Overview

TA Instruments are used in research around the world across diverse fields and applications. Our blogs share industry insights, expert ideas, and real-world discoveries made with our instrumentation. Check back frequently for new blogs with up-to-date information and inspiration.

Filter by Technique

Filter by Applications

03/31/2025

In battery development, precise rheological measurements are critical for optimizing material performance, ensuring uniform coatings, and enhancing conductivity. Whether working with cathode, anode, or electrolyte materials, selecting the right rheometer is essential. TA Instruments offers two industry-leading solutions: the Discovery Core Rheometer and the Discovery Hybrid Rheometer. This guide helps battery scientists determine which instrument best suits their needs.

03/11/2025

Pharmaceutical research and discovery rely on accurate characterization of molecular interactions to develop effective and safe drugs. Isothermal Titration Calorimetry (ITC) is a gold-standard technique that provides critical insights into binding affinity, thermodynamics, and stoichiometry—essential components in Structure-Activity Relationship (SAR) studies.

02/10/2025

From smooth moisturizers to voluminous shampoo, the products that support everyday self-care routines are the result of the scientific interplay between deformation and flow. The personal care industry (and your morning routine) is only made possible because of rheology – the study of how a material moves (flow) or changes under varying degrees of stress (deformation).

02/04/2025

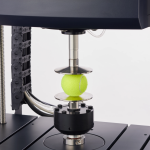

Mechanical testing supports material and product innovation across a variety of industries and applications, from testing the long-term durability of dental implants during chewing to predicting how a car part will bend during an accident. Learn how the latest technology advances mechanical testing to better support cutting-edge product development.

01/27/2025

During the Lunar New Year, sky lanterns are released to symbolize the letting go of the past year's troubles and welcoming new beginnings. The sky lantern tradition is thousands of years old, spreading from Buddhist Monks in the 2nd Century to modern festivals in China, South Korea, Japan, and Taiwan.

01/23/2025

From faster prototyping to ensuring long-term performance, fatigue testing is a critical step in product development across a variety of industries that rely on high-performance materials, like polymers, rubber compounds, and composites. When done properly, fatigue testing accelerates development by helping engineers make informed decisions about prototypes and designs.

01/07/2025

Polymers are everywhere, from components making up the electronic device you’re reading this on to life-saving medical devices, energy efficient solar panels, and lightweight aero or auto components. Material scientists and engineers continue to improve high-performance polymers for strength, durability, and stability under demanding applications.

12/19/2024

In the world of material science, understanding the viscoelastic properties of materials is crucial for developing and optimizing products. Two key parameters in this context are storage modulus (E' or G') and loss modulus (E" or G"). These parameters provide insights into a material's stiffness and damping characteristics, respectively, which are essential for applications ranging from polymers and pharmaceuticals to batteries and composites.

12/11/2024

Electrode slurries are paste-like mixtures made up of active materials, conductive additives, and a binder. The conductive additives must be electrically conducted to the current collector. However, binder is necessary for getting the active materials to stick together and adhere to the current collector.

11/27/2024

Differential Scanning Calorimetry is a thermal analysis technique commonly used to characterize materials across a broad array of applications including chemistry, biochemistry, pharmaceuticals, polymers, and more. Differential Scanning Calorimetry (DSC) measures the heat flow in a material as it is heated or cooled over a specified temperature range.