Leading Research and Quality Control Techniques for Coatings

New coatings are always evolving to enhance productivity and performance. From corrosion-resistant films to glossy car paints and countless other applications, creating the best formulation requires advanced testing technology. Leading developers rely on thorough material characterization and quality control tests to verify their coatings’ properties using less time and resources.

Thermal analysis and rheology offer the complete picture of coatings’ consistency, stability, processability, and drying under realistic environmental conditions. Formulators use this data to optimize coatings for efficient processing and reliable end-use properties.

TA Instruments offers comprehensive testing solutions for each stage of coatings development, from raw powder or liquid materials through to final coated products. Discovering successful formulations and ensuring their quality has never been easier. Explore the leading thermal and rheology techniques supporting cutting-edge coatings development.

Paints, Inks & Coatings Resources

Paints, Inks & Coatings Webinars

Paints, Inks & Coatings Applications

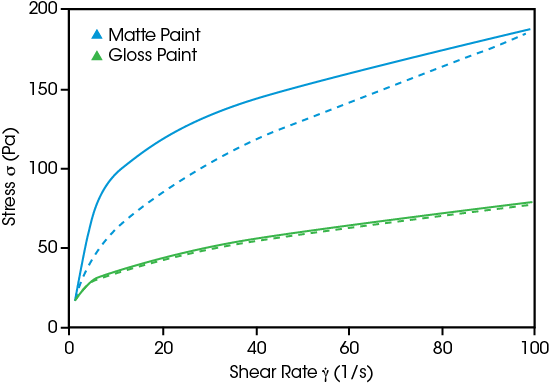

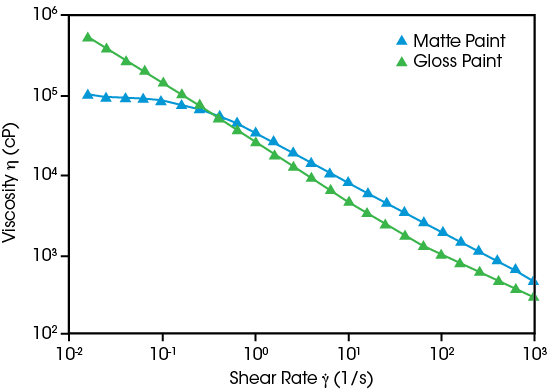

Matte paint is recommended for walls and ceilings, while gloss paint is preferred for doors or molding. But their differences go beyond the surface finish; their rheological behavior is optimized for their target use. At shear rates used in painting, matte paint’s higher viscosity helps prevent drips when painting a ceiling, while gloss paint’s lower viscosity helps uniformly coat complex shapes in doors and molding.

The matte paint shows a significant time-dependent change in viscosity, known as thixotropy. The shear rate is quickly increased from 0 to 100 (1/s), then quickly decreased to 0. The hysteresis seen between the two curves reflects delayed viscosity recovery allowing the paint to spread and produce a uniform, level surface. In contrast, gloss paint shows no thixotropy, indicating instantaneous viscosity recovery.

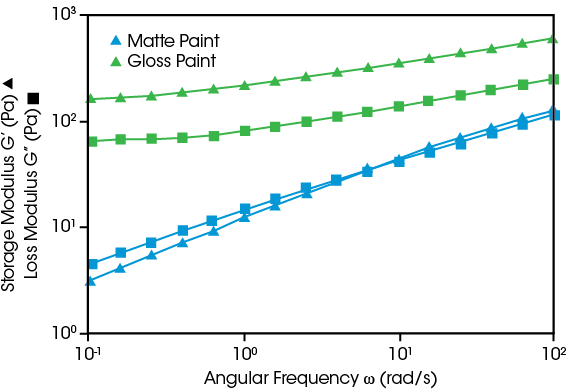

Rheology provides insights beyond flow behavior and goes into the microstructure of materials. Oscillatory measurements of these two paints reflect the structure at rest and indicate dramatic differences. Matte paint presents as a typical viscoelastic liquid. Gloss paint shows a gel-like structure due to its polymeric network, which provides high durability and serves to stabilize the dispersion. These viscoelastic measurements provide an indication of structure not available from traditional viscometers.