Keywords: powder rheology, powder coatings, epoxy resin powder

RH128

Abstract

Powder coatings are more robust and environmentally friendly than their solvent-based counterparts. The quality of the coating can be impacted by the transportation and processing conditions of the powder. Powder rheology measurements of shear and flow properties can aid in quality control of powder coatings. To investigate the impact of temperature, TA Instruments Powder Rheology Accessory for Temperature Control is used to study a filled epoxy resin for powder coatings. The results show that care must be taken in storage and processing, even at temperatures below the glass transition due to the effects on flowability and cohesion.

Introduction

The coatings industry has been impacted by environmental concerns and regulatory constraints, such as reducing the use of volatile organic compounds (VOCs) [1]. As a result, powder coatings with 100% solid content are increasing in popularity. Powder coatings are also more robust than solvent or waterborne systems. In particular, epoxy resin coatings have good chemical stability, adhesion to substrates, and hardness [1] [2] and these properties can be improved with the use of fillers [2] [3]. The coatings are applied electrostatically before undergoing cure in a thermal chamber to create a robust film [1] and it is critical that the film be uniform and repeatable in manufacturing. Transportation, storage, and processing conditions of the powders can impact the quality of the coating. One method to provide quality control is powder rheology, which has been demonstrated previously with lactose [4], graphite [5], and carboxymethyl cellulose powders [6]. Powder rheology can measure shear and flow properties of powders, such as flow energy, cohesion, and yield strength. These measurements can aid in optimizing formulations and processing parameters, as well as be used for quality control of powders. The TA Instruments Powder Rheology Accessory for Temperature Control for Discovery Hybrid Rheometers enables measuring the temperature dependence of powder shear and flow properties. The measurement is performed with interchangeable flow and shear cells compatible with the Peltier Concentric Cylinder as shown in Figure 1. This note will demonstrate the coupling of the Temperature Cell with the Flow and Shear Cells of the Powder Rheology Accessory. The results provide insight into effects of storage, processing, and environmental conditions on powders.

Experimental

Epoxy resin powder with filler and 25% inorganic content was obtained from a powder coating supplier. The glass transition temperature (Tg) was determined by modulated differential scanning calorimetry on the TA Instruments Discovery DSC 2500 to be 47 °C.

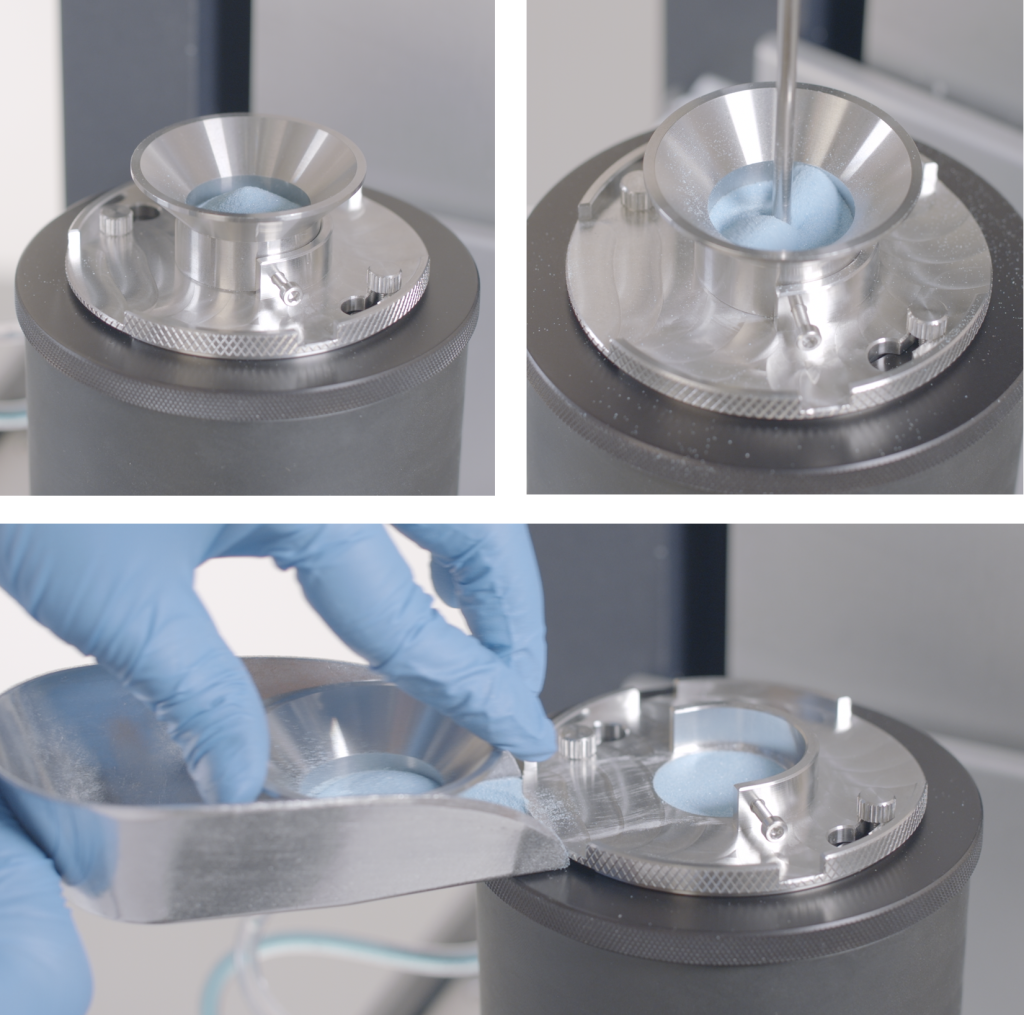

Powder rheology measurements were made below and approach-ing the Tg using the TA Instruments Peltier jacket for temperature control with compatible powder shear cell and powder flow cell. The powder temperature control cup has interchangeable lower inserts for flow and shear as shown in Figure 2. The flow insert is smooth and is paired with the impeller rotor. The shear insert has short, raised vanes and is paired with the 28 mm diameter shear rotor with corresponding short, raised vanes.

Flow Procedure

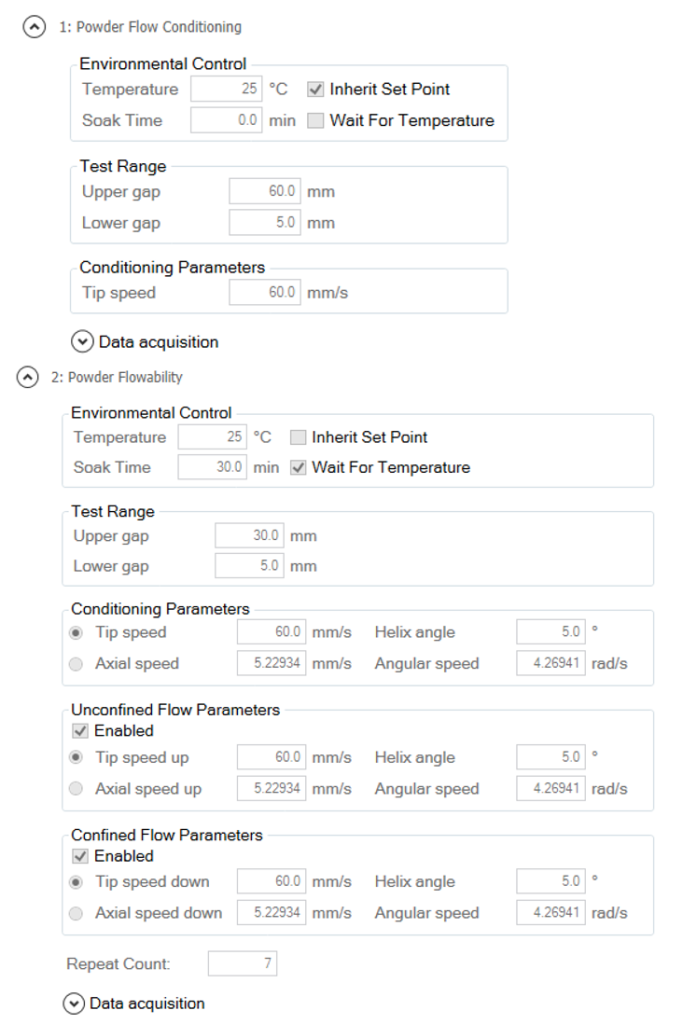

The flow procedure is programmed into TRIOS as shown in Figure 3. The powder is conditioned using Powder Flow Conditioning and then the sample is trimmed by sliding the loading funnel and depositing excess material before continuing to the next step as shown in Figure 4. The Powder Flowability step includes a 30-minute temperature soak followed by conditioning and flow measurements at a tip speed of 60 mm/s and a helix angle of 5°. Temperature is incremented in successive Powder Flowability steps. The flow results include measurements at 25, 35, and 45 °C, followed by repeat measurements at 35 and 25 °C.

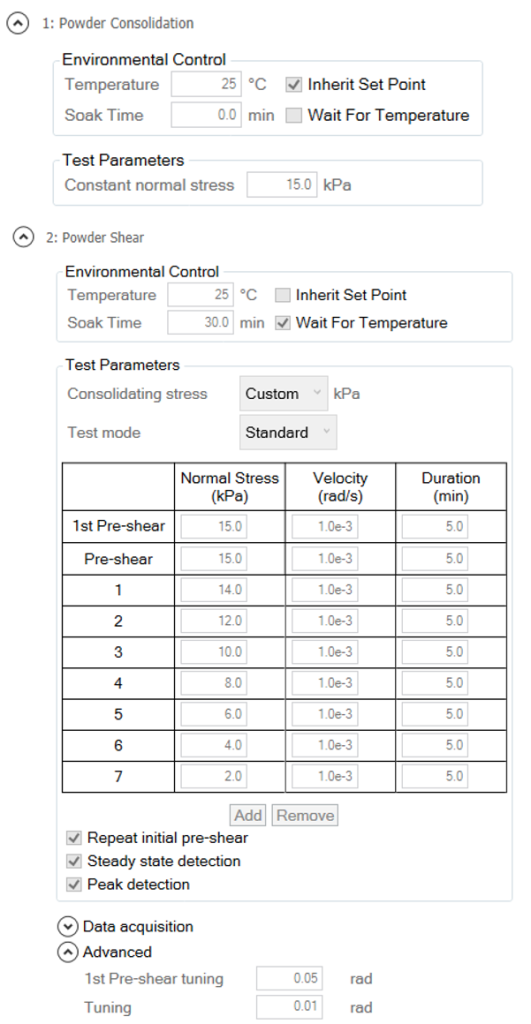

Shear Procedure

The shear procedure is programmed in TRIOS as shown in Figure 5. The powder is conditioned using Powder Consolidation and then the sample is trimmed by sliding the loading funnel and depositing excess material before continuing to the next step. The Powder Shear step includes a 30-minute temperature soak followed by a series of consolidation, pre-shear, and shear steps with decreasing normal stress. Isothermal experiments were performed by consolidating and trimming the powder, then executing one shear step. Temperature cycling experiments were performed by consolidating and trimming the powder, then executing multiple shear steps on the same sample.

Additional tuning parameters are available under Advanced options. These parameters include 1st Pre-shear tuning and Tuning, which define the wait periods after a peak in stress is detected using automatic peak detection. The default values are 0.05 and 0.01 rad as shown in Figure 5. When performing successive shear steps, these values may be modified if the user determines the steps are ending too early or too late for their particular test setup. Values of 0.01 rad are used for both 1st Pre-shear tuning and Tuning after the first shear step in temperature cycling experiments.

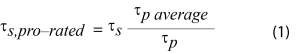

Where:

- ts,pro–rated = pro-rated shear stress

- ts = measured shear stress

- tp,average = average of all pre-shear shear stresses

- tp = measured pre-shear shear stress preceding shear step

Results and Discussions

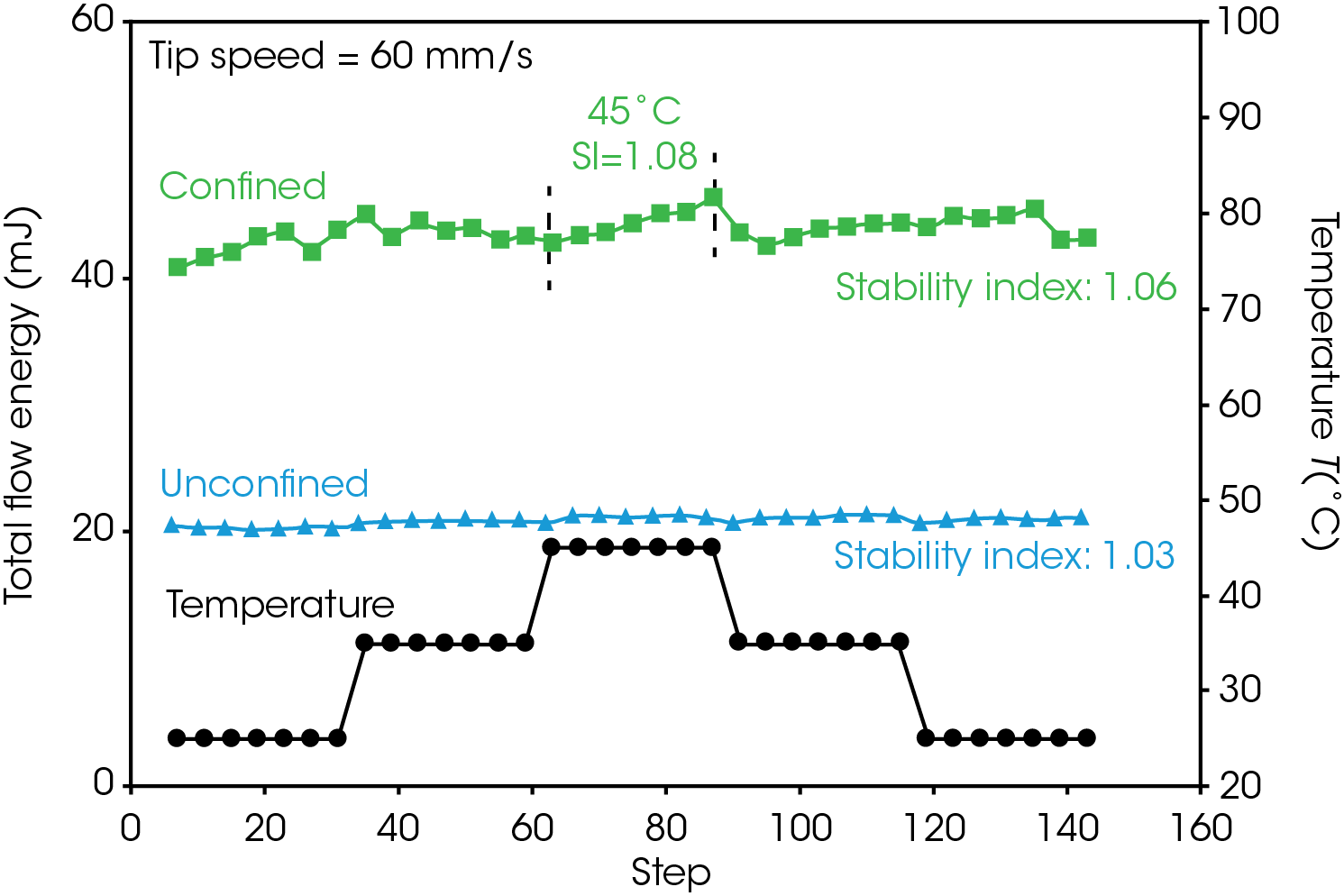

The total flow energy for confined and unconfined flow measurements is shown in Figure 6 at a tip speed of 60 mm/s. The stability index (SI) is the ratio of the last flow energy measurement to the first flow energy measurement over a user specified interval. A more stable powder formulation is expected to have a value closer to one. The stability index may be used to identify if a processing temperature step is causing instability in the powder. It can also be used to confirm quality from batch to batch or assess the impact of a formulation change.

The stability index is reported from the first and last flow values after temperature cycling and is 1.06 for confined flow and 1.03 for unconfined flow. The stability index is also reported for confined flow energy at 45 °C, where the flow energy appears to vary more and is equal to 1.08. The values are close to one indicating that this powder is stable under these flow conditions and temperature cycling.

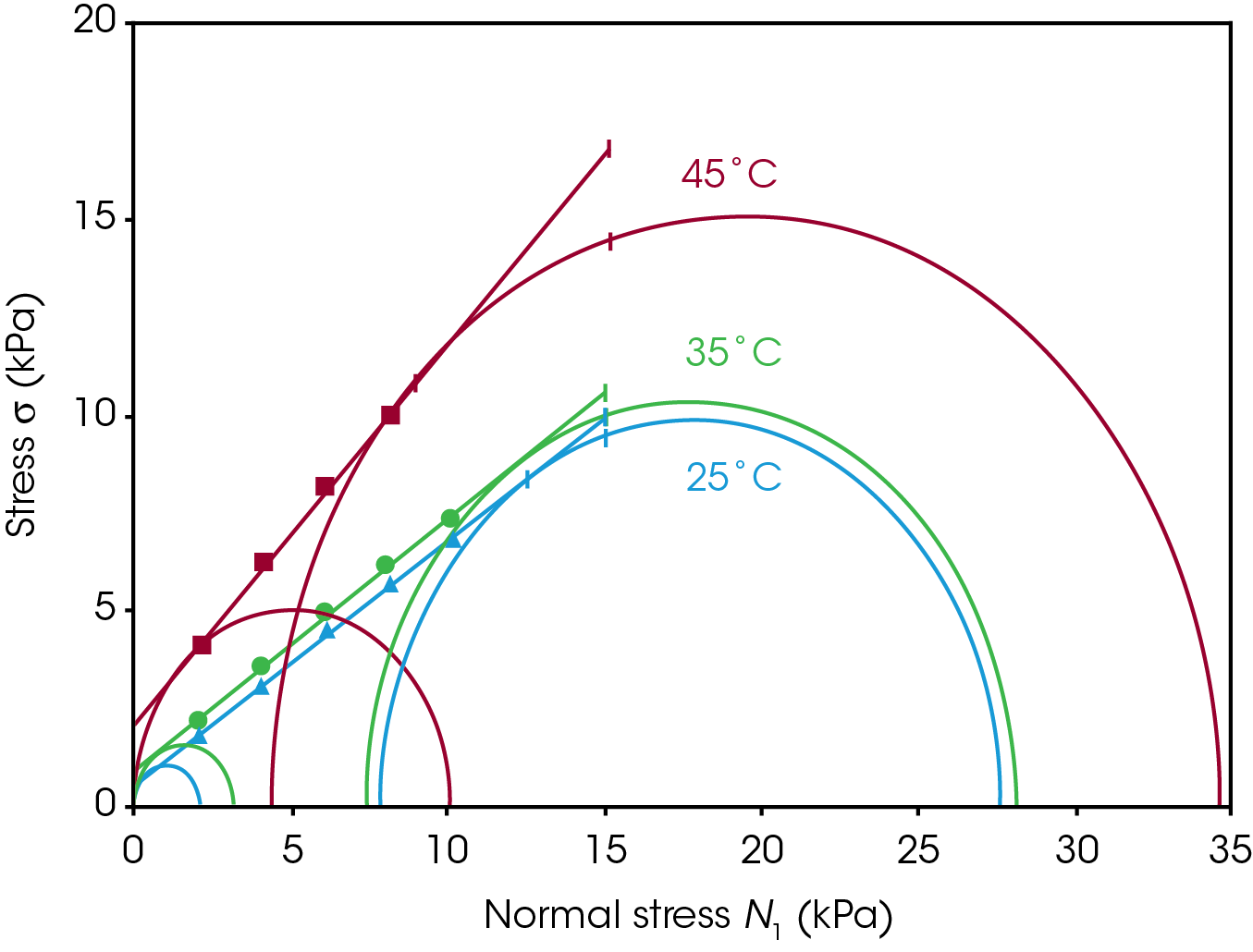

Results with temperature control are shown in Figures 7 and 8. In Figure 7 and Table 1, three samples total were tested at either 25, 35, or 45 °C. As temperature increases, there is an increase in cohesion, unconfined yield strength, major principal stress, and angle of internal friction and there is a decrease in flow function. These parameters can be used to optimize environmental and processing conditions of the powders. As the measurement approaches the Tg, the powder becomes more difficult to flow.

Table 1. Isothermal temperature results for 25, 35, and 45 °C

| 25 °C | 35 °C | 45 °C | |

|---|---|---|---|

| Cohesion (kPa) | 0.6 | 0.9 | 2.1 |

| Unconfined Yield Strength (kPa) | 2.1 | 3.1 | 10.0 |

| Major Principal Stress (kPa) | 27.6 | 28.1 | 34.6 |

| Flow Function | 13.2 | 8.9 | 3.4 |

| Angle of Internal Friction (rad) | 0.56 | 0.58 | 0.77 |

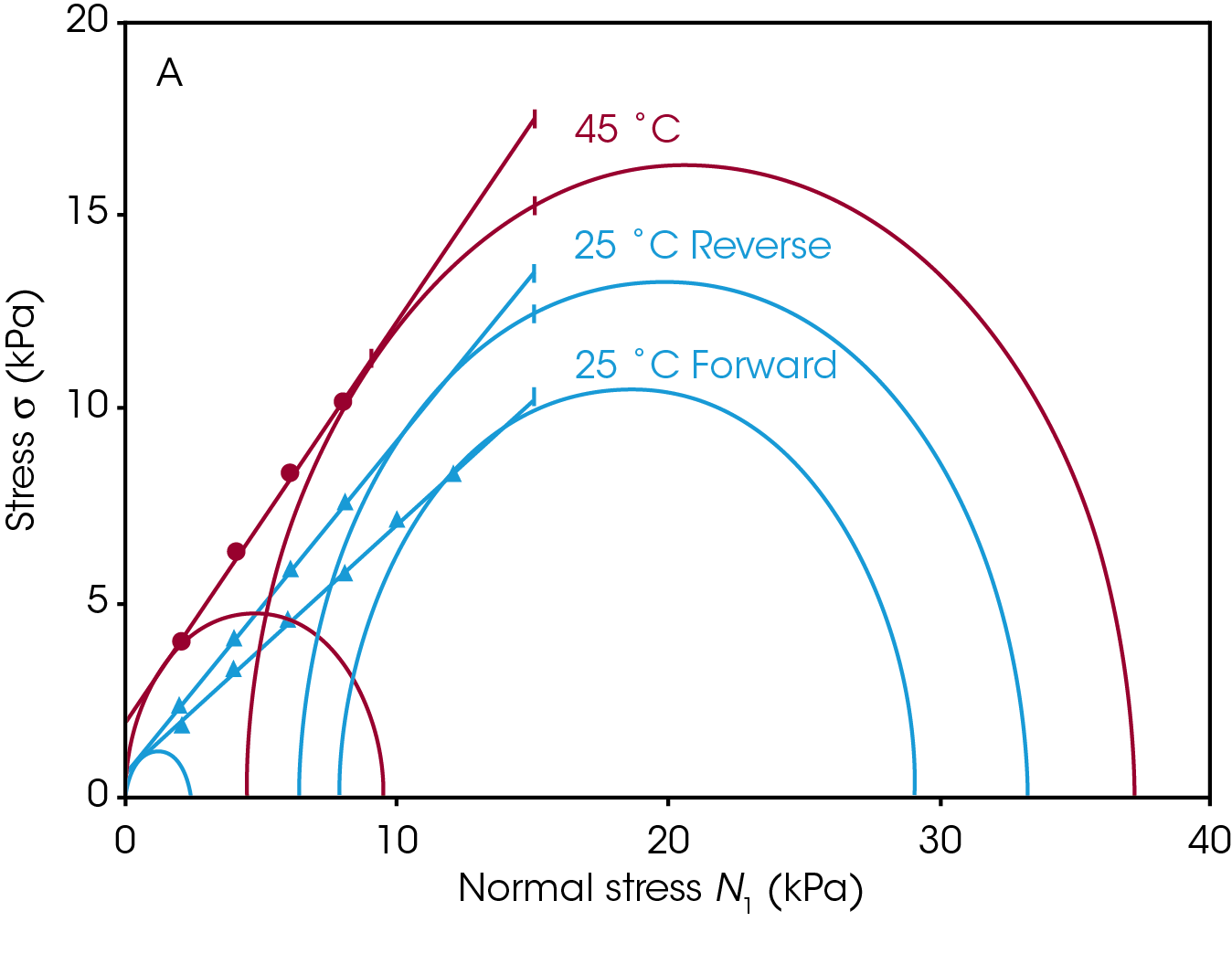

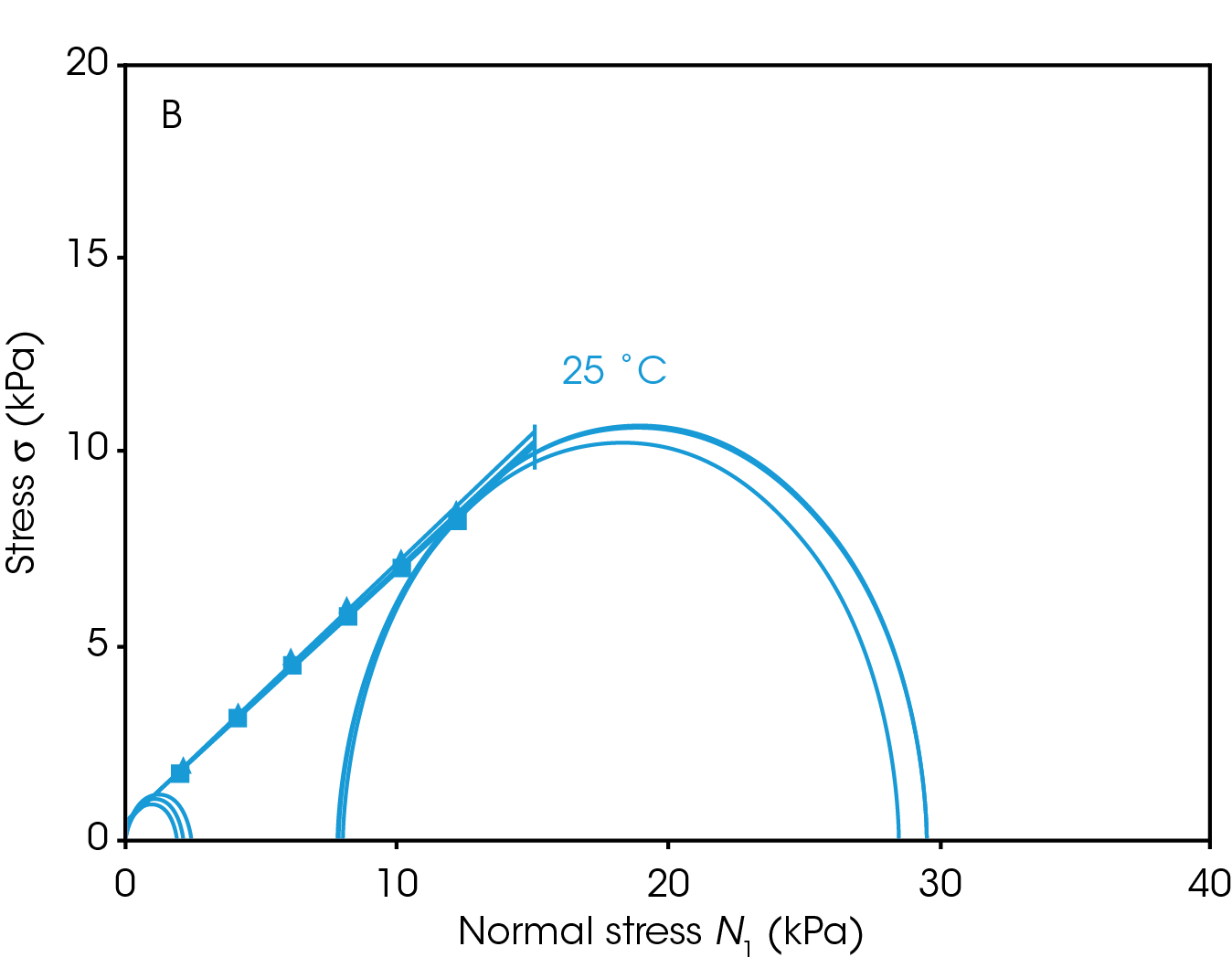

Temperature cycling shear results are shown in Figure 8 and Table 2. Temperature cycling was completed by performing a measurement at 25 °C, increasing the temperature to 45 °C for the next measurement, and finally returning the temperature to 25 °C for the final measurement (25-45-25 °C). To verify the temperature dependence of the shear measurement in Figure 8A, the same cycling experiment was performed with each measurement taken at 25 °C (25-25-25 °C) as shown in Figure 8B. Temperature cycling measurements to 45 °C and returning to 25 °C demonstrate irreversible changes in the powder. There is an appreciable change in the cohesion, major principal stress, flow function, and angle of internal friction. These differences can affect how the powder performs in a process for creating films even though the powder was cycled below Tg. The results in Figure 8B show that the 25-25-25 °C results align well with each other with some variability in data fitting. The change in shear properties when cycling close to the Tg is due to temperature and is not time dependent consolidation.

Table 2. Temperature cycling results for 25-45-25 °C.

| 25 °C FORWARD | 25 °C REVERSE | % CHANGE | |

|---|---|---|---|

| Cohesion (kPa) | 0.7 | 0.5 | -29 |

| Unconfined Yield Strength (kPa) | 2.4 | 2.4 | 0 |

| Major Principal Stress (kPa) | 29.1 | 33.2 | 14 |

| Flow Function | 12.2 | 13.8 | 13 |

| Angle of Internal Friction (rad) | 0.57 | 0.71 | 25 |

Conclusions

Temperature dependent flow and shear properties were measured for an epoxy powder using the TA Instruments Temperature Control Powder Rheology Accessory. The data can be used for quality control and formulation, showing the impact of environmental and processing conditions on flow and cohesion. The flow cell was used to measure confined and unconfined flow energies at 25, 35, and 45 °C followed by decreasing temperature measurements at 35 and 25 °C. The flow measurements demonstrated that the powder is relatively stable over time and temperature cycling. This powder would flow similarly in a process with low consolidation stresses as the temperature was increased close to the Tg of 47°C.

Shear cell measurements with temperature control provided insight into temperature dependent consolidation conditions. When the epoxy powder was cycled from 25 to 45 to 25 °C, irreversible changes in the powder properties were noted. These results demonstrate that while the powder may flow easily and consistently up to 45 °C, care should be taken when consolidated powders are subjected to higher temperatures. Variability in powder performance may be observed if a powder is shipped or stored in temperatures that approach Tg where it may not be visually apparent that the powder has been exposed to elevated temperatures. If a process or hopper has been designed for powders with specific cohesive and frictional properties, then variations may be observed if different samples from the same batch have varying thermal histories.

References

- Z. Du, S. Wen, J. Wang, C. Yin, D. Yu and J. Luo, The Review of Powder Coatings, J. Mater. Sci. Chem. Eng. 2016, 4, 54 – 59.

- H. J. Yu, L. Wang, Q. Shi, G. H. Jiang, Z. R. Zhao and X. C. Dong, Study on Nano-CaCO3 Modified Epoxy Powder Coatings, Prog. Org. Coat. 2006, 55 (3).

- M. Fernandez-Alvarez, F. Velasco, A. Bautista, Epoxy powder coatings hot mixed with nanoparticles to improve their abrasive wear, Wear, 2020, 448-449, 203211.

- J. R. Vail and S. Cotts, “Powder Rheology of Lactose: Impacts of powder morphology on performance of pharmaceutical excipients,” TA Instruments, New Castle, DE, 2022.

- K. Dennis and S. Cotts, “Powder Rheology of Graphite: Characterization of Natural and Synthetic Graphite for Battery Anode Slurries,” TA Instruments, New Castle, DE, 2022.

- J. Vail, K. Dennis, and T. Chen, “Effect of Moisture on Cohesion Strength of Carboxymethyl Cellulose Powder,” TA Instruments, New Castle, DE, 2022.

- “ASTM D7891-15 Standard Test Method for Shear Testing of Powders Using the Freeman Technology FT4 Powder Rheometer Shear Cell,” ASTM International, 2016.

Acknowledgement

This paper was written by Kimberly Dennis, PhD at TA Instruments.

Click here to download the printable version of this application note.