Keywords: Thermomechanical Analysis, Stress, Strain, Universal Analysis

TA414

Problem

Stress/strain measurements are widely used to assess and compare materials. Although conventional physical testing devices can accommodate single-filament fibers, the results are difficult to obtain and the accuracy of those results is doubtful since the mass and inertia of the grips (clamps) is much greater than the tensile strength of the fibers being evaluated.

Solution

Thermomechanical analysis (TMA), which is a thermal analysis technique that measures dimensional change with temperature, provides a more suitable method for evaluating the stress/strain of fibers because of low system inertia, as well as high sensitivity to small stress and strain changes. Furthermore, the sample mounting flexibility and force programming capability (1mN-1.0N) of the TA Instruments TMA 2940 make it ideal for these fiber evaluations.

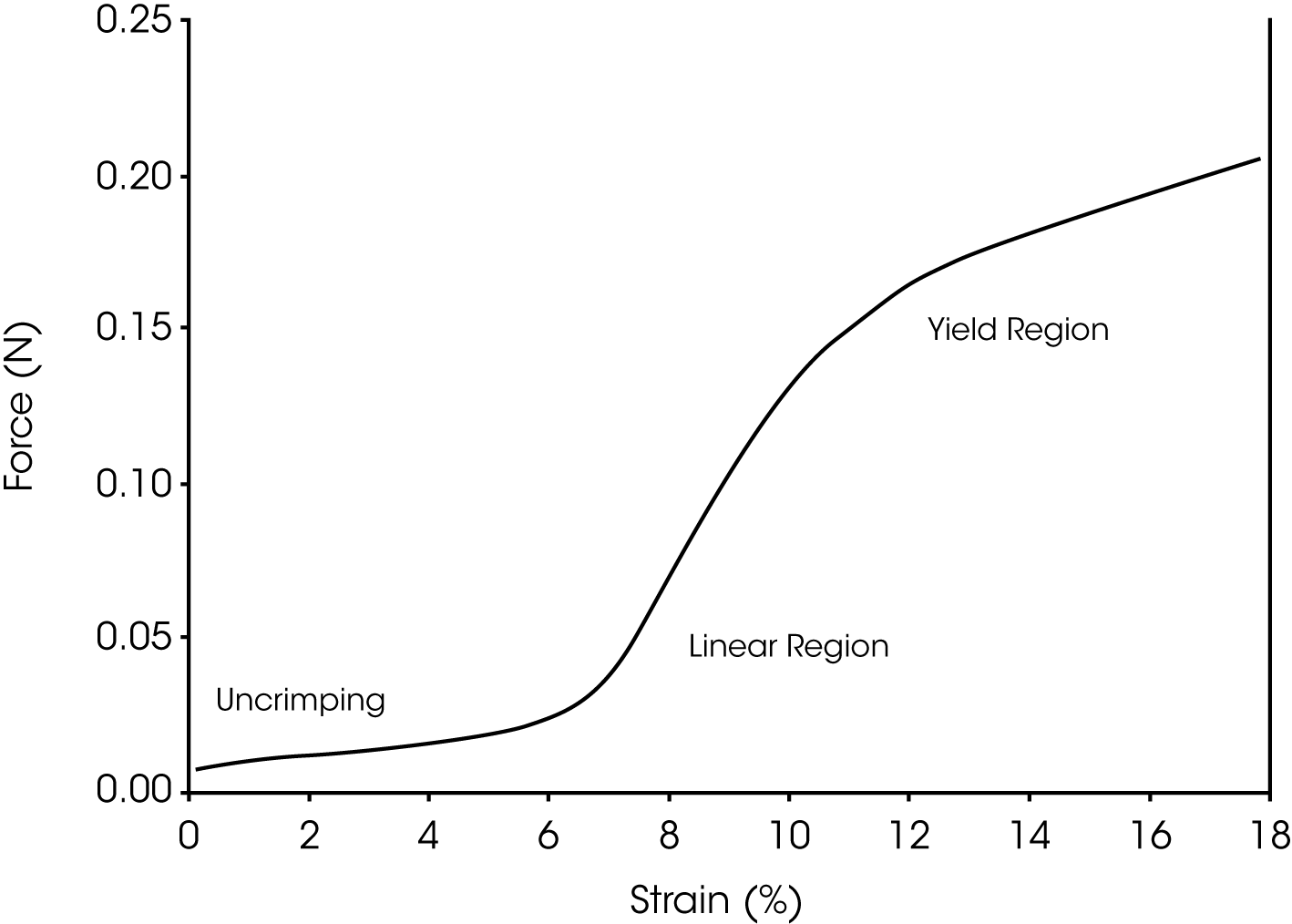

Figures 1 and 2 show typical TMA results obtained on single (15 denier) fibers of polyethyleneterephthalate (PET). These results were obtained at ambient temperature. A low initial stress (3mN or 0.2 g/denier) was applied to eliminate “crimps” in the fibers when mounted in the TMA. The force was then increased linearly at 0.2N/min until the probe travel reached the measurement limits of the transducer. Figure 1 illustrates the different regions of stress/strain behavior for virgin PET fiber. This curve is typical of the output obtained from common physical testing devices. From this curve, quantitative information, such as the fiber’s amount of crimp, initial modulus and yield elongation, can be obtained.

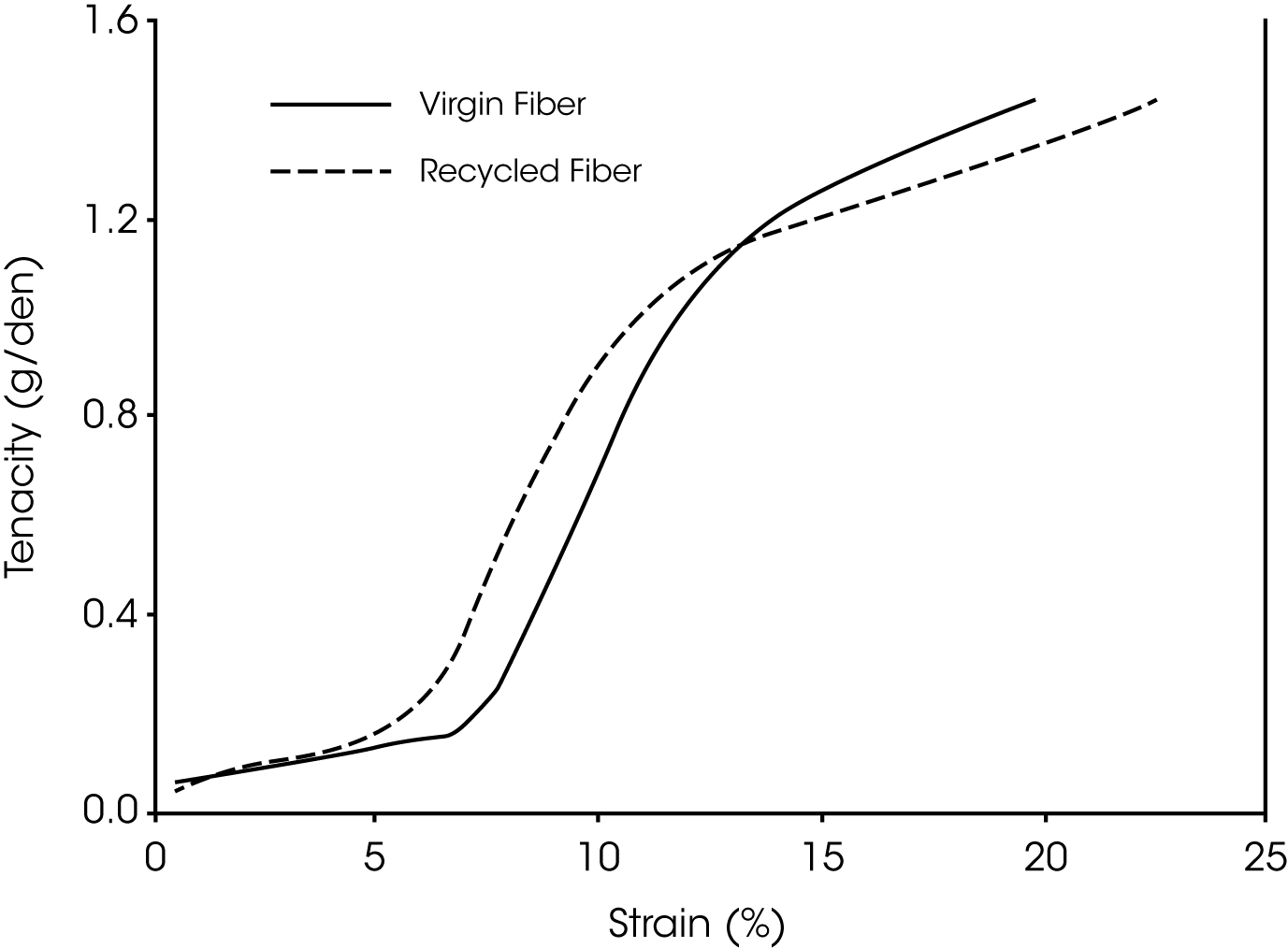

The TA Instruments Thermal Solutions Universal Analysis Software allows stress/strain data to be displayed in other useful ways. Figure 2, for example, shows the stress/strain curves for virgin and recycled PET fibers overlaid after the stress has been normalized against linear density to obtain “tenacity”. The virgin fiber has a greater initial crimp, modulus and yield tenacity. Because of the length of the fibers evaluated (15-18 mm), the elongation to break can not be determined from these curves. However, that information could be obtained with shorter samples.

Acknowledgement

Click here to download the printable version of this application note.