The best value for money for single sample direct measurement for routine evaluation

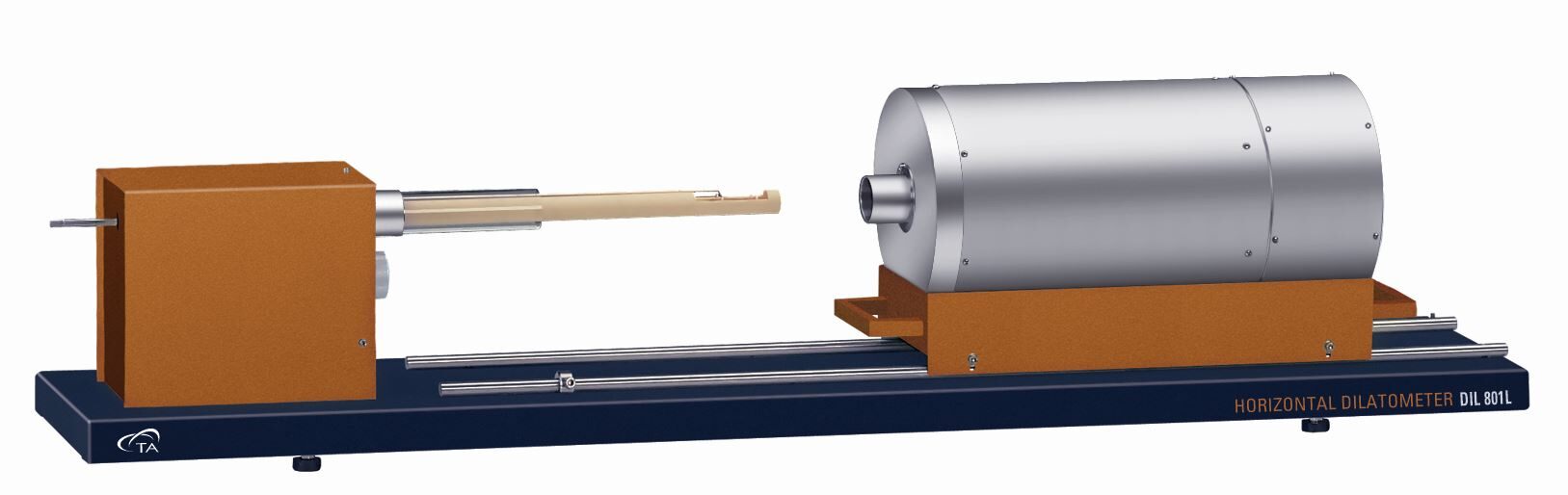

Suitable for a wide range of routine dilatometric tests, the DIL 801 and DIL 801L are horizontally configured single-sample dilatometers. The DIL 801 is designed for measurements under vacuum or inert gas while the DIL 801L is designed for measurements in air, making the DIL 801L ideally suited to measuring ceramic materials which are often processed in air.

Without a doubt DIL 801 and DIL 801L represent today the dilatometers with the best price / performance ratio on the market.

| DIL 801 | DIL 801L | |

| Sample length | 0 to 50 mm | 0 to 50 mm |

| Sample diameter: | max. 14 or 20 mm | max. 14 or 20 mm |

| Measuring systems: | Fused silica, Al2O3 | Fused silica, Al2O3 |

| Change of length: | 4 mm | 4 mm |

| Length Resolution: | 10 nm | 20 nm |

| Temperature Resolution: | 0.05°C | 0.1°C |

| Accuracy in α: | 0.03 x 10-6 K-1 | 0.05 x 10-6 K-1 |

| Atmosphere: | vacuum, inert gas, air | air |

| Operation mode: | horizontal | horizontal |

| Temperature range: | -160°C to 1700°C according to furnace type | RT to 1700°C according to furnace type |

| Contact force: | 0.02 to 1 N, adjustable | 0.02 to 1 N, adjustable |

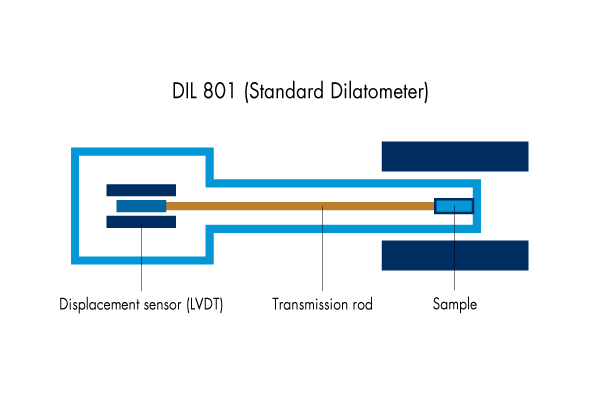

The horizontal furnace configuration guarantees optimal temperature uniformity and precludes air currents associated with convection. High sensitivity displacement measurements are made using a high resolution LVDT, guaranteeing that even the smallest thermal expansion events are measured accurately. The measuring head of the DIL801 is thermally stabilized and insensitive to shocks.

DIL 801 can be configured with a number of different furnaces ranging from -160 to 1700°C, while DIL 801L can fit furnaces with temperature ranges between RT to 1700°C. These furnaces can be easily exchanged and multiple furnaces can be used with a single instrument. Accurate temperature measurements are made through the selection of the appropriate thermocouple or pyrometer type for the temperature range of interest.

Inert measuring systems are available in a variety of materials. These sample tubes, bearings, and pushrods are easily interchanged to meet the needs of the measurement at hand. In order to prevent system interaction with the sample, these measuring systems are available in fused silica, Al2O3, sapphire, graphite and tungsten. Certified reference materials are also available for calibration and verification of instrument performance.

- Description

-

Suitable for a wide range of routine dilatometric tests, the DIL 801 and DIL 801L are horizontally configured single-sample dilatometers. The DIL 801 is designed for measurements under vacuum or inert gas while the DIL 801L is designed for measurements in air, making the DIL 801L ideally suited to measuring ceramic materials which are often processed in air.

Without a doubt DIL 801 and DIL 801L represent today the dilatometers with the best price / performance ratio on the market.

- Specifications

-

DIL 801 DIL 801L Sample length 0 to 50 mm 0 to 50 mm Sample diameter: max. 14 or 20 mm max. 14 or 20 mm Measuring systems: Fused silica, Al2O3 Fused silica, Al2O3 Change of length: 4 mm 4 mm Length Resolution: 10 nm 20 nm Temperature Resolution: 0.05°C 0.1°C Accuracy in α: 0.03 x 10-6 K-1 0.05 x 10-6 K-1 Atmosphere: vacuum, inert gas, air air Operation mode: horizontal horizontal Temperature range: -160°C to 1700°C according to furnace type RT to 1700°C according to furnace type Contact force: 0.02 to 1 N, adjustable 0.02 to 1 N, adjustable - Measurement Principle

-

The horizontal furnace configuration guarantees optimal temperature uniformity and precludes air currents associated with convection. High sensitivity displacement measurements are made using a high resolution LVDT, guaranteeing that even the smallest thermal expansion events are measured accurately. The measuring head of the DIL801 is thermally stabilized and insensitive to shocks.

- Temperature Range

-

DIL 801 can be configured with a number of different furnaces ranging from -160 to 1700°C, while DIL 801L can fit furnaces with temperature ranges between RT to 1700°C. These furnaces can be easily exchanged and multiple furnaces can be used with a single instrument. Accurate temperature measurements are made through the selection of the appropriate thermocouple or pyrometer type for the temperature range of interest.

- Measuring System

-

Inert measuring systems are available in a variety of materials. These sample tubes, bearings, and pushrods are easily interchanged to meet the needs of the measurement at hand. In order to prevent system interaction with the sample, these measuring systems are available in fused silica, Al2O3, sapphire, graphite and tungsten. Certified reference materials are also available for calibration and verification of instrument performance.