Keywords: Discovery TMA 450EM, glass transition, tan delta, nylon, polyester terephthalate, PET

TA449

A thermomechanical analyzer (TMA) measures dimensional change of a sample as a function of time, temperature, and force. Historically, TMAs have been utilized to determine coefficient of thermal expansion (CTE), a crucial material property. When run in “Enhanced Mode,” the Discovery TMA 450EM is able to execute a number of advanced testing methods which are normally not available in a traditional thermomechanical analyzer. These include Modulated TMA (MTMATM), creep, stress relaxation, and dynamic temperature ramp tests.

In the Dynamic Temperature Ramp Mode of a Discovery TMA 450EM a sinusoidal force and linear temperature ramp are applied to a sample, similar to what is done on a Dynamic Mechanical Analyzer (DMA). While an oscillatory force is applied, the instrument is able to monitor the sample’s response to the stress. If a material is perfectly elastic the response will be exactly in phase with the applied force, and if a material is perfectly viscous it will be exactly 90 degrees out of phase with the sinusoidal wave. Most polymers are viscoelastic and their response to applied stress lies between these two extremes. The delay in response to the applied deformation can be quantified as the phase angle (δ).

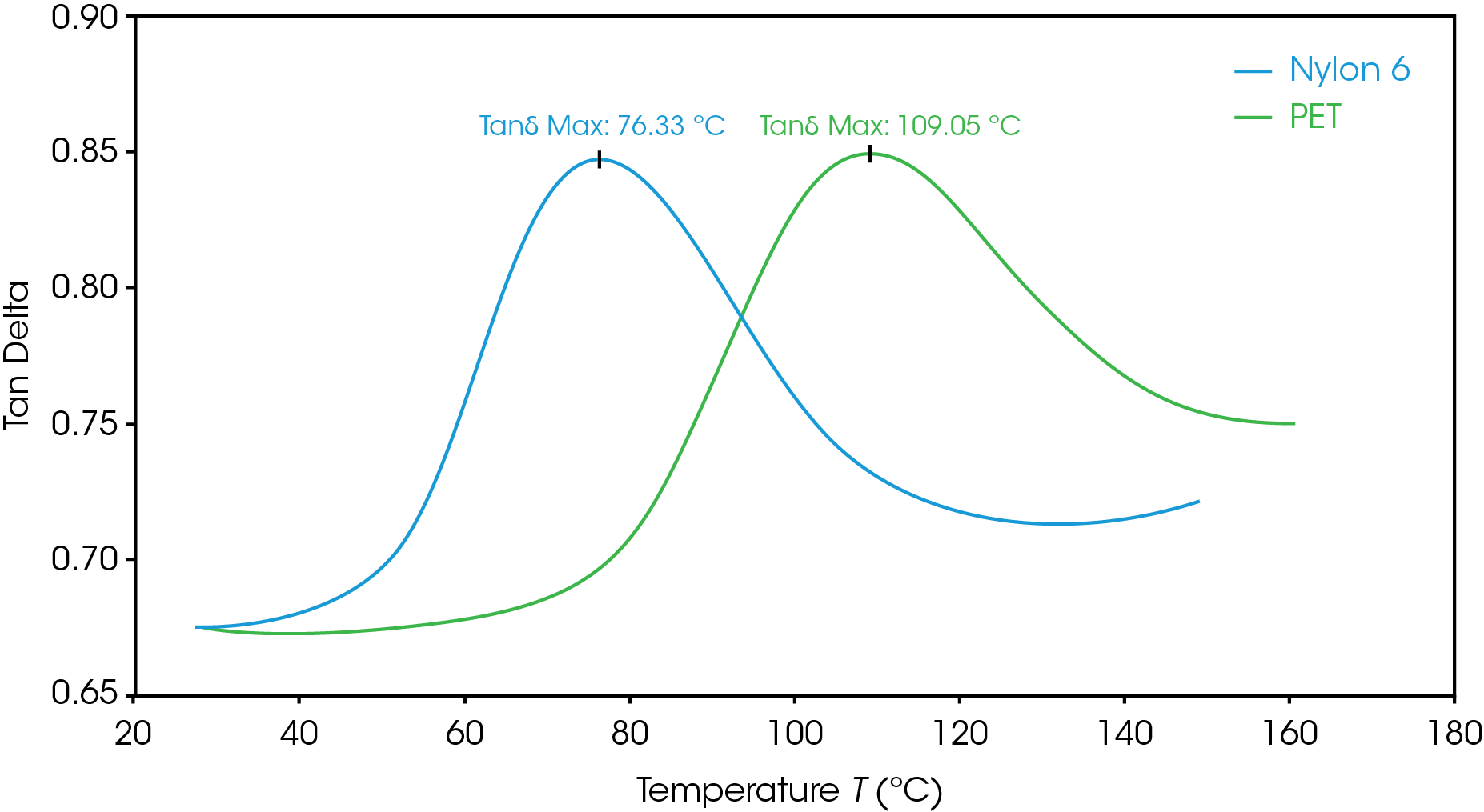

The tangent of the phase angle (Tanδ) can be analyzed to determine the mechanical damping behavior of a material as a function of temperature. The peak of the tan(δ) signal is the point in the transition region where the material has the most viscous response to deformation as previously glassy polymer chains begin to gain long rang mobility. This point, the peak of the Tanδ curve, can be taken to be glass transition temperature (Tg). The ability to monitor a response in viscoelastic behavior in this way allows the Discovery TMA 450EM an added degree of sensitivity in determining the glass transition temperature.

Figure 1 shows Tanδ peaks for two thermoplastic films run in Dynamic Mode in the TMA 450EM. Nylon 6 and polyethylene terephthalate (PET) were run in tension using the Film/Fiber probe. Both samples were equilibrated at 25 °C. The probe applied a static force of 0.10 N to ensure the films were kept in tension and would not buckle during the experiment. An oscillatory force of 0.50 N was applied at a frequency of 0.50 Hz and the chamber was thermally ramped at 3.0 °C/min to an upper temperature more than 50 °C past the individual sample’s glass transition temperatures. The value of the Tg from the peak of Tanδ of these samples was compared to values recorded on a TA Instruments Discovery DMA 850 with excellent agreement.

While the Discovery TMA 450EM can’t offer all the same abilities as the Discovery DMA 850, this TMA is able to probe the Tg of a material as a function of viscoelastic response with the use of a Dynamic Temperature Ramp.

Acknowledgement

This note was written by Andrew Janisse, Ph.D., Applications Scientist at TA Instruments.

Click here to download the printable version of this application note.