Keywords: coatings, outdoor applications, humidity, DVS, sorption analysis, TMA

TA485

Abstract

Coatings are often exposed to a range of weather conditions which may affect the coating’s adhesive behavior. To investigate the impact of this, the influence of humidity on mass changes and dimension changes of various coatings is tested. By establishing a relationship with humidity, the adhesion behavior of new formulations can be predicted through relatively quick dynamic vapor sorption analysis and/or thermomechanical analysis.

Introduction

New coating formulations for outdoor applications may behave differently with respect to adhesion to the substrate. A typical adhesion test method involves exposure of the coated panel to a constant condensation-water atmosphere, at a slightly elevated temperature of 30-40 °C to speed up the interaction effect. After exposure of approximately 1000 hours, the adhesion is verified by cutting a checkered pattern on the coating, putting adhesive tape over it and counting how many squares are removed when pulling off the tape. Needless to say, this is a time-consuming method.

For multicomponent materials that are frequently temperature cycled, failure is quite often related to differences in thermal expansion coefficient of the different layers. These differences create stresses at the interface, resulting in premature failure. The coefficient of thermal expansion (CTE) can be measured with a thermomechanical analyzer (TMA). The formulations can then be tuned to avoid mismatch in CTEs. When these multicomponent structures experience relative humidity (RH) changes, a larger change in dimensions as a function of RH could potentially also lead to earlier failure. This coefficient of hygroscopic expansion (CHE) can be measured in a TMA where the RH is strictly controlled in the sample chamber. A big advantage is that testing can be done in the time frame of a day. However, a drawback of TMA testing is that test samples need to be a couple of millimeters thick (for testing with an expansion probe) or long (for testing with a film probe) to obtain accurate results for a material showing very little expansion. If the coating (typically with a thickness of 100 microns) is still on the substrate, it can only be tested with an expansion probe on top of the coated substrate, so coating thickness is too small. However, if the coating can be peeled off from the substrate, the free-standing film can be tested in tension along its length, providing highly accurate results.

Alternatively, if the coating cannot be obtained as a consistent film, but some flakes can be scraped off from the substrate, they can be tested with sorption analysis. This technique measures mass changes as a function of RH using a sorption analyzer (SA). There may be a relationship between the mass uptake of a material and its dimensional stability; therefore, it makes sense to check if there is a relation between sorption analysis tests and the adhesion of different coatings, too.

Experimental: Materials

Samples for this investigation were provided by Akzo Nobel N.V. One coating showed good adhesion to the substrate when exposed for 1000 hours to a constant condensation atmosphere, while the other showed poor adhesion. In this work, they’ll be referred to as the ‘good’ and the ‘bad’ coating.

Some of the coating was peeled from the substrate before the exposure test. The free-standing films had a thickness of approximately 150 μm. They consisted of a primer and a topcoat layer.

Experimental: Techniques & Method

The ‘good’ and the ‘bad’ coating were tested on TA Instruments™ Discovery™ SA and Discovery TMA-RH Systems.

The Discovery SA is a dynamic vapor sorption analyzer (DVS). It is used to measure water vapor adsorption and desorption (mass gain/loss) of a material as a function of relative humidity and temperature [1]. It consists of a high-performance microbalance and a symmetrical humidity control chamber (Figure 1). Relative humidity can be accurately controlled from 0% to 98% and sample temperature from 5 °C to 85 °C.

Temperature or RH is held constant while the other parameter is changed either stepwise or continuously during a test. Stepwise humidity changes are commonly used. This allows the sample sufficient time at each RH and therefore the ability to determine the weight change at equilibrium. The time needed for equilibration depends on the temperature, RH, and characteristic sorption kinetics of the material. For the SA testing, 15 mg sample was cut from the film and tested in a hemispherical 180 microliter metal coated quartz cup.

The Discovery TMA 450 RH is a thermomechanical analyzer measuring the dimensional change of a sample as a function of time and temperature, but also RH. It contains a non-contact frictionfree motor, wide-range and high-resolution transducer for accurate dimensional change measurement, and an integrated humidity-controlled sample chamber (Figure 2). Sample temperature can be changed from 5 °C to 120 °C and relative humidity from 5% to 95%, depending upon the temperature. CTE and CHE can be studied. Transition temperatures (Tg) and the influence of humidity on the glass transition temperature can be tracked [2].

For the TMA-RH testing, a film of 4.5 mm width was clamped in a probe dedicated for thin films (Figure 3), with the sample length between the clamps fixed at 16.0 mm to allow the fairest comparison of both coatings. To prevent buckling of the film a small force must be applied, typically 0.001 N – 0.01 N. The two coatings had a different thickness, so the force was adapted such that the ratio of force to cross-sectional area was 0.010 N/mm2.

The samples were tested isothermally at 35 °C. A temperature above room temperature was chosen to speed up the interaction with moisture and reduce the experimental time, as well as to mimic the typical temperatures used in the adhesion testing. The coatings were exposed to 50% RH until equilibrium conditions had been achieved. Subsequently humidity was increased to 95% and again held until the mass (SA) and dimension change (TMARH) had reached equilibrium conditions (adsorption step). Finally, RH was decreased back to 50% and again held until equilibrium conditions had been achieved (desorption). The 50% RH to 95% RH range reflects all expected weather conditions.

Results and Discussion

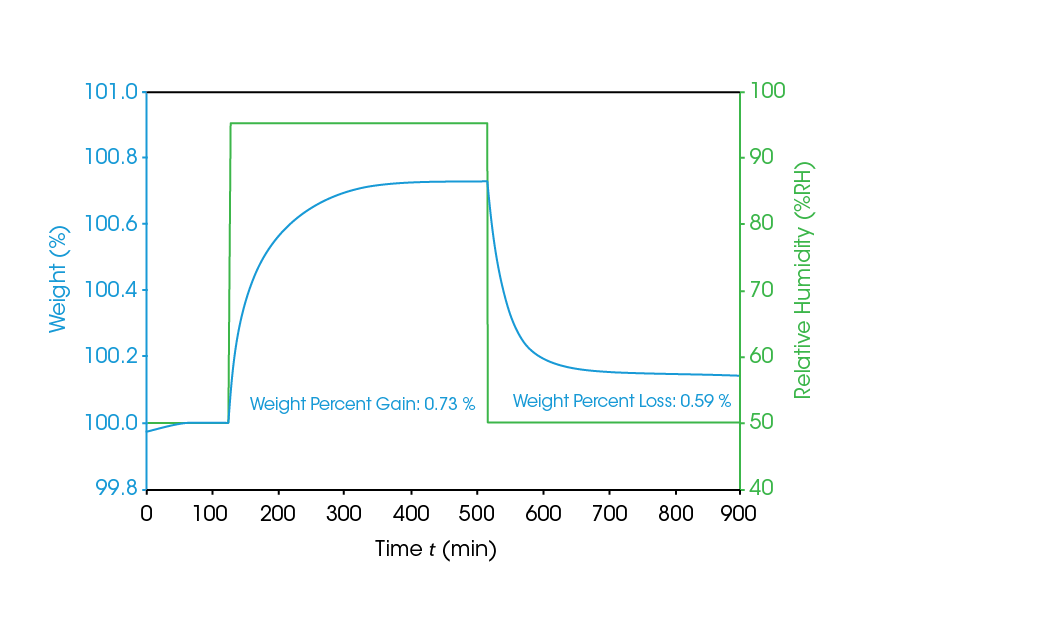

Figure 4 shows the weight changes for the good coating when cycling RH. To eliminate the influence of previous storage conditions of the samples, the equilibrium mass at 50% RH was used as a starting mass by resetting it to 100 % through the TRIOS™ software. The weight gain as a result of increasing RH from 50 to 95% was 0.73%; when decreasing RH back to 50%, not all water is released – weight loss is only 0.59%.

In Table 1, the results for the good and bad coating are compared. The good coating adsorbs less moisture than the bad; the bad coating clearly releases more water than the good coating when RH is decreased.

Table 1. Mass increase and decrease when changing from 50% RH to 95% RH and back to 50% RH

| Adsorption (%) | Desorption (%) | |

|---|---|---|

| Good coating | 0.73 | 0.59 |

| Bad coating | 0.79 | 0.85 |

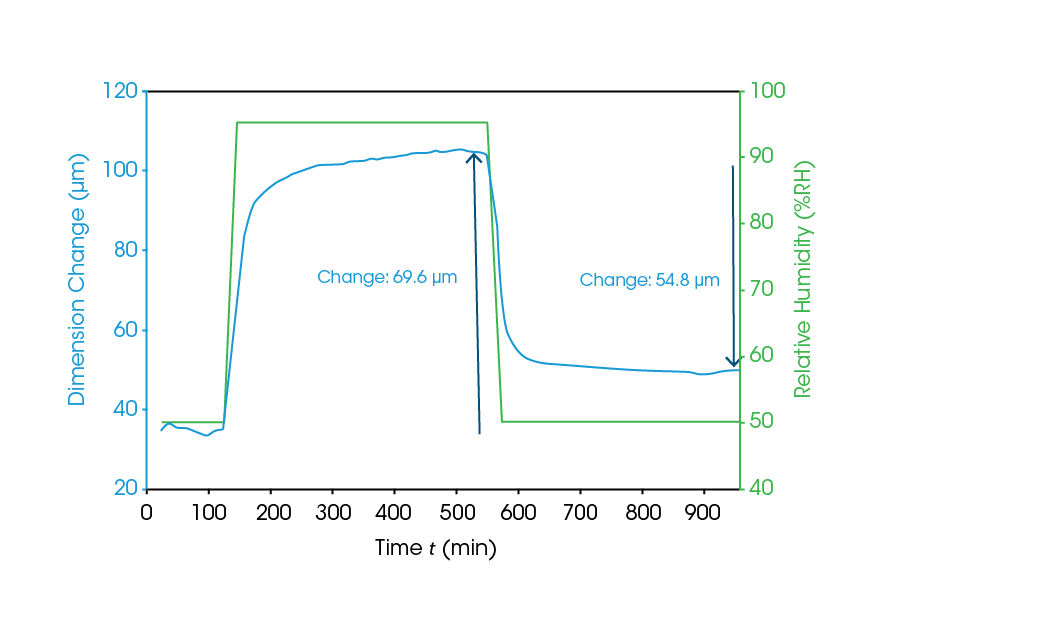

Figure 5 shows the dimension changes for the bad coating when cycling RH. The humidity increase from 50% to 95% resulted in a length increase of almost 70 μm; when decreasing RH back to 50%, a shrinkage of 55 μm was observed.

In Table 2 the results for the good and bad coating are compared. The good coating is clearly undergoing smaller changes in dimensions than the bad coating when RH is cycled.

Table 2. Length increase and decrease when changing from 50% RH to 95% RH and back to 50% RH

| Length Increase (micron) | Length Decrease (micron) | |

|---|---|---|

| Good coating | 38.4 | 44.3 |

| Bad coating | 69.6 | 54.8 |

As expected, the coating showing good adhesion changed less in dimensions when RH is cycled. This is also consistent with a lower change in mass for this coating. Both TMA-RH and SA tests took about 1000 min (less than a day), as opposed to the standard coating adhesion test that took over 40 days. The testing time could be lowered even more by defining the equilibrium criterium for mass or length stability less strictly.

Conclusions

This note describes the usefulness of TMA-RH and SA testing to predict the adhesion behavior of coatings in all weather conditions. Differences in mass and dimension with moisture exposure were seen between a good and bad coating, with the bad coating absorbing and releasing more water, as well as expanding and contracting more than the good coating. Manufacturers and researchers can use these results to efficiently develop and screen new coating formulations. The test time is relatively short (one day) compared to ‘classical’ adhesion tests, where the coatings are subjected for approximately 1.5 months to a humid environment before conclusions can be drawn.

Acknowledgements

This application note was written by Els Verdonck, Ph.D, Application Engineer at TA Instruments. It was realized in close collaboration with Kristian Lüschen (Specialist in Automotive & Specialty Coatings) from Akzo Nobel N.V. (Sassenheim, The Netherlands). He kindly provided all test materials and was involved in fruitful discussions related to proper interpretation.

For more information or to request a product quote, please visit www.tainstruments.com to locate your local sales office information.

TA Instruments, Discovery, and TRIOS are a trademark of Waters Technologies Corporation.

Click here to download the printable version of this application note.