Keywords: Rheology, Cheese, Viscoelastic Properties, Strain Sweep, Frequency Sweep, Temperature Ramp

RH098

Abstract

Cheese has unique viscoelastic behavior. Its viscoelastic properties are sensitive to its storage and use conditions. At room temperature, cheese behaves like a soft solid where G’ is greater than G”. As temperature is increased, cheese undergoes a solid-to-liquid transition. Above this transition temperature, cheese flows like a viscous liquid which makes it possible to coat and cover the surface of food like pizza. In this paper, the viscoelastic properties of cheddar cheese are analyzed using a TA Instruments Discovery Hybrid Rheometer (DHR). Dynamic strain sweep, frequency sweep, and temperature ramp test methods are described for quantitative analyses of the viscoelastic properties of cheeses.

Introduction

In the cheese production industry, not only is sensory perception important, but the physical properties, such as flow behavior and elasticity, are also important to cheese production and processing. Cheese is made from milk. The major components in cheese are casein protein, fat, and an aqueous component [1-2]. At ambient temperatures, cheese behaves like a viscoelastic gel. This is because casein at this temperature is solid and exists as micelles in the viscous matrix. Casein is the main contributor to the elastic properties of the cheese. Fat in cheese exists in both solid and liquid forms. The fat globules are normally held in place by entrapment within the casein network. The aqueous phase in the cheese is usually made up of the soluble constituents of the milk serum (e.g. minerals, lactic acid, peptides, and amino acids) and any enzyme or salt (e.g. residual rennet) that may have been added during processing. The amount of aqueous phase in cheese significantly affects its firmness, and at high temperature, affects its flow behavior. As temperature is increased, cheese undergoes heat induced softening, which is mainly due to the melting of the fat and an increase in casein protein solvation or hydration. At elevated temperatures, cheese will melt and flow as a viscoelastic liquid.

Understanding the rheological properties of cheese is important to help guide cheese processing. Over the past decades, food scientists have developed analytical test methods using rotational shear rheometers for quantitative analysis of the viscoelastic properties of cheese [3-7]. The most commonly used tests methods include a dynamic strain sweep, which is used to investigate the linear viscoelastic region (LVR), a frequency sweep for evaluating the viscoelastic properties, and a dynamic temperature ramp to quantitatively study the properties of cheese from storage to cooking temperatures. This paper discusses in detail how to use a TA Instruments Discovery Hybrid Rheometer (DHR) to perform rheological analyses on cheese and correlate the data to its physical behavior.

Experimental

A commercial cheddar cheese was used as an example cheese sample for all of the rheological testing. The viscoelastic properties of the cheddar cheese were examined using a TA Instruments DHR-3 rheometer with the Peltier temperature control system. A 25-mm sandblasted upper and lower parallel plate geometry was selected for the purpose of reducing wall slip during the measurements.

The sample was loaded onto the parallel plate geometry at 70 °C, where cheese is in the molten state, to eliminate any manufacturing process and storage history. It was then cooled down to the initial measurement temperature. A low viscosity silicon oil was used to coat the edge of the geometry to prevent the cheese from drying during the measurements. Oscillation strain sweeps were performed at 20 °C and at 60 °C. The strain amplitude was increased from 0.01% to 100% at a test frequency of 1Hz (6.28 rad/s). The temperature ramp cooling test was conducted from 70 °C to 10 °C at a cooling rate of 2 °C/min. A 0.05% strain amplitude was used, which was within the linear viscoelastic region throughout the entire test temperature range, and the test frequency was set at 1 Hz. During the temperature ramp test, the axial force was controlled at 0± 0.1N in order to compensate for sample shrinkage. The oscillation frequency sweep tests were conducted at multiple isothermal temperatures to quantitatively evaluate the viscoelastic properties of the cheddar cheese at different temperatures.

Results and Discussion

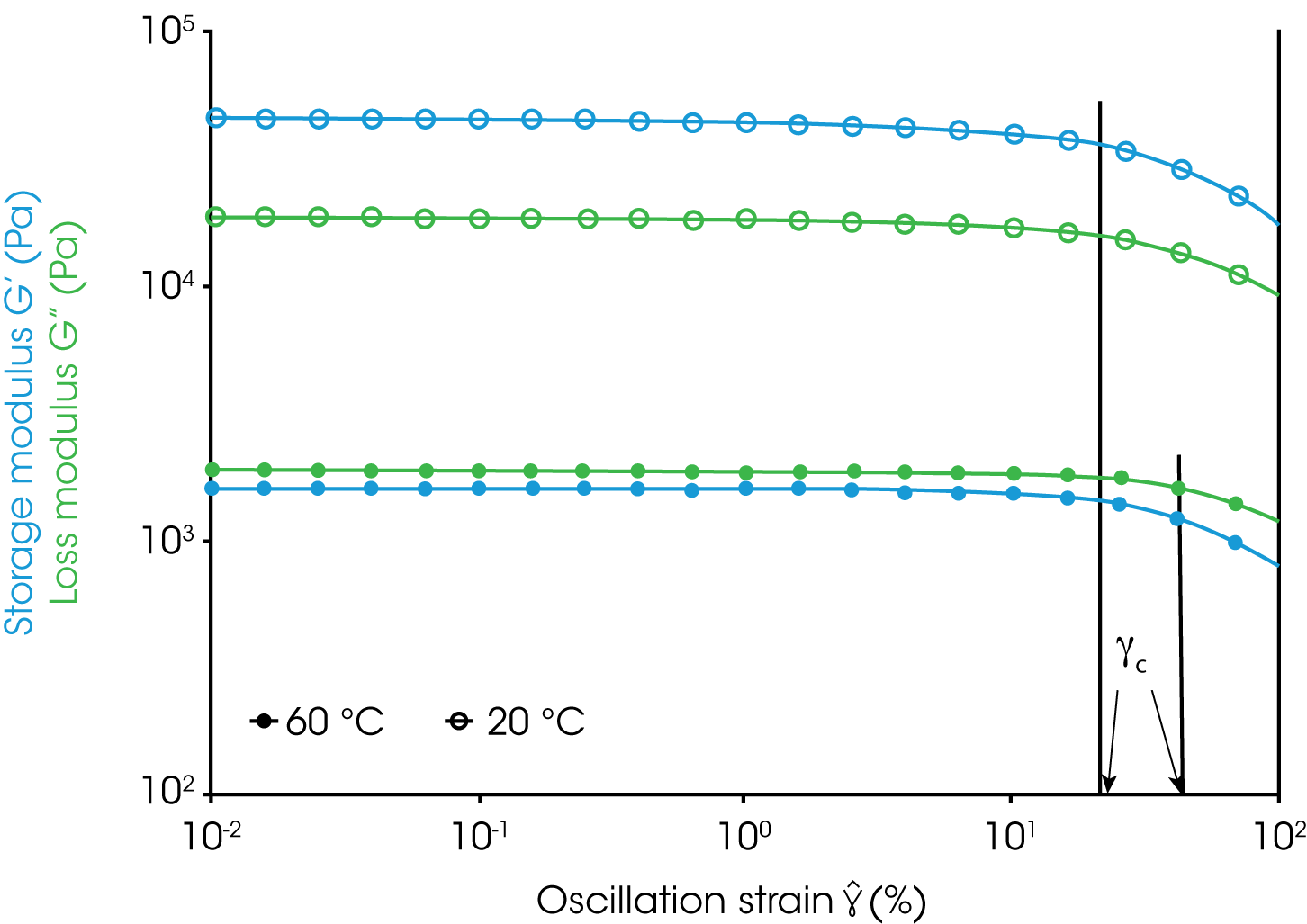

Dynamic oscillatory testing is the fundamental method for quantitative determination of the viscoelastic properties of cheese. In an oscillatory test, a sinusoidal strain amplitude is applied to the sample, and the resulting stress signal is measured by the rheometer. This strain amplitude must remain in the linear viscoelastic region of the sample. Within the linear region, the measured moduli (storage modulus (G’) and loss modulus (G”)) are independent of the oscillation strain. These moduli represent the viscoelastic properties of the material. At large amplitude oscillations, the sample structure is destroyed and undergoes irreversible change. In this case, the measured moduli become strain dependent. A common method to determine the critical strain at the end of the linear region is usually observed at the point where G’ shows a decrease of greater than 5%.

The oscillation strain sweep test is the method for determining the linear viscoelastic region at different temperatures and frequencies. Figure 1 shows the strain sweep tests conducted at 2 different temperatures. At 20 °C, cheddar cheese is in the solid state, and the results show that G’ is greater than G”. Both moduli are significantly higher at 20 °C than they are at 60 °C. At 60 °C, G” is greater than G’, which indicates that cheddar cheese is in the viscoelastic liquid state. At both temperatures, cheddar cheese shows good viscoelasticity and a broad linear viscoelastic region up to over 10% strain.

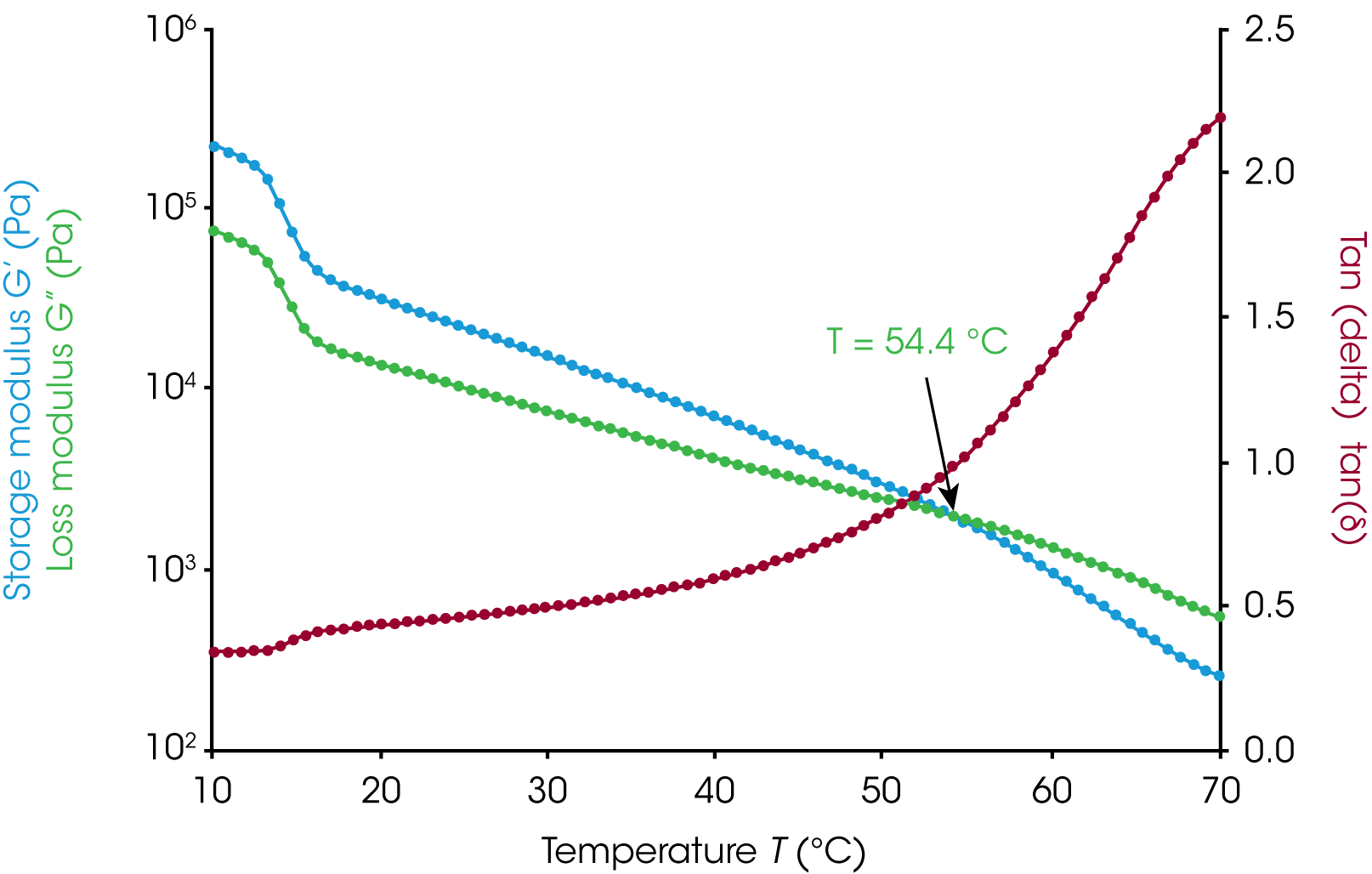

The oscillation temperature ramp test (Figure 2) was conducted from 70 °C down to 10 °C at a cooling rate of 2 °C/min. At high temperatures, cheddar cheese behaves like a viscous liquid, where G” is greater than G’ and tan delta (=G”/G’) is greater than 1. Both moduli increase dramatically with decreasing temperature. At 54.4 °C, cheddar cheese undergoes a liquid-to-solid transition where G’ equals G” (tan delta =1). This can also be described as the gelation point. Below this temperature, G’ is greater than G”, indicating that cheese is in solid state. The step increase in G’ and G” at temperature below 20 °C is associated with the crystallization of the fat component in cheese.

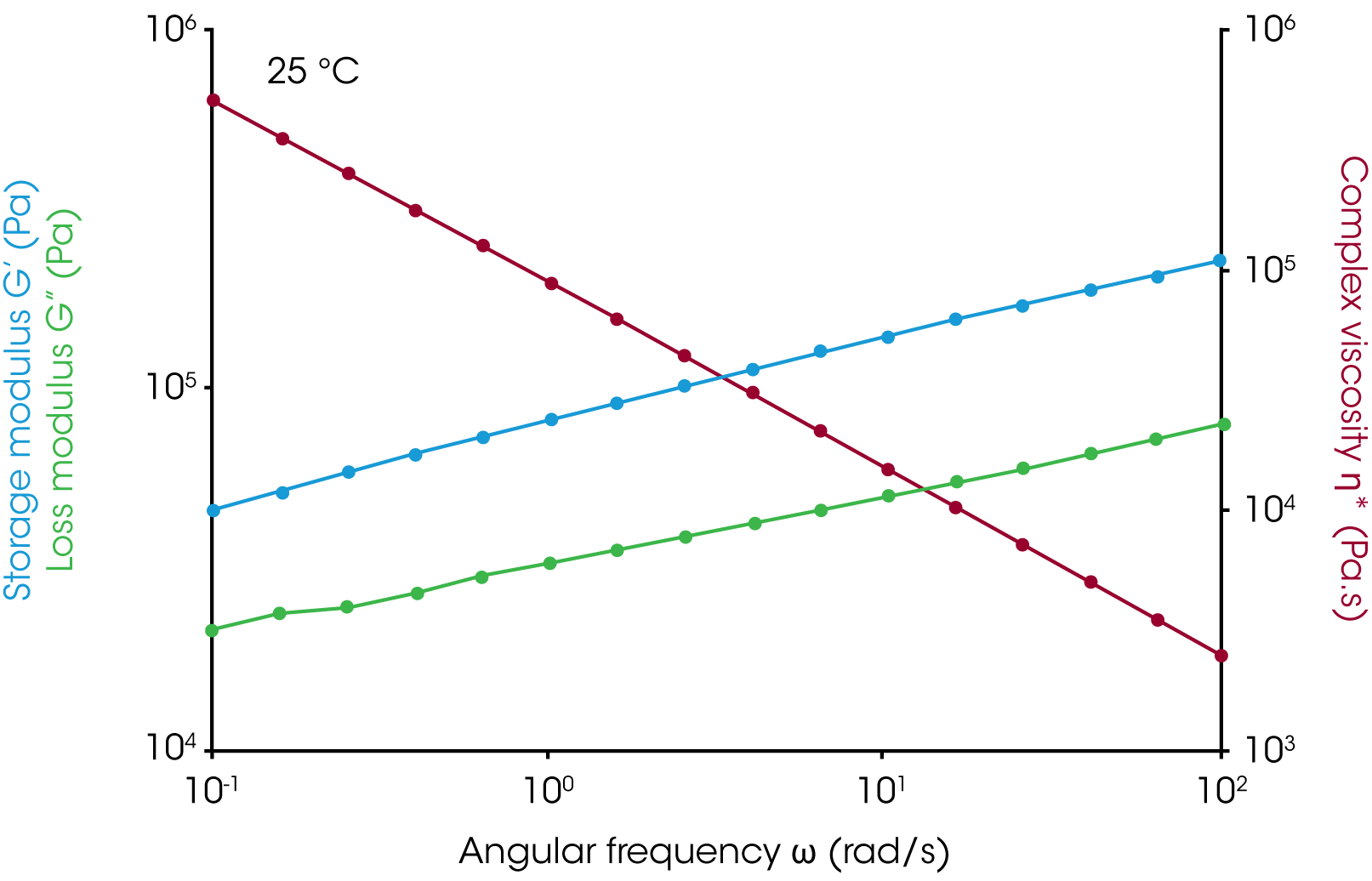

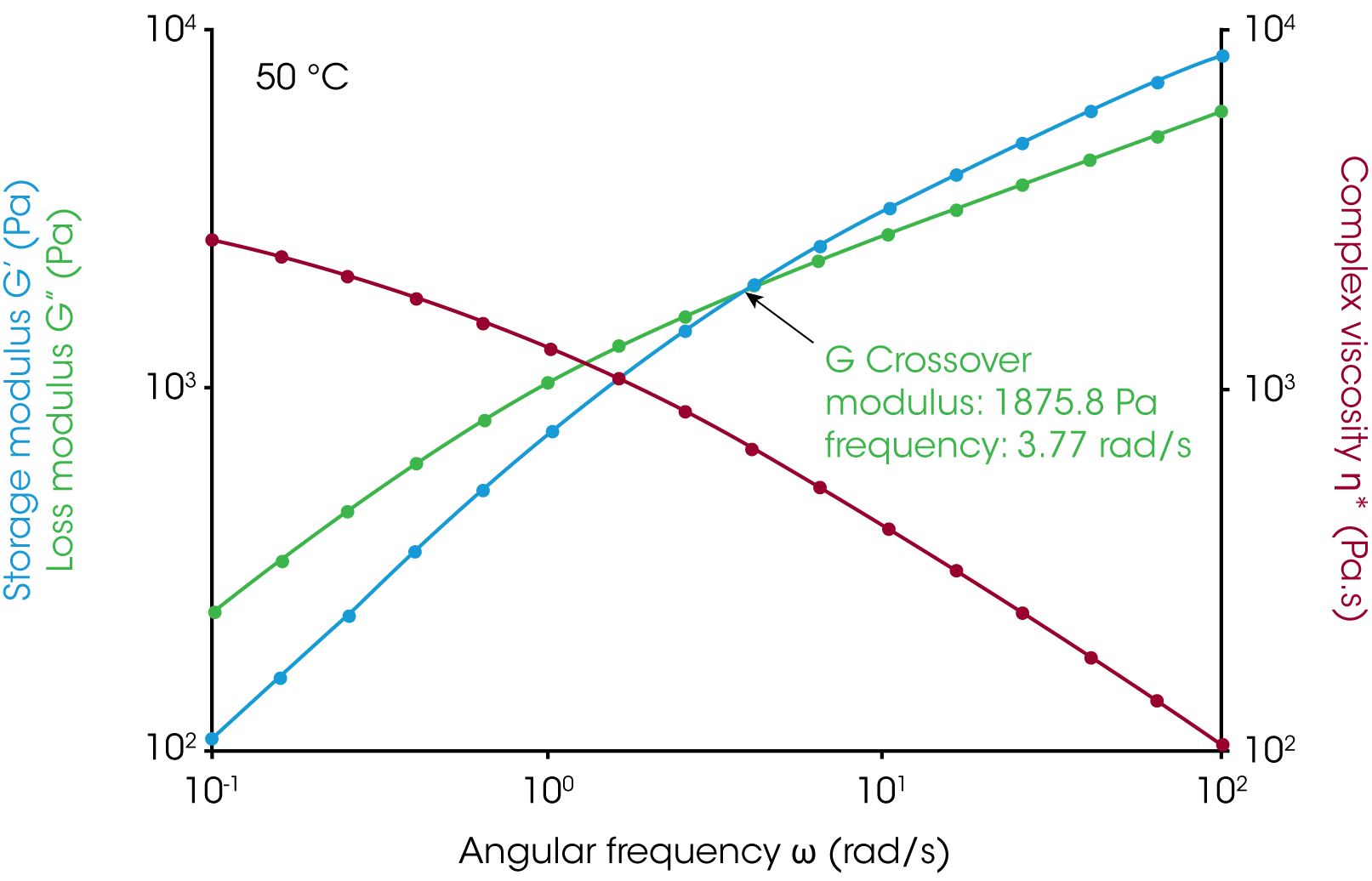

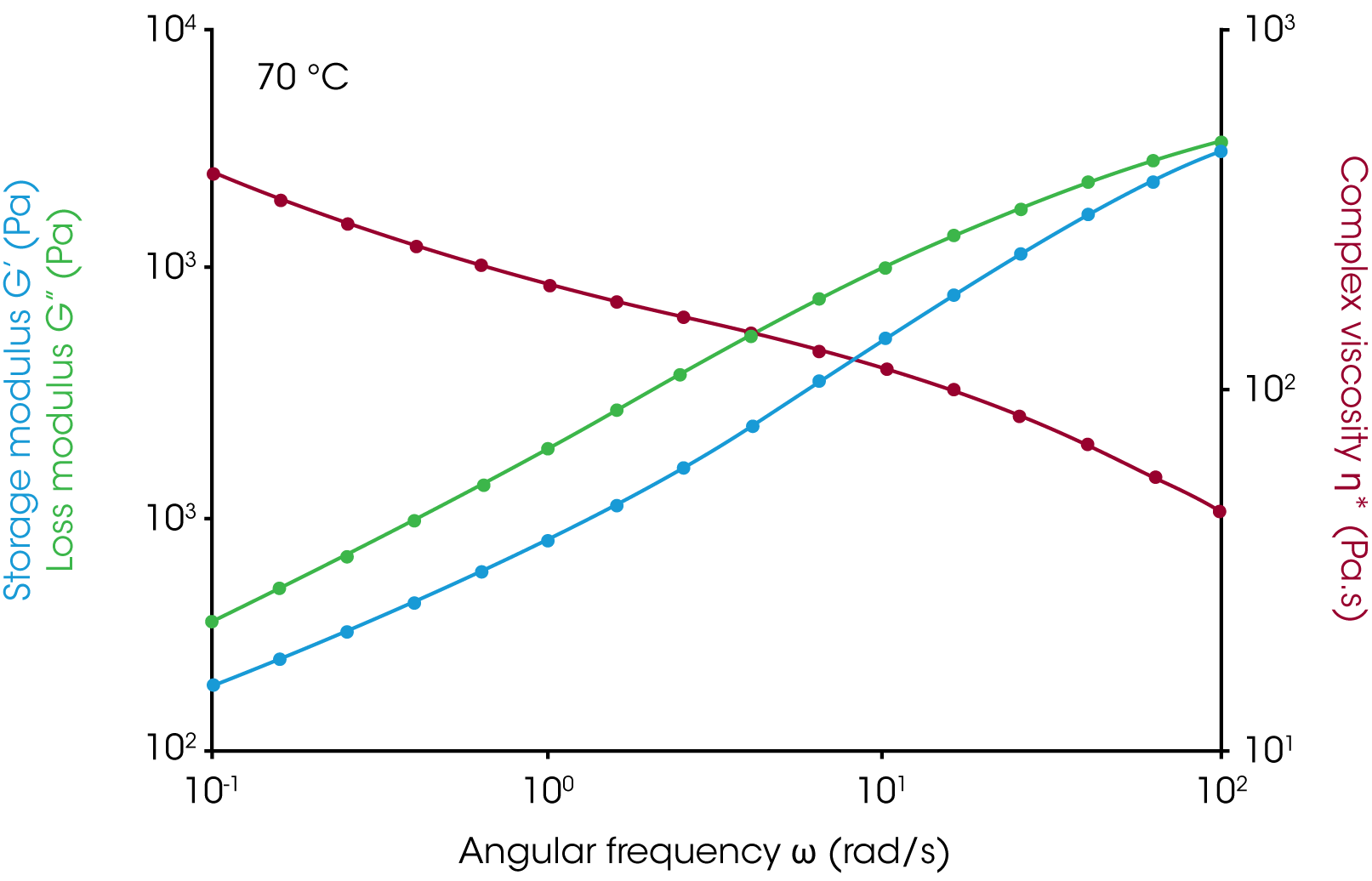

The oscillation frequency sweep test provides a quantitative method to evaluate and to compare the viscoelastic properties of cheeses of different brands, different aging times and/or at different use temperatures. Figure 3 shows the frequency sweep results at 3 representative temperatures. At room temperature (Figure 3a), cheddar cheese behaves like a viscoelastic soft solid. The storage modulus (G’) is greater than loss modulus (G”) within the measurement frequency range. Cheddar cheese melts at 54-55 °C. The frequency sweep test conducted at 50 °C (Figure 3b) shows that it behaves like a semi-solid. At higher measurement frequencies, the molecular relaxation in cheese cannot follow the test frequency, therefore, G’ is greater than G” and the sample behaves more solid-like. While at lower test frequencies, when the molecular relaxation time is shorter than the test frequency, the sample behaves liquid-like with G” greater than G’. The G crossover point is observed at a frequency of 3.77 rad/s. Figure 3c shows the frequency sweep test result at 70 °C. At this temperature, cheddar cheese melts and flows like a viscoelastic liquid. G” is greater than G’ and both moduli decrease with decreasing measurement frequency. In a frequency sweep test, G’ can be used to indicate the physical strength (e.g. firmness) of cheese in the solid state. The complex viscosity (η*) is a good parameter to estimate the flow behavior of cheese in the molten state. Tan delta gives a quantitative measure of the elasticity of cheese at a certain temperature and frequency.

Figure 3. Dynamic frequency sweeps at multiple isothermal temperatures: (a) 25 °C; (b) 50 °C; (c) 70 °C

Conclusion

Rheological testing is the key method for quantitative evaluation of the viscoelastic properties of cheese. The oscillation strain sweep method is used to determine the linear viscoelastic region of cheese at a defined temperature and frequency. The oscillation frequency sweep method provides a quantitative evaluation of the rheological properties of cheese at different isothermal temperatures and frequencies. The temperature ramp test shows the changes in the viscoelastic properties of cheese from storage to cooking temperatures.

References

- S. Gunasekaran, and M.M. Ak. Cheese rheology and texture. Boca Ration, Florida: CRC Press LLC. 2003.

- J.H. Prentice. Dairy Rheology: A Concise Guide. New York: VCH Publishers, Inc. 1992.

- S.Taneya, T. Izutsu, T. Kimura, and T. Shioya. Structure and rheology of string cheese. Food Structure 11:61-71. 1992.

- E. Nolan, V. Holsinger, and J. Shieh. Dynamic rheological properties of natural and imitation Mozzarella cheese. Journal of Texture Studies 20:179-189. 1989.

- M.M. Ak, and S. Gunasekaran. Dynamic rheological properties of Mozzarella cheese during refrigerated storage. Journal of Food Science 61(3):556-568, 584. 1996.

- M. H. Tunick, E. J. Nolan, J. J. Shieh, J. J. Basch, M. P. Thompson, B. E. Maleeff, and V. H. Holsinger. Cheddar and Cheshire Cheese Rheology. J Dairy Sci 73:1671-1675. 1990.

- J. Hort, G. Grys, J. Woodman. The relationships between the chemical, rheological and textural properties of Cheddar cheese. Le Lait, INRA Editions, 77 (5), pp.587-600. 1997. hal-00929549

Acknowledgement

This note was written by Tianhong Terri Chen, Applications Support Engineer at TA Instruments.

Click here to download the printable version of this application note.