Keywords: Polyethylene Terephthalate (PET), Thermomechanical Analysis (TMA), DSC, D648

TA420

Problem

Polyethylene Terephthalate (PET) is often used as a thin film substrate for magnetic recording tapes. These PET films are prepared by rapid extrusion so that high biaxial orientation and high dimensional stability are obtained. Processors of these films are interested in quickly evaluating their dimensional stability (expansion) properties as well as the presence of a glass transition. The latter is undesirable in the temperature range of usage because the dimensional stability usually decreases substantially at the glass transition temperature (Tg.)

Solution

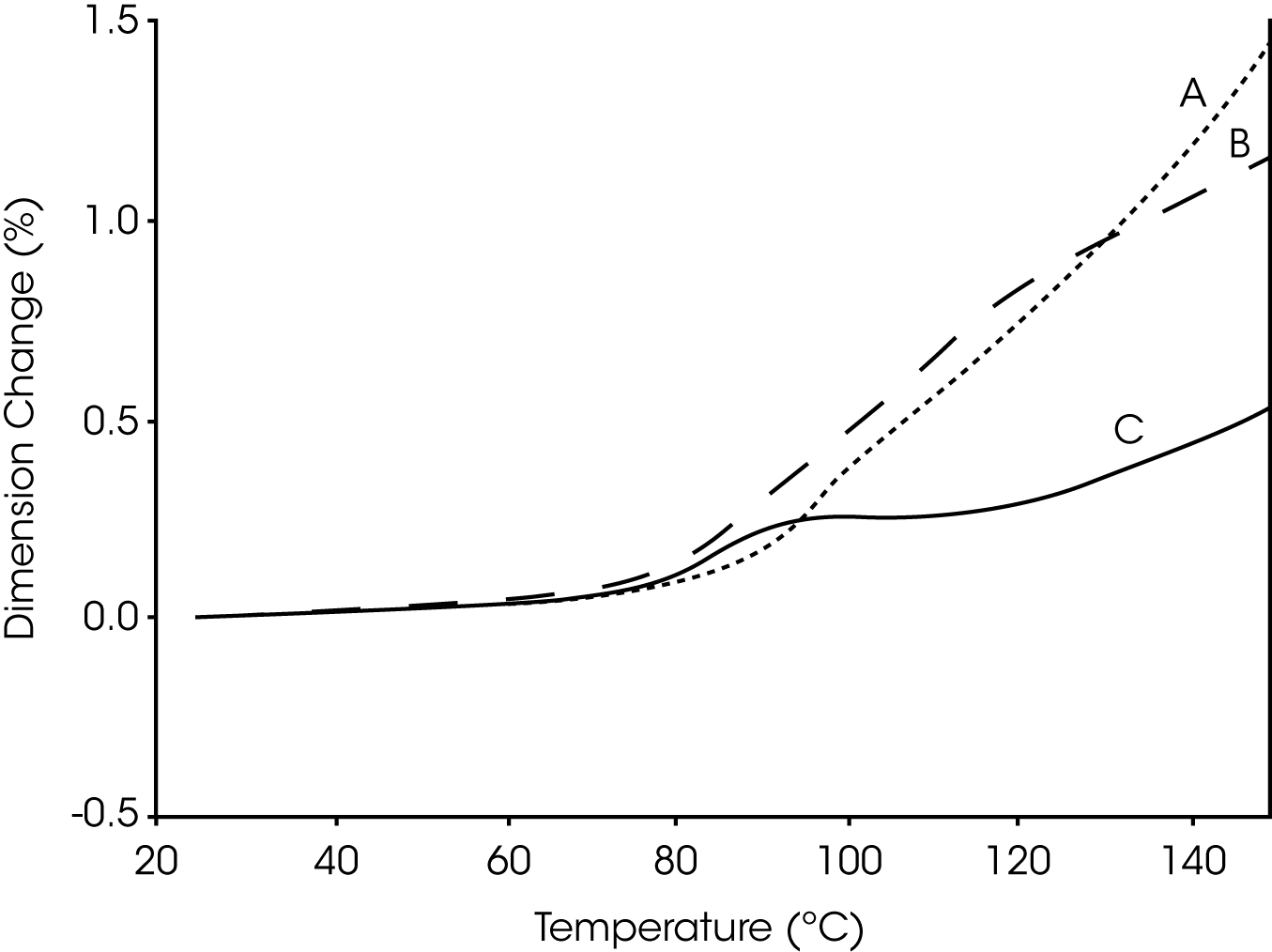

Figure 1 shows the thermomechanical analysis (TMA) for three commercial tape materials. TMA is an ideal technique for evaluating thin films since it directly measures dimensional change with temperature. Furthermore, since the coefficient of expansion changes dramatically at the Tg, TMA is more sensitive for detecting this and related transitions than differential scanning calorimetry (DSC). The sensitivity of TMA is particularly valuable in oriented films which usually have high crystallinity which further limits detection by techniques such as DSC.

In this study, the results obtained indicated that the Tg’s for all three films evaluated were above the highest temperature of actual end-use and that the dimensional stabilities up to the Tg were acceptable for tape applications. Above Tg, tape C had the highest dimensional stability. These TMA tests were run using small samples (4-5 mm) in about one hour, making this an easy method for evaluating the effects of changes in process conditions.

References

- ASTM Standard Test Method D648.

Acknowledgement

TA Instruments | Waters Corporation

Click here to download the printable version of this application note.