(APS)

Stable, responsive Peltier temperature control technology featuring interchangeable plates or cylinders.

The APS is a Smart SwapTM Peltier temperature controlled environmental system with a temperature range of -10 to 150 °C, with a maximum heating rate of 20°C/min and a temperature accuracy of +/- 0.1 °C. Unlike other Peltier temperature systems, the APS features parallel plate (cone and plate) as well as DIN conforming concentric cylinder geometries to meet the most demanding applications. The new quick-change lower plate comes standard with a 60 mm diameter hardened chromium surface and a unique bayonet fixture that allows the user to quickly and easily adapt the plate surfaces to crosshatched or sandblasted finishes. The APS also features an efficient heated solvent trap cover for blocking evaporation during testing of volatile materials.

Technology

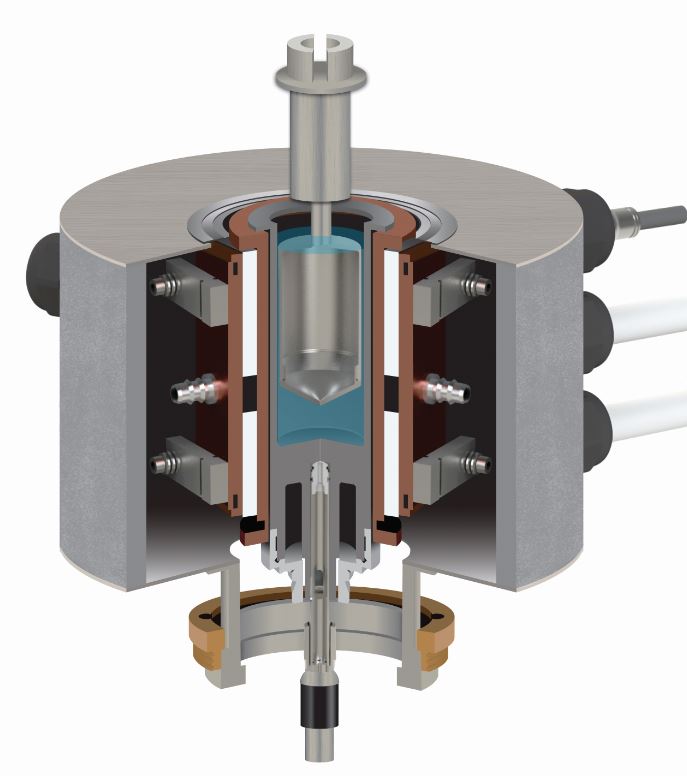

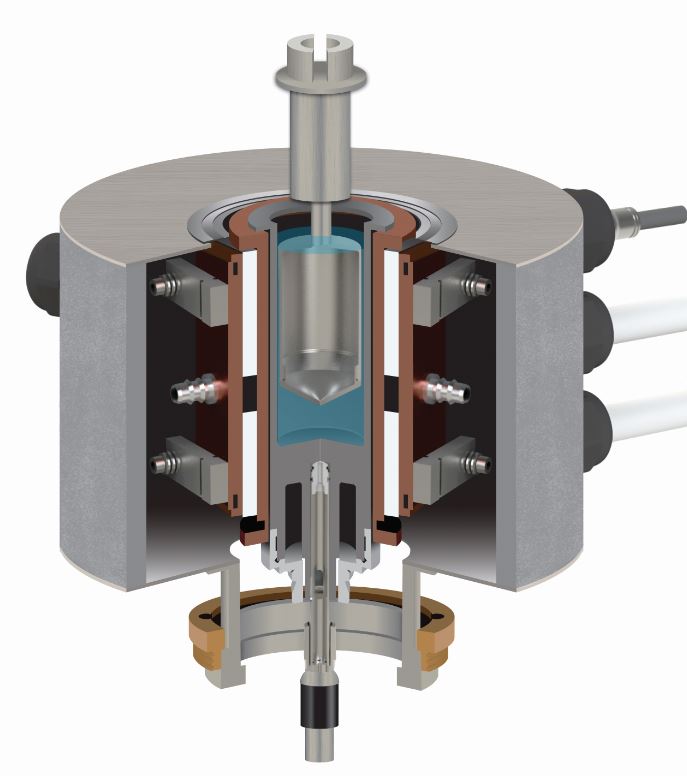

The Advanced Peltier System, equipped with an array of multiple Peltier elements, controls temperature through a non-contact heat transfer mechanism. A 50 μm gap between the Peltier elements and the system core allows for the most pure sample deformation while allowing efficient heat transfer across the thin gap. Temperature measurements are made using PRTs placed in intimate contact with the center of the lower plate or cup. The temperature signal is transmitted to Printed Circuit Boards, from which the temperature reading is transferred through a non-contact (wireless) mechanism to secondary boards in the motor. These temperature readings enable direct control the temperature, resulting in accurate and responsive temperature control.

The Advanced Peltier System, equipped with an array of multiple Peltier elements, controls temperature through a non-contact heat transfer mechanism. A 50 μm gap between the Peltier elements and the system core allows for the most pure sample deformation while allowing efficient heat transfer across the thin gap. Temperature measurements are made using PRTs placed in intimate contact with the center of the lower plate or cup. The temperature signal is transmitted to Printed Circuit Boards, from which the temperature reading is transferred through a non-contact (wireless) mechanism to secondary boards in the motor. These temperature readings enable direct control the temperature, resulting in accurate and responsive temperature control.

Cone and Parallel Plate Geometries

Cone and Parallel Plate Geometries:

Several upper geometry types are available based on the needs of the test at hand. Heat break collars reduce heat transfer and improve temperature uniformity while maintaining the ruggedness and chemical resistance of a stainless steel plate. Low expansion and low thermal conductivity polyphenyl sulfone (PPS) plates further improve temperature uniformity.

Plate Surface Textures

Plate Surface Textures:

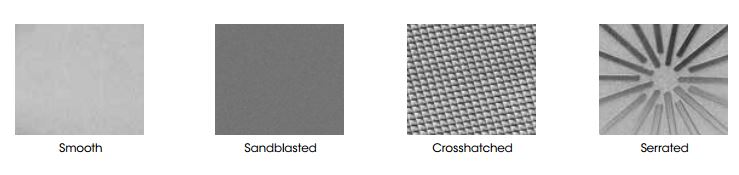

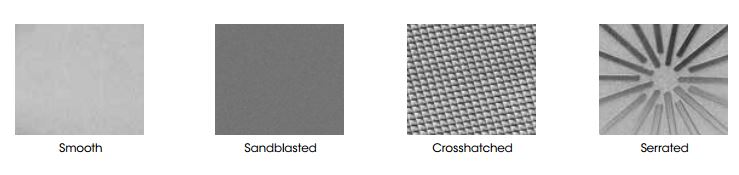

Both upper geometries and lower quick change plates are available with a range of surface textures. Roughened surfaces effectively eliminate slip, an artifact which can occur with many materials, particularly filled systems.

Both upper geometries and lower quick change plates are available with a range of surface textures. Roughened surfaces effectively eliminate slip, an artifact which can occur with many materials, particularly filled systems.

Quick Change Plates

Quick Change Plates:

The APS features a Quick Change Plate system that allows several lower plate covers to be easily attached using a simple bayonet-style locking ring. These plates can be selected based on material, diameter, and surface finish. Disposable plates are also available for curing materials.

Cup and Bob Geometries

Cup and Bob Geometries:

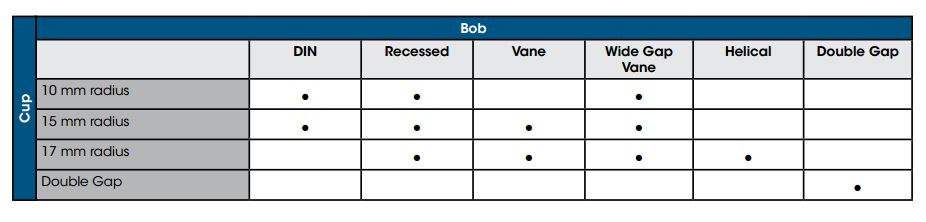

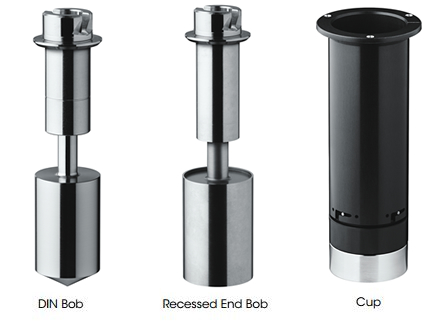

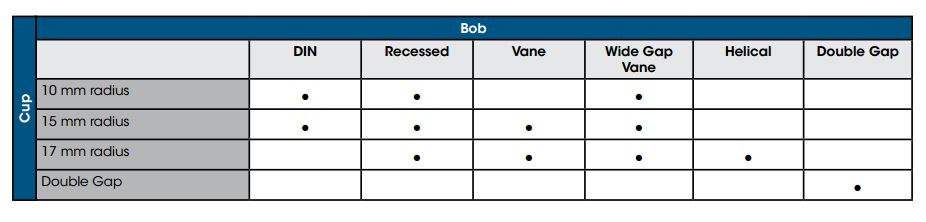

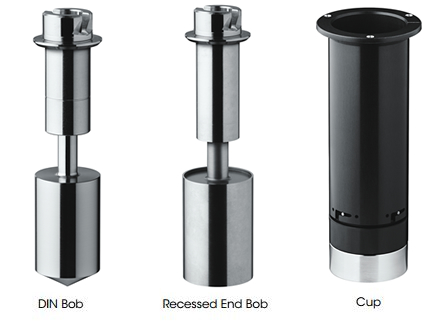

The APS geometries include cups of 10, 15 and 17 mm radius, configured with either a Recessed End or DIN Bob. The bobs have 9.3, 14 and 16 mm radii and, when used in conjunction with the corresponding cups, adhere to the DIN standards. The double gap concentric cylinder has an additional shearing surface over single gap providing lower stress and higher sensitivity for extremely low viscosity solutions. Specially designed cup and bob geometries are also offered for the unique and powerful Orthogonal Superposition (OSP) and 2 Dimensional Small Amplitude Oscillatory Shear (2D-SAOS) techniques.

The APS geometries include cups of 10, 15 and 17 mm radius, configured with either a Recessed End or DIN Bob. The bobs have 9.3, 14 and 16 mm radii and, when used in conjunction with the corresponding cups, adhere to the DIN standards. The double gap concentric cylinder has an additional shearing surface over single gap providing lower stress and higher sensitivity for extremely low viscosity solutions. Specially designed cup and bob geometries are also offered for the unique and powerful Orthogonal Superposition (OSP) and 2 Dimensional Small Amplitude Oscillatory Shear (2D-SAOS) techniques.

Special Cups and Bobs

Special Cups and Bobs:

Specialty geometries include vanes and helical bobs. These special concentric cylinder geometries are very valuable for characterizing dispersions with limited stability, preventing error from slip at the material/geometry interface, and for bulk materials with larger particulates. Vane geometries are available in both 7.5 mm and 14 mm radii. The helical bob can be configured with the large cup to keep a sample mixed or particles suspended during shearing.

Specialty geometries include vanes and helical bobs. These special concentric cylinder geometries are very valuable for characterizing dispersions with limited stability, preventing error from slip at the material/geometry interface, and for bulk materials with larger particulates. Vane geometries are available in both 7.5 mm and 14 mm radii. The helical bob can be configured with the large cup to keep a sample mixed or particles suspended during shearing.

Peltier Solvent Trap and Evaporation Blocker

Peltier Solvent Trap and Evaporation Blocker:

The Solvent Trap cover and Solvent Trap geometry work in concert to create a thermally stable vapor barrier, virtually eliminating solvent loss during the experiment. The geometry includes a reservoir that is filled with a very low viscosity oil or the volatile solvent present in the sample. The Solvent Trap cover includes a blade that is placed into the solvent contained in the well without touching any other part of the upper geometry. A uniform temperature, saturated vapor, environment is established, preventing loss from the sample and condensation from the cover. The Solvent Trap sits directly on a centering ring at the top of the APS surface for easy positioning.

The Solvent Trap cover and Solvent Trap geometry work in concert to create a thermally stable vapor barrier, virtually eliminating solvent loss during the experiment. The geometry includes a reservoir that is filled with a very low viscosity oil or the volatile solvent present in the sample. The Solvent Trap cover includes a blade that is placed into the solvent contained in the well without touching any other part of the upper geometry. A uniform temperature, saturated vapor, environment is established, preventing loss from the sample and condensation from the cover. The Solvent Trap sits directly on a centering ring at the top of the APS surface for easy positioning.

Immersion Cup

Immersion Cup:

The APS Immersion Cup allows samples to be measured while fully immersed in a fluid. It attaches easily to the top of the APS Plate with the bayonet fixture. A rubber ring provides the fluid seal and allows for easy sample loading, trimming, and subsequent sealing and filling. The Immersion Cup system can accommodate plates or cones up to 40 mm in diameter. This accessory is ideal for studying the properties of hydrogels.

The APS Immersion Cup allows samples to be measured while fully immersed in a fluid. It attaches easily to the top of the APS Plate with the bayonet fixture. A rubber ring provides the fluid seal and allows for easy sample loading, trimming, and subsequent sealing and filling. The Immersion Cup system can accommodate plates or cones up to 40 mm in diameter. This accessory is ideal for studying the properties of hydrogels.

- Description

-

The APS is a Smart SwapTM Peltier temperature controlled environmental system with a temperature range of -10 to 150 °C, with a maximum heating rate of 20°C/min and a temperature accuracy of +/- 0.1 °C. Unlike other Peltier temperature systems, the APS features parallel plate (cone and plate) as well as DIN conforming concentric cylinder geometries to meet the most demanding applications. The new quick-change lower plate comes standard with a 60 mm diameter hardened chromium surface and a unique bayonet fixture that allows the user to quickly and easily adapt the plate surfaces to crosshatched or sandblasted finishes. The APS also features an efficient heated solvent trap cover for blocking evaporation during testing of volatile materials.

- Technology

-

Technology

The Advanced Peltier System, equipped with an array of multiple Peltier elements, controls temperature through a non-contact heat transfer mechanism. A 50 μm gap between the Peltier elements and the system core allows for the most pure sample deformation while allowing efficient heat transfer across the thin gap. Temperature measurements are made using PRTs placed in intimate contact with the center of the lower plate or cup. The temperature signal is transmitted to Printed Circuit Boards, from which the temperature reading is transferred through a non-contact (wireless) mechanism to secondary boards in the motor. These temperature readings enable direct control the temperature, resulting in accurate and responsive temperature control.

The Advanced Peltier System, equipped with an array of multiple Peltier elements, controls temperature through a non-contact heat transfer mechanism. A 50 μm gap between the Peltier elements and the system core allows for the most pure sample deformation while allowing efficient heat transfer across the thin gap. Temperature measurements are made using PRTs placed in intimate contact with the center of the lower plate or cup. The temperature signal is transmitted to Printed Circuit Boards, from which the temperature reading is transferred through a non-contact (wireless) mechanism to secondary boards in the motor. These temperature readings enable direct control the temperature, resulting in accurate and responsive temperature control. - Geometries

-

Cone and Parallel Plate Geometries

Cone and Parallel Plate Geometries:

Several upper geometry types are available based on the needs of the test at hand. Heat break collars reduce heat transfer and improve temperature uniformity while maintaining the ruggedness and chemical resistance of a stainless steel plate. Low expansion and low thermal conductivity polyphenyl sulfone (PPS) plates further improve temperature uniformity.

Plate Surface Textures

Plate Surface Textures:

Both upper geometries and lower quick change plates are available with a range of surface textures. Roughened surfaces effectively eliminate slip, an artifact which can occur with many materials, particularly filled systems.

Both upper geometries and lower quick change plates are available with a range of surface textures. Roughened surfaces effectively eliminate slip, an artifact which can occur with many materials, particularly filled systems.

Quick Change Plates

Quick Change Plates:

The APS features a Quick Change Plate system that allows several lower plate covers to be easily attached using a simple bayonet-style locking ring. These plates can be selected based on material, diameter, and surface finish. Disposable plates are also available for curing materials.

Cup and Bob Geometries

Cup and Bob Geometries:

The APS geometries include cups of 10, 15 and 17 mm radius, configured with either a Recessed End or DIN Bob. The bobs have 9.3, 14 and 16 mm radii and, when used in conjunction with the corresponding cups, adhere to the DIN standards. The double gap concentric cylinder has an additional shearing surface over single gap providing lower stress and higher sensitivity for extremely low viscosity solutions. Specially designed cup and bob geometries are also offered for the unique and powerful Orthogonal Superposition (OSP) and 2 Dimensional Small Amplitude Oscillatory Shear (2D-SAOS) techniques.

The APS geometries include cups of 10, 15 and 17 mm radius, configured with either a Recessed End or DIN Bob. The bobs have 9.3, 14 and 16 mm radii and, when used in conjunction with the corresponding cups, adhere to the DIN standards. The double gap concentric cylinder has an additional shearing surface over single gap providing lower stress and higher sensitivity for extremely low viscosity solutions. Specially designed cup and bob geometries are also offered for the unique and powerful Orthogonal Superposition (OSP) and 2 Dimensional Small Amplitude Oscillatory Shear (2D-SAOS) techniques.Special Cups and Bobs

Special Cups and Bobs:

Specialty geometries include vanes and helical bobs. These special concentric cylinder geometries are very valuable for characterizing dispersions with limited stability, preventing error from slip at the material/geometry interface, and for bulk materials with larger particulates. Vane geometries are available in both 7.5 mm and 14 mm radii. The helical bob can be configured with the large cup to keep a sample mixed or particles suspended during shearing.

Specialty geometries include vanes and helical bobs. These special concentric cylinder geometries are very valuable for characterizing dispersions with limited stability, preventing error from slip at the material/geometry interface, and for bulk materials with larger particulates. Vane geometries are available in both 7.5 mm and 14 mm radii. The helical bob can be configured with the large cup to keep a sample mixed or particles suspended during shearing.

- Accessories

-

Peltier Solvent Trap and Evaporation Blocker

Peltier Solvent Trap and Evaporation Blocker:

The Solvent Trap cover and Solvent Trap geometry work in concert to create a thermally stable vapor barrier, virtually eliminating solvent loss during the experiment. The geometry includes a reservoir that is filled with a very low viscosity oil or the volatile solvent present in the sample. The Solvent Trap cover includes a blade that is placed into the solvent contained in the well without touching any other part of the upper geometry. A uniform temperature, saturated vapor, environment is established, preventing loss from the sample and condensation from the cover. The Solvent Trap sits directly on a centering ring at the top of the APS surface for easy positioning.

The Solvent Trap cover and Solvent Trap geometry work in concert to create a thermally stable vapor barrier, virtually eliminating solvent loss during the experiment. The geometry includes a reservoir that is filled with a very low viscosity oil or the volatile solvent present in the sample. The Solvent Trap cover includes a blade that is placed into the solvent contained in the well without touching any other part of the upper geometry. A uniform temperature, saturated vapor, environment is established, preventing loss from the sample and condensation from the cover. The Solvent Trap sits directly on a centering ring at the top of the APS surface for easy positioning.

Immersion Cup

Immersion Cup:

The APS Immersion Cup allows samples to be measured while fully immersed in a fluid. It attaches easily to the top of the APS Plate with the bayonet fixture. A rubber ring provides the fluid seal and allows for easy sample loading, trimming, and subsequent sealing and filling. The Immersion Cup system can accommodate plates or cones up to 40 mm in diameter. This accessory is ideal for studying the properties of hydrogels.

The APS Immersion Cup allows samples to be measured while fully immersed in a fluid. It attaches easily to the top of the APS Plate with the bayonet fixture. A rubber ring provides the fluid seal and allows for easy sample loading, trimming, and subsequent sealing and filling. The Immersion Cup system can accommodate plates or cones up to 40 mm in diameter. This accessory is ideal for studying the properties of hydrogels.