Keywords: Thixotropy, thixotropic index, thixotropic recovery, rheology, shear thinning, time dependent property

RH106

Introduction

Thixotropy is a time-dependent shear thinning property. It is used to characterize structure change reversibility. A thixotropic fluid takes a finite time to attain equilibrium viscosity when introduced to a step change in shear rate [1]. Many structured fluids such as dispersions, suspensions or gels all exhibit thixotropic behavior. One typical example of a thixotropic material is mayonnaise. Under a low shear condition, mayonnaise shows high viscosity. But the viscosity is significantly reduced when being sheared at higher rate. The ratio of low shear to high shear (usually the difference is by a factor of 10) viscosity is defined as the thixotropic index (TI). Thixotropy is purposely generated through formulation. It provides desired properties for many applications such as controlled sagging or leveling, or startup of a pipeline flow after rest.

Thixotropy can be quantitatively measured using a rotational rheometer. The most commonly used testing geometries are 20-40 mm parallel plate or a cup/rotor geometry. To avoid slippage during shear, a roughen surface plate (e.g. crosshatched or sand blasted), a vane or a sand blasted rotor with a grooved cup can be used. In this paper, we introduced 4 typical rheology methods that are used to quantitively measure thixotropy and/or to monitor thixotropic recovery on structured fluids. Commercial paints are selected as example samples for demonstrating the analysis. However, one thing to emphasize here is that thixotropy is a time dependent characteristic. The measured thixotropy value will vary depending on specific experimental test parameters. It is important to use the same experimental methods and parameters to ensure good test reproducibility and reliable comparison between different formulations.

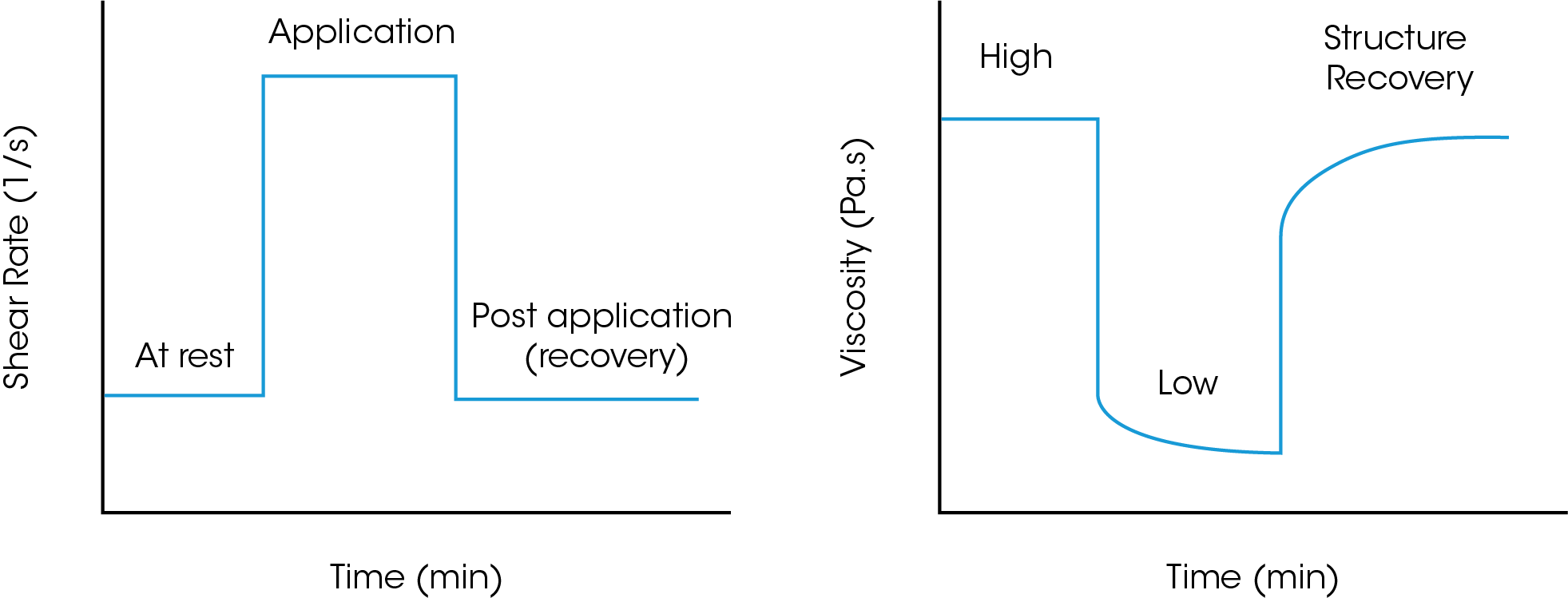

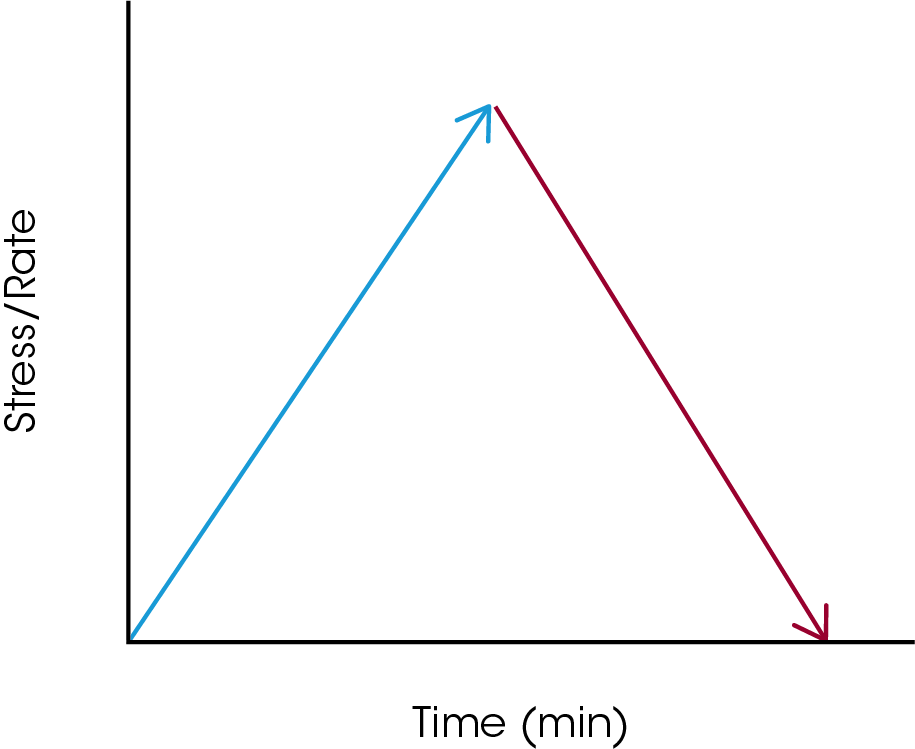

1. Three-Step Flow Method

The most commonly used rheological method to quantify thixotropy is a three-step flow test. This method is used to measure low to mid viscosity samples. In the first step, sample viscosity was measured under low shear rate (e.g. 0.1 1/s). This low shear viscosity represents sample’s status at rest condition. Then the shear rate is increased by a factor of 10 or greater (e.g. 1 or 10 1/s). At this high shear rate, the microstructure of the material is destroyed so the measured viscosity is lower. Thixotropic index (TI) is defined as the ratio between the low shear viscosity to high shear viscosity. In the third step, the measurement jumps back to the initial low shear rate. This step is to monitor the time it takes for the material to recovery its microstructure back to equilibrium. Figure 1 demonstrates the design of this three-step flow test method and the viscosity behavior of a thixotropic material.

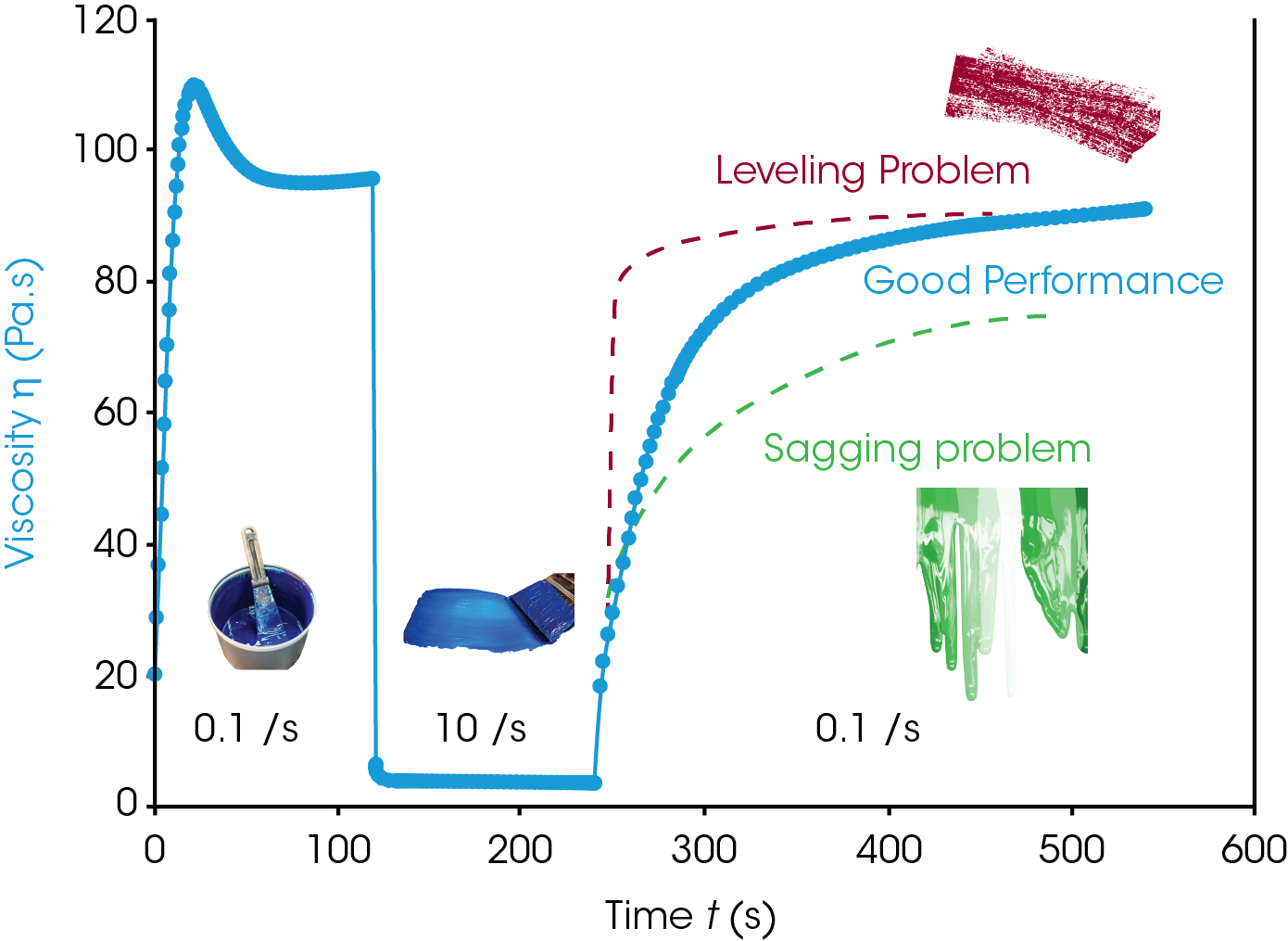

Figure 2 shows an example of measuring the thixotropic properties of a blue paint at 25 °C. The test is conducted on a Discovery Hybrid Rheometer using a 40 mm parallel plate geometry. The three-step flow test is designed as follows:

Step 1: Low Shear (e.g. 0.1 1/s), structure at rest

Step 2: High Shear (e.g. 10 1/s), structural destruction

Step 3: Low Shear (e.g. 0.1 1/s), structural regeneration

From this test result, thixotropy index can be calculated from the ratio of equilibrium shear viscosity measured at 0.1 1/s and at 10 1/s. In the third step, the time it takes for the paint to recover its original viscosity is critical to its application performance. If the recovery time is too short (red dashed line), the paint will have some leveling issue in its application. However, if the recovery time is too long (green dashed line), it will exhibit sagging during application. Adding appropriate rheology modifier to adjust this thixotropic recovery time is the key to ensure a good performance of paint product.

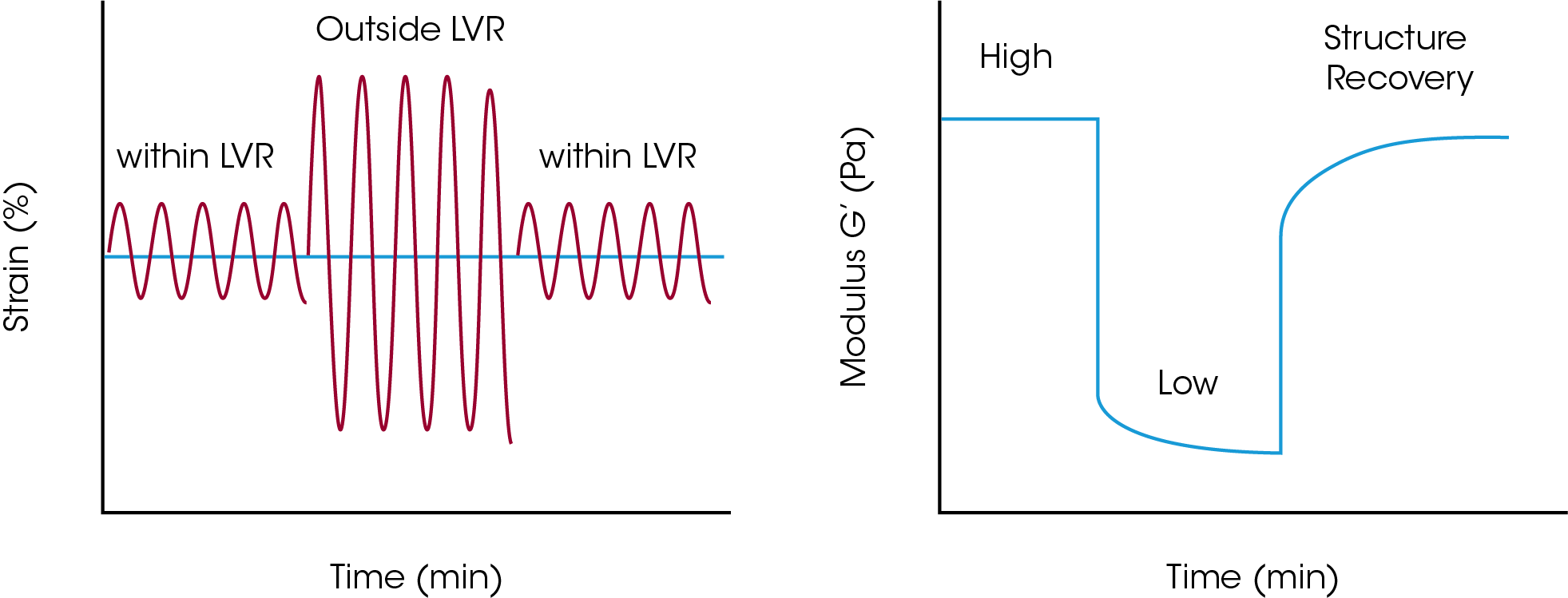

2. Three-Step Oscillation Method

Instead of performing a three-step flow test, one can also design and use a three-step oscillation method for thixotropy analysis. This oscillation method is designed by using three oscillation time sweeps with different strain amplitudes that is within and outside the linear viscoelastic region (LVR) of the sample. Figure 3 demonstrates this test method and the viscoelastic performance (G’) of a thixotropic material.

Step 1: Oscillation time sweep within LVR, structure at rest

Step 2: Oscillation time sweep outside LVR, structural destruction

Step 3: Oscillation time sweep within LVR, structural regeneration

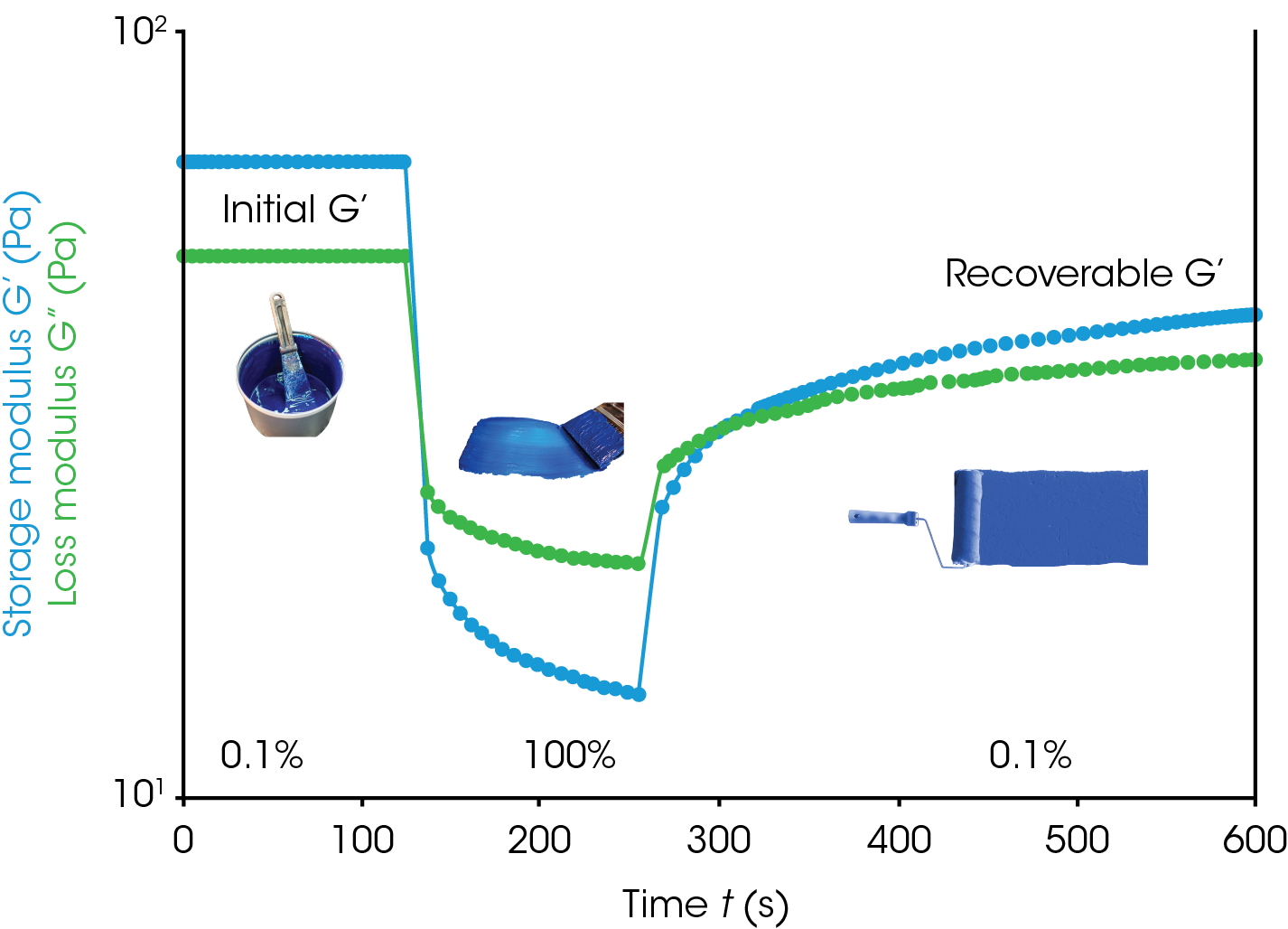

Figure 4 shows the oscillation measurement results of the same thixotropic paint. In the first step, oscillation time sweep is conducted using a small strain of 0.1% that is in the linear viscoelastic region (LVR). The sample shows higher moduli with G’ greater than G”, which indicates that this paint contains a structure and behaves solid-like at rest. Both the input (blue) and output (red) waveforms are sinusoidal. When the strain amplitude is increased up to 100% in the second time sweep, the structure of the paint sample is destroyed. Sample moduli decrease sharply and G” becomes greater than G’. This means sample behaves liquid-like under high shear. For non-linear oscillation, the output waveform (red) is not sinusoidal. The thixotropic index can also be quantified by taking the ratio of G’ measured at low and high strain. The third step time sweep is used to monitor thixotropic recovery. When the strain amplitude is decreased back to within the LVR, it takes finite time for the sample structure to recover. G’/G” crossover is observed within less than one minute of the test. The time it takes for G’ to reach final equilibration is the recovery time of this paint sample. A good control of this recovery time is critical to the applications performance.

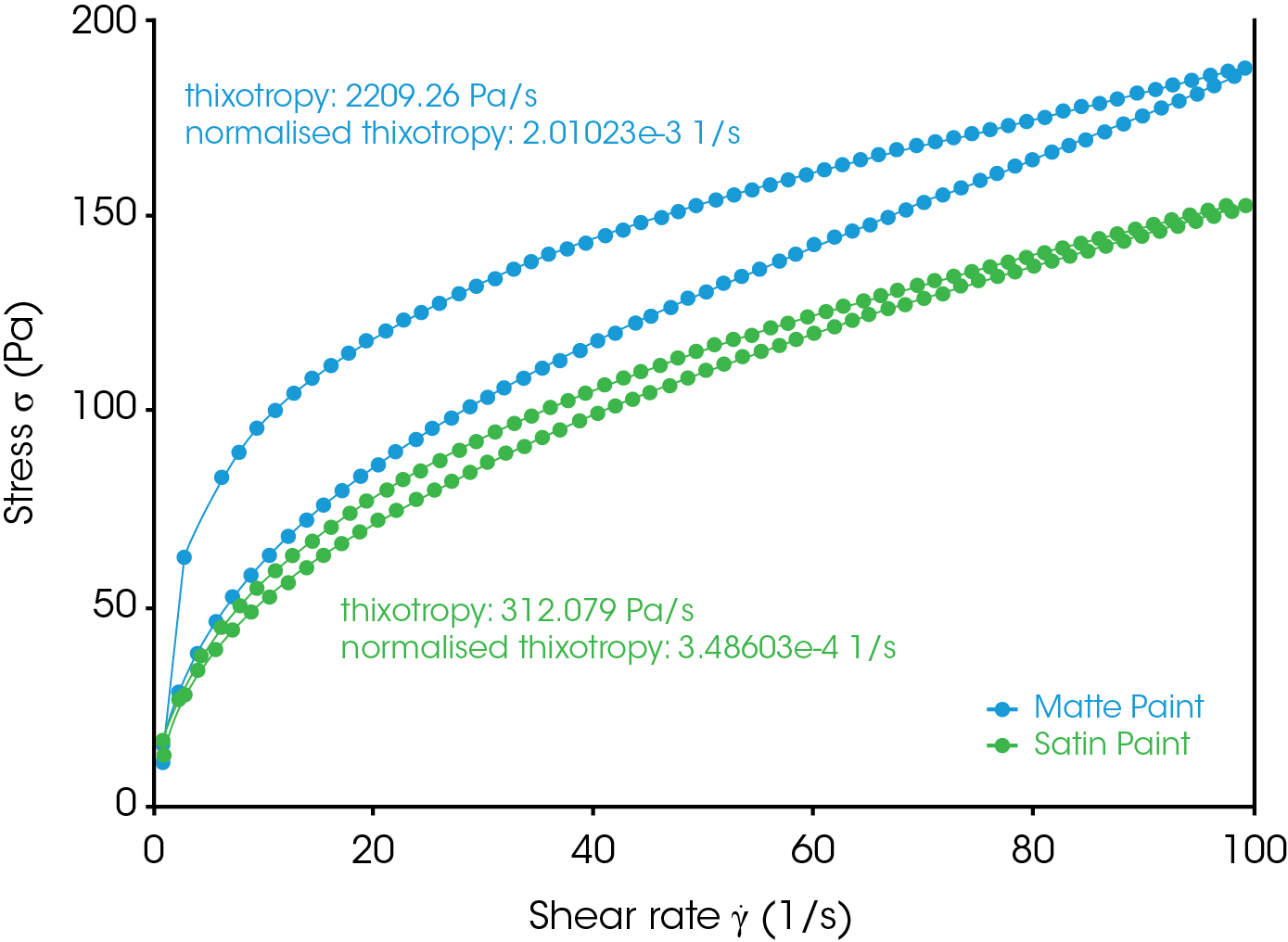

3. Flow Ramp Up and Down Method – Thixotropic Loop

The third method to quantify thixotropy is by using a flow ramp up and down experiment. It is also called as a thixotropic loop test. In this method (shown in Figure 5), a shear stress or a shear rate is ramped from zero up to a certain value at a certain speed, and then ramp down to zero with the same time.

Figure 6 shows the thixotropic loop test results on a matte and satin paint sample. The tests are conducted at 25 °C using a concentric cylinder cup with a recessed end rotor. Sample shear rate is ramped up from 0 to 100 1/s in 60 seconds, and then ramped back down to 0 in another 60 seconds. During the rate ramp up step, sample structure is destroyed, so the down curve exhibits a hysteresis. The thixotropic index is calculated by taking the area between the up and down curves. However, since this method is a non-equilibrium ramp, the measurement result is highly depending on the ramp up and down time. The normalized thixotropy is defined as the area between the up and down curves divided by the maximum rate, the maximum stress, and the step time. It is used to compare results obtained from different test conditions. From the test results, one can see that the matte paint is more thixotropic compare to the satin paint. But this thixotropic loop test method does not provide information of structure recovery.

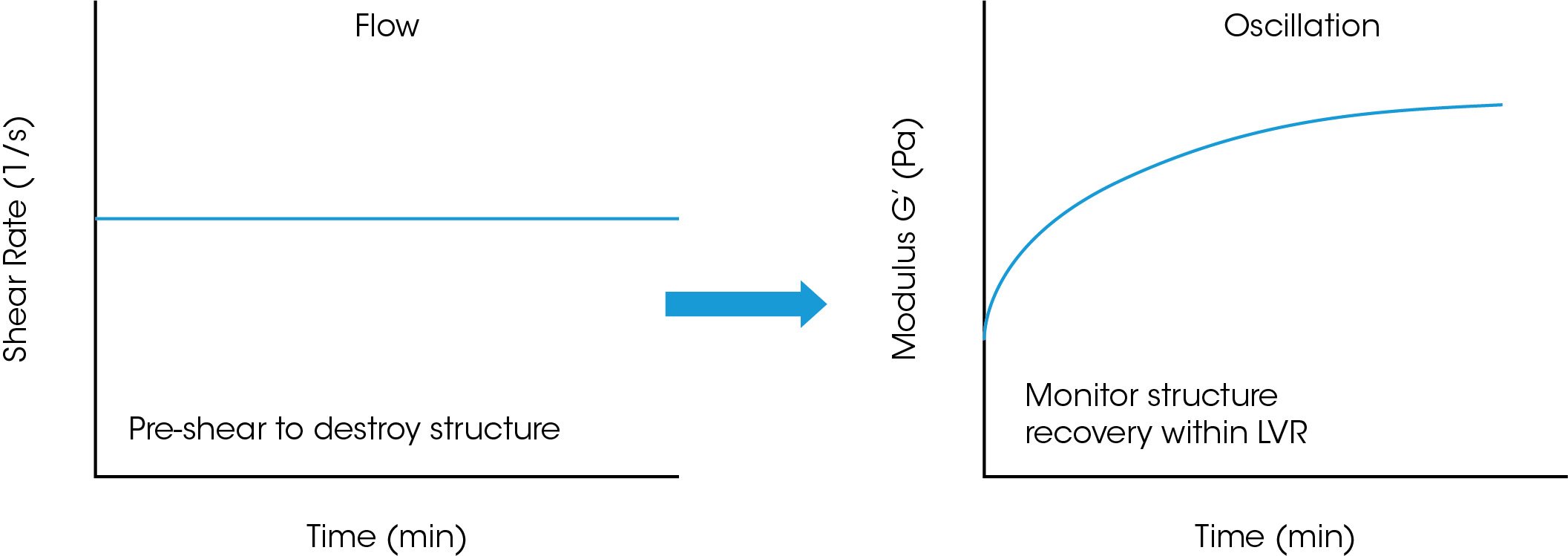

4. Pre-Shear Followed By Oscillation Time Sweep Method – Monitor Thixotropic Recovery

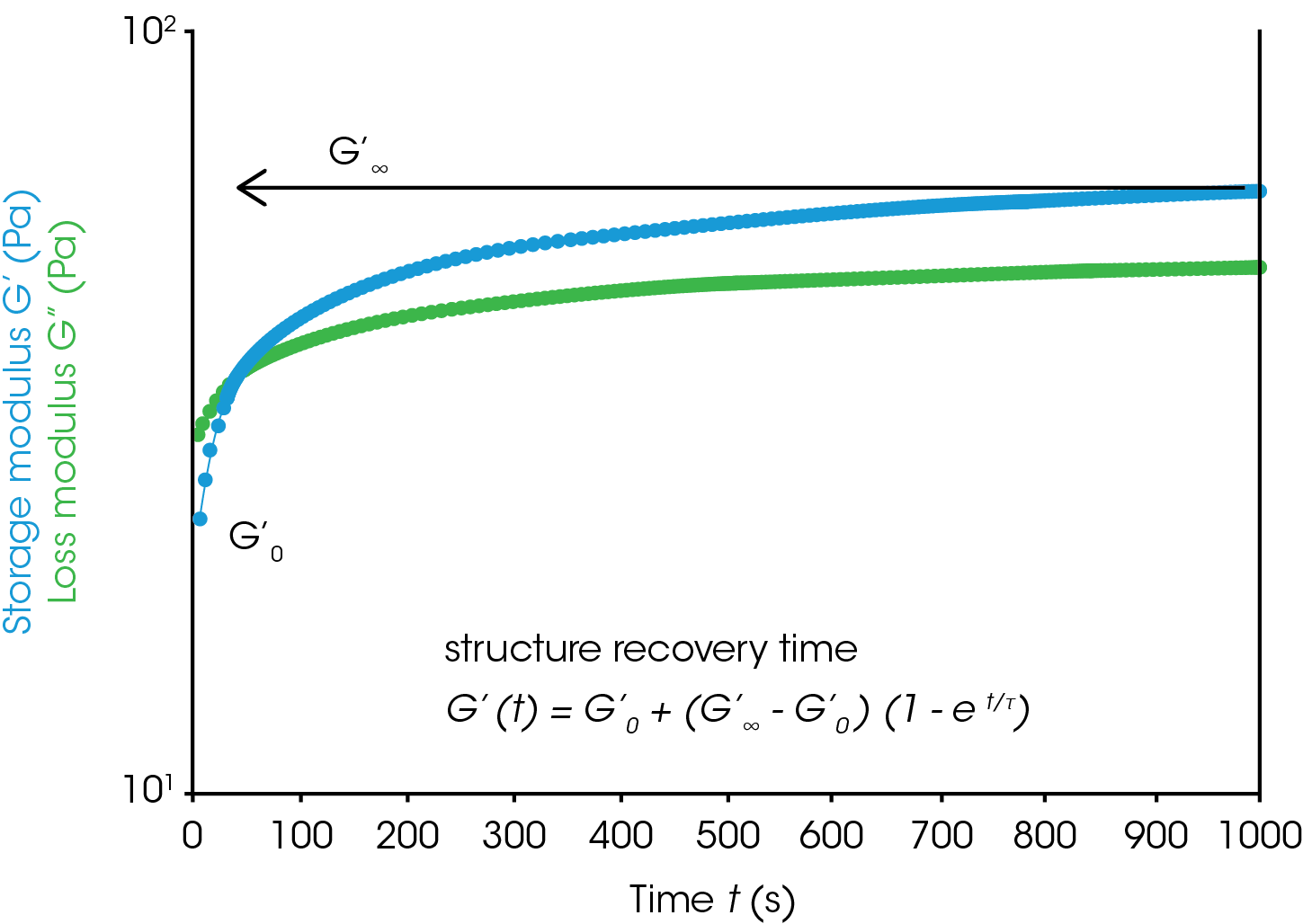

In recent years, thixotropic analysis has been more focused on studying the structure recovery than quantifying the structure destruction. Another commonly used method for monitoring the thixotropic structure recovery is by doing a flow pe-shear followed by an immediate oscillation time sweep (shown in Figure 7). The pre-shear step is for the purpose of destroying the structure. No data is collected in this step. The oscillation time sweep monitors the structure recovery over time.

Figure 8 shows the time sweep test result of the blue paint after underwent a pre-shear at 100 1/s for 60 seconds. At the beginning, sample behaves liquid-like with G” greater than G’. Both moduli increase rapidly, and the G crossover is observed within the first 1 minute of measurement. After G crossover, sample exhibits certain structure with G’ greater than G”. Fit the G’ curve with a polynomial equation, one can calculation the recovery time (τ) for sample structure to reach final equilibration. This test method is only focused on studying the structure recovery of a thixotropic material.

Summary

Four practical rheology test methods are introduced for quantifying thixotropy and thixotropic recovery. The users can select to use either one or multiple methods based on their need. However, since thixotropy is a time dependent characteristic, the measurement results will be depending on the selected test method and specific test parameters. To achieve comparative results, it is highly recommended to use the same set of test parameters for one series of samples.

References

- Howard A. Barns, Thixotropy – a Review, J. Non-Newtonian Fluid Mech., 70 (1997) 1-33

Acknowledgement

This paper was written by Dr. Tianhong Terri Chen, Senior Applications Support Scientist at TA Instruments.

Click here to download the printable version of this application note.