Keywords: Rheology, dielectric, epoxy curing, viscoelastic property, conductance, capacitance, permittivity

RH104

Abstract

When using an epoxy-based material in electronic industry, it must meet the requirement of specific dielectric and rheological performance. TA Instruments provides a dielectric accessory (DETA), which can be attached to any TA Instruments rotational rheometers. This allows a simultaneous rheological and dielectric measurement performed with one sample loading and in the same environmental temperature profile. The rheometer is a powerful instrument that can measure the viscoelastic property change of the sample during curing. The dielectric LCR meter is used to monitoring the changes of the mobility of the ions and dipoles in the material. In this study, we discuss in detail on how to properly design an appropriate test protocol for this kind of simultaneous measurement.

Inrtoduction

Epoxies and epoxy-based composites are preferred insulating materials for many electrical applications, especially printed circuit boards, adhesives, GIS spacers, generator ground wall insulation system and cast resin transformers etc. [1-3]. These materials exhibit excellent mechanical strength, ideal electrical property, and good chemical and heat stability. A quantitative measurement of the dielectric and mechanical properties is critical for guiding formulation and manufacturing of these kinds of products.

The mechanical performance of the epoxy-based products can be quantitatively evaluated using rheological analysis. Rheology is a powerful tool, which measures viscosity and viscoelasticity of a material. For characterizing the curing of an epoxy, a dynamic oscillatory test is commonly used either isothermally or with a programmed temperature profile, which mimic the curing conditions in manufacturing. In an oscillatory test, sample moduli (G*, G’ and G”), complex viscosity (η*) and damping factor (tan delta) are recorded as a function of the mechanical test frequencies and with a small shear amplitude that is within the linear viscoelastic region of the sample. The rheological measurements help better understanding of the physical property change throughout curing. The modulus measurement for a fully cured product also provides quantitative evaluation to the performance of the final products.

Dielectric analysis is the study of the mobility of dipoles or ions in a material [4]. In a dielectric measurement, two fundamental electrical characteristics are reported: capacitance and conductance. The capacitance represents the material’s ability to store electrical energy. The conductance represents both the material’s ability to transfer electrical charge and the loss of electric energy through relaxation processes. These properties allow probing the chemistry and molecular relaxation in materials such as epoxies. It is a more sensitive technique than DMA to probe local motions along the polymer chain since the polar bonds are affected by the electrical field. Epoxy resins are good electric insulators due to low concentration of free charge carriers. Their dielectric measurements can be carried out using a LCR meter under a certain temperature profile and with a wide range of dielectric frequencies. During the measurements, all dielectric parameters such as capacitance (C), conductance (G), storage permittivity (ε’), loss factor (ε”) and the loss tangent (tan δDE) are recorded as a function of time, temperature and dielectric frequency.

TA Instruments provide a dielectric testing accessory (DETA), which can be used in combination with general rheological measurement. Figure 1 shows a picture of this dielectric accessory attached to a Discover Hybrid Rheometer. This system allows a simultaneous measurement of rheological and dielectric properties with one single sample loading and in one test.

In this study, we elaborate in detail on how to properly setup a simultaneous rheology-dielectric measurement to monitoring an epoxy curing process.

Experimental

One commercially available 60-minute epoxy was used as an example sample for this analysis. The dielectric accessory (Keysight LCR meter E4980A) was attached to a TA Instruments Discovery Hybrid Rheometer with the environment test chamber. A pair of 25 mm aluminum disposable parallel plates was used for the test. The two-part epoxy sample was mixed 50/50 at ambient temperature and then loaded immediately to the plate set at the initial test temperature.

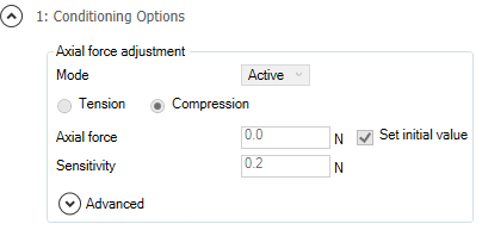

During the test, the axial force control was set at 0 ± 0.2 N to compensate for sample shrinkage during curing.

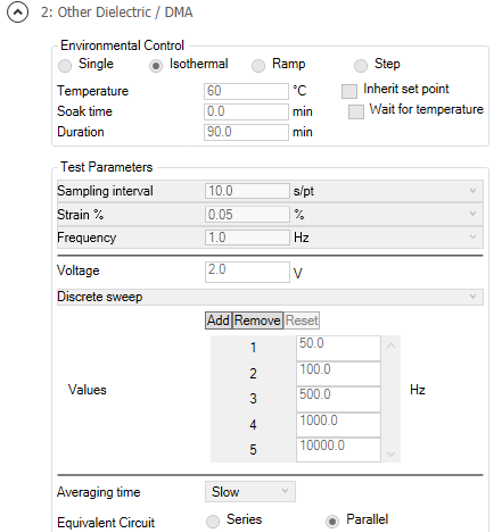

The axial force control was set at 0 ± 0.2 N to compensate for sample expansion as temperature increases and shrinkage as sample cures.

The dielectric frequencies were selected at 50 Hz, 100 Hz, 500 Hz, 1000 Hz and 10000 Hz, respectively. Since epoxy material has high impedance, the measurement voltage was set at 2 V and the equivalent circuit was under parallel.

The isothermal curing test was programmed as follows:

The temperature ramp curing test was programmed as follows:

Results and Discussions

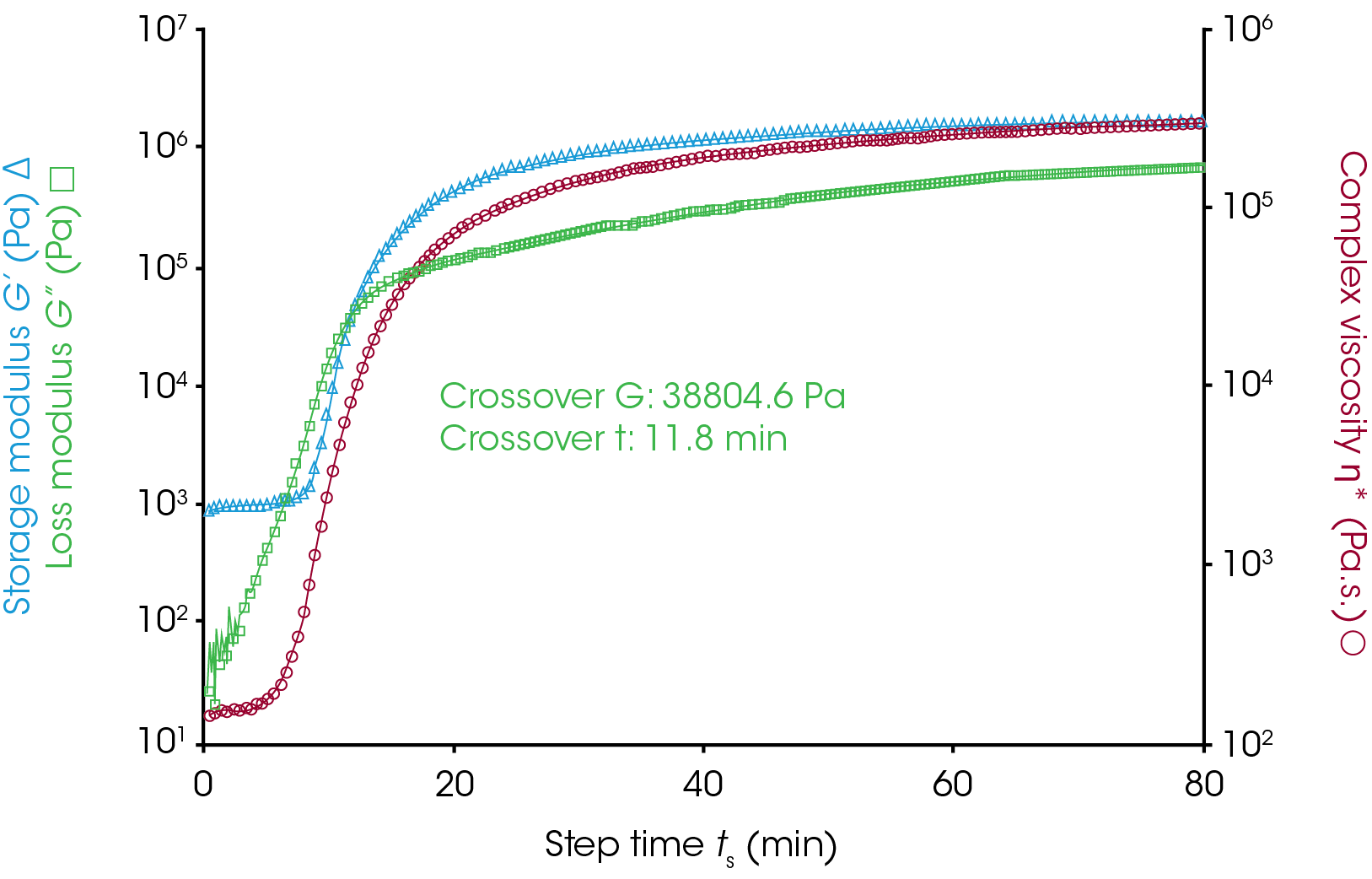

During the isothermal testing at 60 °C, the rheometer applies an oscillatory shear deformation to the sample at a mechanical frequency of 1 Hz (6.28 rad/s), then measures the sample response in stress. This mechanical testing reports sample moduli (G’ and G”), complex viscosity (η*) and tan delta as a function of curing time. Figure 2a shows the rheological testing results. The gelation time (i.e. the G’/G” crossover time) of this epoxy sample is observed at 11.8 minute. After 1 hour, both moduli and complex viscosity curves reach to a plateau, which indicate that the curing is mostly completed.

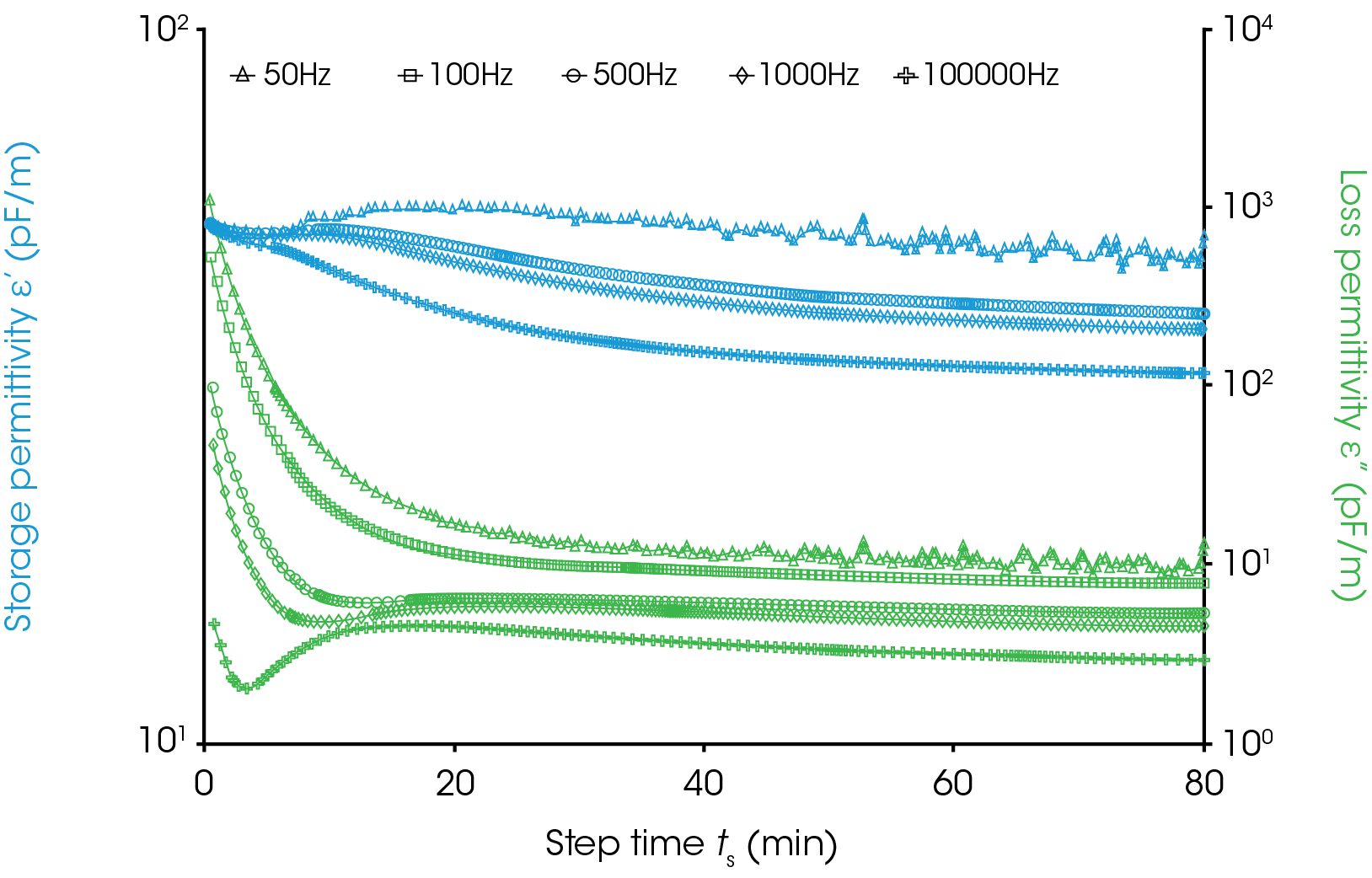

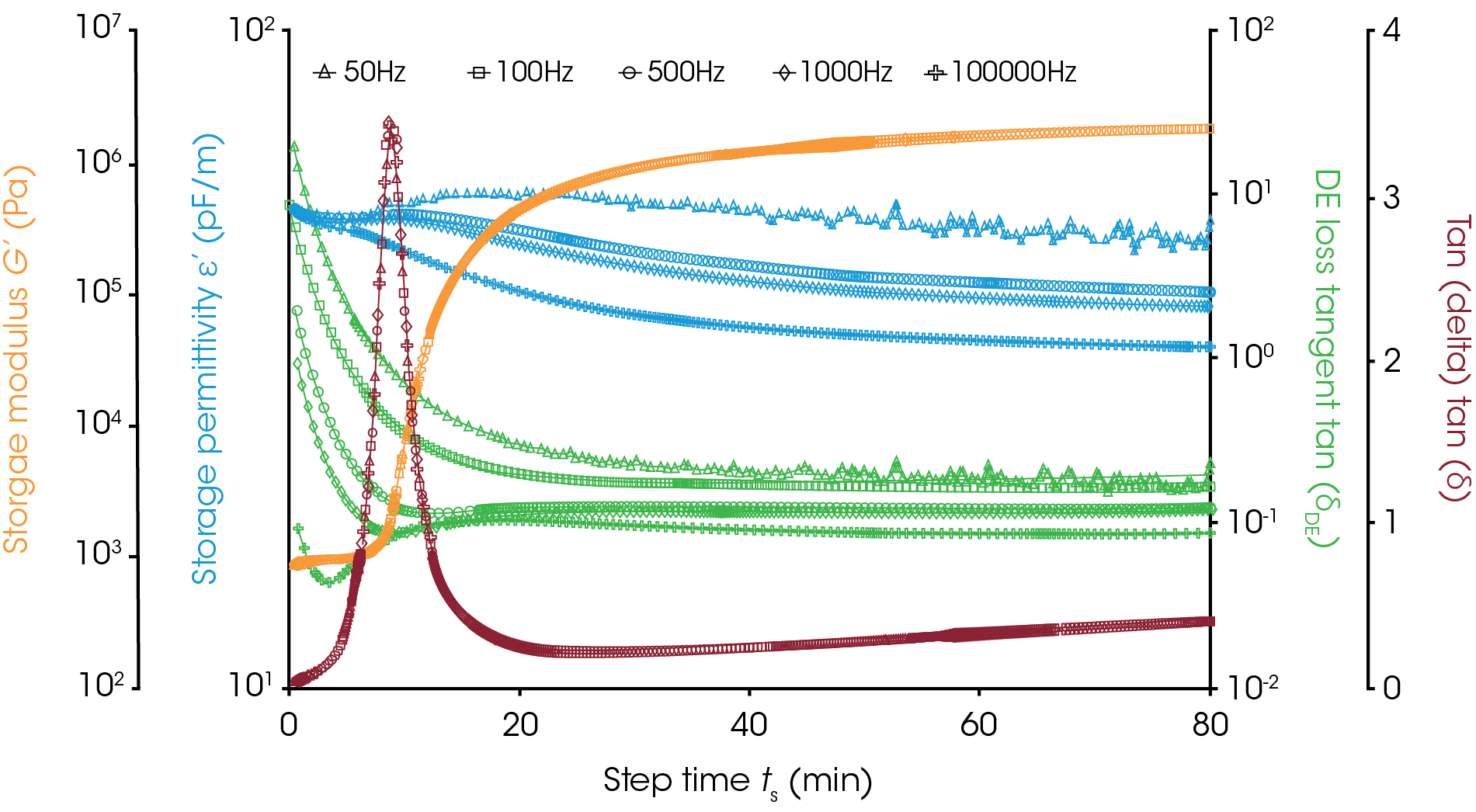

Simultaneously the LCR meter applies an AC current at 5 separate dielectric frequencies (i.e. 50 Hz, 100 Hz, 500 Hz, 1000 Hz and 10000 Hz, respectively) (Figure 2b). At the beginning of the cure, the dipoles and ions move easily and align with the field as polarity changes owing to the low sample moduli and viscosity. The storage permittivity and loss factor are consequently high. As the cure proceeds and larger molecules are formed, the mobility of the dipoles decreases, and the relaxation time increases. The sample becomes more viscous and the resistivity (1/conductance) to the free ions increases. Therefore, both the storage permittivity and the loss factor decrease. Figure 2c shows the overlay plot of rheological and dielectric measurement results. This plot provides a good correlation between the rheological property and the dielectric property changes through curing process. The results show that after the sample gels, the mechanical strength increases, while the mobility of the dipoles and ions decreases.

Figure 2 Simultaneous rheology-dielectric measurement of an isothermal curing of a 60-minute epoxy at 60 °C. (a) Rheological results; (b) Dielectric results; and (c) Overlay of both rheological and dielectric parameters.

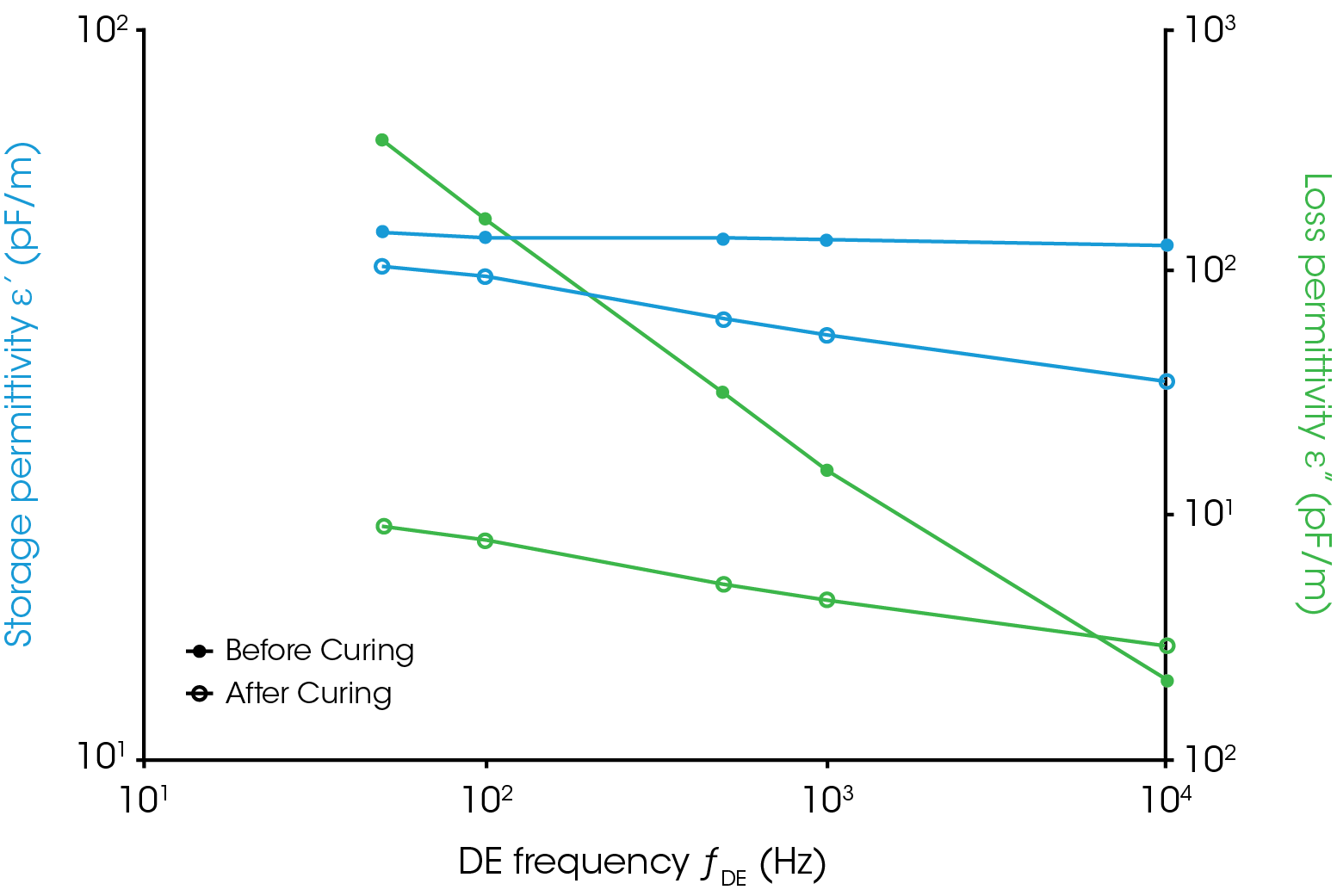

A quantitative dielectric measurement of the uncured resin helps to guide epoxy formulation, and a quantitative dielectric measurement of the final cured material provides good evaluation of the product performance. The rheometer-dielectric system can perform individual dielectric analysis for the uncured and cured samples. Figure 3 shows the overlay dielectric frequency sweep test results of the uncured and fully cured epoxy. After the sample is fully cured, the mobility of the dipoles is highly restricted, so both permittivity and loss factor are lower compare to the sample that is uncured.

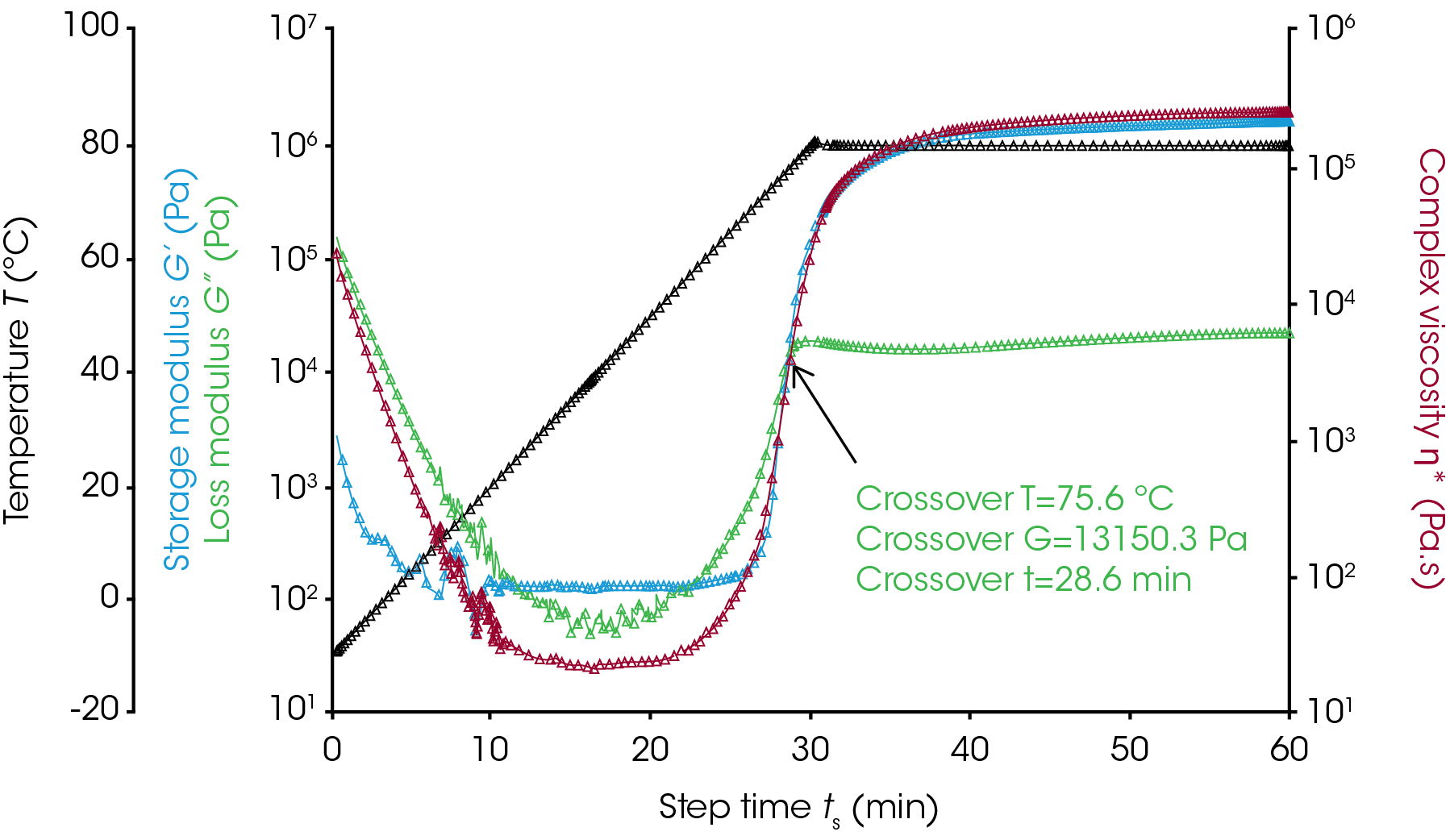

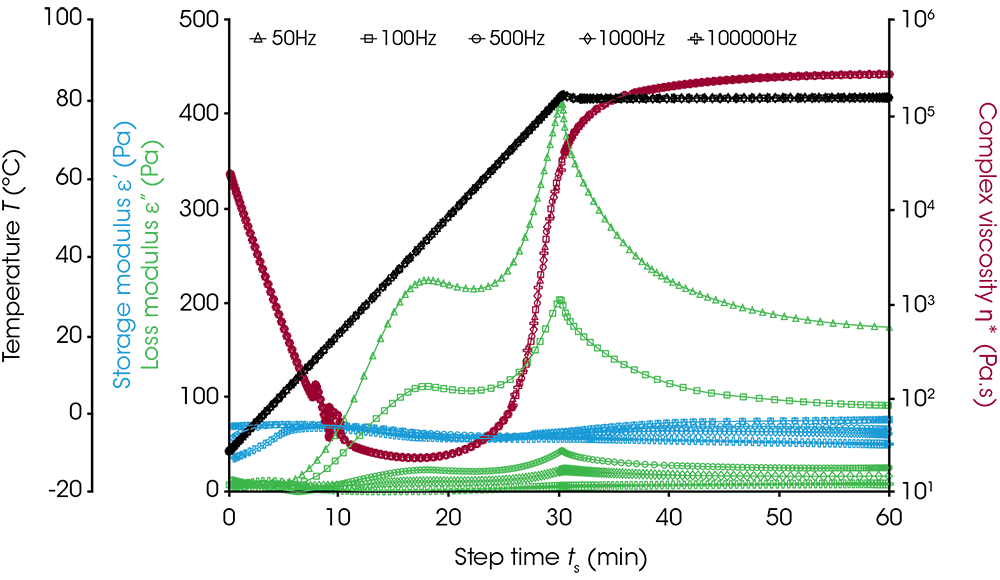

In addition to performing isothermal analysis, the rheometer-dielectric system can also monitor the curing process with a certain temperature profile. Figure 4 shows the results of a temperature ramp followed by isothermal curing profile. The rheological data shows that the sample is liquid-like at the beginning with G” greater than G’. Both moduli and complex viscosity decrease as temperature increases. Simultaneously, the increase of loss factor shows the mobility of the ions and dipoles are higher with increasing temperature. The minimum viscosity is observed at about 40 °C, at which temperature the loss factor also shows a peak indicating a high molecular mobility. Above this temperature, curing starts, both moduli and complex viscosity increase rapidly with further increase of temperature. In the meantime, the mobility of the molecules is affected by both temperature increase, which leads to an increase in mobility, and viscosity increase, which leads to a decrease in mobility. The gelation, which is the G’/G” crossover is occurred after 28.6 minutes of reaction, and at temperature of 75.6 °C. Beyond gelation, sample becomes solid-like (i.e. G’ is greater than G”), and the mobility of the ions and diploes are more and more restricted. As the test transition to the isothermal stage, the loss factor (ε”) shows an immediate sharp decrease, because at this stage, the molecular mobility is only affected by the vitrification of the material.

Figure 4 Simultaneous rheology-dielectric measurement of a 60-minute epoxy curing with a temperature ramp and hold profile.(a) rheological results; and (b) dielectric results versus viscosity.

Conclusion

The TA Instruments dielectric testing accessory (DETA) for rheometers can be used to perform simultaneous rheological and dielectric measurements. It can be used to quantitatively monitor epoxy curing with one sample loading and in one single test protocol. The rheometer conducts shear measurement and reports mechanical properties such as modulus and viscosity, while the LCR meter performs simultaneous dielectric measurements and monitor molecular mobility and relaxation. The results provide good correlation to the material’s structure-property relationship.

References

- W. Jilani, N. Mzabi, O. Gallot-Lavall´ee, N. Fourati, C. Zerrouki, R. Zerrouki and H. Guermazi, Dielectric relaxations investigation of a synthesized epoxy resin polymer, Eur. Phys. J. Plus 130: 76, (2015)

- S. Singha and M. J. Thomas, Dielectric Properties of Epoxy Nanocomposites, IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 15, No. 1; February (2008)

- M. J. Kadhim, A. K. Abdullah, I. A. Al-Ajaj, and A. S. Khalil, Dielectric Properties of Epoxy/Al2O3 Nanocomposites, International Journal of Application or Innovation in Engineering & Management (IJAIEM), Volume 3, Issue 1, January (2014)

- Aly Franck, Dielectric Characterization, TA Instruments applications notes APN032

Acknowledgement

This paper was written by Tianhong Terri Chen, PhD, Senior Applications Support Scientist at TA Instruments.

Click here to download the printable version of this application note.