Keywords: Dynamic Mechanical Testing, DMA, Sustainability, Straws, Plastic, Plastic Alternatives, Submersion Clamp

TA460

Background

As the world increases its attention on consumer waste, single use plastics are moving to the forefront of many personal, local, and global initiatives [1]. There is interest in addressing plastics waste and end of life as well as identifying suitable alternatives. One example that has influenced everyday life is plastic drinking straws, which are difficult to recycle and whose function is tied to sensory experience.

After being formed through an extrusion process, straws are transported and made readily available in restaurants. Such straws are intended to be used once from minutes to hours. They are then discarded in municipal waste because they are too lightweight for mechanical recycling. Plastic straws remain in the environment for hundreds of years and improper waste management results in aquatic environment pollution [2].

Plastic straw substitutes include reusable metal straws and alternative materials that take a fraction of the time to degrade rather than persisting in the environment; however, the key challenge is replacing plastic straws with an alternative that creates a similar sensory experience. While reusable straws are an option, they can be difficult to clean. Paper straws have become prevalent but soften readily in beverages and create a poor sensory experience for the user. Other alternative materials include bamboo fiber (cellulose) and polylactic acid (PLA).

To assess how alternative materials perform as compared to traditional plastic materials, dynamic mechanical analysis (DMA) may be used in addition to previously reported tensile, compressive, and hardness methods [3,4]. The advantage of DMA is that it provides information about the viscoelasticity of the material by applying a linear deformation. The material’s viscous and elastic nature determines how it dissipates or stores energy, respectively. These properties add important insights into sensory perception and mouthfeel of the material, which have been shown to vary between straw types [4,5].

Experimental Procedure

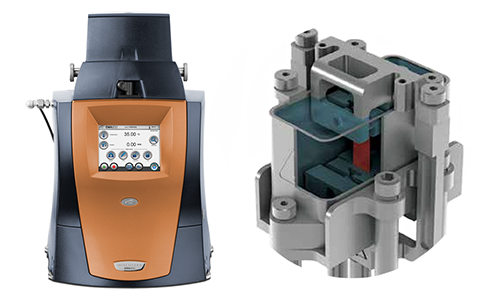

Dynamic mechanical analysis was performed using a TA Instruments DMA 850 paired with the submersion film clamp as shown in Figure 1. This clamp enables mechanical analysis of films while submerged in a liquid. Materials were tested in both water and soda for this study. The performance of environmentally friendly straws as compared to plastic straws was assessed through the stiffness, elastic modulus, and tan delta.

Large diameter commercial plastic, paper, and bamboo fiber straws were tested. Bamboo and plastic straws were uniform and extruded as single pieces with thicknesses of 0.25 mm. Paper straws were 0.35 mm thick composites of several sheets wound together with food safe adhesive. To obtain samples, the straws were cut in half lengthwise. A punch was then used to cut 5.6 mm wide strips. The samples were loaded into the clamp and submerged in chilled (~10 °C) or ambient (~26 °C) water immediately prior to testing at constant temperature for 30 minutes.

Materials were also tested in soda, which is often served chilled but over time the beverage equilibrates to room temperature. Refrigerator chilled soda was loaded into the clamp and allowed to equilibrate to ambient temperature to replicate end use conditions. The temperature increased from ~16 °C to 24 °C over the 30-minute testing period.

Oscillatory Measurements

To monitor the performance of the different types of straws, oscillatory DMA measurements in the linear viscoelastic region (LVR) were selected. These measurements may be used to compare the viscoelasticity of the samples and monitor changes with time.

In the LVR, a small perturbation, that does not affect the mechanical integrity of the sample, is applied. At sufficiently low strains, stress and strain have a linear relationship. The lower limit of the LVR is determined by the signal-to-noise ratio at the selected strain [6].

An oscillatory time sweep test was used to monitor the stability of different types of straws over time under different submersion conditions. The test frequency was at 1 Hz and the strain amplitude was within the LVR of each sample.

Results

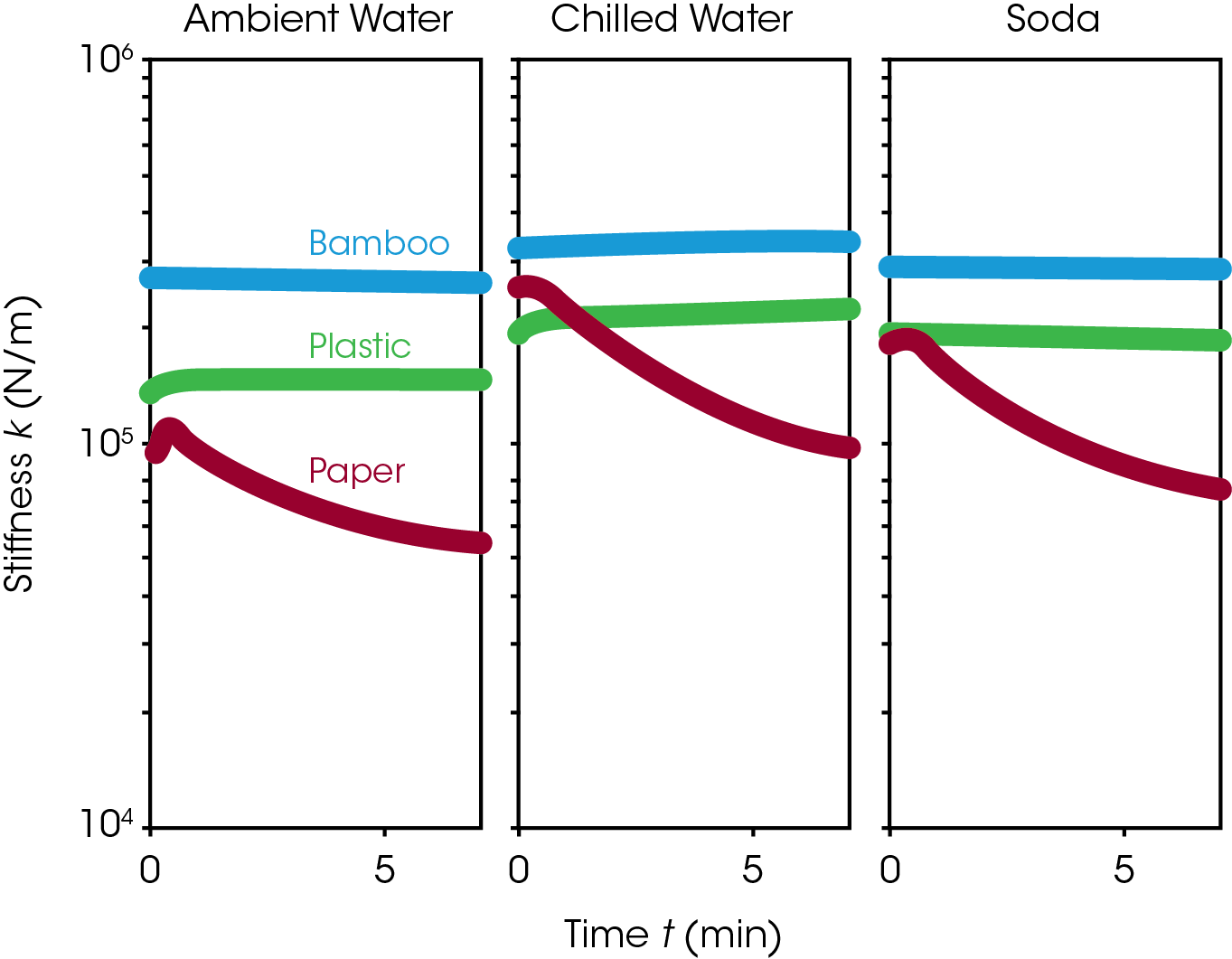

Stiffness is a measure of the amount of force it takes to deform a material and it is dependent on the physical dimensions of the material. For example, it is easier to bend aluminum foil than aluminum bars. The initial stiffness of straws plays a key role in maintaining the shape while puncturing lids or being tapped on a table to remove the wrapper. If the stiffness changes too much during submersion, the user may have a poor sensory experience and render the straw unusable.

Comparisons of straw stiffness for the first 7 minutes in each submersion condition are shown in Figure 2. Bamboo is the stiffest followed by plastic. Paper has a similar stiffness to plastic initially, but the stiffness quickly decreases with exposure to liquid. To improve the mechanical properties, the paper straws were engineered to be almost 40% thicker than the plastic and bamboo fiber straws tested. Increasing the thickness results in a higher stiffness, but paper straws are susceptible to wetting and degradation over time in beverages. While the bamboo straws have the same thickness as the plastic straws, the bamboo straws are about twice as stiff. In this case, the thickness of the bamboo straws can be reduced to engineer the same sensory experience as a plastic straw.

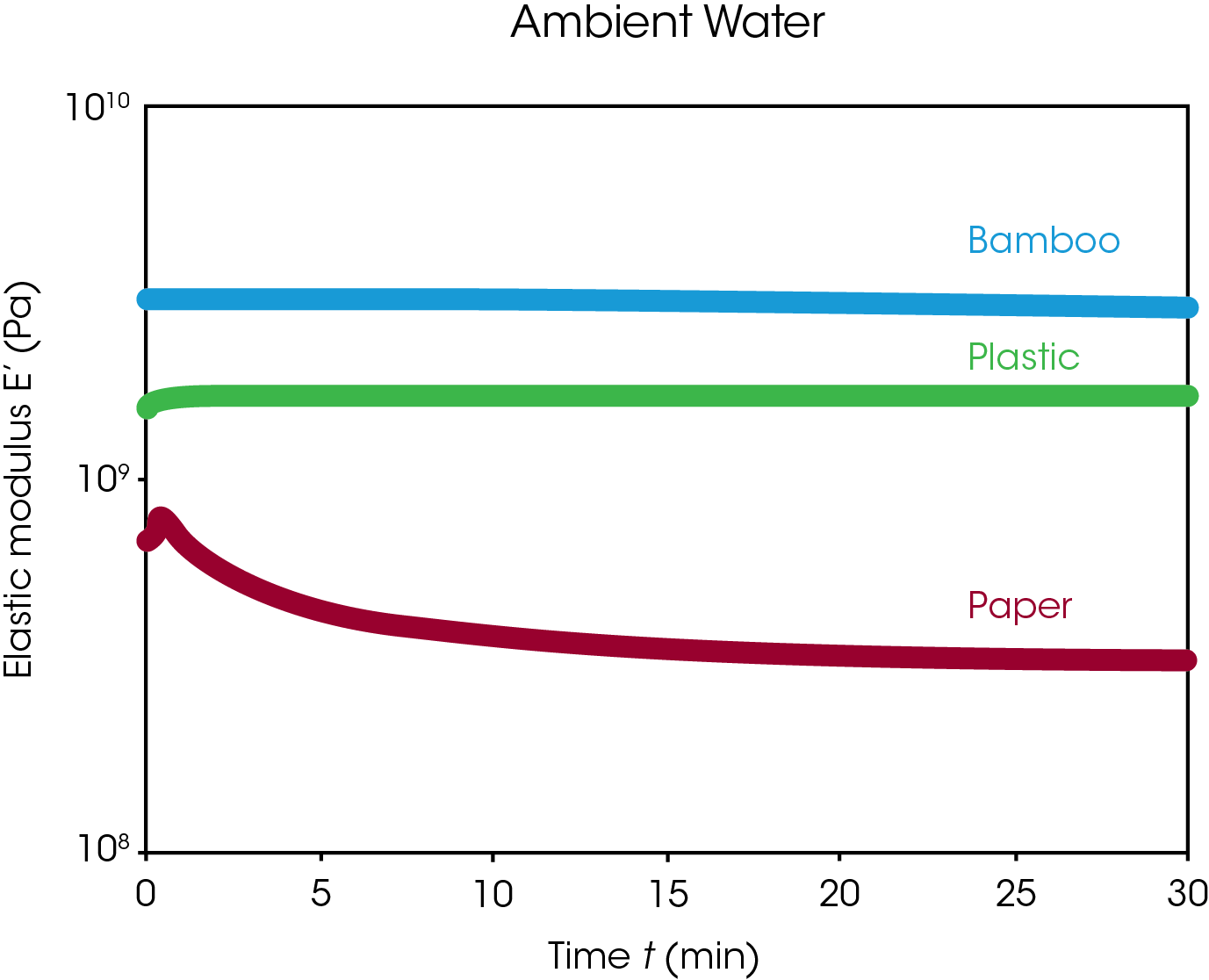

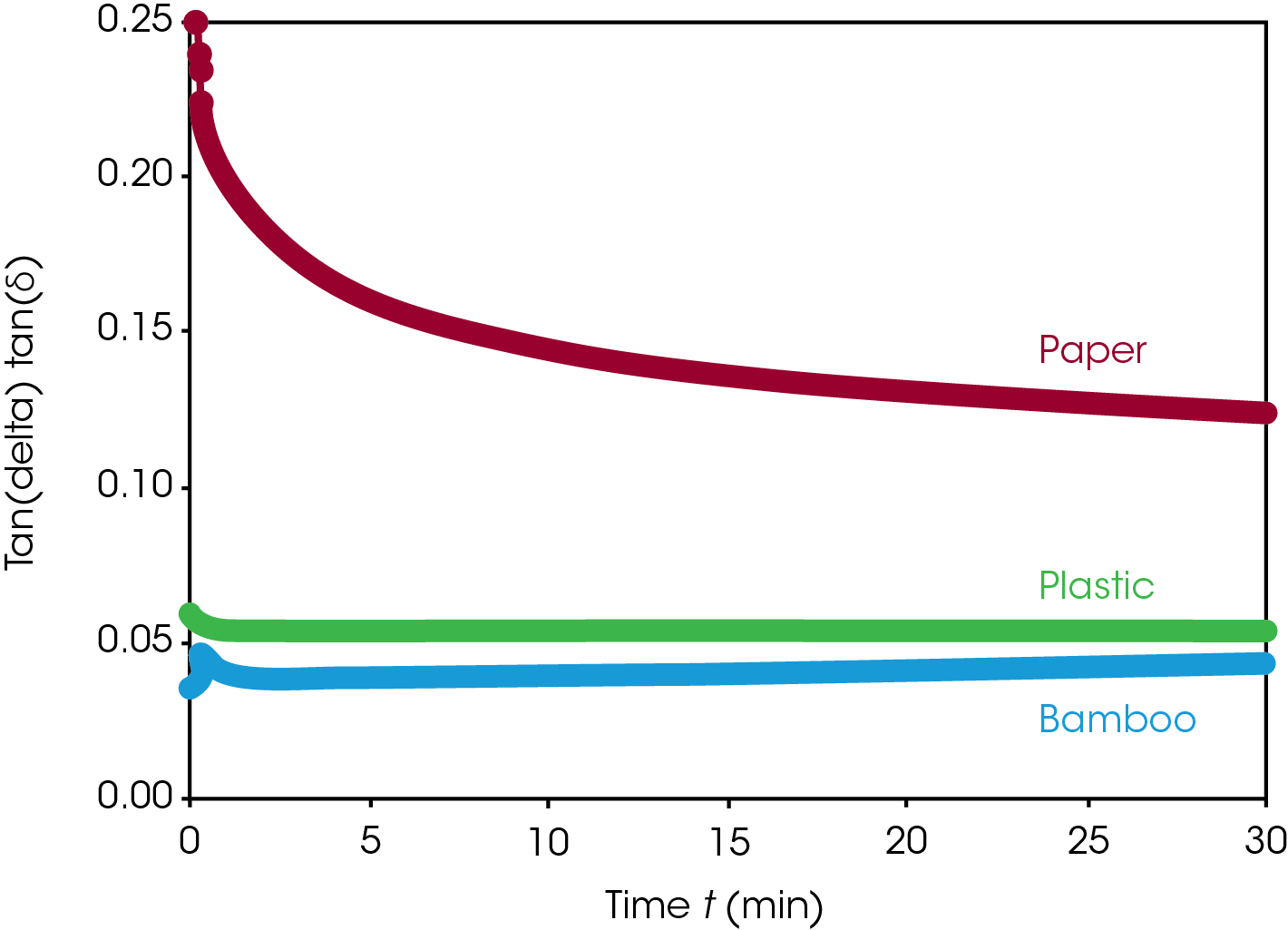

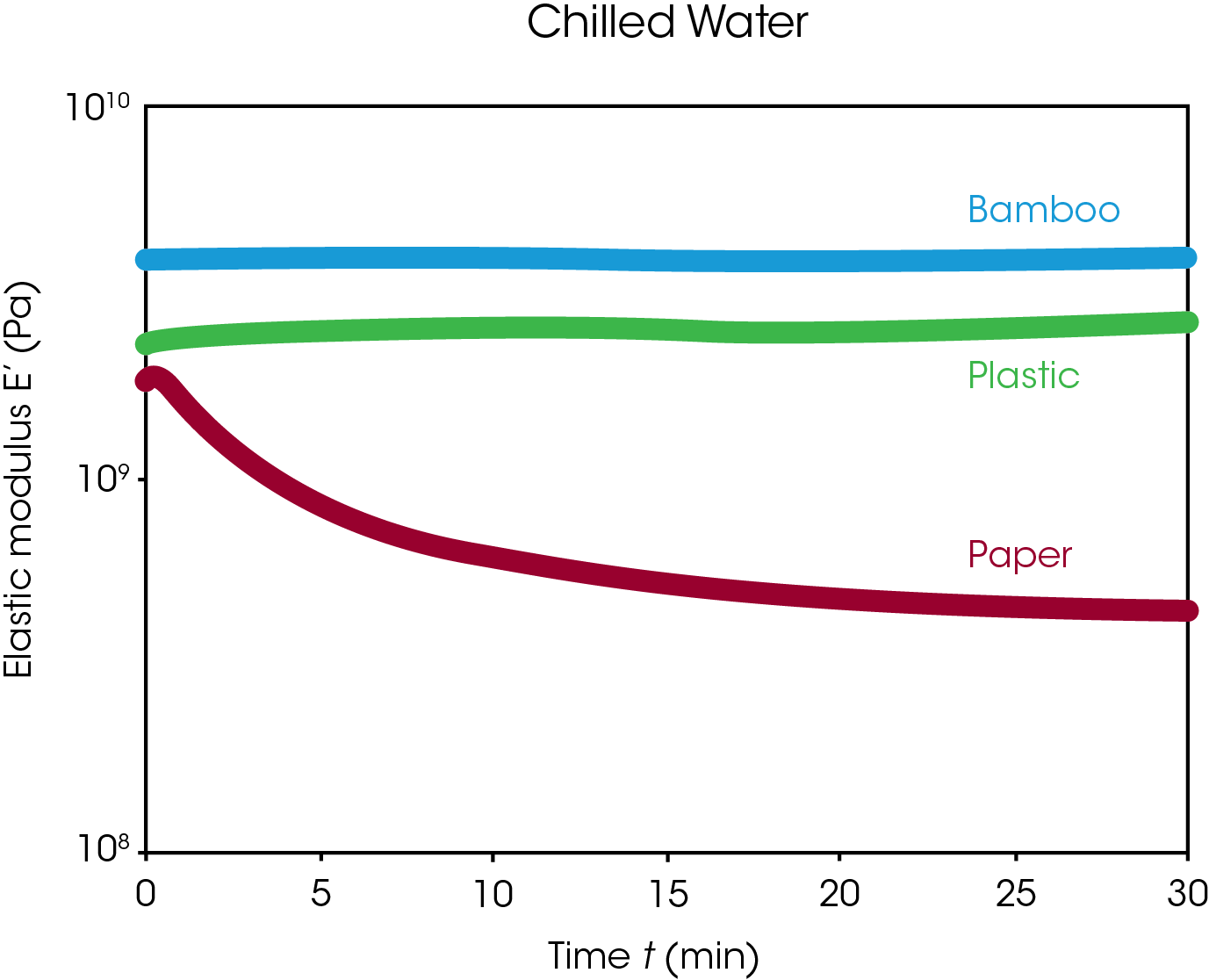

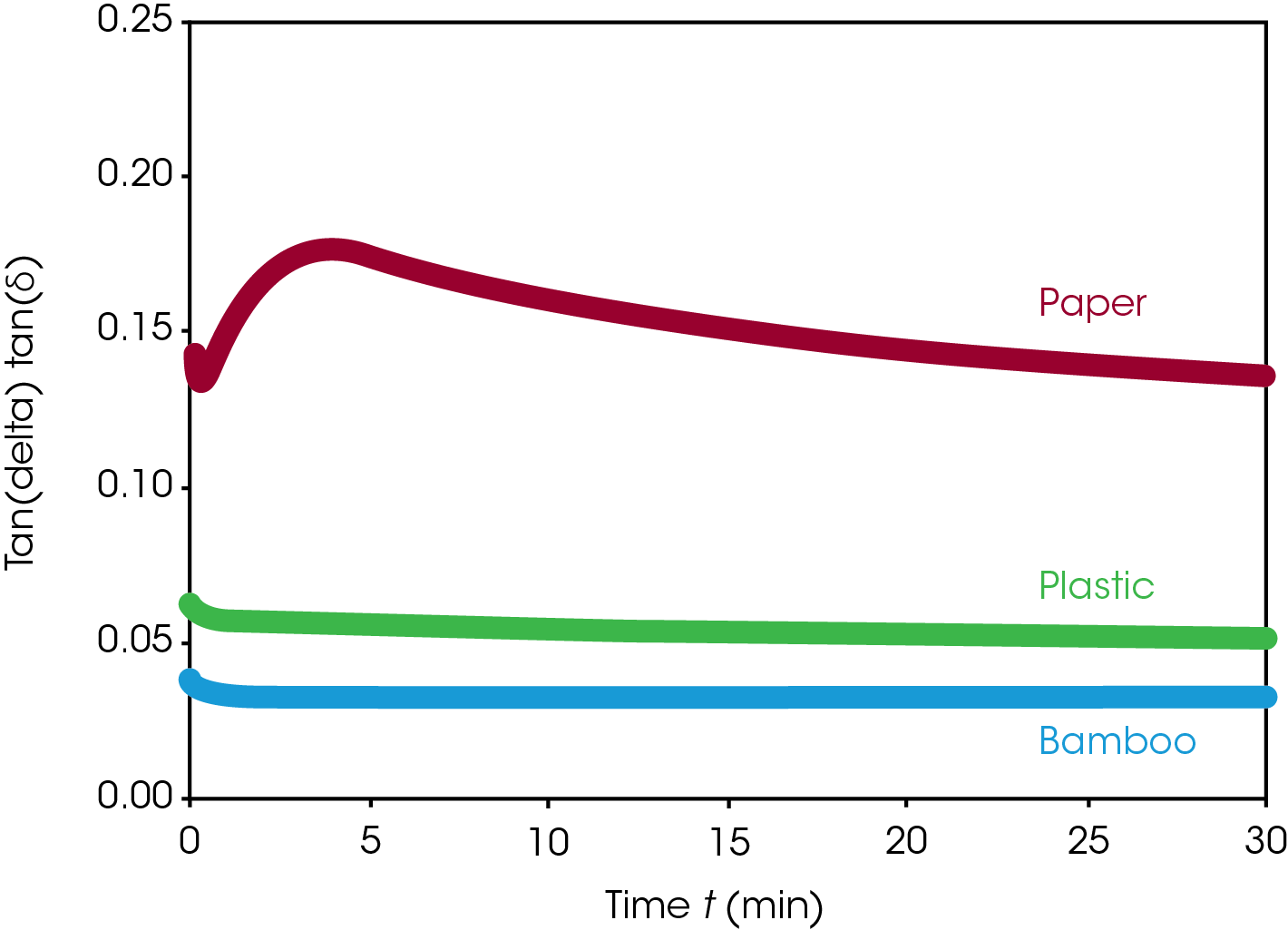

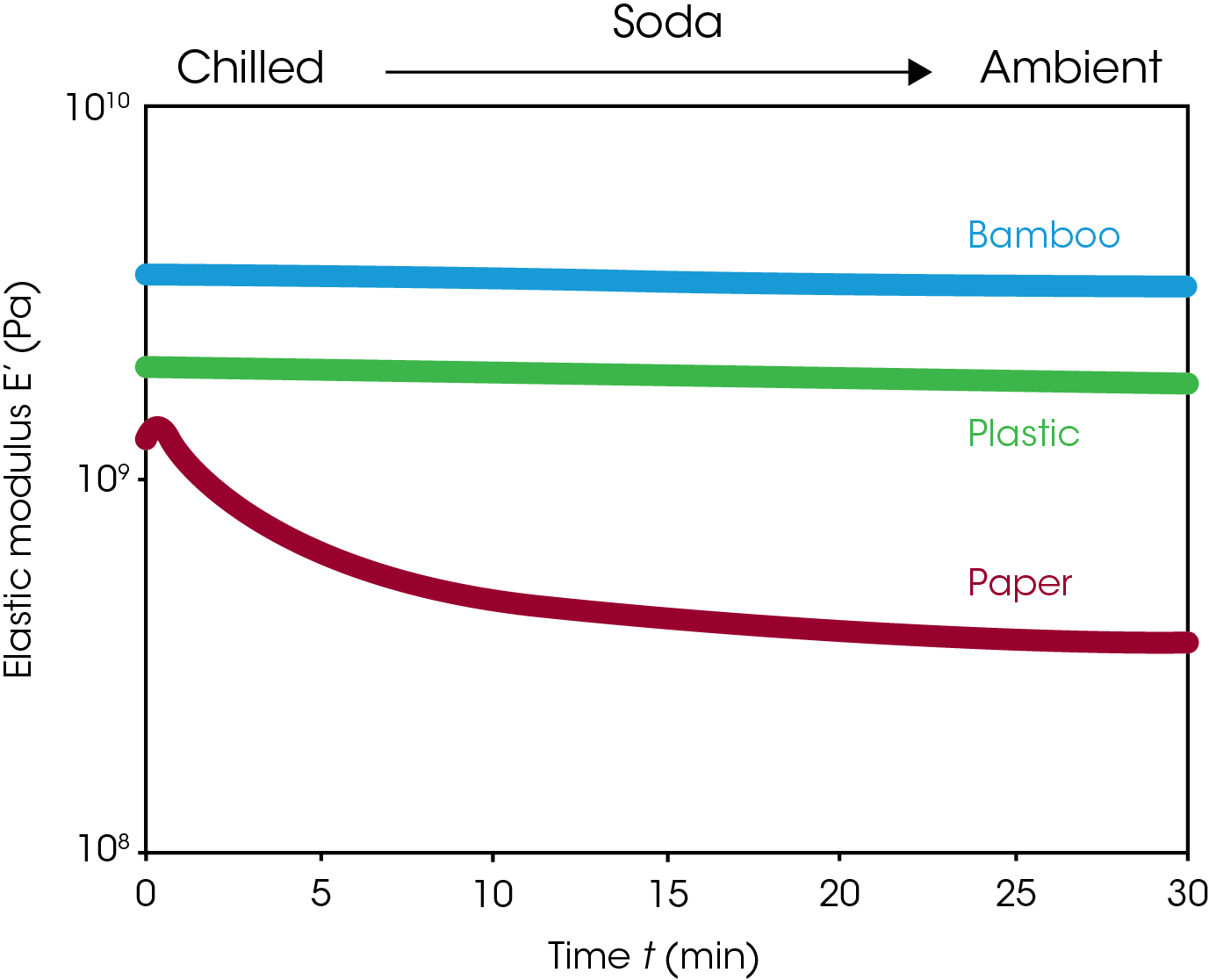

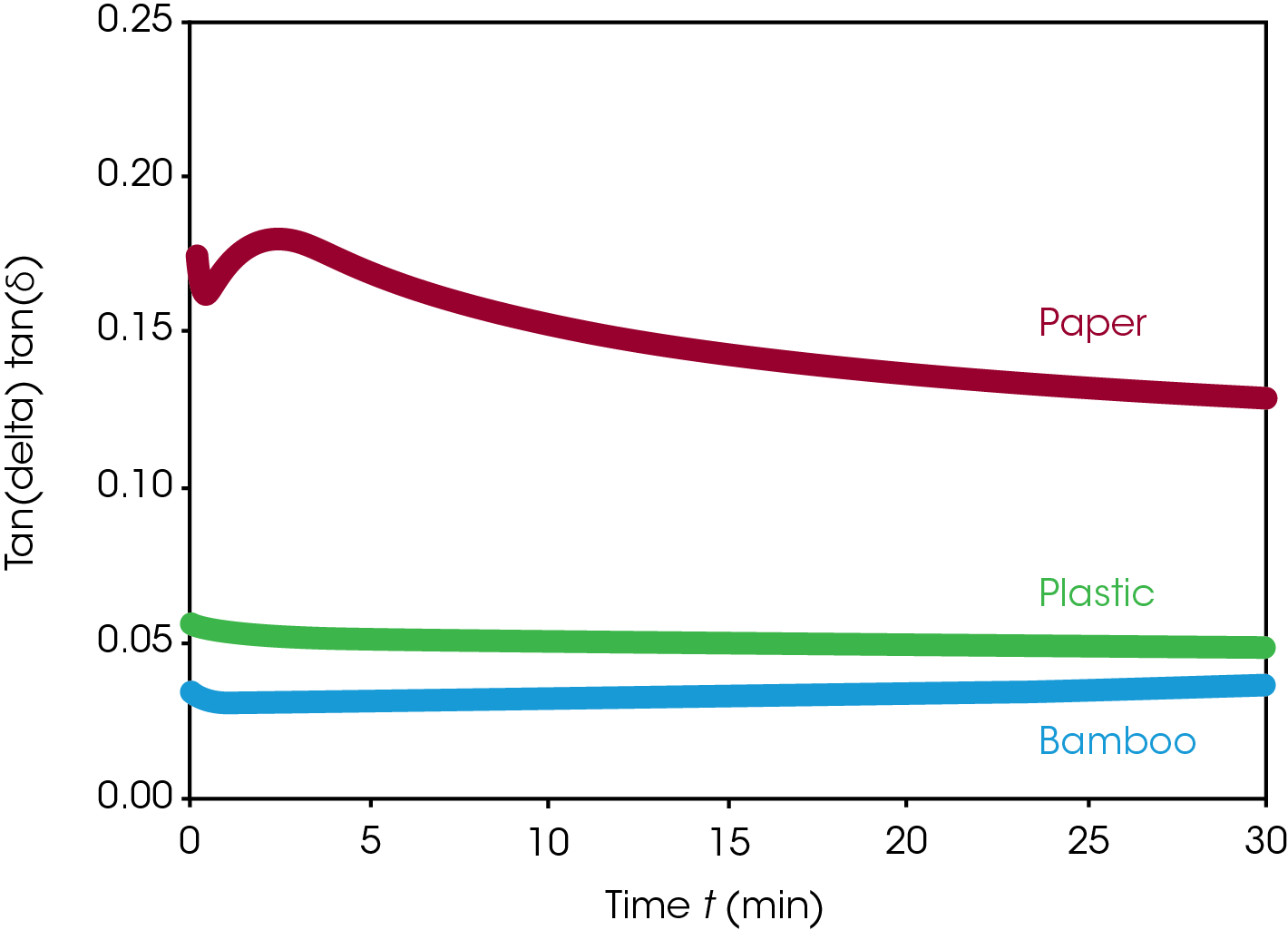

The elastic moduli and tan delta of plastic, paper, and bamboo straws are shown in Figures 3-5. The elastic modulus correlates with the mechanical rigidity (or stiffness) of the sample, but it is independent of physical dimensions. Tan delta is the ratio of the viscous modulus to the elastic modulus and correlates with elasticity. The higher the tan delta, the lower the elasticity or ability for the sample to bounce back from an applied deformation. Ideally, these parameters would remain constant during liquid submersion as a function of time, so that there is no change in mouthfeel. As shown here, these properties remain relatively constant for plastic straws over the tested conditions and set performance metrics for alternative materials.

At all conditions tested, the elastic moduli and tan delta remain relatively constant for plastic and bamboo straws. The starting properties are maintained over 30 minutes. The results show that bamboo and plastic straws show similar mechanical performance and elasticity. Both materials appear to be stable when submersed in a liquid at ambient and chilled conditions. The sensory experience of the bamboo straw would resemble that of the plastic straw.

In contrast, paper straws show a decrease in elastic modulus of about 80% for chilled and diet soda conditions. A decrease in storage modulus of about 60% was observed for the ambient water condition. The tan delta for paper straws in ambient water decreases sharply at short times until it begins to level off. For the chilled and soda conditions, there is a peak in the tan delta at short times. This peak corresponds to a sharper decay in the storage modulus at short times. The decrease in modulus over time is due to liquid absorption, which results in a decrease in mechanical properties. Significant softening was observed at the conditions tested, which impacts the sensory experience.

Conclusions

The composition and degradation of drinking straws has garnered significant attention in recent years. The concern is that a simple device used over a short time persists in the environment and significantly affects aquatic life. Alternative materials that limit environmental impact provide a solution to plastic straws if similar properties and sensory experience can be engineered. DMA measurements such as stiffness, elastic modulus, and tan delta can aid material design and selection for environmentally friendly drinking straws.

Plastic, bamboo fiber, and paper straws were tested using small strain oscillatory measurements on TA Instruments DMA 850 with submersion film clamp. Plastic and bamboo straws maintained consistent properties over 30 minutes in water and diet soda at chilled and ambient conditions. Paper straws showed significant decrease in elastic modulus during the first 7 minutes. While paper degrades more easily in the environment than bamboo fiber, poor sensory experience and mechanical function may result in these straws not being used at all.

References

- Ellen Macarthur Foundation, “The New Plastics Economy: Rethinking the Future of Plastics and Catalysing Action,” 2017.

- Roy, Poritosh et al., “Evolution of Drinking Straws and Their Environmental, Economic, and Societal Implications,” Journal of Cleaner Production, 2021.

- Gutierrez, Joseph N. et al., “Evaluation of Paper Straws versus Plastic Straws: Development of a Methodology for Testing and Understanding Challenges for Paper Straws”, BioResources, 2019.

- Pramudya, Ragita C. et al., A Sip of Joy: Straw Materials Can Influence Emotional Responses to, and Sensory Attributes of Cold Tea, Food Quality and Preference, 2021.

- Jonsson, Amanda et al., “An Evaluation of Alternative Biodegradable and Reusuable Drinking Straws as Alternatives to Single-use Plastics”, Journal of Food Science, 2021.

- Whitcomb, Kevin, Determining the Linear Viscoelastic Region In Oscillatory Measurements, https://www.tainstruments. com/pdf/literature/RH107.pdf.

Acknowledgement

This note was written by Kimberly Dennis, Ph.D., Applications Scientist at TA Instruments.

Click here to download the printable version of this application note.