Keywords: photocalorimetry, UV curing, DSC, adhesives, coatings, LED, TZero

TB103

Abstract

The LED PCA is a compact photocalorimeter accessory for the TA Instruments™ Discovery™ II Series Differential Scanning Calorimeters (DSC) with TZero™ Technology, which permits samples placed inside the DSC cell to be irradiated with single wavelength ultraviolet or visible light from a light-emitting diode (LED). The evolved heat from light-activated reactions is measured and used to study the relative reactivity and/or reaction kinetics. The chemical reactions studied are typically rapid and results are obtained in less than ten minutes.

Introduction

Ultraviolent (UV) light is used to cure some materials, such as some adhesives or coatings. Photocalorimetry can be used to understand the curing process. This technique introduces a UV light to the DSC cell, exposing the materials to the light as the DSC captures the heat flow resulting from the curing reaction.

Until recently, mercury lamp systems have been the dominant systems for these types of experiments [1]. But the passage of the Minamata Convention on Mercury treaty in 2013 initiated the phase out of mercury-based products. In photocalorimetry work, the advent of LED systems is leading to the rapid replacement of mercury lamp systems. LED systems provide the advantage of a more environmentally friendly curing system (no mercury lamp to dispose of), with the ability to provide a single wavelength for curing, which is how most industrial curing is performed [2].

TA Instruments provides the Discovery 250 / 2500 series DSCs with the Excelitas OmniCure® LX500 system. Standard provided wavelengths include 365 nm, 385 nm, 395 nm, and 405 nm. Custom wavelengths are also available.

The unique ability of TZero Technology to measure heat flow individually from the sample and reference sensors allows for a higher quality cure exotherm to be captured. This application note demonstrates the use of the LX500 with a Discovery 2500 System.

Experimental

A standard urethane UV curable optical adhesive was studied. The LX500 System was equipped with two 365 nm UV heads. These probes are mounted on top of the DSC so that they are positioned directly over the sample and reference sensors. Figure 1 shows the LED-PCA attached to a Discovery 2500 DSC. The LED-PCA is compatible with TA Instruments Finned Air Cooling System (FACS) and Refrigerated Cooling System (RCS) coolers (RCS 120, RCS 90, and RCS40). PCA experiments can be performed in the temperature range -50 to 250 °C with the LED heads supplied. Furthermore, once the PCA experiment is complete, a standard DSC experiment can be run on the fully / partially cured sample to a maximum temperature of 550 °C by making only a few minor changes to the system.

Results and Discussion

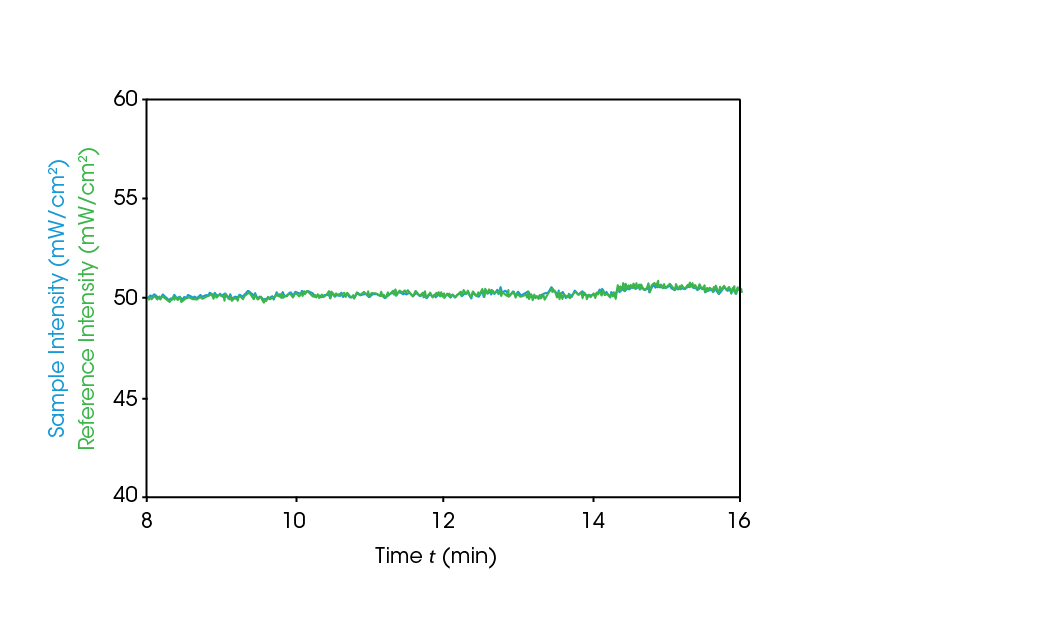

Figure 2 demonstrates the unique ability of TZero Technology in the Discovery 2500 System to separately measure the sample and reference heat flows, and thus set and balance the light intensities for each probe using the heat flow sensors in the DSC cell. This helps ensure precise control of the intensity the sample is exposed to and helps minimize any bias in the heat flow baseline that would result from unequal sensor intensities.

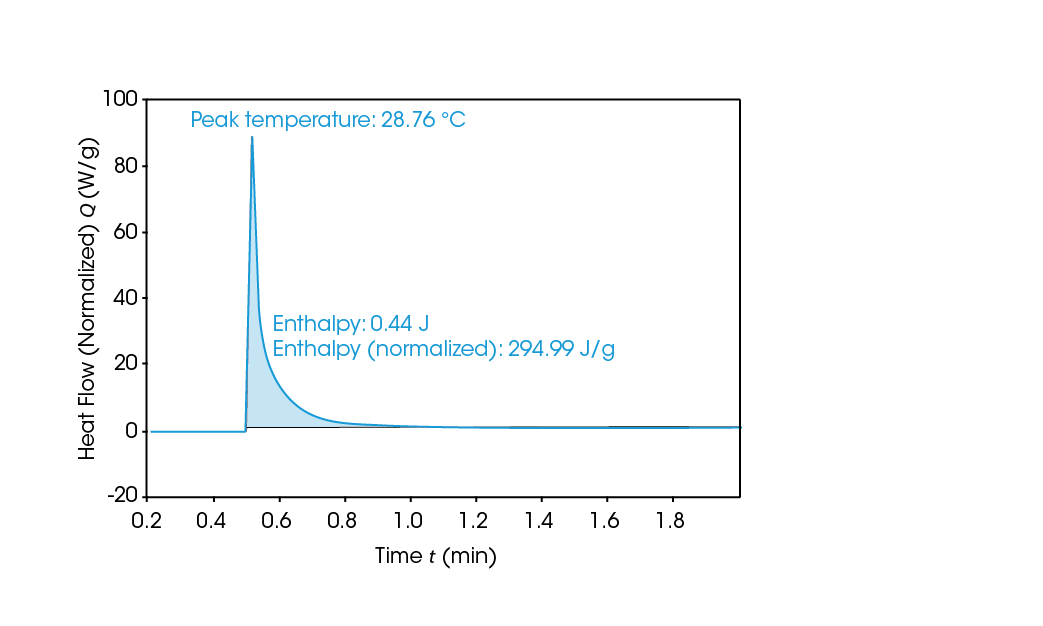

Figure 3 shows a typical cure experiment. For this experiment, the Shutter Open/Close command was used. The method was the same as shown earlier with the exposure time equal to five minutes. To integrate the peak, a horizontal baseline is extrapolated from the right back to where it intercepts the onset of the exotherm.

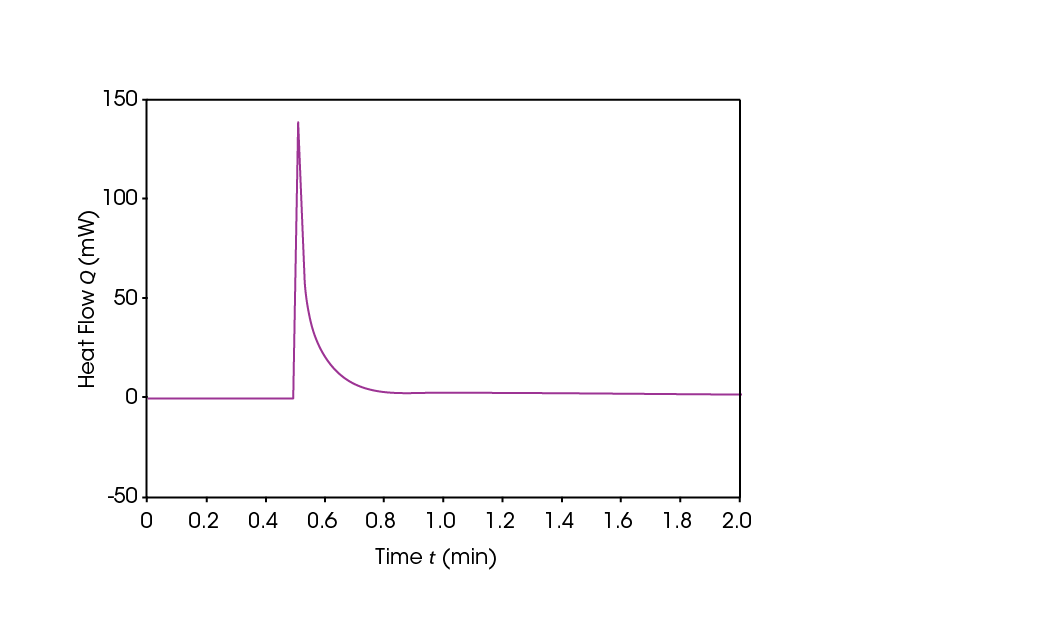

Figure 4 shows multiple cure experiments where the sample mass is tightly controlled using a pipette. The sample masses were controlled to within about 2% at 1.44 mg ± 0.03 mg. Enthalpy reproducibility is excellent. The average of the enthalpies was computed to be 296.40 J/g ± 1.28 J/g, which is a relative standard deviation of 0.43%. This excellent reproducibility results from the tight sample mass control and the superb heat flow signal provided by the TZero™ Technology of the Discovery™ 2500 System.

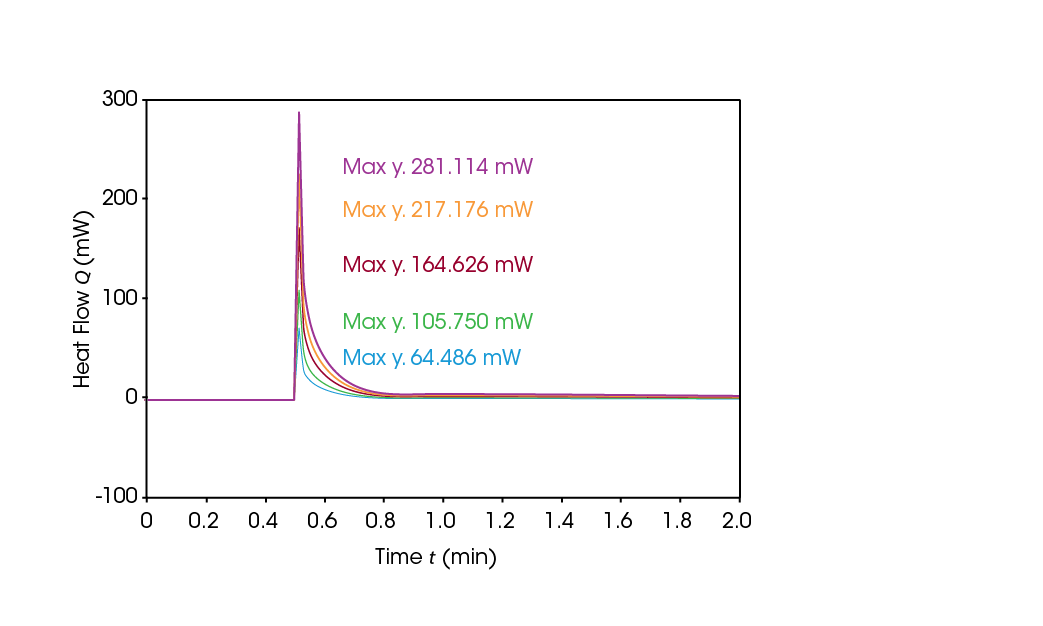

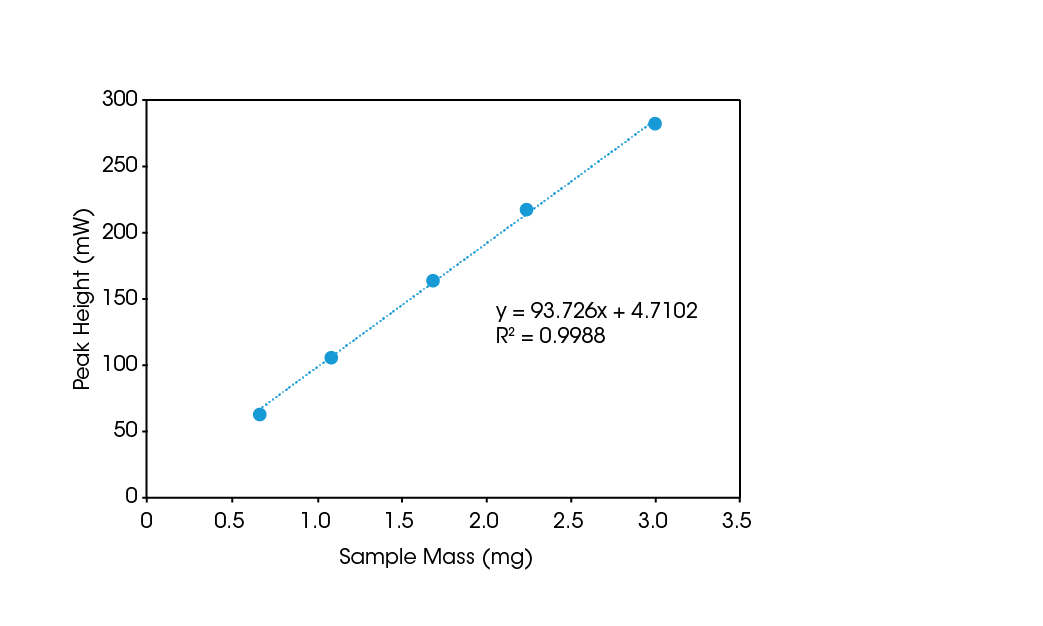

Figure 5 shows how the cure exotherm varies with mass. The sample masses for this set of experiments were varied from approximately 0.5 mg to approximately 3.0 mg. Figure 6 shows that the peak in heat flow grows as a linear function. This again illustrates the excellent heat flow characteristics of the Discovery™ 2500 System and TZero™ Technology and the linearity of that signal over a large range. The average cure enthalpy measured for these five samples was 295.71 J/g ± 2.35 J/g, for a relative standard deviation of 0.79%. This result is exceptional and within the error of the measurement on the carefully controlled sample mass data shown in Figure 4.

Conclusions

The new LED-PCA unit from TA Instruments provides a more environmentally friendly accessory for UV curing experiments as compared to mercury lamp systems. Combining the LED Photocalorimetry Accessory with a Discovery DSC with Tzero Technology permits the measurement of the light intensity directly at the DSC sensor, and the balancing of the intensity at the sample and reference platforms. These benefits, combined with the unique technology of Tzero Technology, provide for an improved cure heat flow measurement as demonstrated by the data presented in this application note.

References

- TA Instruments–Waters LLC, “TA305, Use of the Photocalorimetry Accessory (PCA) with a Tzero™ DSC,” TA Instruments–Waters LLC, New Castle.

- A. Chapman, “What wavelength is used for UV curing,” ProPhotonix, 7 March 2023. [Online]. Available: https://www.prophotonix.com/blog/what-wavelength-is-used-for-uv-curing/.

Acknowledgement

For more information or to request a product quote, please visit www.tainstruments.com to locate your local sales office information.

This paper was written by Gray Slough, PhD at TA Instruments.

TA Instruments, Discovery, and TZero are trademarks of Waters Technologies Corporation. OmniCure is a registered trademark of Excelitas Technologies Corp.

Click here to download the printable version of this application note.