Measure the fastest UV curing processes with true inertia-free rheology.

UV curable materials use ultraviolet light or other radiation sources to initiate curing, which allows the formation of permanent bonds without heating. This behavior can be characterized on the ARES-G2 rheometer using the UV Curing Accessory. The accessory uses a light guide and reflecting mirror assembly to transfer UV radiation from a high-pressure Mercury light source to the sample for measurement of the storage and loss moduli during the curing reaction. The accessory includes the upper and lower geometry with removable 20 mm diameter plates, collimator, 5 mm waveguide, and remove radiometer/dosimeter. The system interfaces with a UV light source (Excelitas Omnicure S2000) with wavelengths in the range of 320 to 500 nm. Temperature control up to 150 °C is available using the Advanced Peltier System, APS. Disposable plates are also available for hard UV coatings, which cannot be removed from the plates after curing.

Features and Benefits:

- Broad-spectrum Hg light source with main peak at 365 nm

- Maximum intensity at plate: 300 mW/ cm2

- Collimated light and mirror assembly ensure uniform irradiance across plate diameter

- Compatible with Advanced Peltier System for temperature control up to 150 °C

- Optional filters available for filtering UV light to specific wavelengths

- Completely integrated with TRIOS software with programmable trigger time and intensity control

- Optional disposable acrylic plates available

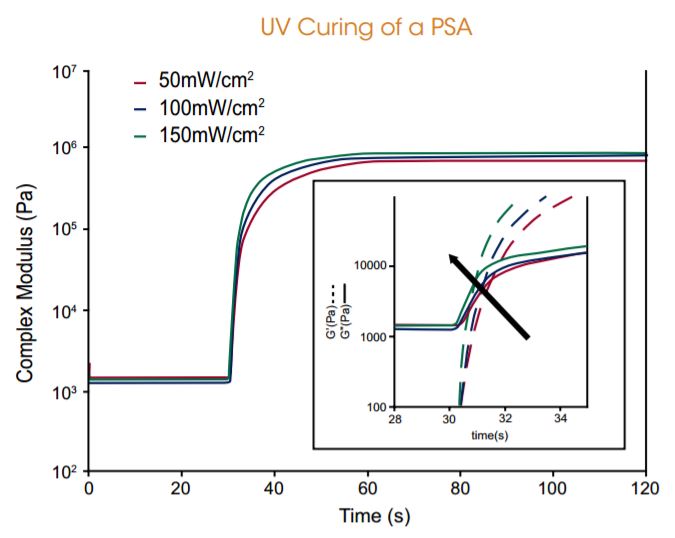

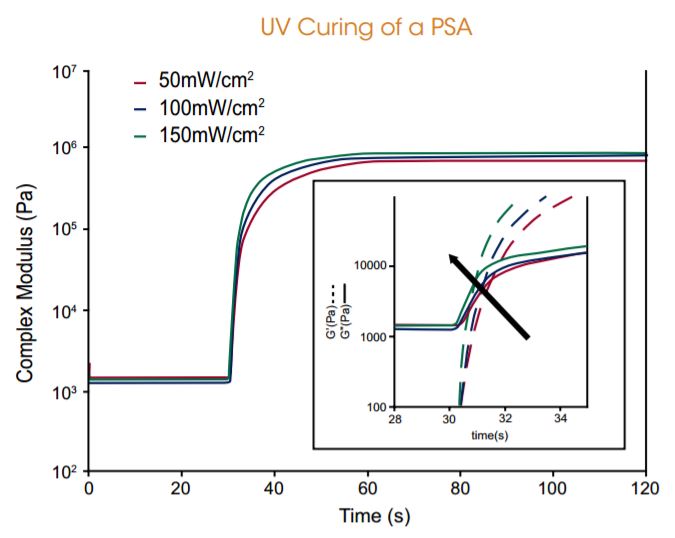

A pressure sensitive adhesive (PSA) was characterized with the UV Curing Accessory. The PSA was held at an isothermal temperature of 25 °C and the curing profile was measured at radiation intensities from 50 mW/cm² to 150 mW/cm². The sample was measured for 30 seconds before the light was turned on. The data show faster reaction kinetics with increasing intensity, as evidenced by the shorter time for crossover of G’ and G”. Similar results can be obtained with controlled temperature, where the reaction is seen to occur more quickly at higher temperatures. The curing reaction happens in less than two seconds. The fast data acquisition of the ARES-G2 (up to 50 pts/sec) enables clear identification of the liquid to solid transition. Note that changing the intensity and temperature by small amounts shifts the crossover point by a fraction of a second. This information is important for understanding adhesive control parameters for high-speed UV curing processes, as well as for understanding differences in initiators when formulating materials.

- Description

-

UV curable materials use ultraviolet light or other radiation sources to initiate curing, which allows the formation of permanent bonds without heating. This behavior can be characterized on the ARES-G2 rheometer using the UV Curing Accessory. The accessory uses a light guide and reflecting mirror assembly to transfer UV radiation from a high-pressure Mercury light source to the sample for measurement of the storage and loss moduli during the curing reaction. The accessory includes the upper and lower geometry with removable 20 mm diameter plates, collimator, 5 mm waveguide, and remove radiometer/dosimeter. The system interfaces with a UV light source (Excelitas Omnicure S2000) with wavelengths in the range of 320 to 500 nm. Temperature control up to 150 °C is available using the Advanced Peltier System, APS. Disposable plates are also available for hard UV coatings, which cannot be removed from the plates after curing.

- Features

-

Features and Benefits:

- Broad-spectrum Hg light source with main peak at 365 nm

- Maximum intensity at plate: 300 mW/ cm2

- Collimated light and mirror assembly ensure uniform irradiance across plate diameter

- Compatible with Advanced Peltier System for temperature control up to 150 °C

- Optional filters available for filtering UV light to specific wavelengths

- Completely integrated with TRIOS software with programmable trigger time and intensity control

- Optional disposable acrylic plates available

- Applications

-

A pressure sensitive adhesive (PSA) was characterized with the UV Curing Accessory. The PSA was held at an isothermal temperature of 25 °C and the curing profile was measured at radiation intensities from 50 mW/cm² to 150 mW/cm². The sample was measured for 30 seconds before the light was turned on. The data show faster reaction kinetics with increasing intensity, as evidenced by the shorter time for crossover of G’ and G”. Similar results can be obtained with controlled temperature, where the reaction is seen to occur more quickly at higher temperatures. The curing reaction happens in less than two seconds. The fast data acquisition of the ARES-G2 (up to 50 pts/sec) enables clear identification of the liquid to solid transition. Note that changing the intensity and temperature by small amounts shifts the crossover point by a fraction of a second. This information is important for understanding adhesive control parameters for high-speed UV curing processes, as well as for understanding differences in initiators when formulating materials.