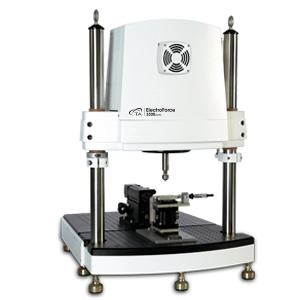

TGA 5500

The TGA 5500 is designed for the researcher that requires the highest level of performance and features in one package. Built to maximize temperature control and minimize drift, the TGA 5500 has less drift than any competitive TGA – even after they use post-test data manipulation! The TA patented IR furnace delivers the fastest heating and cooling rates available. The all new autosampler makes high productivity standard.