View Dilatometers Applications Request a Quote

A dilatometer is a precision instrument for the measurement of dimensional changes in material as a function of temperature. Dilatometry is used to test a wide range of materials such as traditional and advanced ceramics, glasses, metals, and polymers. Dilatometry offers a variety of measurements including linear thermal expansion, coefficient of thermal expansion, sintering temperature, shrinkage steps, phase transitions, density change, softening point and decomposition temperature, anisotropic behavior, and glass transition temperature.

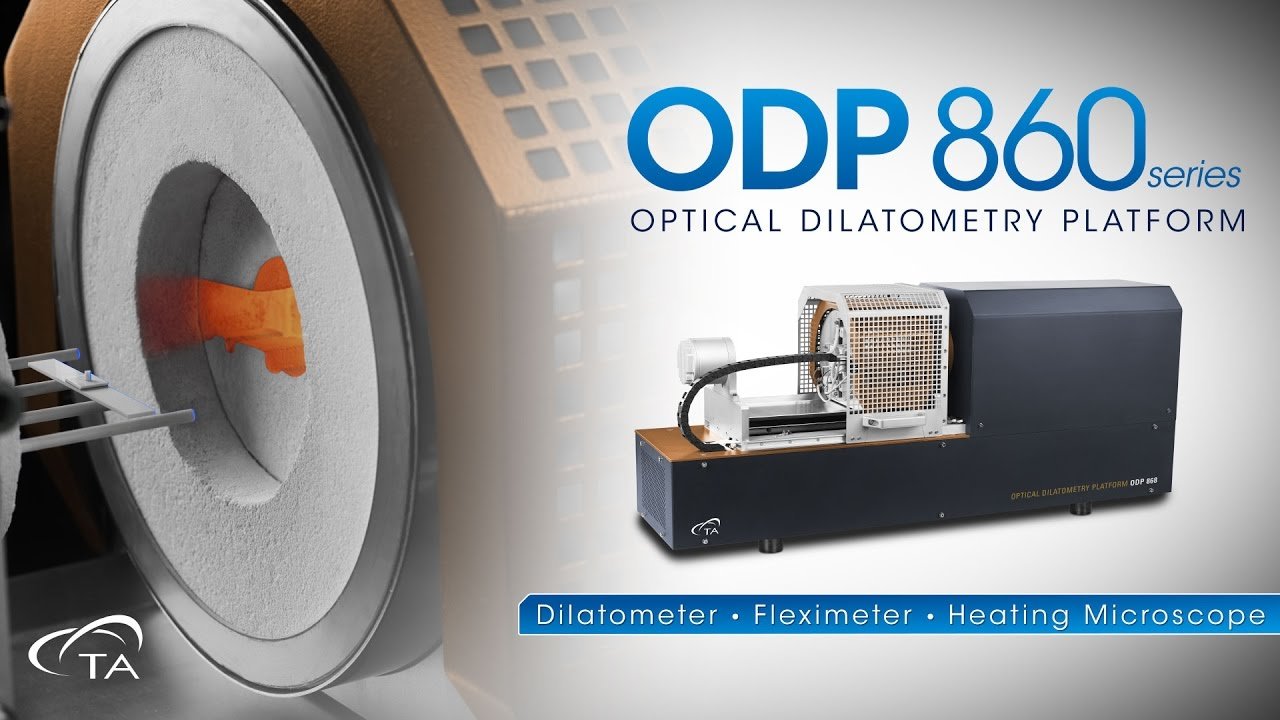

Dilatometers measure dimensional changes through mechanical contact by a pushrod or through non-contact optical CCD sensors. As the dilatometer furnace is heated, cooled, or kept isothermal, the linear dimensional change (expansion or contraction) of the sample is measured by a highly accurate displacement sensing system. Measurement accuracy can be affected by numerous sample-specific factors, including sample stiffness, changes in rigidity, the magnitude of dimension change, the temperature range or rate required, or irregularity in sample shape, which underscores the importance of choosing between mechanical contact of optical non-contact devices.

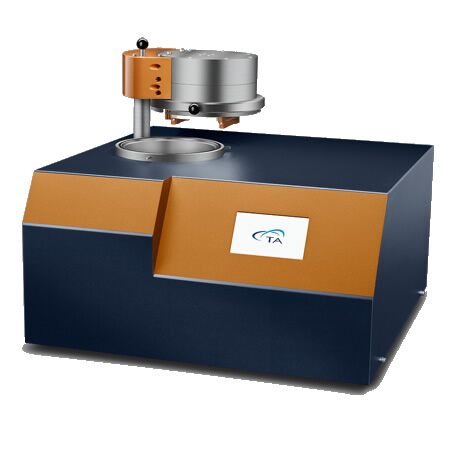

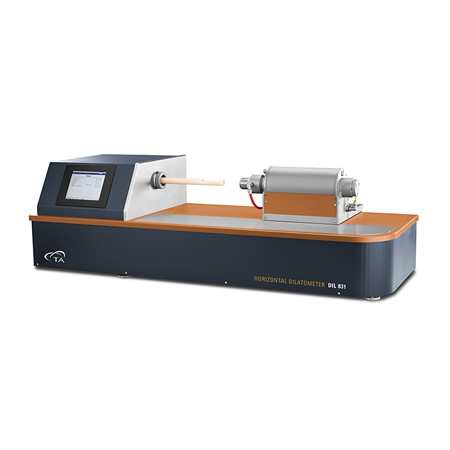

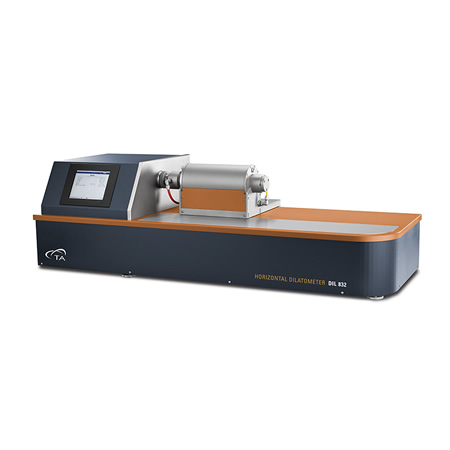

No single dilatometer can effectively and precisely meet the testing requirements of such a wide range of materials and material property measurements. Only TA Instruments offers a complete line of horizontal, vertical, and optical dilatometers to meet every testing need. Our material testing expertise and global support will help you find the right dilatometry instrument for your unique application.