Applying Dynamic Mechanical Analysis (DMA) to Test the Durability of Protective Sports Equipment

Morgan Ulrich | Mark Staub | Andy Simon

February 1, 2024

There is a renewed interest in the durability of protective sports equipment after Patrick Mahomes’ helmet recently cracked apart in -4 degrees Fahrenheit (-20 degrees Celsius) weather. Scientists from Waters TA Instruments division ran tests to find out if materials found in protective sports equipment can break due to cold weather.

Polycarbonate (PC) is often a major component in protective equipment for high impact sports due to its well-suited impact properties at ambient conditions. Application Scientist Mark Staub, PhD., of Waters TA Instruments division ran tests on a PC sample to study the material behavior in cold weather conditions.

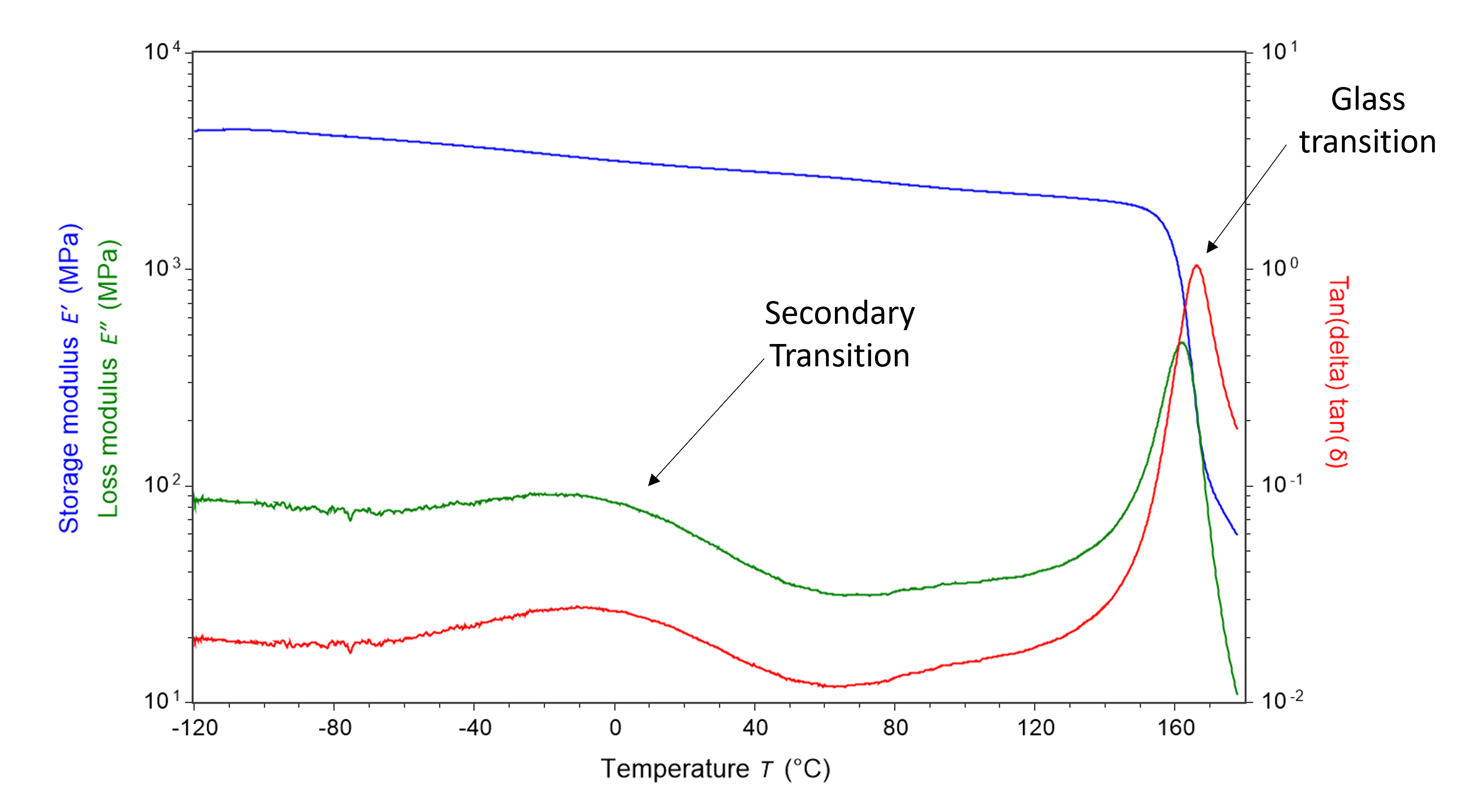

Polycarbonate is known to show ductile to brittle behavior at sub-zero temperatures. Dr. Staub ran a temperature ramp using single cantilever deformation on a TA Instruments™ DMA 850. As seen below, the glass transition occurs at high temperatures. This transition is significantly above equipment use temperatures and is important for materials processing. However, there is another peak in the loss modulus and tan delta between -40 °C and 0 °C which is known as a secondary transition. This transition is relevant to environments where the material may be used and is directly related to material performance.

High impact sports such as football can be played in warmer fall months and colder winter months where temperatures can reach as low as -4 °F (-20 °C) and fall within polycarbonate’s secondary transition. This transition relates to the mobility of the material’s short chain segments in the glassy state. These typically sub-ambient transitions play a major role in mechanical properties, including impact resistance, toughness, and damping. At -20 °C, PC has very little chain mobility, hence it is susceptible to brittle failure. Playing a game in the equipment’s secondary transition may render the material vulnerable to failures that are unforeseen at higher temperatures. DMA is sensitive enough to measure these transitions and is therefore an incredibly valuable tool for high-impact materials design.

However, brittle failure of PC depends on the rate of impact as well as temperature. Athletes in high-impact sports such as football collide with high speed, strength, and mass, such that the protective equipment must withstand high impacts under varying environmental conditions.

Considering football as an example, Dr. Staub estimated the impact force that may be applied to a quarterback being sacked by a defensive lineman using the following assumptions:

- Estimated quarterback time to get rid of ball before hit (2.5 s)

- Estimated drop back distance 5 yards (4.6 m)

- Estimated lineman speed to reach QB for hit (4.6 m / 2.5 s) = 1.8 m/s (4.0 mph)

- Estimated weight of defensive lineman (300 pounds = 136 kg)

- Estimated Impact time (1 to 2 tenths of a second); assume 0.1 s here

Impact force F = mv/2t = (136 kg * 1.8 m/s) / 2 * 0.1 s = 1224 N impact force

The estimated force of 1224 N force is a significant impact force, especially if it is assumed that the entire estimated force is applied to the material. Such force can be studied using a TA Instruments ElectroForce™ Load Frame, which can apply up to 15,000 N from -150 to 350 °C. While the DMA data predicts polycarbonate’s brittle nature at low temperatures, load frames can confirm the material’s failure point with certainty – valuable information for equipment manufacturers.

With this information, polycarbonate behavior at cold temperatures can be predicted given the assumed force applied on impact. While outcomes of sporting events can be unpredictable, materials utilized in protecting athletes can be tested by DMAs and Load Frames from TA Instruments to predict behavior of the materials under varying conditions.

TA Instruments and ElectroForce are trademarks of Waters Technologies Corporation.

The material tested was a general purpose polycarbonate material and no representation is made as to the suitability of polycarbonate for use in protective sports equipment or helmets.

Other Resources

- Application Note – Evaluation Of The Loss Of Polymer Strength And Durability Due To Fatigue Loading And Manufacturing Artifacts

- Application Note – Introduction to Dynamic Mechanical Analysis and its Application to Testing of Polymer Solids

- Application Note – Measurement of Glass Transition Temperatures by Dynamic Mechanical Analysis and Rheology

- Application Note – Quantifying Polymer Crosslinking Density Using Rheology and DMA

- Blog – 4 Polymer Insights from Dynamic Mechanical Analysis

- Webinar – Connecting Polymer Processing and Product Performance through Rheology & DMA on the New DHR