Combines ultimate flexibility with exceptional temperature performance in a single Peltier Plate temperature system designed to cover the widest range of applications.

View brochure Contact Us

Advanced Peltier Plates

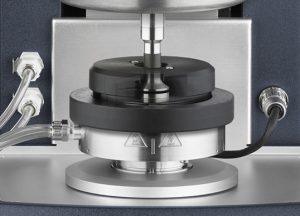

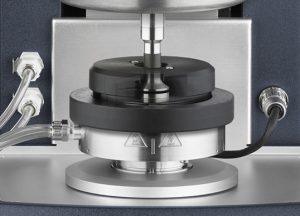

The Advanced Peltier Plates (APP) combine ultimate flexibility with exceptional temperature performance in a single Peltier Plate temperature system designed to cover the widest range of applications. The testing temperature range can be further extended to 200 °C with the new High Temperature-Advanced Peltier Plate (HT-APP), when paired with the Upper Peltier Plate (UPP). This allows users to make rheological measurements in a rugged, reliable and accurate manner. The unique Quick Change Plate system provides the ability to easily attach lower plates of different materials and surface finishes, disposable plates for testing curing materials, and an Immersion Cup for characterizing materials in a fluid environment.

Features and Benefits

- Smart Swap™ technology

- Wide temperature range: -40 °C to 200 °C*

- Accurate temperature control: ± 0.1 °C

- Plates and cones up to 50 mm in diameter

- Robust hardened finish

- Quick Change Plates provide flexibility for modifying lower geometry surface

- Stainless steel, Anodized Aluminum and Titanium plates

- Smooth, Sandblasted and Crosshatched plates

- Disposable plates available for curing materials

- Fully accessorized

- Extremely efficient Solvent Trap to eliminate solvent loss during experiments

- Immersion Cup

- Camera Viewer option

*Testing up to 200 °C requires HT-APP with the UPP

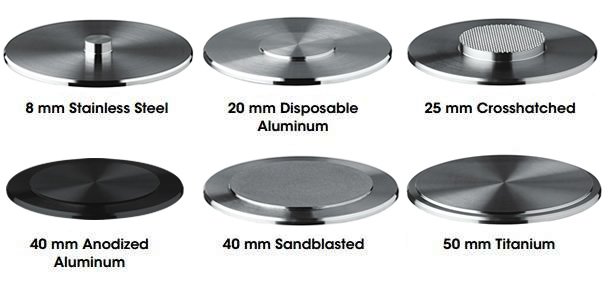

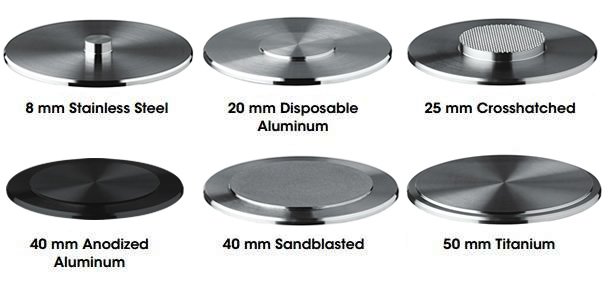

Quick Change Plates

Quick Change Plates

The Advanced Peltier Plate’s simple bayonet-style locking ring facilitates the effortless attachment of a wide range of different lower plate covers including hard-anodized aluminum, titanium and stainless steel plates with smooth, sandblasted or crosshatched surface finishes. Standard disposable aluminum plates expand the capabilities of the system to test curing materials using a single Peltier Plate.

Immersion Cup

Immersion Cup

The Advanced Peltier Plate’s Immersion Cup adds the capability of characterizing material properties when completely immersed in a fluid. It is easily attached to the top of the Advanced Peltier Plate through the bayonet fixture and gives access to the sample for loading, trimming, and subsequent sealing and filling – a rubber ring provides the fluid seal. The Immersion Cup is ideally suited for investigating hydrogel materials and can accommodate plates or cones up to 40 mm in diameter.

Peltier Solvent Trap and Evaporation Blocker

Peltier Solvent Trap and Evaporation Blocker

The Solvent Trap cover and Solvent Trap geometry work in concert to create a thermally stable vapor barrier, virtually eliminating any solvent loss during the experiment as shown in data for water at 40 ˚C to the right. The geometry includes a well that contains very low viscosity oil, or even the volatile solvent present in the sample. The Solvent Trap cover includes a blade that is placed into the solvent contained in the well without touching any other part of the upper geometry. The Solvent Trap sits directly on top of the Peltier Plate surface and an insulating, centering ring ensures perfect placement for quick and easy sample loading. The solvent trap is also available in an insulated model. See Insulating Thermal Covers section for details.

Purge Gas Cover

Purge Gas Cover

The Purge Gas Environmental Cover is a hard-anodized aluminum two-piece split cover with 4 mm diameter compression fittings. An insulating location ring ensures precise and easy location of the cover. This cover is ideal for purging the sample area with nitrogen to prevent condensation during experiments performed below room temperature or with a humidified purge to keep a sample from drying.

Insulating Thermal Covers

Insulating Thermal Covers

Thermal Insulation Covers are constructed of an anodized aluminum core surrounded by an insulating exterior. The aluminum core conducts heat to the upper geometry, providing uniform temperature throughout the sample. The cover is available in standard and solvent trap models. The standard cover accommodates up to 25 mm plates and can be used with all Peltier plate models. It is recommended for use over a temperature range of -10 °C to 90 °C, with samples not susceptible to drying such as oils, caulk, epoxy, and asphalt binder. The Insulated Solvent Trap Cover is compatible with the Standard Peltier Plate and geometries up to 60 mm in diameter. It is recommended for testing of low viscosity materials over the same temperature range above and offers the added benefit of evaporation prevention. Heat break geometries are recommended for use with both covers.

Peltier Plate Camera Viewer

Peltier Plate Camera Viewer

The camera viewer is used in conjunction with streaming video and image capture software. Real-time images can be displayed in the software and an image can be stored with each data point for subsequent viewing during data analysis. The camera viewer is perfect for long experiments with unattended operation for visual inspections of data integrity.

- Description

-

Advanced Peltier Plates

The Advanced Peltier Plates (APP) combine ultimate flexibility with exceptional temperature performance in a single Peltier Plate temperature system designed to cover the widest range of applications. The testing temperature range can be further extended to 200 °C with the new High Temperature-Advanced Peltier Plate (HT-APP), when paired with the Upper Peltier Plate (UPP). This allows users to make rheological measurements in a rugged, reliable and accurate manner. The unique Quick Change Plate system provides the ability to easily attach lower plates of different materials and surface finishes, disposable plates for testing curing materials, and an Immersion Cup for characterizing materials in a fluid environment.

- Features

-

Features and Benefits

- Smart Swap™ technology

- Wide temperature range: -40 °C to 200 °C*

- Accurate temperature control: ± 0.1 °C

- Plates and cones up to 50 mm in diameter

- Robust hardened finish

- Quick Change Plates provide flexibility for modifying lower geometry surface

- Stainless steel, Anodized Aluminum and Titanium plates

- Smooth, Sandblasted and Crosshatched plates

- Disposable plates available for curing materials

- Fully accessorized

- Extremely efficient Solvent Trap to eliminate solvent loss during experiments

- Immersion Cup

- Camera Viewer option

*Testing up to 200 °C requires HT-APP with the UPP

- Technology

-

Quick Change Plates

Quick Change Plates

The Advanced Peltier Plate’s simple bayonet-style locking ring facilitates the effortless attachment of a wide range of different lower plate covers including hard-anodized aluminum, titanium and stainless steel plates with smooth, sandblasted or crosshatched surface finishes. Standard disposable aluminum plates expand the capabilities of the system to test curing materials using a single Peltier Plate.

Immersion Cup

Immersion Cup

The Advanced Peltier Plate’s Immersion Cup adds the capability of characterizing material properties when completely immersed in a fluid. It is easily attached to the top of the Advanced Peltier Plate through the bayonet fixture and gives access to the sample for loading, trimming, and subsequent sealing and filling – a rubber ring provides the fluid seal. The Immersion Cup is ideally suited for investigating hydrogel materials and can accommodate plates or cones up to 40 mm in diameter.

- Accessories

-

Peltier Solvent Trap and Evaporation Blocker

Peltier Solvent Trap and Evaporation Blocker

The Solvent Trap cover and Solvent Trap geometry work in concert to create a thermally stable vapor barrier, virtually eliminating any solvent loss during the experiment as shown in data for water at 40 ˚C to the right. The geometry includes a well that contains very low viscosity oil, or even the volatile solvent present in the sample. The Solvent Trap cover includes a blade that is placed into the solvent contained in the well without touching any other part of the upper geometry. The Solvent Trap sits directly on top of the Peltier Plate surface and an insulating, centering ring ensures perfect placement for quick and easy sample loading. The solvent trap is also available in an insulated model. See Insulating Thermal Covers section for details.

Purge Gas Cover

Purge Gas Cover

The Purge Gas Environmental Cover is a hard-anodized aluminum two-piece split cover with 4 mm diameter compression fittings. An insulating location ring ensures precise and easy location of the cover. This cover is ideal for purging the sample area with nitrogen to prevent condensation during experiments performed below room temperature or with a humidified purge to keep a sample from drying.

Insulating Thermal Covers

Insulating Thermal Covers

Thermal Insulation Covers are constructed of an anodized aluminum core surrounded by an insulating exterior. The aluminum core conducts heat to the upper geometry, providing uniform temperature throughout the sample. The cover is available in standard and solvent trap models. The standard cover accommodates up to 25 mm plates and can be used with all Peltier plate models. It is recommended for use over a temperature range of -10 °C to 90 °C, with samples not susceptible to drying such as oils, caulk, epoxy, and asphalt binder. The Insulated Solvent Trap Cover is compatible with the Standard Peltier Plate and geometries up to 60 mm in diameter. It is recommended for testing of low viscosity materials over the same temperature range above and offers the added benefit of evaporation prevention. Heat break geometries are recommended for use with both covers.

Peltier Plate Camera Viewer

Peltier Plate Camera Viewer

The camera viewer is used in conjunction with streaming video and image capture software. Real-time images can be displayed in the software and an image can be stored with each data point for subsequent viewing during data analysis. The camera viewer is perfect for long experiments with unattended operation for visual inspections of data integrity.