Keywords: Thermal Diffusivity, Thermal Conductivity, Waxes, Laser Flash, Melting Point, Lipstick

TPP030

Introduction

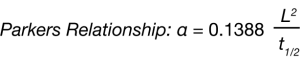

Thermal Diffusivity is defined as the speed with which a material transports heat: the ability of a material to conduct thermal energy versus its ability to store thermal energy. It is calculated based on a given sample thickness and the halftime of a laser flash shot dissipation through the sample.

Waxes and Thermal Diffusivity

Waxes commonly have low melting points which relegates any thermal diffusivity testing of a solid sample to a relatively small temperature window. In order to fully characterize the thermal diffusivity of the wax, the use of a liquid cell will allow wax samples to be tested from a solid state, through the melt and beyond.

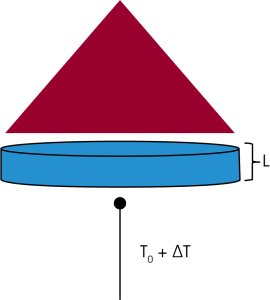

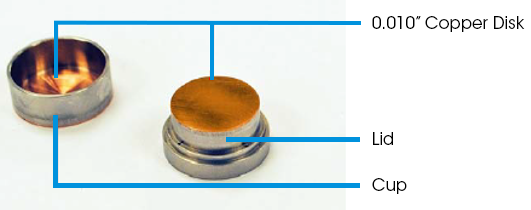

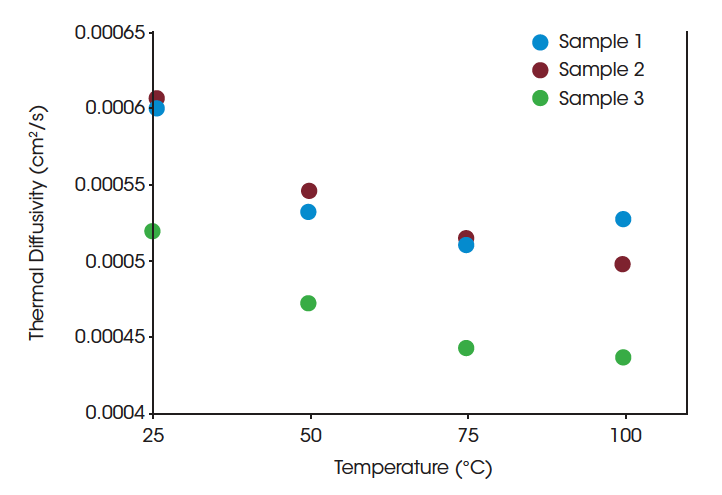

In this note, three different types of lipstick wax were tested using the liquid cell. All three samples were solid at room temperature and have melting temperatures around 80°C. They were tested from Room Temperature to 100°C. The samples were prepared for testing by filling the Liquid Cell Cup up to the point where there would be solid contact between the sample surface and the Liquid Cell Lid.

With the Lid placed on the Cell Cup, it can be run via Laser Flash without any concern over how to wax will melt over time or temperature. Contact is maintained throughout the temperature profile, even through the melt. Calibrations and Software corrections allow for the test results to be strictly that of the wax, not the wax and the cell.

Results

The three tested samples, each with different filler amounts, remained in agreement in terms of decreasing thermal diffusivity with increasing temperature. This asserts the Liquid Cell setup as a viable process for testing wax and wax-like materials for Thermal Diffusivity.

Acknowledgement

This note was written by Justin Wynn, Applications Engineer at TA Instruments

Click here to download the printable version of this application note.