Vertical Dilatometer

High sensitivity optical encoder and vertical design for the most difficult samples.

Sales PromotionsThe 820 Series operate in a vertical orientation, making it uniquely set up for the analysis of sintering, studies in Rate Controlled Sintering (RCS) mode and the determination of dilatometric parameters of samples otherwise difficult to be analyzed on classic dilatometers with horizontal design.

Available in two different models (DIL 821 and DIL 822), both the units feature the new optical encoder with 1nm resolution. That when combined with the True Differential of the DIL822, the result is simply the best possible sensitivity and CTE accuracy on the market.

Unlike in horizontal dilatometry the vertical design does not require the sample to be supported. The specimen stands free on the bottom plate and the pushrod is loaded on its tip.

The vertical configuration is particularly well suited for sintering studies as well as for all those samples difficult to be tested with horizontal pushrod dilatometers. As, for instance, powder samples and samples developing vitreous phases during the test.

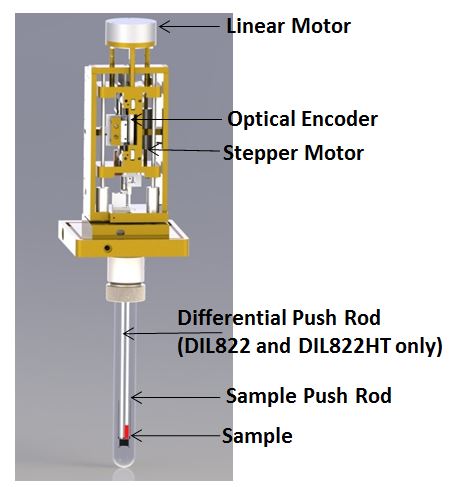

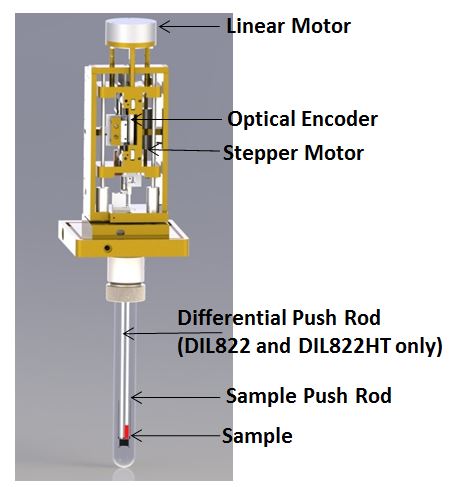

Equipped with a linear motor capable to generate a constant force throughout the experiment, DIL 820 Series allows for the lightest possible force regardless of the extent of specimen’s dimensional changes.

| DIL 821 | DIL 822 | |

| Sample length | 0 to 25 mm | |

| Sample diameter: | 10mm | 5mm |

| Material of sample holder: | Fused silica, Al2O3 | |

| Contact Force: | 0.01 – 1.0N | |

| Change of length: | 5mm | |

| Resolution ∆L°C: | 1nm, 0.05°C | |

| Accuracy in α: | 0.03 x 10-6 K-1 | 0.01 x 10-6 K-1 |

| Atmosphere: | Vacuum, Inert gas, Air (Optional gas unit with massflow controller and optional vacuum unit required for software control of atmosphere.) |

|

| Temperature range: | RT – 150°C – 700°C RT – 1100°C RT – 1500°C RT – 1700°C |

|

Unlike in horizontal dilatometry the vertical design does not require the sample to be supported. The specimen stands free on the bottom plate and the pushrod is loaded on its tip.

The vertical configuration is particularly well suited for high temperature measurements in syntherization studies and for powder samples. It also prevents the measuring systems and furnace tubes from sagging when used over long test periods at high temperatures, resulting in extended operational life.

The incremental optical encoder delivers resolution up to 1 nm over a wide measuring range. This allows for the option of using smaller samples that results in significantly better test measurements due to the reduced thermal gradient. Additionally the linear actuator produces a very precise and truly constant sample load ranging from 0.01 to 1 N

The combination of the innovative techniques and design of the DIL 820 series makes TA Instrument´s vertical dilatometers the ideal instruments for high sintering rate measurements and experiments with specimens with high shrinkage.

As an example, WinTA software’s new T-RCS (True-Rate Controlled Sintering) functionality automatically corrects the heating profile to achieve a constant sintering rate (shrinkage per time) of a ceramic green body. The true, absolute shrinkage of the sample has to be recorded and interpreted in real time. In this case, the True Differential system of the DIL 822 and DIL 822HT becomes the perfect solution.

In another example, the use of an alumina disc under and on top of the sample allows the user to run experiments up to the sample’s softening point without damaging the measuring system. A key advantage of the vertical design is it does not require the sample be placed on a support. This eliminates friction during the shrinkage/expansion preventing any and all of the possible related measurement errors, as well as damages to the measuring systems.

Additionally, fragile, powdery or softening samples can be measured easily as the vertical design and precise force control prevent specimens from collapsing or sagging.

Advantage of Vertical Dilatometer for Sintering

TA’s unique vertical push-rod dilatometers are ideal for the study and optimization of sintering processes. When the sample is oriented in the vertical position, negligible force can be applied to the sample which minimizes excessive deformation that occurs in a horizontal dilatometer. In addition, the frictional interactions between the sample and the holder are also minimized. Both of these effects lead to incorrect shrinkage results in a horizontal dilatometer. In the example at the bottom right, the same ceramic body has been sintered both at constant heating rate and in Rate Controlled Sintering (RCS). Constant heating rate is preferred for faster sintering process and is usually employed for the manufacturing of traditional ceramic products. RCS maximizes the densification of the sample and is preferred in the advanced ceramics industry.

DIL 820 Series Vertical Dilatometers

The New ODP860 Series – Optical Dilatometry Platform

DIL 830 Series High Resolution Horizontal Dilatometers

- Description

-

The 820 Series operate in a vertical orientation, making it uniquely set up for the analysis of sintering, studies in Rate Controlled Sintering (RCS) mode and the determination of dilatometric parameters of samples otherwise difficult to be analyzed on classic dilatometers with horizontal design.

Available in two different models (DIL 821 and DIL 822), both the units feature the new optical encoder with 1nm resolution. That when combined with the True Differential of the DIL822, the result is simply the best possible sensitivity and CTE accuracy on the market.

Unlike in horizontal dilatometry the vertical design does not require the sample to be supported. The specimen stands free on the bottom plate and the pushrod is loaded on its tip.

The vertical configuration is particularly well suited for sintering studies as well as for all those samples difficult to be tested with horizontal pushrod dilatometers. As, for instance, powder samples and samples developing vitreous phases during the test.

Equipped with a linear motor capable to generate a constant force throughout the experiment, DIL 820 Series allows for the lightest possible force regardless of the extent of specimen’s dimensional changes.

- Specifications

-

DIL 821 DIL 822 Sample length 0 to 25 mm Sample diameter: 10mm 5mm Material of sample holder: Fused silica, Al2O3 Contact Force: 0.01 – 1.0N Change of length: 5mm Resolution ∆L°C: 1nm, 0.05°C Accuracy in α: 0.03 x 10-6 K-1 0.01 x 10-6 K-1 Atmosphere: Vacuum, Inert gas, Air

(Optional gas unit with massflow controller and optional vacuum unit required for software control of atmosphere.)Temperature range: RT – 150°C – 700°C

RT – 1100°C

RT – 1500°C

RT – 1700°C - Measuring Principle

-

Unlike in horizontal dilatometry the vertical design does not require the sample to be supported. The specimen stands free on the bottom plate and the pushrod is loaded on its tip.

The vertical configuration is particularly well suited for high temperature measurements in syntherization studies and for powder samples. It also prevents the measuring systems and furnace tubes from sagging when used over long test periods at high temperatures, resulting in extended operational life.

The incremental optical encoder delivers resolution up to 1 nm over a wide measuring range. This allows for the option of using smaller samples that results in significantly better test measurements due to the reduced thermal gradient. Additionally the linear actuator produces a very precise and truly constant sample load ranging from 0.01 to 1 N

- Applications

-

The combination of the innovative techniques and design of the DIL 820 series makes TA Instrument´s vertical dilatometers the ideal instruments for high sintering rate measurements and experiments with specimens with high shrinkage.

As an example, WinTA software’s new T-RCS (True-Rate Controlled Sintering) functionality automatically corrects the heating profile to achieve a constant sintering rate (shrinkage per time) of a ceramic green body. The true, absolute shrinkage of the sample has to be recorded and interpreted in real time. In this case, the True Differential system of the DIL 822 and DIL 822HT becomes the perfect solution.

In another example, the use of an alumina disc under and on top of the sample allows the user to run experiments up to the sample’s softening point without damaging the measuring system. A key advantage of the vertical design is it does not require the sample be placed on a support. This eliminates friction during the shrinkage/expansion preventing any and all of the possible related measurement errors, as well as damages to the measuring systems.

Additionally, fragile, powdery or softening samples can be measured easily as the vertical design and precise force control prevent specimens from collapsing or sagging.

Advantage of Vertical Dilatometer for Sintering

TA’s unique vertical push-rod dilatometers are ideal for the study and optimization of sintering processes. When the sample is oriented in the vertical position, negligible force can be applied to the sample which minimizes excessive deformation that occurs in a horizontal dilatometer. In addition, the frictional interactions between the sample and the holder are also minimized. Both of these effects lead to incorrect shrinkage results in a horizontal dilatometer. In the example at the bottom right, the same ceramic body has been sintered both at constant heating rate and in Rate Controlled Sintering (RCS). Constant heating rate is preferred for faster sintering process and is usually employed for the manufacturing of traditional ceramic products. RCS maximizes the densification of the sample and is preferred in the advanced ceramics industry.

- Videos

-

DIL 820 Series Vertical Dilatometers

The New ODP860 Series – Optical Dilatometry Platform

DIL 830 Series High Resolution Horizontal Dilatometers