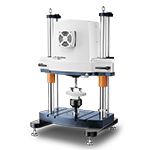

ElectroForce 5500

The ElectroForce 5500 test instrument provides characterization and stimulation capabilities for a variety of synthetic materials such as composites and elastomers, biomaterials, tissue samples, and tissue-engineered constructs. It features a 200 N maximum force.

This test instrument is versatile and can meet the individualized needs of educators and researchers through a variety of fixtures and software options.