Advancing Polymers For a Better Future, Today

Products made from polymers are all around us – from safe and hygienic food and personal care packaging to clothing made of synthetic fibers that protect us from harmful UV rays, polymers are a critical part of our daily lives. The versatility of plastics makes them a lightweight, cost-effective option for replacing traditional materials like wood, metal, ceramics, and glass across applications in the building and construction, automotive, and household segments. Success of plastics is partly driven by their durability; yet, it has also led to an accumulation of plastic waste in the environment due to improper end-of-life waste handling.

High environmental cost of plastics waste is placing significant pressure on scientists and engineers in the polymers industry to innovate and develop more sustainable materials that account for end-of-life waste management while still maintaining product performance. TA Instruments’ robust polymer analysis solutions are designed to support your laboratory’s drive for innovation, so you can focus on building sustainable solutions for a better future, today.

Sustainability in Polymers Drives Innovation

Demand from consumers, brand owners and public policy are driving a need for sustainability in plastics, affecting companies at every stage of plastics production – from resin manufacturers, to compounders, masterbatchers and converters. In response, the plastics industry is tackling the problem of plastics waste through a wide range of sustainable solutions including the use of post-consumer recycled (PCR) and post-industrial recycled (PIR) resins, bio-sourced/ bio-degradable polymers, and the development of new and innovative polymers that are designed with end-of-life recycling considerations. Of these options, there is a strong focus on the use of recycled resins due to brand owner commitments mandating and regulatory landscape minimum quantities of post-consumer content in new products.

For the plastics industry, the processing of PCR resins introduces a new set of challenges due to the inherent variability and contamination in the waste plastic feedstock, especially when compared to well-characterized batches of virgin resins. Further, recycled resins have to be incorporated without compromising the product performance that customers and consumers expect. In an increasingly dynamic market space, the growing demand for high-performance, sustainable materials and intense competition create a heightened sense of urgency for polymer companies to innovate while responding to and staying ahead of these broader market trends.

Polymer analysis solutions from Waters | TA Instruments enable R&D scientists and process engineers to characterize complex recycled resin feedstocks more effectively and explore their impact on their products and processes while improving the operational efficiency of their analytical laboratories. Accelerate product innovation, implement process improvements, and position your lab for success in meeting your organization’s sustainability goals with an in-depth understanding of polymer processing and functional properties with Waters | TA’s broad portfolio of thermal analyzers, rheometers and mechanical testers.

Polymers Resources

Polymer Characterization & Analytical Testing Across the Supply Chain

Measure fundamental polymer properties, such as melting point, crystallinity, and viscoelasticity, with ease through thermal analysis, rheology, and mechanical testing. At every stage of product development and manufacturing, accurate measurements enable you to optimize processing conditions and improve product performance under end-use conditions.

Relevant Polymers Products

Webinars

Polymer Applications

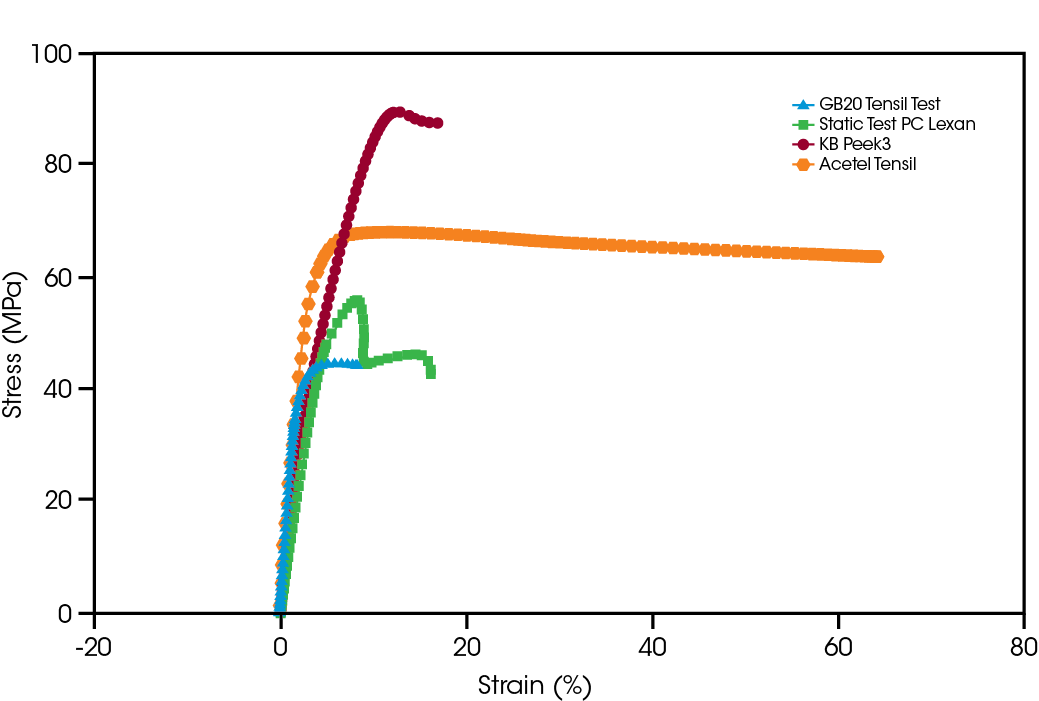

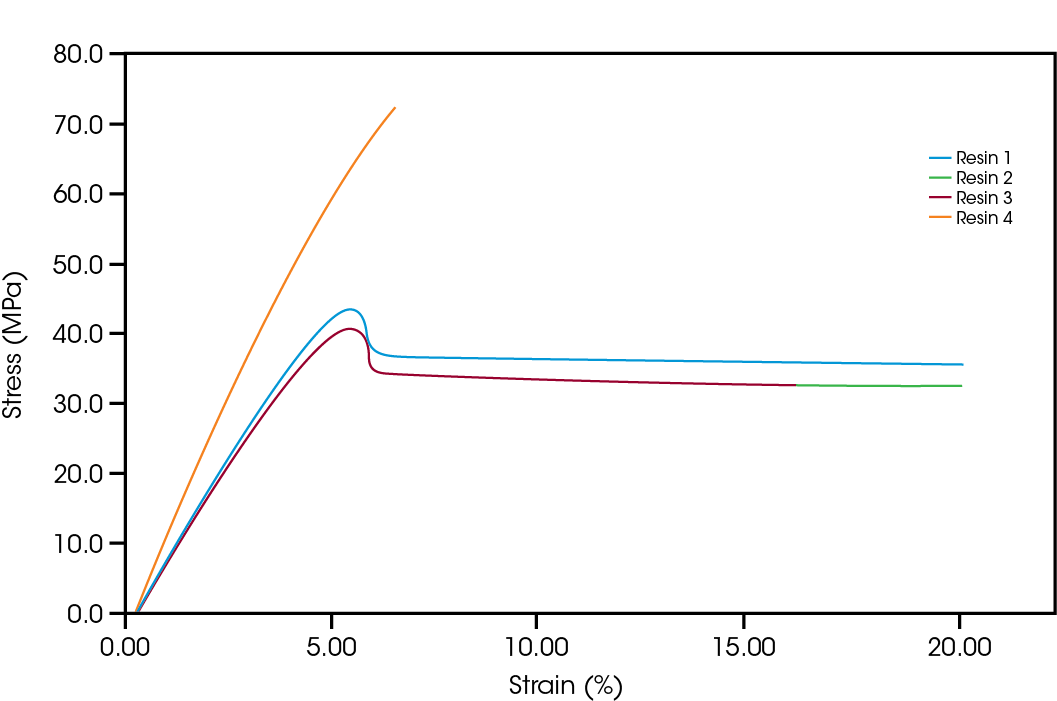

Monotonic tensile tests (AKA tensile tests) provide important information about a material’s mechanical response as it is slowly deformed. The sample is deformed at a constant strain rate and the stress response is measured by the instrument. Tensile tests provide a reliable measurement of the material’s modulus, strength, and elongation. As this figure shows, the characteristics shown in the stress-strain curve also provide significant insights into a material’s properties. Understanding a material’s complete stress-strain curve is important to know how its response will change as it is stressed to its maximum strength and beyond.

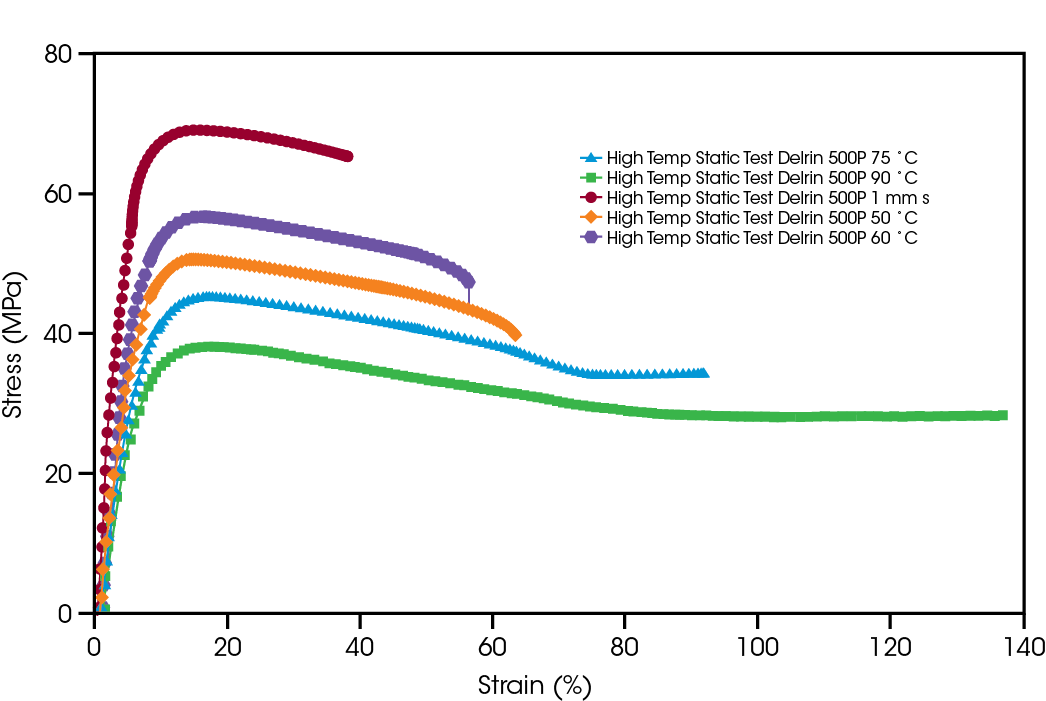

The properties of polymer materials are highly influenced by temperature. As this stress-strain data shows, increasing temperature affects the material’s properties in a variety of ways. The acetel material shows that increasing temperature results in a lower modulus (indicated by the slope of the initial line), lower strength (lower peak stress) and higher elongation (strain at break). Additionally, the material begins to have distinctly different behavior at higher temperatures and strains. Testing at different temperatures is very important to understand how the material will behave across the range of expected storage and operating temperatures.

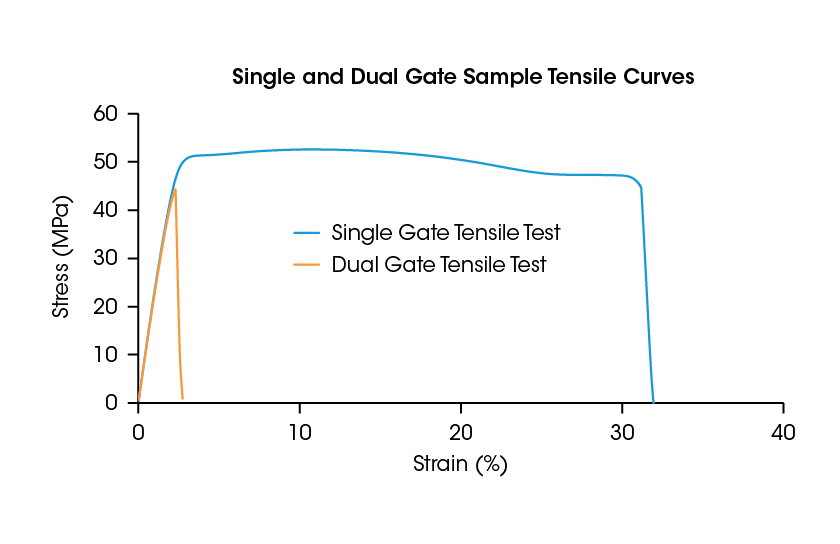

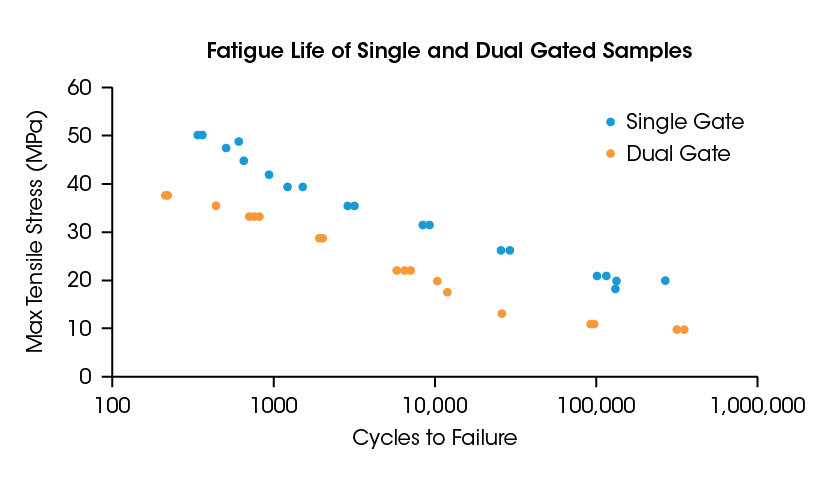

Material properties are typically tested in ideal conditions. This serves to provide a consistent and reproduceable measurement, but it can also tend to overstate a material’s ability to perform in a given application. A good example is that standard tensile test “dogbone” samples are molded with a single gate providing optimal material flow and entanglement of the molecular chains. Real parts rarely can replicate the material performance in dogbone form. This data shows the effect on the strength and durability of a material when the sample is molded where the material must flow together in the mold creating a knit line.

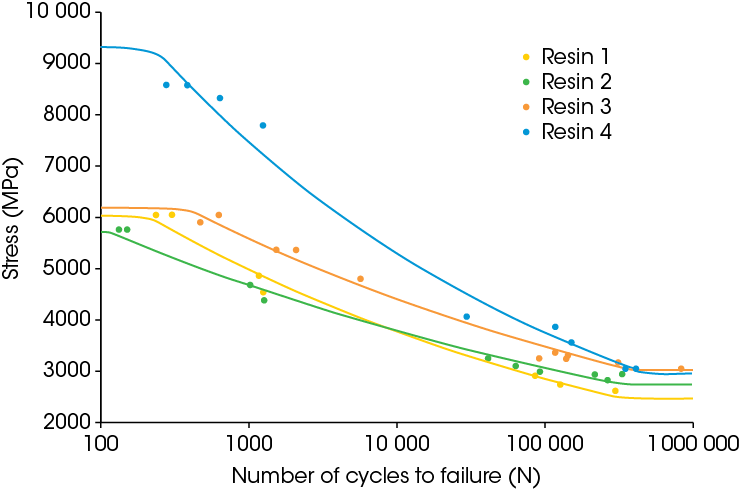

This tensile testing data shows a marginal loss of strength, but there is a significant loss of elongation. The fatigue testing data is represented as an S-N curve which plots the cyclic stress level (y-axis) to the cycles to failure (x-axis). At a given stress level, the dual gate sample had significantly lower cycles to failure. Other manufacturing artifacts such as voids or filler orientation could have similar effects. It is important to understand a material’s performance after it is processed and formed into the real part.

Polymer materials come in a wide variety of formulations with many options for different blends, different types and amounts of fillers, and various additives for processing and other performance characteristics. Their properties on the datasheet might look very similar, but that does not mean that they will have the same performance.

This data shows three different ABS resin blends and the base SAN resin. The three ABS resins have similar responses in their tensile tests, but significantly different fatigue performance. It is also clear that the best material for fatigue could not be predicted from the tensile testing data.

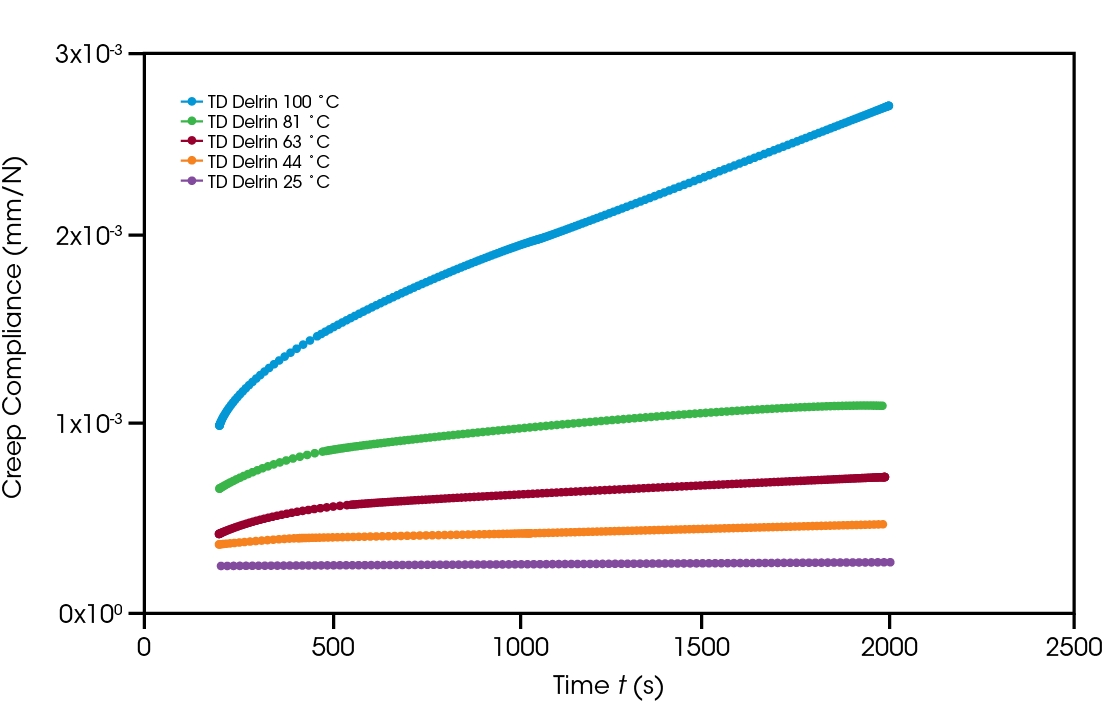

The viscoelastic nature of polymer materials means that they continue to deform under a steady load. This behavior is called creep. Increasing temperatures result in accelerated creep behavior due to the higher mobility of the molecular chains. Creep resistance is often overlooked as an important property of polymer materials. Creep can cause component failure in multiple ways. One way is that the material deforms under constant load and is no longer able to perform its function. The second creep failure mode is creep rupture, where the material has a brittle fracture due to creep.

A more complete picture of a material’s creep resistance can be seen by performing successive creep measurements at increasingly elevated temperature. The ElectroForce Apex 1 Instrument is particularly valuable for these types of experiments with its high force capacity and long motor stroke, helping ensure that measurements can be completed on a wide range of materials and use cases.

Blog

Application Notes

- Thermogravimetric Analysis (TGA) as a Screening Tool for Plastic Waste Pyrolysis

- DSC: Oxidative Stability of Polyethylene Terephthalate

- DSC: Comparison of Crystallization Behavior of Different Colored Parts Made from PP Using a Single DSC Experiment

- DSC: Semi-Crystalline Thermoplastic Analysis Using the Discovery X3 DSC

- DSC: Comparison of the Thermal Behavior of Different Types of Recycled PET for Advanced Honeycomb Structures

- TGA: Estimation of Polymer Lifetime by TGA Decomposition Kinetics

- TGA: Effect of Thermal Degradation on Polymer Thermal Properties

- TGA: Thermal Degradation Study of Nylon 66 using Hyphenation Techniques TGA-MS and TGA-FTIR-GC/MS

- Rheology: Understanding Rheology of Thermoplastic Polymers

- DMA: Measurement of Glass Transition Temperatures by Dynamic Mechanical Analysis and Rheology

- Rheology: Using Rheolgoy and Thermal Analysis to Help Optimize Processing Conditions of Recycled PET

- DMA: Characterization of Bio-Derived Polymer Under Controlled Humidity

- View all Application Notes