Unlock complete viscoelastic characterization of fluids in pressurized environments.

The new High Sensitivity Pressure Cell (HSPC) for the DHR unlocks complete viscoelastic characterization of fluids in a pressurized environment. The HSPC is the only device that provides a wide range of dynamic oscillatory testing capabilities under controlled atmospheric pressure on low viscosity polymer solutions and structured fluids. Conventional pressure cells employ mechanical bearings that severely limit low torque sensitivity and make viscoelastic characterization impractical for most samples. The HSPC employs an innovative air bearing seal that allows unrivaled low torque performance with up to 100x better torque sensitivity than conventional devices, allowing users to characterize critical material behavior such as time, frequency, and strain-dependence on the widest range of fluids, including at temperatures above the boiling point of volatile components. This new range of test conditions can provide insight to material properties representative of extreme processing or use conditions, such as downhole or extrusion environments.

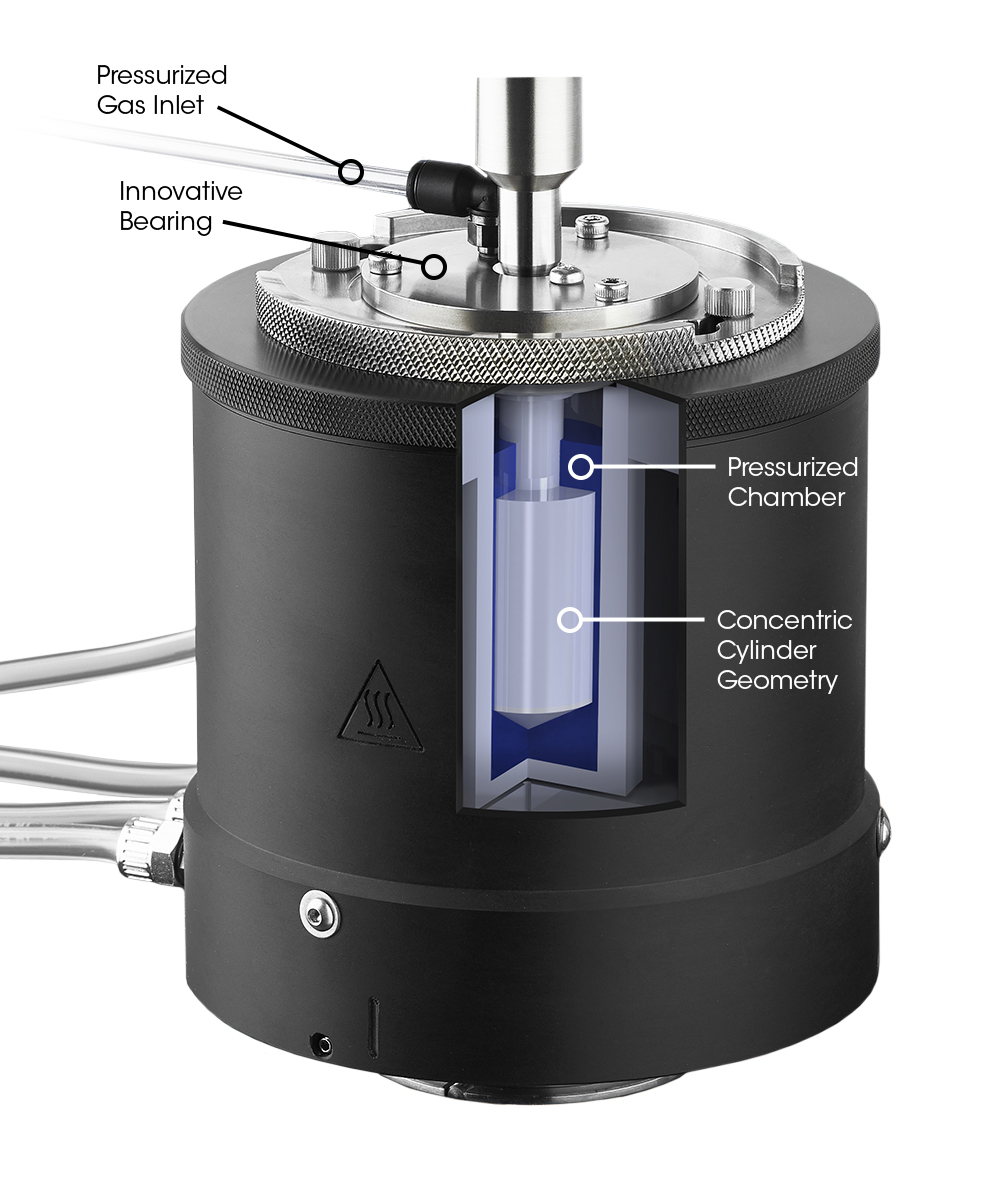

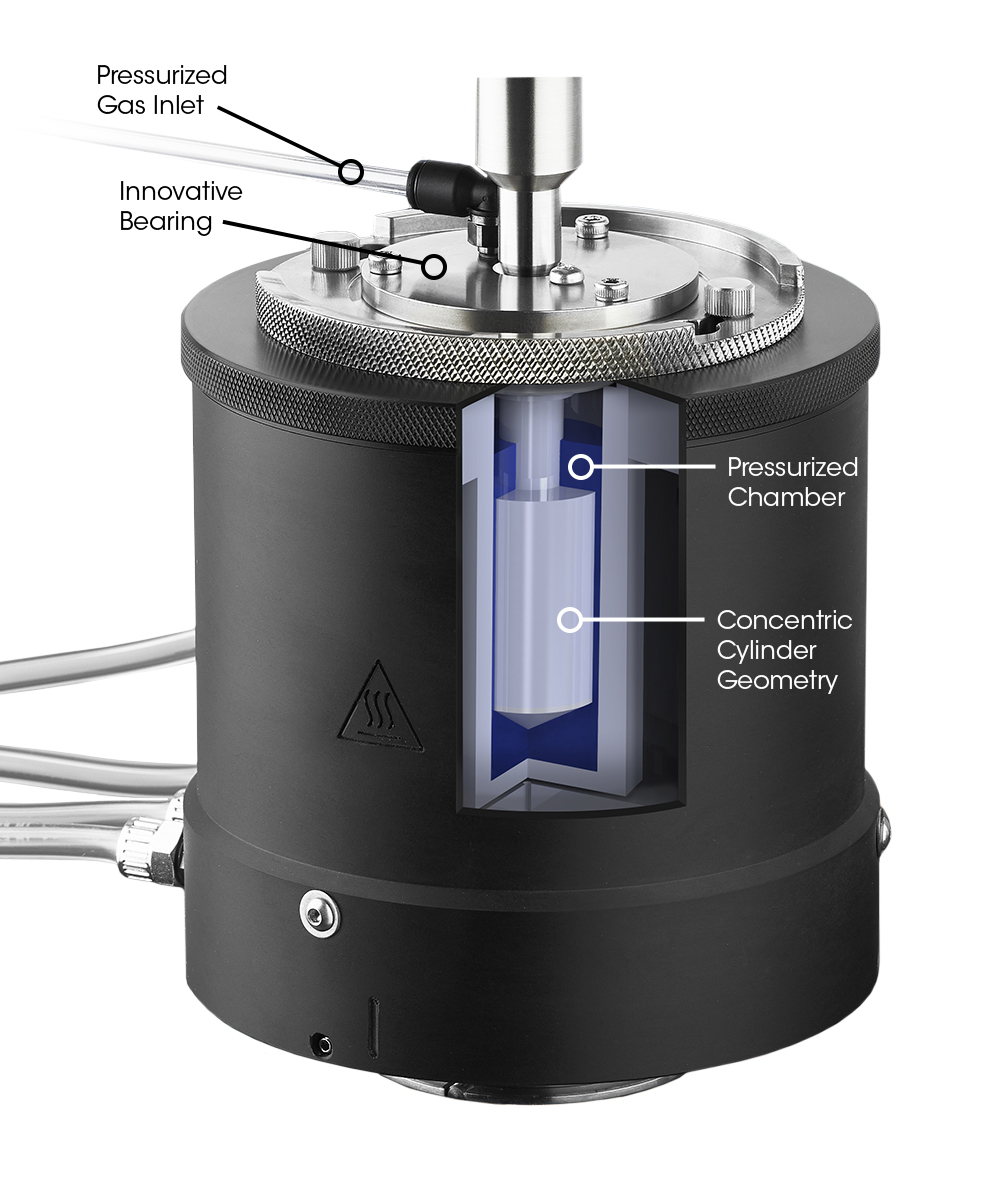

The HSPC’s concentric cylinder measurement system utilizes compressed air flows and an innovative cap design to pressurize the sample volume. A self-aligning design makes the HSPC quick and easy to assemble for anyone, resulting in guaranteed low torque measurements, outstanding reproducibility, and more time for testing. Sample pressure is directly measured and saved for a complete record of the sample environment, storing all relevant test information in one convenient TRIOS data file. The High Sensitivity Pressure Cell (HSPC) extends the DHR’s capabilities for studying materials under pressurized conditions to include dynamic oscillatory testing capabilities enabling the full spectrum of viscoelastic characterization.

The HSPC’s concentric cylinder measurement system utilizes compressed air flows and an innovative cap design to pressurize the sample volume. A self-aligning design makes the HSPC quick and easy to assemble for anyone, resulting in guaranteed low torque measurements, outstanding reproducibility, and more time for testing. Sample pressure is directly measured and saved for a complete record of the sample environment, storing all relevant test information in one convenient TRIOS data file. The High Sensitivity Pressure Cell (HSPC) extends the DHR’s capabilities for studying materials under pressurized conditions to include dynamic oscillatory testing capabilities enabling the full spectrum of viscoelastic characterization.

Features and Benefits

- Innovative, non-mechanical bearing design provides up to 100x improved torque sensitivity

- Unrivaled torque sensitivity to characterize viscoelastic behavior

- Stable and accurate temperature control from -5 °C to 150 °C with the Peltier Concentric Cylinder Jacket

- Atmospheric pressure control up to 5 bar to simulate processing and use conditions

- Completely integrated with powerful TRIOS software to directly measure and record sample pressure with rheological data

- User-friendly, self-aligning design guarantees low torque performance every time

Performance Specifications

| Temperature Range | -5 to 150 °C |

| Pressure Range | 0 – 5 bar |

| Minimum Torque (Dynamic) | 1 µN.m |

| Minimum Torque (Steady State) | 10 µN.m |

| Pressurized Gas | Air or Nitrogen |

Characterization of Xanthan Gum Solution Under Pressure

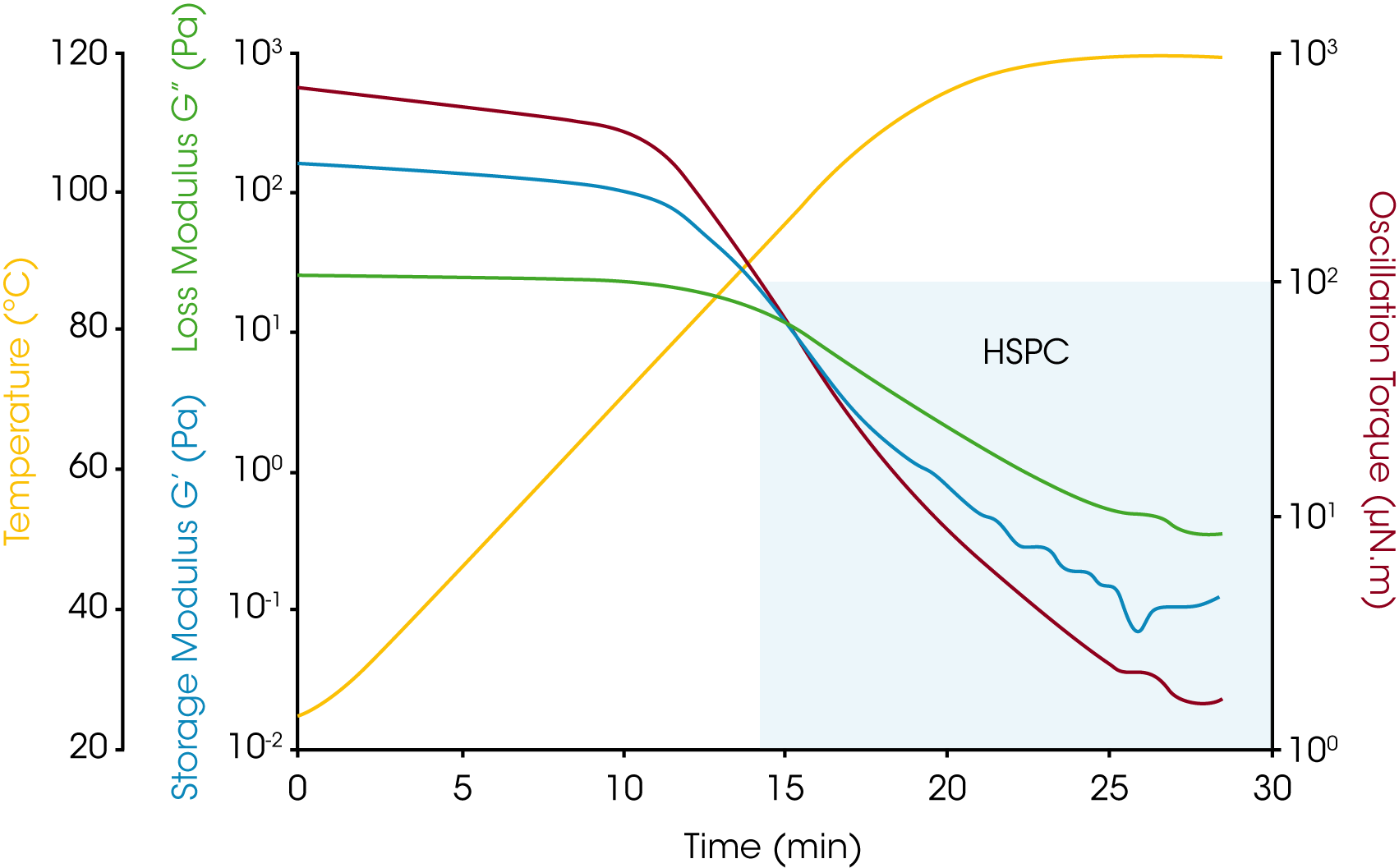

Measuring the viscoelastic properties of fluids at temperatures above boiling poses significant challenges, most notably the loss of volatile ingredients resulting in changes to material composition. Various methods and devices have been employed to trap solvents or suppress evaporation; these can delay compositional changes at higher temperatures but are ineffective beyond the boiling point. A pressurized testing environment is the only means to characterize the rheological properties of materials under such conditions.

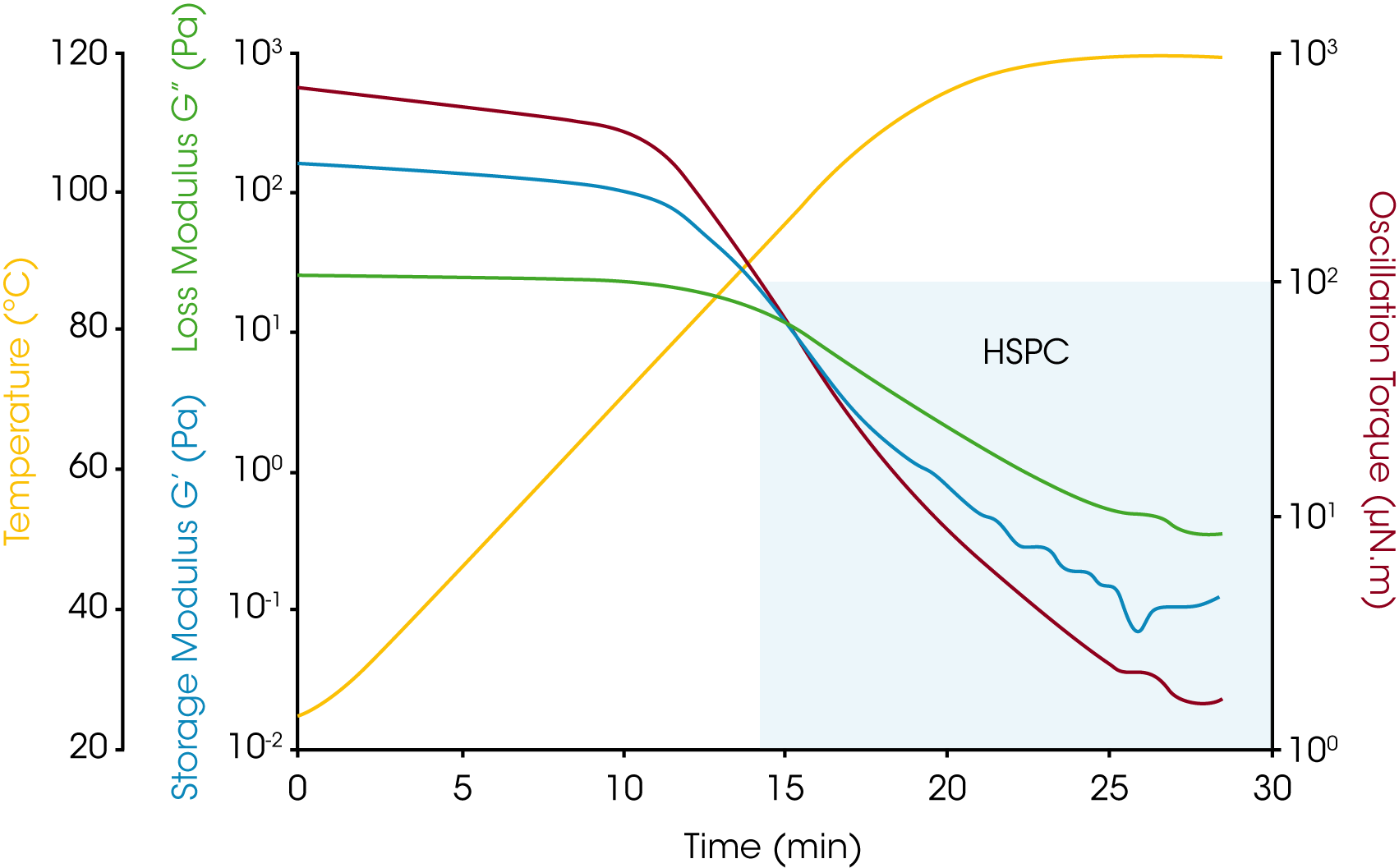

Xanthan gum is often used as an additive for gelling and food applications. A solution of 2.5 wt% of xanthan gum in water was tested in the High Sensitivity Pressure Cell as the temperature was increased at 5°C/min from 25°C to 120°C. The evolution of the dynamic moduli (G’ and G”) was measured over the entire temperature range, even above the boiling temperature of water. A crossover point is clearly identified near 95 °C, indicating the transition from a gelled state to a liquid-like polymer solution. Tracking the changing viscoelastic properties and identifying important points of interest such as the modulus crossover provide insight into the full viscoelastic behavior of materials in extreme processing or use conditions.

- Description

-

The new High Sensitivity Pressure Cell (HSPC) for the DHR unlocks complete viscoelastic characterization of fluids in a pressurized environment. The HSPC is the only device that provides a wide range of dynamic oscillatory testing capabilities under controlled atmospheric pressure on low viscosity polymer solutions and structured fluids. Conventional pressure cells employ mechanical bearings that severely limit low torque sensitivity and make viscoelastic characterization impractical for most samples. The HSPC employs an innovative air bearing seal that allows unrivaled low torque performance with up to 100x better torque sensitivity than conventional devices, allowing users to characterize critical material behavior such as time, frequency, and strain-dependence on the widest range of fluids, including at temperatures above the boiling point of volatile components. This new range of test conditions can provide insight to material properties representative of extreme processing or use conditions, such as downhole or extrusion environments.

- Technology

-

The HSPC’s concentric cylinder measurement system utilizes compressed air flows and an innovative cap design to pressurize the sample volume. A self-aligning design makes the HSPC quick and easy to assemble for anyone, resulting in guaranteed low torque measurements, outstanding reproducibility, and more time for testing. Sample pressure is directly measured and saved for a complete record of the sample environment, storing all relevant test information in one convenient TRIOS data file. The High Sensitivity Pressure Cell (HSPC) extends the DHR’s capabilities for studying materials under pressurized conditions to include dynamic oscillatory testing capabilities enabling the full spectrum of viscoelastic characterization.

The HSPC’s concentric cylinder measurement system utilizes compressed air flows and an innovative cap design to pressurize the sample volume. A self-aligning design makes the HSPC quick and easy to assemble for anyone, resulting in guaranteed low torque measurements, outstanding reproducibility, and more time for testing. Sample pressure is directly measured and saved for a complete record of the sample environment, storing all relevant test information in one convenient TRIOS data file. The High Sensitivity Pressure Cell (HSPC) extends the DHR’s capabilities for studying materials under pressurized conditions to include dynamic oscillatory testing capabilities enabling the full spectrum of viscoelastic characterization. - Features

-

Features and Benefits

- Innovative, non-mechanical bearing design provides up to 100x improved torque sensitivity

- Unrivaled torque sensitivity to characterize viscoelastic behavior

- Stable and accurate temperature control from -5 °C to 150 °C with the Peltier Concentric Cylinder Jacket

- Atmospheric pressure control up to 5 bar to simulate processing and use conditions

- Completely integrated with powerful TRIOS software to directly measure and record sample pressure with rheological data

- User-friendly, self-aligning design guarantees low torque performance every time

- Specifications

-

Performance Specifications

Temperature Range -5 to 150 °C Pressure Range 0 – 5 bar Minimum Torque (Dynamic) 1 µN.m Minimum Torque (Steady State) 10 µN.m Pressurized Gas Air or Nitrogen - Applications

-

Characterization of Xanthan Gum Solution Under Pressure

Measuring the viscoelastic properties of fluids at temperatures above boiling poses significant challenges, most notably the loss of volatile ingredients resulting in changes to material composition. Various methods and devices have been employed to trap solvents or suppress evaporation; these can delay compositional changes at higher temperatures but are ineffective beyond the boiling point. A pressurized testing environment is the only means to characterize the rheological properties of materials under such conditions.

Xanthan gum is often used as an additive for gelling and food applications. A solution of 2.5 wt% of xanthan gum in water was tested in the High Sensitivity Pressure Cell as the temperature was increased at 5°C/min from 25°C to 120°C. The evolution of the dynamic moduli (G’ and G”) was measured over the entire temperature range, even above the boiling temperature of water. A crossover point is clearly identified near 95 °C, indicating the transition from a gelled state to a liquid-like polymer solution. Tracking the changing viscoelastic properties and identifying important points of interest such as the modulus crossover provide insight into the full viscoelastic behavior of materials in extreme processing or use conditions.