Dilatometry Platform

Above and beyond the limits of classic push-rod dilatometry.

Result of over twenty years of R&D of optical instruments for the study of the thermo-mechanical behavior of materials, ODP 868 makes possible the analysis of samples beyond the limits of classical heating microscopy. Its versatility makes of ODP 868 the most innovative tool for production and R&D laboratories for the optimization of all the industrial processes that involve thermal cycles.

The Heating Microscope mode uses a 5Mpix high resolution camera to study the physical behavior of the materials during the industrial firing cycles.

With the Morphometrics applicative it is possible, in real-time during the analysis, to automatically calculate and visualize different characteristic temperatures and parameters selectable by the user.

Capable to analyze samples in a wide range of shapes and sizes (for example a 3mm sample and simultaneously a 10mm sample), ODP 868 can simultaneously analyze up to 8 samples of ISO standard size.

Read more >>

The HORIZONTAL DILATOMETER mode has 2 HiRes videocameras and is used to study expansion and shrinkage of samples 30 to 60mm long. It is possible to easily determine the most significant parameters like linear thermal expansion, coefficient of thermal expansion (CTE), glass transition temperature (Tg) and the dilatometric softening temperature.

Used to study the sintering of materials without significant vitreous phases, can follow contractions of up to 50% with heating rates up to 100°C/min. For samples that melt, a disposable holding plate is provided.

The whole measuring system is thermally isolated from the furnace chamber.

FLEXIMETER and ABSOLUTE FLEXIMETER modes, through 3 high resolution independent cameras, enable non-contact bending measurements simulating real industrial heat treatments in order to optimize manufacturing processes of ceramic products as well as have a better and deeper understanding of the materials.

In absolute fleximetry mode the 3 cameras allow to measure simultaneously the sample position in three different points (TA patent), removing the need of a correction curve.

The bending experiments can be carried out on samples 80-85mm or 25-30mm long and it is possible to:

- analyze bending caused by the difference in thermal expansion between coupled materials (i.e.: body and a glaze)

- determine coupling temperature (formerly done with a Steger tensiometer);

- measure bending caused by the difference in sintering behaviour between several coupling materials (i.e.: glaze, engobe and ceramic body);

- measure bending during cooling, caused by the volume variation of the glassy phases;

- study pyroplastic deformation and speed of deformation occurring in the material at high temperature due to its weight;

measure bending caused by absorption of water on one face of the green material.

|

ODP 868 |

|

| Optical measuring system | Optical bench with 4 independent optical measuring systems, each equipped with a high-resolution camera and fully automated focus |

| Operating modes | Heating microscope, optical dilatometer horizontal, optical fleximeter and absolute fleximeter |

| International Standards | ASTM D1857, CEN/TR 15404, BS 1016:Part 15, CEN/TS 15370-1, DIN 51730, IS 12891, ISO 540, NF M03-048 |

| Sample displacement | Bidimensional |

| Sample number | Optical dilatometry and fleximetry: 1 Heating microscopy: up to 8 (depending on sample sizes) |

| Temperature range on specimen | RT – 1650 °C |

| Temperature resolution | 0,2 °C |

| Heating rate | 0,1 – 100 °C/min 200 °C/sec in Flash mode |

| Resolution | 3 ppm in Heating Microscopy

250 nm in Horizontal Dilatometry 500 μm in Fleximetry |

| Sample dimensions: | Up to 85 mm width and up to 19 mm height (depending upon operating mode) |

| Morphometrics | Height, Width, Contact angle, Height/Width Ratio, Perimeter, Area, Roundness, Eccentricity, Center of mass. More and freely user-selectable also possible |

| Atmosphere | Air |

| Light source | LED |

| Software | Misura 4 Thermal Analysis software |

With Misura 4 Thermal Analysis software it is possible to define, easily and intuitively, analytical methods comprising an unlimited number of segments of unlimited duration and complexity.

Structured in “Apps”, Misura 4 Thermal Analysis software includes instrument control and data analysis for all the five different operating modes.

HSM App allows to run tests of heating microscopy.

Because of Misura 4’s advanced morphometrical applicative for the image analysis, during the sintering process it is possible to automatically detect: characteristic temperatures (sintering beginning, softening, sphere, half-sphere and melting / fusion), flattening curve, contact angle curve, sample area variation curve, ratio curve between width and height, bloating effects, combustion, theoretical glass viscosity (V.F.T. equation) and, optionally, surface tension (glasses) using the Young-Laplace equation.

The recognition of shapes can be done accordingly to a wide range of international standards or to user-defined parameters and concepts.

All the results, the complete series of original frames and the sample shapes are stored in a database together with analytical parameters in a non-proprietary format file. To validate the integrity of the results, the output file is cryptographically validated and signed.

Through the browser-based interface it is possible to access test files and view all the configuration options, analysis results and archived images and:

- print graphs of single tests;

- export images selecting single or multiple frames;

- generate customized, interactive PDF reports;

- export all images in movie format (.AVI) usable in presentations or video reports;

- re-define standard methods to recognize automatically the characteristic temperatures;

- input key data as glass transition temperature (Tg), dilatometric softening temperature softening temperature, hemisphere temperature in order to calculate theoretical viscosity of materials according to V.F.T. equation;

- store analysis and related data without overwriting the original data;

- validate cryptographically the original data.

Files can be opened in a graphic module providing printing and advanced mathematical functionalities.

Multiple tests can be overlapped on the same graph, and all the curves can be displayed or printed separately or overlapped to other curves, also related to tests performed with other thermal techniques.

It is possible to view all the measured parameters characterizing the softening and melting behavior and the fusibility according to international standards.

Graphs can import data from a large variety of formats (CSV, FITS, NPY, QDP, HDF) and drawn in Misura® data sets.

All the graphs have quality and resolution necessary to be edited and to be exported in PNG raster format, PDF or SVG vectorial format.

Furthermore it is possible to open directly and automatically the data archive related to each analysis.

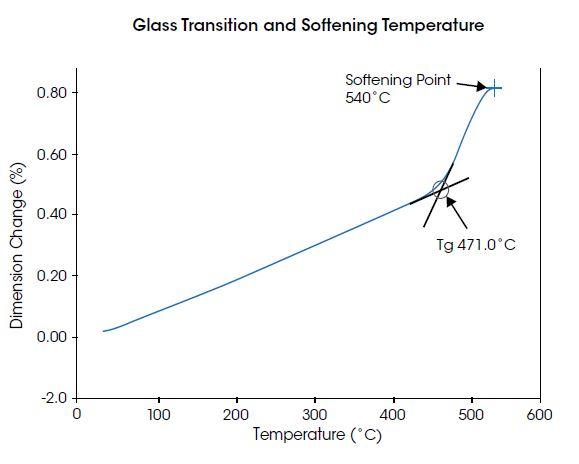

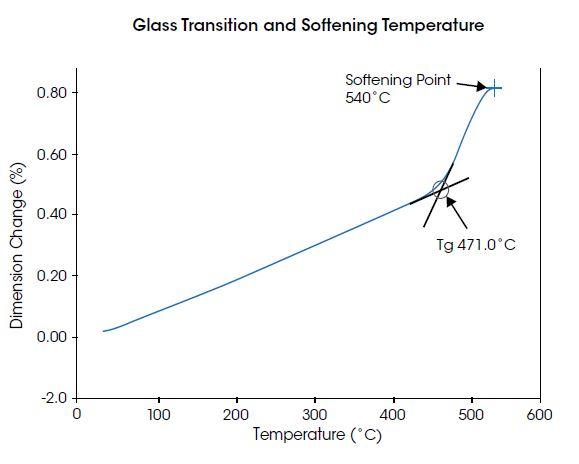

Measurements of Glass Transition and Softening Temperature

Measurements of Glass Transition and Softening Temperature

Two important measurements commonly made on a dilatometer are the determinations of the glass transition temperature, Tg, and the softening point. The figure to the top right shows results of thermal expansion for glass material as measured on TA Instruments True Differential™ Dilatometer. It can be seen here that the sample was heated through the Tg, observed at 471°C, to the softening point, observed at a temperature of 540°C.

The instrument control software includes a unique “automatic softening point detection” function to terminate the test. This feature allows these properties to be measured for unknown materials without concern of damage to the instrument that could result if the sample is melted and flows onto components.

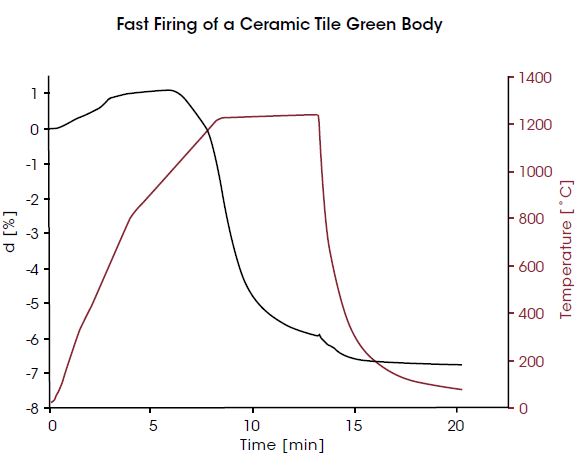

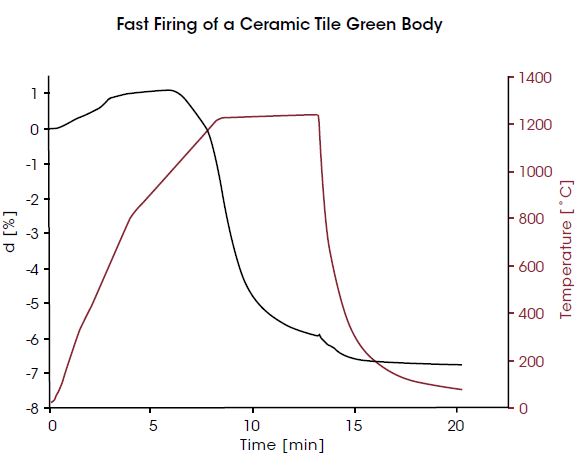

Simulating a Fast Firing Cycle in the Lab with Optical Dilatometry

Simulating a Fast Firing Cycle in the Lab with Optical Dilatometry

Fast firing of traditional ceramics has quickly become the preferred processing technology because of the reduction in cost and increased productivity it provides. Because fast firing requires all materials within the ceramic body to obtain optimal stabilization within a few minutes, some raw materials used in slower firing process may not be suitable. Therefore, it is important to understand the suitability of all raw materials in the laboratory before scaling a batch up for production. TA Instruments’ optical dilatometer, ODP 868, includes a furnace capable of rapid heating and cooling, allowing the simulation of thermal profiles of fast firing kilns and eliminating the need for expensive and time-consuming pilot-scale tests. An example is shown in the figure at the top right. Here a green body was heated to 800°C in 4 minutes, then to 1220°C in 4.2 minutes, and held isothermally for five minutes to allow the body to fully sinter. Subsequently, the furnace was fast cooled to 680°C in 30 seconds and then to 100°C in 5.3 minutes. It can be seen in the figure that, at the end of the process, the sample was properly sintered and dimensionally stable.

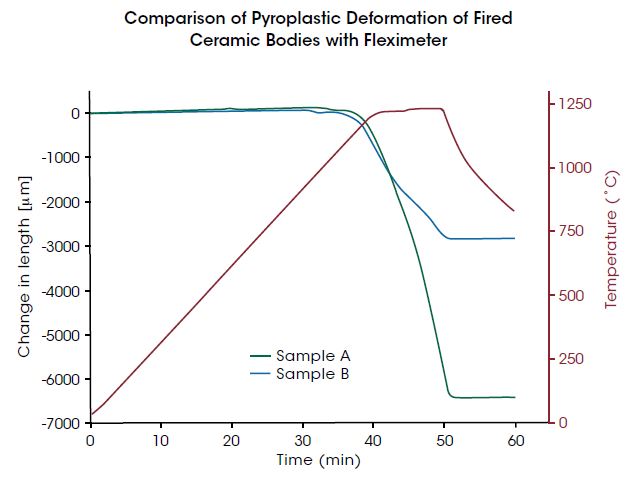

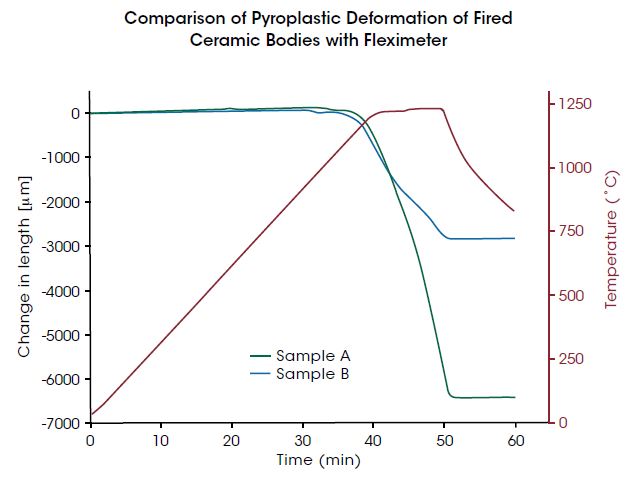

Pyroplasticity Study of Sintered Bodies with Absolute Fleximeter

Pyroplasticity Study of Sintered Bodies with Absolute Fleximeter

The ceramic tile market is trending towards larger formats and faces the challenge of reducing the tile thickness while maintaining planarity. Flatness defects can be induced during pressing, firing, or cooling. During firing, the amount of deformation is dependent on the viscosity of the glassy phases. The viscosity follows an Arrhenius relationship. However, some materials will exhibit a change in the composition of the glassy phase during the firing process which results in an increase of viscosity as the temperature increases. The figure to the right shows results of two different sintered bodies that were tested using the Absolute Fleximetry mode of the ODP 868. It can be seen here that “Sample A” starts bending, and as the temperature continues to increase, the sample can no longer support its own weight and ultimately flexes over 6 mm (i.e. 7.5%). “Sample B” shows dramatically different flexing behavior. For this sample, the softening vitreous phases dissolve other mineral components present in the body. As a result, the viscosity increases with the temperature, and the body tends to flex less. The latter result will produce a tile in a larger format that is easier to process and with better planarity.

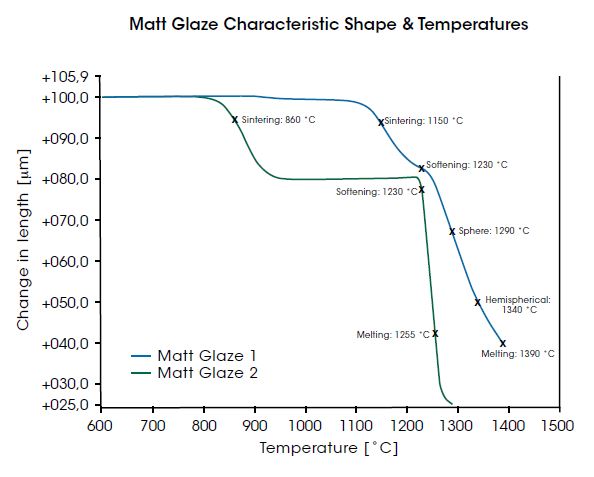

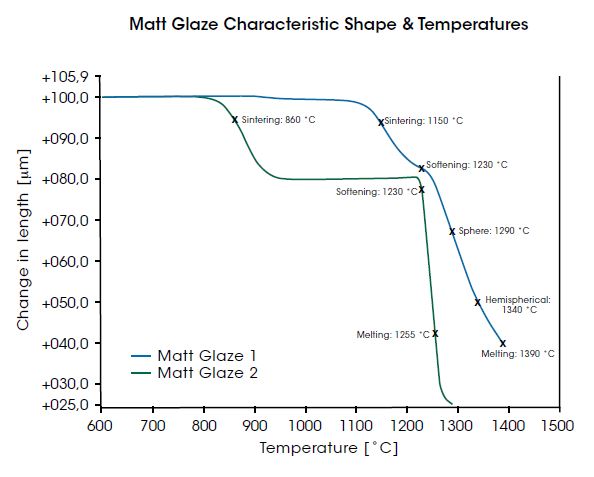

Identification of Characteristic Shapes and Temperatures with Heating Microscopy

Identification of Characteristic Shapes and Temperatures with

Heating Microscopy

Heating microscopy identifies a material’s characteristic shapes and corresponding temperatures, and is a must-have tool for optimizing manufacturing processes in ceramics, metals and alloys. The top right graph shows a comparison of two matt glazes. For Matt Glaze 1 all the five basic characteristic shapes were identified, and the data reveals the sample has a strong surface tension and a poor compatibility with the substrate of the sample holder. In contrast, Matt Glaze 2 not only melts at lower temperature but has a great degree of compatibility with the substrate. After Matt Glaze 2 melts, it spreads evenly over the surface of the substrates making it an ideal candidate for bodies of the same or similar composition of the substrate. The characteristic temperatures were automatically identified by MorphometriXTM, TA Instruments’ image analysis software engine equipped with pattern-matching models for recognition of transformations in materials in real-time with precision superseding the eye of a human operator.

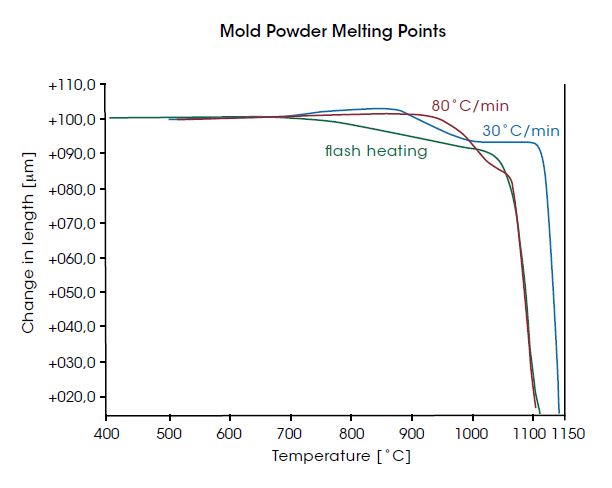

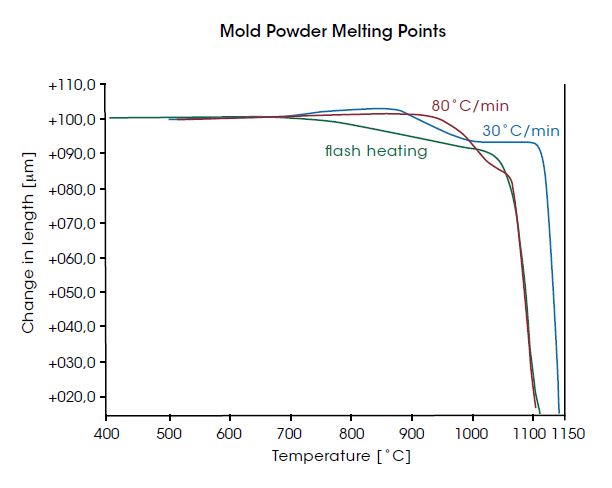

Characterization of Mold Powders for Continuous Casting

Characterization of Mold Powders for Continuous Casting

Mold powders are added to the top of molten steel in a continuous casting mold.

The powder partially melts, forming a liquid layer next to the molten steel protecting it from reoxidation, absorbing the non-metallic inclusions, lubricating the steel shell as it passes through the mold, and controlling the heat transfer from the solidifying steel shell to the mold. If the mold powder does not readily flow, and completely covers the exposed surface of the molten steel, the thermal insulation it is meant to provide is not sufficient leading to unwanted reoxidation and inefficient removal of non-metallic inclusions. Because the melting behavior of mold powders is dependent on heating rate, it is very important to accurately measure this behavior at actual ballistic heating rates of the process to understand performance during the casting process. TA’s Optical Dilatometer Platform, ODP 868, with flash and rapid heating capabilities is the perfect tool to characterize and understand this behavior. Because the approach is optical, there is no complicated sample preparation as would be the case with traditional push-rod instruments. The figure to the right shows melting points for a mold powder determined at 30°C/min, 80°C/min, and under the most rapid flash conditions. It can be seen that the melting point of the powder decreases with increasing heating rate.

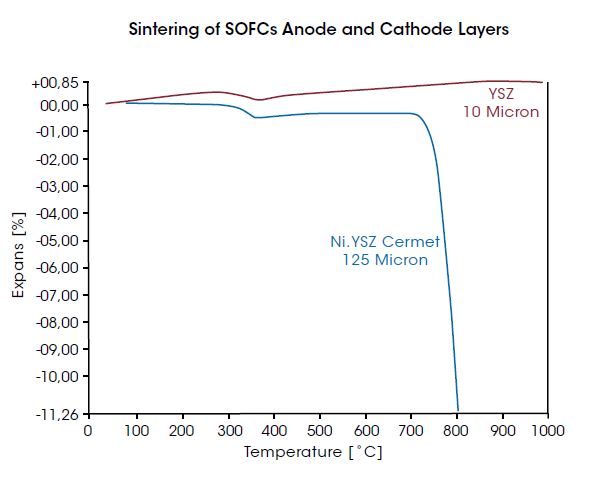

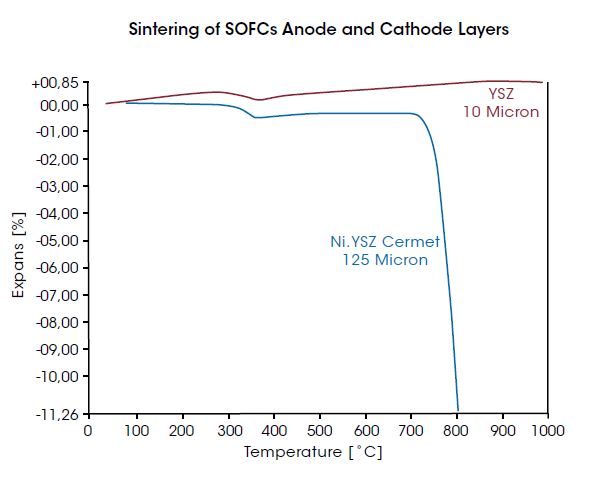

Solid Oxide Fuel Cell Stack Compatibility Study

Solid Oxide Fuel Cell Stack Compatibility Study

Solid Oxide Fuel Cells (SOFC) are devices that convert chemical energy into electrical and thermal energy by combining oxygen and hydrogen. The base of a SOFC cell consists of two porous electrode layers separated by a high-density oxygen-conducting electrolyte layer. The thickness of the entire structure is less than 1 mm. The fabrication process consists of forming the anode and cathode layers, deposition of the electrolyte, and co-sintering of the stack. It is important to understand the behavior of the layers during co-sintering to successfully process SOFCs because a mismatch in shrinkage leads to distortion of the final piece. It is virtually impossible to make these measurements on a traditional pushrod dilatometer because the layers are so thin and not mechanically self-supporting.

However, such measurements are possible using TA’s unique optical dilatometer and film sample holder. The graph to the right shows a sintering study of two materials proposed for an SOFC consisting of a 125 μm thick Nickel/Yttria-stabilized Zirconia ceramic metal (Ni- YSZ cermet) anode and 10 μm thick YSZ electrolyte performed by TA Instruments’ optical dilatometer with Thin Film Holder. It can be seen in the graph that the results measured by the optical dilatometer show significant mismatch of the shrinkage during sintering, demonstrating the two materials are incompatible for the co-sintering process.

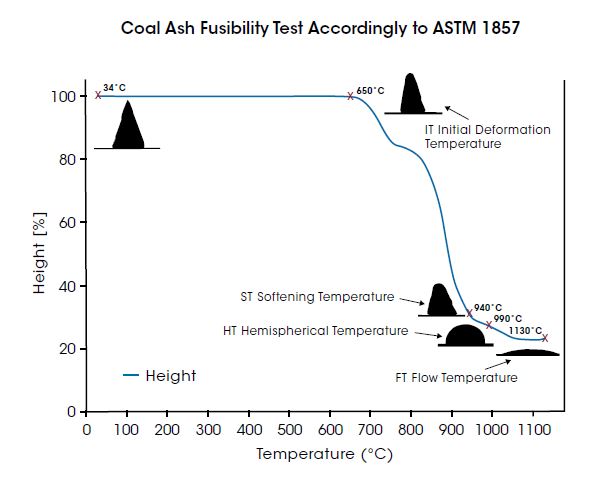

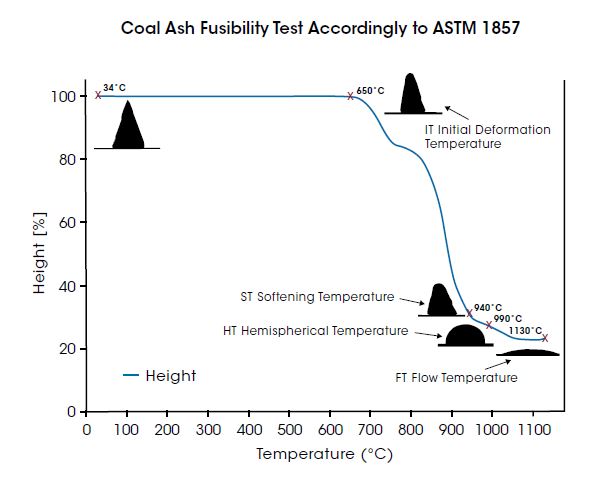

Ash Flow Temperature of Solid Fuels

Ash Flow Temperature of Solid Fuels

Coal, solid recovered fuel, wood and other biomasses are commonly burned to generate heat. During the combustion process, alkaline metals present in these fuels can generate complex eutectic salts and lower the melting point of the ashes. This causes fouling and slagging problems in heat exchangers and superheater tubes, leading to equipment damage and expensive downtime of the power plant. The ash flow temperature (AFT) of a solid fuel gives an indication to what extent ash agglomeration and ash clinkering is likely to occur during gasification. The results of an AFT analysis consist of four temperatures, namely the initial deformation temperature (IDT), softening temperature (ST), hemispherical temperature (HT) and flow temperature (FT). These temperatures can be measured under either oxidizing or reducing conditions (or both), with the difference between the oxidizing and reducing results often correlating strongly with fluxing agents such as iron. Several standard methods, of which the most common are ASTM 1857, ISO 540 and DIN 51730, define how to prepare and test specimens. All methods require the use of a heating microscope like TA Instruments HM 867. The graph on the right shows a fusibility test performed on a 19 mm tall pyramidal coal sample according to ASTM standard 1857. The temperatures of the characteristic shapes were automatically determined with MorphometriXTM Software.

Optical Contact-less Measurement

Optical Contact-less Measurement

The sample is allowed to freely expand/shrink without any interference due to mechanical contact. This results in a more precise determination of specimen’s behaviour when heated/cooled, as well as of the temperature at which the events are detected. Also, the lack of any load on the sample due to the contact with a measuring system enables to extend the analysis well beyond softening point into the melt, and also analyze soft samples that would otherwise be impossible to test.he HiRes CCD videocamera frames the sample up to 14 times a second, enabling an extremely refined image analysis software to automatically determine the characteristic shapes and temperatures necessary to optimize processing parameters for the production of ceramics as well as the processing of metals or the combustion parameters in power plants.

Morphometrix software

Morphometrix software

The evolution of Misura 3 Image Analysis application, Morphometrics can capture up to 14 frames per second making it possible to automatically determine and visualize, in real-time during the analysis, sample’s characteristic shape’s temperatures. The recognition of shapes can be performed accordingly to a wide range of international standards or also by user-defined parameters and concepts.

All the results, the complete series of original frames and the sample shapes are stored in a database together with analytical parameters in a non-proprietary format file.

Temperature Stabilized Optical Bench

Temperature Stabilized Optical Bench

To ensure the ultimate reproducibility and prevent any short-to-mid term drift, regardless of possible temperature fluctuations due to changed environmental conditions, the housing of the optical bench is temperature stabilized by an water cooling.

As a further measure, the support of the optical bench is made of thermally stable materials.

High-performance LED source

High-performance LED source

The LED illumination system operates in the blue range. This significatively improves the resolution as it lowers the limit posed by scattering. As a result it is possible to appreciate smaller changes in shape hence determine with a higher level of accuracy the temperatures of characteristic shapes

Fully Motorized Kiln Operation

Fully Motorized Kiln Operation

For completely automated, error-free operations ODP 868’s furnace rests on a motorized stage ensuring the maximum safety for the user

Flash Mode

Flash Mode

Designed to reproduce the industrial processing conditions, it allows to increase the furnace temperature to a set temperature and then to automatically introduce the specimen in the kiln.

So to heat the sample in a few seconds with heating rates of up to 200°C/sec like in standard manufacturing processes

100 ° C / min Temperature Heating Rates

100 ° C / min Temperature Heating Rates

Up to the temperature range, ODP 868 allows to program heating rates of up to 100°C, enabling users to study the behavior of materials in conditions virtually identical to those used in today’s most demanding manufacturing processes

The New ODP860 Series – Optical Dilatometry Platform

DIL 830 Series High Resolution Horizontal Dilatometers

DIL 820 Series Vertical Dilatometers

- Description

-

Result of over twenty years of R&D of optical instruments for the study of the thermo-mechanical behavior of materials, ODP 868 makes possible the analysis of samples beyond the limits of classical heating microscopy. Its versatility makes of ODP 868 the most innovative tool for production and R&D laboratories for the optimization of all the industrial processes that involve thermal cycles.

The Heating Microscope mode uses a 5Mpix high resolution camera to study the physical behavior of the materials during the industrial firing cycles.

With the Morphometrics applicative it is possible, in real-time during the analysis, to automatically calculate and visualize different characteristic temperatures and parameters selectable by the user.

Capable to analyze samples in a wide range of shapes and sizes (for example a 3mm sample and simultaneously a 10mm sample), ODP 868 can simultaneously analyze up to 8 samples of ISO standard size.

Read more >>

The HORIZONTAL DILATOMETER mode has 2 HiRes videocameras and is used to study expansion and shrinkage of samples 30 to 60mm long. It is possible to easily determine the most significant parameters like linear thermal expansion, coefficient of thermal expansion (CTE), glass transition temperature (Tg) and the dilatometric softening temperature.

Used to study the sintering of materials without significant vitreous phases, can follow contractions of up to 50% with heating rates up to 100°C/min. For samples that melt, a disposable holding plate is provided.

The whole measuring system is thermally isolated from the furnace chamber.

FLEXIMETER and ABSOLUTE FLEXIMETER modes, through 3 high resolution independent cameras, enable non-contact bending measurements simulating real industrial heat treatments in order to optimize manufacturing processes of ceramic products as well as have a better and deeper understanding of the materials.

In absolute fleximetry mode the 3 cameras allow to measure simultaneously the sample position in three different points (TA patent), removing the need of a correction curve.

The bending experiments can be carried out on samples 80-85mm or 25-30mm long and it is possible to:

- analyze bending caused by the difference in thermal expansion between coupled materials (i.e.: body and a glaze)

- determine coupling temperature (formerly done with a Steger tensiometer);

- measure bending caused by the difference in sintering behaviour between several coupling materials (i.e.: glaze, engobe and ceramic body);

- measure bending during cooling, caused by the volume variation of the glassy phases;

- study pyroplastic deformation and speed of deformation occurring in the material at high temperature due to its weight;

measure bending caused by absorption of water on one face of the green material.

- Specifications

-

ODP 868

Optical measuring system Optical bench with 4 independent optical measuring systems, each equipped with a high-resolution camera and fully automated focus Operating modes Heating microscope, optical dilatometer horizontal, optical fleximeter and absolute fleximeter International Standards ASTM D1857, CEN/TR 15404,

BS 1016:Part 15, CEN/TS 15370-1, DIN 51730, IS 12891, ISO 540, NF M03-048Sample displacement Bidimensional Sample number Optical dilatometry and fleximetry: 1

Heating microscopy: up to 8 (depending on sample sizes)Temperature range on specimen RT – 1650 °C Temperature resolution 0,2 °C Heating rate 0,1 – 100 °C/min

200 °C/sec in Flash modeResolution 3 ppm in Heating Microscopy 250 nm in Horizontal Dilatometry

500 μm in Fleximetry

Sample dimensions: Up to 85 mm width and up to 19 mm height (depending upon operating mode) Morphometrics Height, Width, Contact angle, Height/Width Ratio, Perimeter, Area, Roundness, Eccentricity, Center of mass.

More and freely user-selectable also possibleAtmosphere Air Light source LED Software Misura 4 Thermal Analysis software - Software

-

With Misura 4 Thermal Analysis software it is possible to define, easily and intuitively, analytical methods comprising an unlimited number of segments of unlimited duration and complexity.

Structured in “Apps”, Misura 4 Thermal Analysis software includes instrument control and data analysis for all the five different operating modes.

HSM App allows to run tests of heating microscopy.

Because of Misura 4’s advanced morphometrical applicative for the image analysis, during the sintering process it is possible to automatically detect: characteristic temperatures (sintering beginning, softening, sphere, half-sphere and melting / fusion), flattening curve, contact angle curve, sample area variation curve, ratio curve between width and height, bloating effects, combustion, theoretical glass viscosity (V.F.T. equation) and, optionally, surface tension (glasses) using the Young-Laplace equation.

The recognition of shapes can be done accordingly to a wide range of international standards or to user-defined parameters and concepts.

All the results, the complete series of original frames and the sample shapes are stored in a database together with analytical parameters in a non-proprietary format file. To validate the integrity of the results, the output file is cryptographically validated and signed.

Through the browser-based interface it is possible to access test files and view all the configuration options, analysis results and archived images and:

- print graphs of single tests;

- export images selecting single or multiple frames;

- generate customized, interactive PDF reports;

- export all images in movie format (.AVI) usable in presentations or video reports;

- re-define standard methods to recognize automatically the characteristic temperatures;

- input key data as glass transition temperature (Tg), dilatometric softening temperature softening temperature, hemisphere temperature in order to calculate theoretical viscosity of materials according to V.F.T. equation;

- store analysis and related data without overwriting the original data;

- validate cryptographically the original data.

Files can be opened in a graphic module providing printing and advanced mathematical functionalities.

Multiple tests can be overlapped on the same graph, and all the curves can be displayed or printed separately or overlapped to other curves, also related to tests performed with other thermal techniques.

It is possible to view all the measured parameters characterizing the softening and melting behavior and the fusibility according to international standards.

Graphs can import data from a large variety of formats (CSV, FITS, NPY, QDP, HDF) and drawn in Misura® data sets.

All the graphs have quality and resolution necessary to be edited and to be exported in PNG raster format, PDF or SVG vectorial format.

Furthermore it is possible to open directly and automatically the data archive related to each analysis.

- Applications

-

Measurements of Glass Transition and Softening Temperature

Measurements of Glass Transition and Softening Temperature

Two important measurements commonly made on a dilatometer are the determinations of the glass transition temperature, Tg, and the softening point. The figure to the top right shows results of thermal expansion for glass material as measured on TA Instruments True Differential™ Dilatometer. It can be seen here that the sample was heated through the Tg, observed at 471°C, to the softening point, observed at a temperature of 540°C.

The instrument control software includes a unique “automatic softening point detection” function to terminate the test. This feature allows these properties to be measured for unknown materials without concern of damage to the instrument that could result if the sample is melted and flows onto components.Simulating a Fast Firing Cycle in the Lab with Optical Dilatometry

Simulating a Fast Firing Cycle in the Lab with Optical Dilatometry

Fast firing of traditional ceramics has quickly become the preferred processing technology because of the reduction in cost and increased productivity it provides. Because fast firing requires all materials within the ceramic body to obtain optimal stabilization within a few minutes, some raw materials used in slower firing process may not be suitable. Therefore, it is important to understand the suitability of all raw materials in the laboratory before scaling a batch up for production. TA Instruments’ optical dilatometer, ODP 868, includes a furnace capable of rapid heating and cooling, allowing the simulation of thermal profiles of fast firing kilns and eliminating the need for expensive and time-consuming pilot-scale tests. An example is shown in the figure at the top right. Here a green body was heated to 800°C in 4 minutes, then to 1220°C in 4.2 minutes, and held isothermally for five minutes to allow the body to fully sinter. Subsequently, the furnace was fast cooled to 680°C in 30 seconds and then to 100°C in 5.3 minutes. It can be seen in the figure that, at the end of the process, the sample was properly sintered and dimensionally stable.

Pyroplasticity Study of Sintered Bodies with Absolute Fleximeter

Pyroplasticity Study of Sintered Bodies with Absolute Fleximeter

The ceramic tile market is trending towards larger formats and faces the challenge of reducing the tile thickness while maintaining planarity. Flatness defects can be induced during pressing, firing, or cooling. During firing, the amount of deformation is dependent on the viscosity of the glassy phases. The viscosity follows an Arrhenius relationship. However, some materials will exhibit a change in the composition of the glassy phase during the firing process which results in an increase of viscosity as the temperature increases. The figure to the right shows results of two different sintered bodies that were tested using the Absolute Fleximetry mode of the ODP 868. It can be seen here that “Sample A” starts bending, and as the temperature continues to increase, the sample can no longer support its own weight and ultimately flexes over 6 mm (i.e. 7.5%). “Sample B” shows dramatically different flexing behavior. For this sample, the softening vitreous phases dissolve other mineral components present in the body. As a result, the viscosity increases with the temperature, and the body tends to flex less. The latter result will produce a tile in a larger format that is easier to process and with better planarity.

Identification of Characteristic Shapes and Temperatures with Heating Microscopy

Identification of Characteristic Shapes and Temperatures with

Heating MicroscopyHeating microscopy identifies a material’s characteristic shapes and corresponding temperatures, and is a must-have tool for optimizing manufacturing processes in ceramics, metals and alloys. The top right graph shows a comparison of two matt glazes. For Matt Glaze 1 all the five basic characteristic shapes were identified, and the data reveals the sample has a strong surface tension and a poor compatibility with the substrate of the sample holder. In contrast, Matt Glaze 2 not only melts at lower temperature but has a great degree of compatibility with the substrate. After Matt Glaze 2 melts, it spreads evenly over the surface of the substrates making it an ideal candidate for bodies of the same or similar composition of the substrate. The characteristic temperatures were automatically identified by MorphometriXTM, TA Instruments’ image analysis software engine equipped with pattern-matching models for recognition of transformations in materials in real-time with precision superseding the eye of a human operator.

Characterization of Mold Powders for Continuous Casting

Characterization of Mold Powders for Continuous Casting

Mold powders are added to the top of molten steel in a continuous casting mold.

The powder partially melts, forming a liquid layer next to the molten steel protecting it from reoxidation, absorbing the non-metallic inclusions, lubricating the steel shell as it passes through the mold, and controlling the heat transfer from the solidifying steel shell to the mold. If the mold powder does not readily flow, and completely covers the exposed surface of the molten steel, the thermal insulation it is meant to provide is not sufficient leading to unwanted reoxidation and inefficient removal of non-metallic inclusions. Because the melting behavior of mold powders is dependent on heating rate, it is very important to accurately measure this behavior at actual ballistic heating rates of the process to understand performance during the casting process. TA’s Optical Dilatometer Platform, ODP 868, with flash and rapid heating capabilities is the perfect tool to characterize and understand this behavior. Because the approach is optical, there is no complicated sample preparation as would be the case with traditional push-rod instruments. The figure to the right shows melting points for a mold powder determined at 30°C/min, 80°C/min, and under the most rapid flash conditions. It can be seen that the melting point of the powder decreases with increasing heating rate.Solid Oxide Fuel Cell Stack Compatibility Study

Solid Oxide Fuel Cell Stack Compatibility Study

Solid Oxide Fuel Cells (SOFC) are devices that convert chemical energy into electrical and thermal energy by combining oxygen and hydrogen. The base of a SOFC cell consists of two porous electrode layers separated by a high-density oxygen-conducting electrolyte layer. The thickness of the entire structure is less than 1 mm. The fabrication process consists of forming the anode and cathode layers, deposition of the electrolyte, and co-sintering of the stack. It is important to understand the behavior of the layers during co-sintering to successfully process SOFCs because a mismatch in shrinkage leads to distortion of the final piece. It is virtually impossible to make these measurements on a traditional pushrod dilatometer because the layers are so thin and not mechanically self-supporting.

However, such measurements are possible using TA’s unique optical dilatometer and film sample holder. The graph to the right shows a sintering study of two materials proposed for an SOFC consisting of a 125 μm thick Nickel/Yttria-stabilized Zirconia ceramic metal (Ni- YSZ cermet) anode and 10 μm thick YSZ electrolyte performed by TA Instruments’ optical dilatometer with Thin Film Holder. It can be seen in the graph that the results measured by the optical dilatometer show significant mismatch of the shrinkage during sintering, demonstrating the two materials are incompatible for the co-sintering process.

Ash Flow Temperature of Solid Fuels

Ash Flow Temperature of Solid Fuels

Coal, solid recovered fuel, wood and other biomasses are commonly burned to generate heat. During the combustion process, alkaline metals present in these fuels can generate complex eutectic salts and lower the melting point of the ashes. This causes fouling and slagging problems in heat exchangers and superheater tubes, leading to equipment damage and expensive downtime of the power plant. The ash flow temperature (AFT) of a solid fuel gives an indication to what extent ash agglomeration and ash clinkering is likely to occur during gasification. The results of an AFT analysis consist of four temperatures, namely the initial deformation temperature (IDT), softening temperature (ST), hemispherical temperature (HT) and flow temperature (FT). These temperatures can be measured under either oxidizing or reducing conditions (or both), with the difference between the oxidizing and reducing results often correlating strongly with fluxing agents such as iron. Several standard methods, of which the most common are ASTM 1857, ISO 540 and DIN 51730, define how to prepare and test specimens. All methods require the use of a heating microscope like TA Instruments HM 867. The graph on the right shows a fusibility test performed on a 19 mm tall pyramidal coal sample according to ASTM standard 1857. The temperatures of the characteristic shapes were automatically determined with MorphometriXTM Software.

- Technology

-

Optical Contact-less Measurement

Optical Contact-less Measurement

The sample is allowed to freely expand/shrink without any interference due to mechanical contact. This results in a more precise determination of specimen’s behaviour when heated/cooled, as well as of the temperature at which the events are detected. Also, the lack of any load on the sample due to the contact with a measuring system enables to extend the analysis well beyond softening point into the melt, and also analyze soft samples that would otherwise be impossible to test.he HiRes CCD videocamera frames the sample up to 14 times a second, enabling an extremely refined image analysis software to automatically determine the characteristic shapes and temperatures necessary to optimize processing parameters for the production of ceramics as well as the processing of metals or the combustion parameters in power plants.

Morphometrix software

Morphometrix software

The evolution of Misura 3 Image Analysis application, Morphometrics can capture up to 14 frames per second making it possible to automatically determine and visualize, in real-time during the analysis, sample’s characteristic shape’s temperatures. The recognition of shapes can be performed accordingly to a wide range of international standards or also by user-defined parameters and concepts.

All the results, the complete series of original frames and the sample shapes are stored in a database together with analytical parameters in a non-proprietary format file.

Temperature Stabilized Optical Bench

Temperature Stabilized Optical Bench

To ensure the ultimate reproducibility and prevent any short-to-mid term drift, regardless of possible temperature fluctuations due to changed environmental conditions, the housing of the optical bench is temperature stabilized by an water cooling.

As a further measure, the support of the optical bench is made of thermally stable materials.

High-performance LED source

High-performance LED source

The LED illumination system operates in the blue range. This significatively improves the resolution as it lowers the limit posed by scattering. As a result it is possible to appreciate smaller changes in shape hence determine with a higher level of accuracy the temperatures of characteristic shapes

Fully Motorized Kiln Operation

Fully Motorized Kiln Operation

For completely automated, error-free operations ODP 868’s furnace rests on a motorized stage ensuring the maximum safety for the user

Flash Mode

Flash Mode

Designed to reproduce the industrial processing conditions, it allows to increase the furnace temperature to a set temperature and then to automatically introduce the specimen in the kiln.

So to heat the sample in a few seconds with heating rates of up to 200°C/sec like in standard manufacturing processes

100 ° C / min Temperature Heating Rates

100 ° C / min Temperature Heating Rates

Up to the temperature range, ODP 868 allows to program heating rates of up to 100°C, enabling users to study the behavior of materials in conditions virtually identical to those used in today’s most demanding manufacturing processes

- Videos

-

The New ODP860 Series – Optical Dilatometry Platform

DIL 830 Series High Resolution Horizontal Dilatometers

DIL 820 Series Vertical Dilatometers