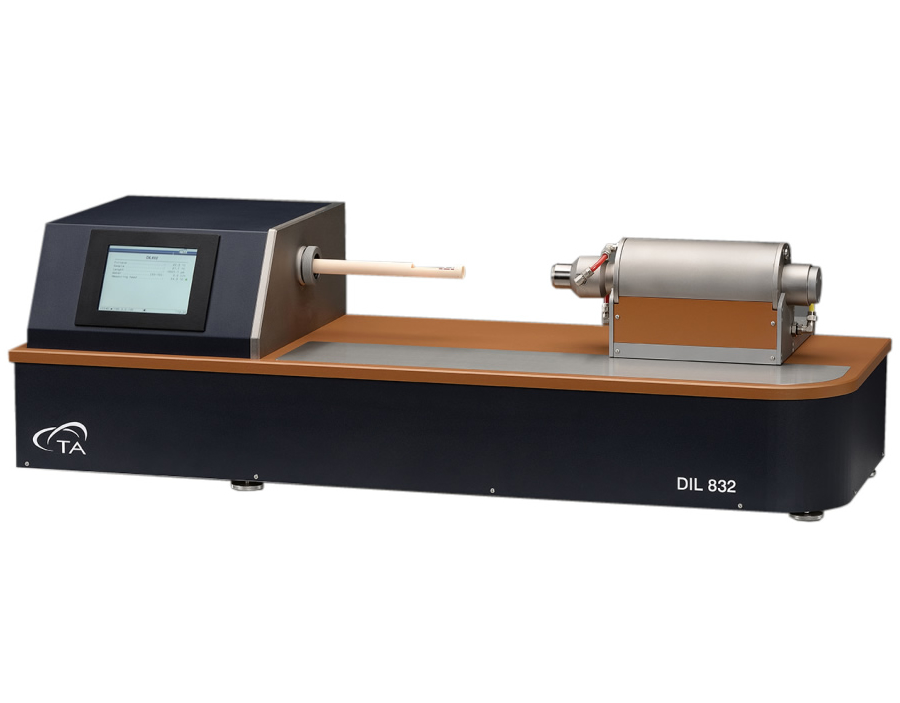

High Resolution True Differential™ Horizontal Push Rod Dilatometer

High sensitivity optical encoder and TA exclusive True Differential technology for the most demanding R&D laboratories .

DIL 832 features an impressive array of unique technologies and capabilities that make of it the ideal tool in any R&D laboratory for the characterization of mechanical and dimensional properties: TA Instruments exclusive True Differential™ technology, the patented 1 nm resolution optical encoder, a family of new dynamic furnaces, and the new linear sample load motor. The result is the best performing horizontal push-rod dilatometer available on the market, regardless of the application or the material to be tested.

The sample load is ensured by a linear motor with a range of 0.01 to 1.00 N, a force resolution of 0.01 N and a linearity better than 0.01 N across the total measuring range of 5000 µm.

The new patented optical incremental encoder brings length measurement’s true resolution down to a best in class 1 nm. This allows for the measurement of shorter samples yet preserving an outstanding ∆L resolution.

The newly designed measuring head housing and the active electrical thermal stabilization ensure unprecedented stability of the detection core. Combined with TA Instruments exclusive True Differential™ technology and the unique design of TA Instruments furnaces, results in the DIL 832 delivering an industry leading CTE accuracy of 0.01 x 10-6 K-1.

The DIL 832 automatically records the initial sample length and is capable of up to a maximum sample length of 25 mm and a maximum diameter of 6 mm .

The water cooled furnaces provide a very dynamic temperature programming capability with a maximum heating rate of 50 K/min, but most of all a cool down time as short as 13 minutes from 1000°C to room temperature, up to 15 times shorter than competitive instruments.

The integrated electronics provide network connection, and the integrated touch screen allows you to perform many functions directly on the instrument and shows, in real time, measurement parameters and test’s time-to-completion.

| Dilatometer type | True DifferentialTM horizontal push rod | |

| Sample dimension length / diameter | 0 to 25 mm / 6mm | |

| Material of sample holder: | Fused silica, Al2O3 | |

| Contact Force: | 0.01 – 1.0 N, linear motor controlled constant sample load | |

| Change of length: | 5000µm | |

| Resolution ΔL, ΔT: | 1 nm, 0.05°C | |

| Accuracy in α: | 0.01 x 10-6 K-1 | |

| Atmosphere: | Vacuum, Inert gas, Air

atmosphere control through optional gas unit with massflow controller and vacuum unit |

|

| Temperature range: | RT – 1100°C RT – 1500°C RT – 1700°C |

|

| Heating rate | 50°C/min | |

| Cooling rates | 1100°C – RT: minimum 13 min 1500°C – RT: less than one hour 1700°C – RT: approximately one hour |

|

The materials in the measuring systems of all dilatometers are stable but not totally free of significant dimensional changes. This is especially true when the method covers a large temperature range of heating or cooling, and these materials can experience dimensional changes equivalent to the specimen. To ensure accuracy, good laboratory practice requires calibration of the instrument for every temperature program, using a reference material of similar properties, similar shape and similar size of the sample. However, the number of different variables contributing to the accuracy of calibration curves can introduce significant errors in repeatability over time, hence of the accuracy of the measurements.

The TA Instruments exclusive True DifferentialTM design of the DIL 832 is the only system that truly and fully compensates for the dimensional changes of the measuring system. This allows for the optical encoder to only measure the sample’s actual variations. The result is a linear thermal expansion curve that is not dependent on the unknown calibration factors. Additionally, accuracy and precision of CTE values greatly improve. Regardless of the material tested.

Based upon the horizontal push rod design, in DIL 832 the specimen rests on a sample support, specially designed to minimize the friction, contained in a sample holder. A load applied through the push-rod itself maintains it in mechanical contact with the measuring system while it is subjected to a thermal treatment.

Depending upon the temperature range, the material of the measuring system and sample holder can be of fused silica, alumina. DIL 832 dimensional changes are detected and measured by an incremental optical encoder with a true resolution of 1 nm

In horizontal dilatometry a critical feature is the load applied on to the sample, especially in case of unknown, difficult or fast shrinking materials, as often R&D laboratories are required to test. The correct load varies dependent upon the events to be measured, the rate at which they occur, the time, and the experiment’s temperature range. The DIL 832 linear magnetic motor ensures a very precise and truly constant load ranging from 0.01 to 1.0N across its entire measuring range of 5000μm.

Materials

polymers, ceramics, glasses, building materials, high performance materials, metals, alloys. Ideal to be used joined to Laser Flash instrumentation

Industries

Academia, Advanced Ceramics, Building Materials, Glass, Automotive, Aerospace, Defense, Metals and non-metals Industry, Electronics and micro-electronics, Renewable energies

DIL 830 Series High Resolution Horizontal Dilatometers

The New ODP860 Series – Optical Dilatometry Platform

DIL 820 Series Vertical Dilatometers

- Description

-

DIL 832 features an impressive array of unique technologies and capabilities that make of it the ideal tool in any R&D laboratory for the characterization of mechanical and dimensional properties: TA Instruments exclusive True Differential™ technology, the patented 1 nm resolution optical encoder, a family of new dynamic furnaces, and the new linear sample load motor. The result is the best performing horizontal push-rod dilatometer available on the market, regardless of the application or the material to be tested.

The sample load is ensured by a linear motor with a range of 0.01 to 1.00 N, a force resolution of 0.01 N and a linearity better than 0.01 N across the total measuring range of 5000 µm.

The new patented optical incremental encoder brings length measurement’s true resolution down to a best in class 1 nm. This allows for the measurement of shorter samples yet preserving an outstanding ∆L resolution.

The newly designed measuring head housing and the active electrical thermal stabilization ensure unprecedented stability of the detection core. Combined with TA Instruments exclusive True Differential™ technology and the unique design of TA Instruments furnaces, results in the DIL 832 delivering an industry leading CTE accuracy of 0.01 x 10-6 K-1.

The DIL 832 automatically records the initial sample length and is capable of up to a maximum sample length of 25 mm and a maximum diameter of 6 mm .

The water cooled furnaces provide a very dynamic temperature programming capability with a maximum heating rate of 50 K/min, but most of all a cool down time as short as 13 minutes from 1000°C to room temperature, up to 15 times shorter than competitive instruments.

The integrated electronics provide network connection, and the integrated touch screen allows you to perform many functions directly on the instrument and shows, in real time, measurement parameters and test’s time-to-completion.

- Specifications

-

Dilatometer type True DifferentialTM horizontal push rod Sample dimension length / diameter 0 to 25 mm / 6mm Material of sample holder: Fused silica, Al2O3 Contact Force: 0.01 – 1.0 N, linear motor controlled constant sample load Change of length: 5000µm Resolution ΔL, ΔT: 1 nm, 0.05°C Accuracy in α: 0.01 x 10-6 K-1 Atmosphere: Vacuum, Inert gas, Air atmosphere control through optional gas unit with massflow controller and vacuum unit

Temperature range: RT – 1100°C

RT – 1500°C

RT – 1700°CHeating rate 50°C/min Cooling rates 1100°C – RT: minimum 13 min

1500°C – RT: less than one hour

1700°C – RT: approximately one hour - Measurement Principle

-

The materials in the measuring systems of all dilatometers are stable but not totally free of significant dimensional changes. This is especially true when the method covers a large temperature range of heating or cooling, and these materials can experience dimensional changes equivalent to the specimen. To ensure accuracy, good laboratory practice requires calibration of the instrument for every temperature program, using a reference material of similar properties, similar shape and similar size of the sample. However, the number of different variables contributing to the accuracy of calibration curves can introduce significant errors in repeatability over time, hence of the accuracy of the measurements.

The TA Instruments exclusive True DifferentialTM design of the DIL 832 is the only system that truly and fully compensates for the dimensional changes of the measuring system. This allows for the optical encoder to only measure the sample’s actual variations. The result is a linear thermal expansion curve that is not dependent on the unknown calibration factors. Additionally, accuracy and precision of CTE values greatly improve. Regardless of the material tested.

Based upon the horizontal push rod design, in DIL 832 the specimen rests on a sample support, specially designed to minimize the friction, contained in a sample holder. A load applied through the push-rod itself maintains it in mechanical contact with the measuring system while it is subjected to a thermal treatment.

Depending upon the temperature range, the material of the measuring system and sample holder can be of fused silica, alumina. DIL 832 dimensional changes are detected and measured by an incremental optical encoder with a true resolution of 1 nm

In horizontal dilatometry a critical feature is the load applied on to the sample, especially in case of unknown, difficult or fast shrinking materials, as often R&D laboratories are required to test. The correct load varies dependent upon the events to be measured, the rate at which they occur, the time, and the experiment’s temperature range. The DIL 832 linear magnetic motor ensures a very precise and truly constant load ranging from 0.01 to 1.0N across its entire measuring range of 5000μm.

- Applications

-

Materials

polymers, ceramics, glasses, building materials, high performance materials, metals, alloys. Ideal to be used joined to Laser Flash instrumentation

Industries

Academia, Advanced Ceramics, Building Materials, Glass, Automotive, Aerospace, Defense, Metals and non-metals Industry, Electronics and micro-electronics, Renewable energies

- Videos

-

DIL 830 Series High Resolution Horizontal Dilatometers

The New ODP860 Series – Optical Dilatometry Platform

DIL 820 Series Vertical Dilatometers