide insights into a material’s microstructure, which impacts upon both performance and behavior.

The rheometer can show how viscosity changes across a range of different situations, rather than at just one point.

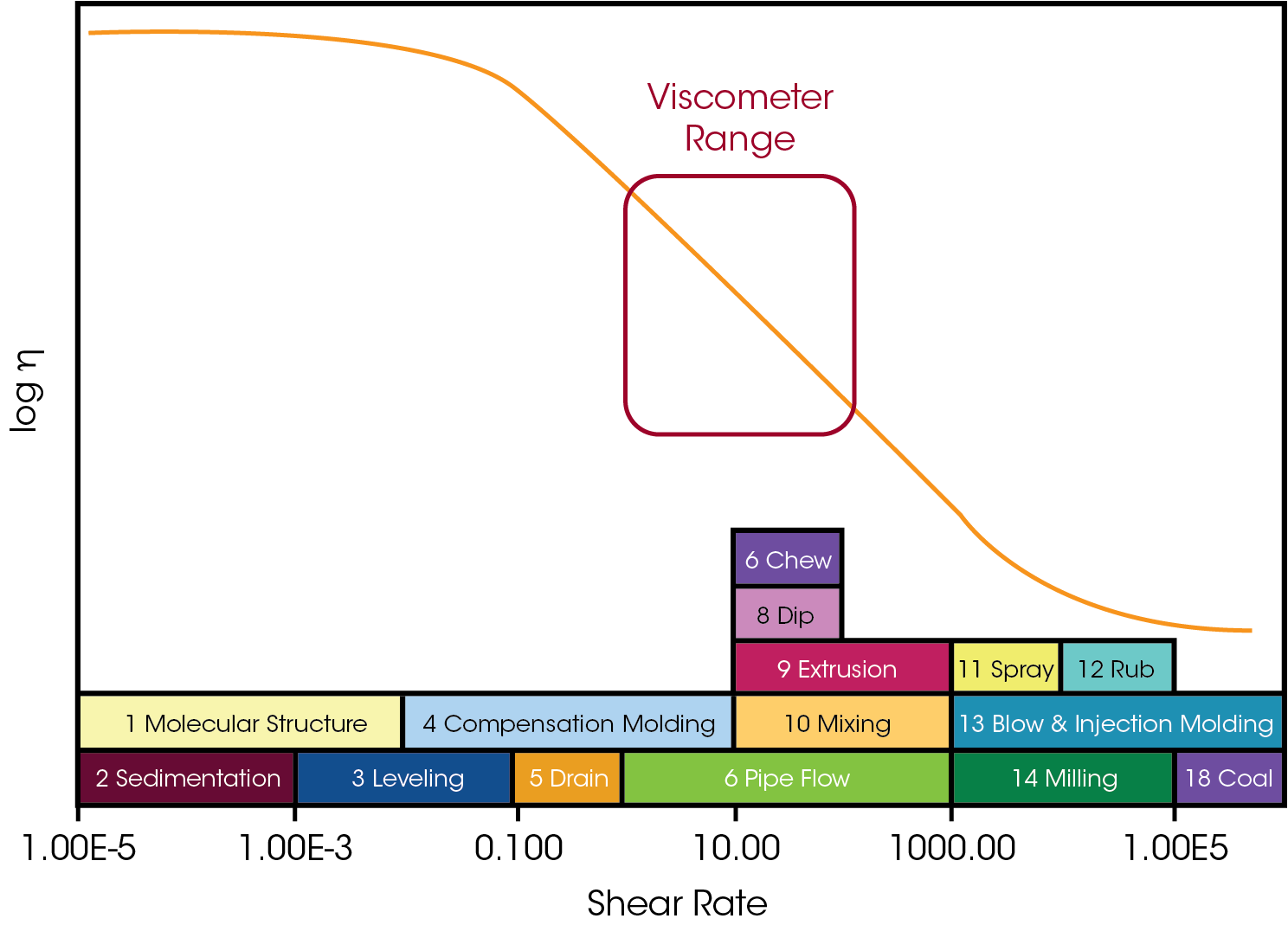

Using the analogy above, a rheometer can give information about the whole iceberg, whereas a viscometer can only give information about the 10% above water. While sometimes this is enough, the additional data from thorough rheological evaluation can reveal important differences between samples and enable modeling of a whole host of process that a product might undergo, either during manufacture or through use by the end-user, shown in figure 1.

Figure 1: Schematic showing the range of shear rates over which process occur, which can all be modelled using a rheometer. The narrow range of shear rates accessible to a viscometer is indicated.

Rheometer: precision engineering for precision measurement

Where a viscometer can provide simple measurements on Newtonian materials (viscosity is independent of shear rate), a rheometer can give in-depth characterization of flow and deformation for both Newtonian and non-Newtonian materials. The key reason for the marked difference in performance between viscometers and rheometers is due to the instrument mechanic. Operationally, a viscometer uses a mechanical bearing, which limits the speed and torque capabilities of the instrument so material is only measurable within a very narrow range. In contrast, a rheometer uses an advanced motor and a low friction bearing, offering unparalleled control of deformation and torque sensitivity. For example, the Discovery Hybrid Rheometer uses a unique magnetically levitated bearing, further reducing friction and enhancing sensitivity to low torque measurements. This enables accurate flow behavior measurements even under very low-shear conditions, such as a paint leveling after application or sedimentation in a suspension.

A rheometer measures more than just viscosity!

Although rheometers measure viscosity (how a material flows), they can also measure viscoelasticity, which is a critical attribute of complex fluids like emulsions, dispersions, polymers, gels, pastes, that is often overlooked. Viscoelasticity data can provide information about how much a material can deform, flex or spring before the structure is destroyed and irrecoverable damage is caused.

With what types of material would a rheometer give me an advantage?

When measuring a liquid, a key consideration is whether it is Newtonian or non-Newtonian. Newtonian liquids have constant viscosity regardless of the shear rate applied, e.g. water and honey. Measuring viscosity at several shear rates allows one to extrapolate the viscosity at high or low shear rates and in these cases, a viscometer would likely deliver the required results.

A non-Newtonian fluid changes viscosity depending upon the shear rate applied: it is not possible to accurately describe the viscosity of a non-Newtonian fluid without specifying the shear rate. Most manufactured materials are non-Newtonian, including cosmetic creams, pharmaceutical formulations, coatings, lubricants and food stuffs. In fact, their non-Newtonian behavior is a desirable property. For example, lotions and creams decrease in viscosity as they are moved faster (shear-thinning behavior), for example while being dispensed or applied. This means that they flow well and can be processed. However, their high viscosity at low flow rates helps with their stability. Shear-thinning behavior is a good thing, as it means that when at rest the materials stay in place, but when we want or need them to move, they do so readily.

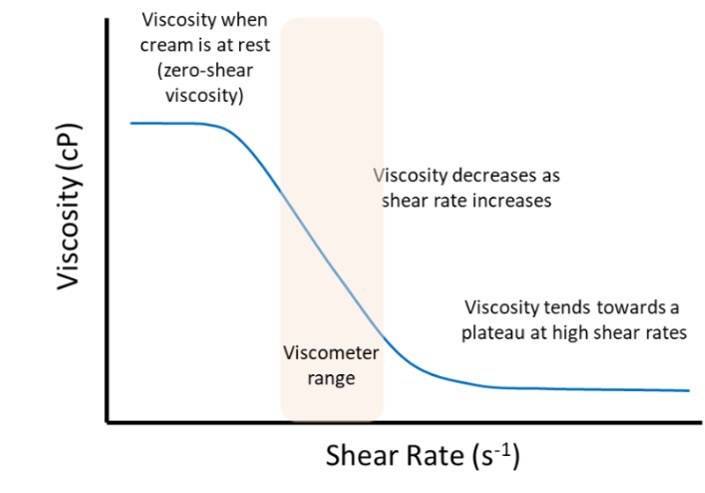

Showcasing a rheometer’s value: Cosmetic creams

Cosmetic products such as face cream, sunscreen, mascara or shampoo, are stored on a shelf in a pot and are only used once or twice per day. In rheological terms, these materials spend the majority of time ‘at rest’ as no external force, or shear, has been applied, Figure 2. As shear is applied, either through agitation during transportation, processing in the factory, or application by the consumer, the sample starts to move and the viscosity changes. Different viscosity values due to different shear rates can have a large impact upon a product:

- If zero-shear viscosity is too low, sedimentation or separation of components may occur;

- Low zero-shear viscosity may lead to consumer perception that the product is ‘thin’ or ‘less luxurious’ when compared with a competitor;

- Higher or lower viscosity while spreading on the skin (where shear is applied by the consumer) may lead to either perception of a thin, poor-quality product, or a thick paste that feels draggy.

Figure 2: Hypothetical data for a face cream showing how viscosity is affected by shear rate. A rheometer should be able to identify all behaviors shown, whereas a viscometer would only show the central portion highlighted.

Showcasing a rheometer’s value: Optimizing a liquid emulsion adhesive for high-speed coating

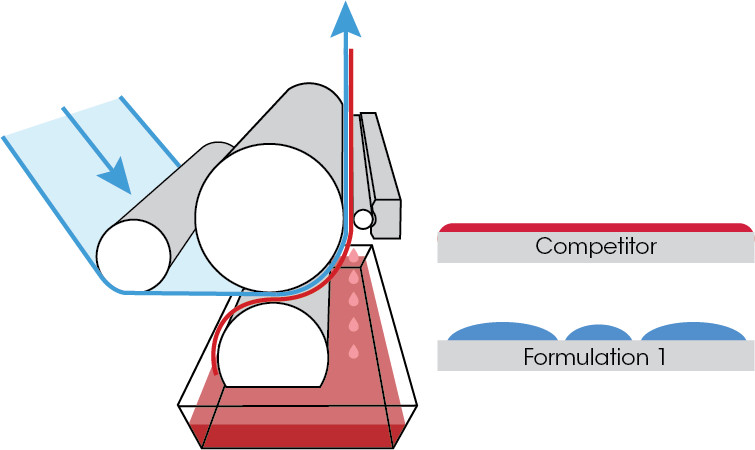

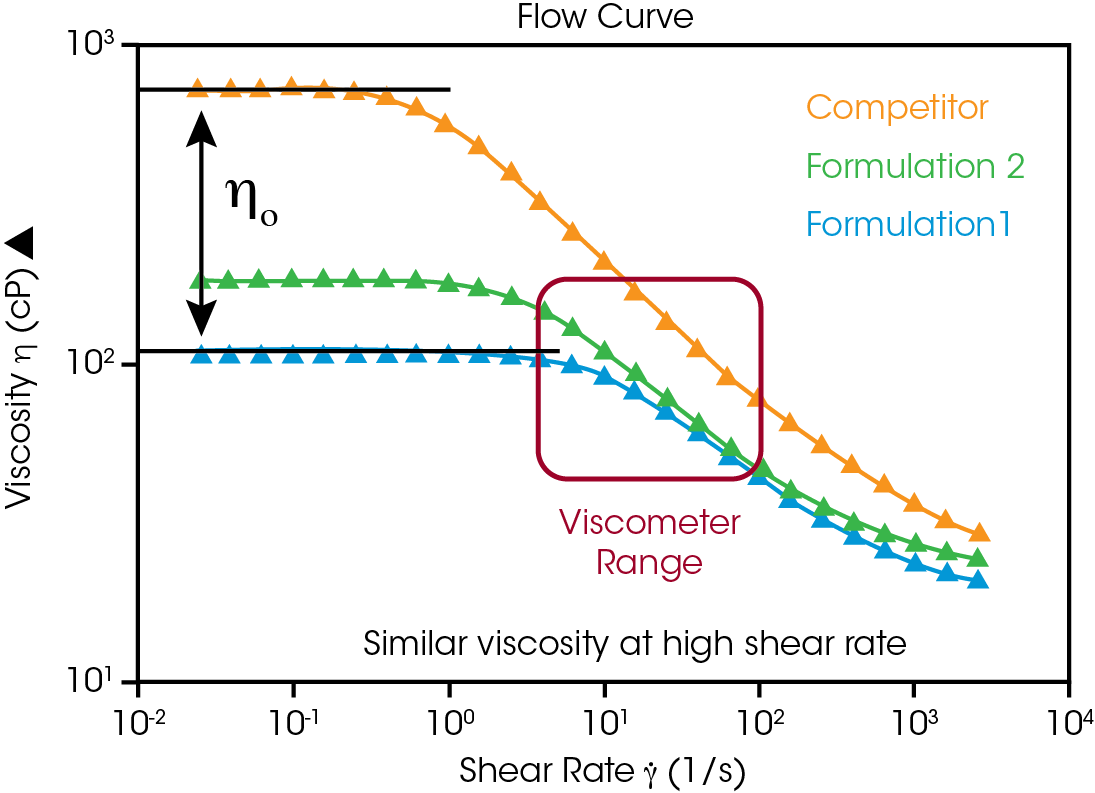

In another example, a TA Instruments rheometer was used to investigate why one formulation of a liquid emulsion adhesive, designed for high-speed coating, significantly under-performed when compared with a competitor. This under-performance led to voids on the metal substrate, with increased instances of adhesive failure, Figure 3a.

Although a viscometer was able to show differences in viscosity between the samples, neither high nor low shear rate data were available. It was only upon use of a rheometer that the 8-fold higher zero-shear viscosity of the competitor product was revealed. This was the key: higher zero-shear viscosity meant that the competitor product did not flow once deposited, and stayed in place.

Figure 3: (a) Schematic showing the difference in behavior between formulation 1 and the competitor; (b) Shear rate vs viscosity data for the competitor, formulation 1 and formulation 2.

Other rheometer capabilities in flow mode

As well as the clear advantage that a rheometer offers in terms of accessing a range of shear rates, a rheometer also allows the user to accurately measure viscosity across a range of temperatures (–40 °C to 200 °C) by simply using a heated or cooled Peltier plate system. This is extremely difficult with a viscometer due to the large volumes of sample required and likelihood of non-uniform heating.

The ability to study viscosity over a range of temperatures is especially useful for materials such as oils, plastics, resins or greases, as it allows modelling of behavior during high-temperature industrial processes, or in materials exhibiting a glass transition. In particular, the Discovery Hybrid rheometer series boasts Smart SWAP technology, giving facile access to a range of conditions and attachments to simulate conditions under which a sample could be used.

Contact TA Instruments’ experts to learn more about how our industry-leading rheometers can revolutionize your research, development and QC processes.

FAQ

A: A rheometer is a scientific instrument used to measure the way materials respond to applied forces, providing detailed insights into the flow and deformation behavior of fluids and soft solids. Rheometers can evaluate complex properties like viscosity, elasticity, and stress, making them essential for studying materials that exhibit more than just simple flow characteristics, such as polymers, gels, and suspensions.

A: Rheometers measure a variety of material properties, including viscosity, elasticity, shear stress, and strain. Unlike viscometers, which only measure viscosity under a single condition, rheometers can analyze materials under various stress and strain conditions, providing a full profile of how a material behaves when subjected to different forces. This makes rheometers valuable for testing materials that change properties over time or under different environmental conditions.

A: While both rheometers and viscometers are used to measure the flow properties of materials, the main difference lies in their capabilities. A viscometer measures viscosity under a single flow condition, providing data on how thick or thin a liquid is. On the other hand, a rheometer offers a more comprehensive analysis by measuring both viscosity and additional properties like elasticity, stress, and strain across a range of flow conditions. If you are only considering viscosity, a viscometer may suffice. However, if you need to understand a material’s behavior under different conditions, such as shear stress, deformation, or temperature changes, a rheometer, like the ARES-G2 or HR-30 from TA Instruments, would be the better choice.

A: A rheometer offers significantly extended capabilities beyond what a viscometer can provide. If you are working with complex fluids like polymers, gels, slurries, or biological materials, a rheometer allows you to analyze material properties that a viscometer cannot, such as shear thinning, viscoelasticity, and thixotropy. This makes rheometers like TA Instruments’ ARES-G2 and HR-30 more versatile and suited for advanced research and quality control across a broader range of industries, including pharmaceuticals, food science, and material development.

A: A rheometer can measure a material’s behavior under different stress, strain, and shear conditions, providing insights into both flow and deformation. For example, the ARES-G2 Rheometer allows for comprehensive testing of linear and nonlinear viscoelasticity, creep, and stress relaxation. The HR-30 Rheometer offers unmatched precision in characterizing shear-thinning, yield stress, and dynamic moduli. These advanced features allow researchers to fully characterize materials that may exhibit time-dependent behavior, something a standard viscometer cannot measure.

A: Industries and research fields dealing with complex fluids, soft solids, or materials that change properties under different conditions will benefit the most from using a rheometer. For example, pharmaceutical researchers can study the flow behavior of drug formulations under various stress conditions, while material scientists can analyze polymers for manufacturing. Rheometers like the ARES-G2 or HR-30 are ideal for anyone needing to understand elasticity, structural integrity, or time-dependent flow behavior, providing much more than simple viscosity measurements.

A: Rheometers can handle a wide range of materials, including viscoelastic solids, gels, foams, slurries, and biological samples, which may not be suitable for a viscometer. For example, the ARES-G2 rheometer is particularly adept at testing complex materials that exhibit both viscous and elastic behavior. The HR-30 rheometer is suited for small-volume samples and high-precision measurements, making it perfect for testing fragile biological samples and high-performance polymers that require advanced material characterization.

A: A rheometer not only measures basic viscosity but also delivers data on elasticity, moduli, yield stress, and dynamic response, which are crucial for understanding material performance in real-world applications. By investing in a rheometer like the ARES-G2 or HR-30, researchers can explore the full rheological profile of a material, gaining insights into how it will behave under different processing conditions, stress, or temperature changes. This makes rheometers more valuable for comprehensive research, leading to better material development, optimization, and quality control.

A: Rheometers are indispensable in industries where understanding the full mechanical behavior of materials is critical. Common sectors include:

- Pharmaceuticals: Testing drug formulations, suspensions, and gels.

- Polymers and Plastics: Studying the flow and deformation properties of polymers under various stress conditions.

- Food and Beverage: Characterizing food products’ flow and texture.

- Cosmetics: Understanding the stability and spreadability of creams, lotions, and gels.

- Energy and Environment: Analyzing complex fluids, slurries, and emulsions for oil, gas, and environmental applications.

For these applications, a rheometer provides a deeper analysis that leads to better product formulation, higher performance, and enhanced stability, compared to what a viscometer can achieve.

A: TA Instruments offers several state-of-the-art rheometers, including the ARES-G2 and HR-30:

- The ARES-G2 rheometer is ideal for complex rheological testing, providing precise control over strain and stress for materials that require advanced testing, such as polymers, gels, and elastomers.

- The HR-30 rheometer offers high precision, particularly suited for small sample volumes and testing that requires high sensitivity. It’s perfect for biological samples, pharmaceutical formulations, and materials that demand rigorous characterization.

A: Investing in a rheometer gives you the ability to perform a wider range of tests and generate more comprehensive data on your materials, ultimately saving time and resources in the long run. Rheometers like the ARES-G2 and HR-30 are versatile instruments that can adapt to different research needs over time, reducing the need for multiple devices. For businesses and research labs, this means greater flexibility, better product development, and improved decision-making based on deeper material insights.

Other Resources

- Rheometers – Rheometers – The most powerful and versatile rheometer for your laboratory

- Blog – What are Rheometry and Rheology?

- Blog – Rheology Theory and Applications

- Blog – Rheology, Easy as Pie

- Application Note – Rheological Analysis of Hydrogel Materials

- Application Note – Polymer Flow and Mechanical Characterization for Material Development, Processing, and Performance

- Contact – Contact TA Instruments Today