The most powerful system for accurate and precise thermal diffusivity measurements up to 2800°C.

The Discovery Laser Flash DLF 2800 is an advanced freestanding instrument for the measurement of thermal diffusivity and specific heat capacity of materials from room temperature to 2800°C. The distinctive design incorporates a proprietary laser, laser optics, detector, and furnace technologies, and along with the unique six-position sample carousel, ensures unprecedented measurement accuracy and sample throughput. With the ability to operate in a variety of atmospheric conditions, including inert gas or under vacuum, the DLF 2800 can characterize a wide variety of materials, including polymers, ceramics, carbons, graphite, composites, glasses, metals, and alloys.

DLF 2800 Features

- Powerful laser provides 40% more energy than any competitive design for the most accurate testing to the highest temperatures and widest range of samples, regardless of thickness and thermal conductivity

- Proprietary fiber optic wand delivers 99% homogeneous beam at the sample for increased measurement accuracy

- Unique six-position carousel for unmatched throughput and accurate heat capacity measurements

- Flexible carousel design configurable with a variety of sample holders, adapters and special fixtures over the widest testing range

- Advanced furnace for uncompromised temperature performance from RT to 2800°C, and measurements in inert gas or vacuum

- High sensitivity IR detector for optimum signal-to-noise ratio, delivering the highest accuracy over the entire temperature range

- Real-time pulse mapping for unmatched accuracy of thermal diffusivity measurements for testing of thin and highly conductive materials

- Meets a variety of industry standard test methods including: ASTM E1461, ASTM C714, ASTM E2585, ISO 13826, ISO 22007-Part4, ISO 18755, BS ENV 1159-2, DIN 30905

*US Patent #6.375.349.81

Laser Source

| Type | Class 1Nd: Glass, Floor-standing |

| Pulse Energy (Variable) | Up to 35 Joules |

| Pulse Width | 300 µs to 400 µsec |

| Proprietary Transfer Optics | Fiber Optic Wand |

Furnace

| Temperature Range | RT to 2800°C |

| Atmosphere | Inert, vacuum (50 mtorr) |

Detection

| Thermal Diffusivity Range | 0.01 to 1000 mm2/s |

| Thermal Conductivity Range | 0.1 to 2000 W/(m*K) |

Accuracy

| Thermal Diffusivity | ±2.3% |

| Thermal Conductivity | ±4% |

Repeatability

| Thermal Diffusivity | ±2.0% |

| Thermal Conductivity | ±3.5% |

Sample

| Round | 8, 10, & 12.7 mm Diameter |

| Square | 8 & 10 mm length |

| Maximum Thickness | 10 mm |

Autosampler

| Type | Six-Position Carousel |

High Power Laser and Advanced Optics

High Power Laser and Advanced Optics

The DLF 2800 features the industry’s most powerful and robust laser light source and most efficient delivery system. The proprietary Class 1 Neodymium-Phosphate Glass laser and fiber optic power wand system, with built-in alignment, ensure effective generation and delivery of laser energy to the sample.

- Proprietary laser designed and manufactured by TA

- 40% more light pulse energy delivered to the sample surface than the closest competitive system

- 99% homogenized laser energy profile ensures unmatched measurement accuracy

- Noise-free design – The separation of the laser and furnace modules eliminates the effect of electromagnetic interference, and ensures long-term optical alignment stability

Dual-Pyrometer Temperature Reading

Dual-Pyrometer Temperature Reading

The DLF 2800 incorporates a proprietary dual-pyrometer design guaranteeing unrivaled high temperature precision and accuracy. This unique feature also enables uninterrupted sample testing from room temperature to 2800°C. Above 900°C, a two-color pyrometer provides a second temperature reading, eliminating the possibility of uncertainty due to changes in the emissivity of the sample, degradation of the optical windows, or the alignment conditions of optical paths.

2800 °C Furnace

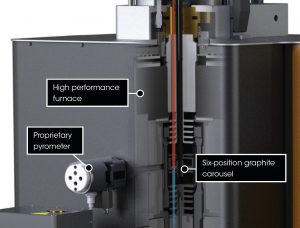

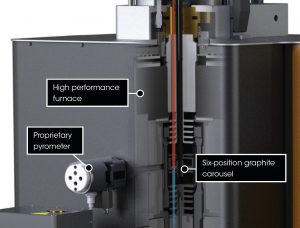

2800°C Furnace

The DLF 2800 is configured with a graphite furnace with a maximum temperature of 2800°C. The intelligent design of the furnace sets it apart from competitive light flash analysis instruments in every aspect of temperature performance. The furnace employs high quality heating elements, a muffle tube, and multiple baffles along its length preventing thermal disturbances. The result is a furnace designed to provide the most stable and uniform heating for reliable control of the sample at 2800°C. When operating the DLF 2800, every sample in the carousel absolutely reaches and maintains the programmed temperature from ambient up to 2800°C throughout the testing time. Sample testing can be conducted in static or dynamic atmospheres, including vacuum or inert gas purge. The DLF 2800 provides the most reproducible thermal diffusivity measurements available from RT to 2800°C.

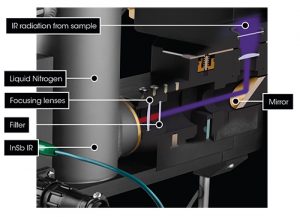

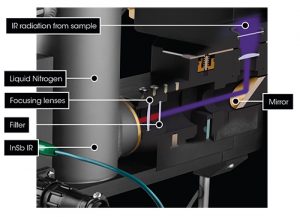

Precision IR Detector and Optics

Precision IR Detector and Optics

The DLF 2800 includes a high sensitivity liquid nitrogen cooled Indium Antimonide (InSb) IR detector with an optimum signal-to-noise ratio over the entire temperature range. A built-in liquid nitrogen dewar provides unattended 24-hour operation for uninterrupted extended experiments. Additionally, the optics in the detector path ensure uniform and accurate measurement of the sample thermogram. The IR detection area covers more than 90% of the sample surface, and representative data is collected without contributions from extraneous radiation, including edge effects such as flash-through caused by imperfect sample preparation.

Flexible High Productivity Sample Carousel

Flexible High Productivity Sample Carousel

The DLF 2800 is the only high temperature flash system on the market that comes standard with a carousel enabling simultaneous testing of up to six samples in a single experiment to 2800°C. This multi-sampling capability significantly increases throughput, and avoids unnecessary downtime between experiments. Additionally, it delivers the most accurate heat capacity (Cp) measurements; Measurements of heat capacity by the flash method rely on comparing a sample and reference tested under identical conditions. With the multi-sample carousel, the sample and reference can be measured sequentially under identical thermal and environmental conditions leading to faster and more accurate results.

The carousel accepts samples up to 12.7 mm diameter and 10 mm thick, 50% thicker than any competitive high-temperature light flash instrument. Optional trays and adapters can accommodate a variety of sample dimensions and shapes, including round and square. Specialty sample holders are available for liquids, powders, pastes, laminates, and in-plane testing of thin films.

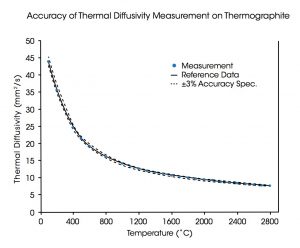

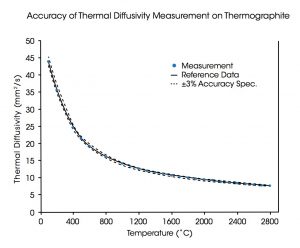

Unmatched Accuracy and Repeatability

Unmatched Accuracy and Repeatability

Accuracy, which defines how close a set of measured data are to the true value, is paramount in understanding how well an instrument performs under known conditions. The figure to the right shows results of a graphite sample tested to 2800°C compared to the reference value. The data shows the accuracy is better than ±3% across the entire temperature range.

The Proven Software Platform for Easy, Accurate Flash Analysis Data

All Discovery Light Flash instruments include FlashLine™ software for Instrument Control and Data Analysis. The Microsoft Windows based software features an intuitive tablebased format for simple programming of experimental parameters in the instrument control interface. Real-time monitoring allows for immediate assessment of the data quality and instrument performance during each test. The Data Analysis module’s automated routines provide users with advanced analysis tools, including models for heat loss correction in both conduction and radiation. Integrated with the pulse-shape mapping measuring system, FlashLine determines the exact shape of the laser pulse versus time to make pulse shape and width correction. It also identifies the flash zero origin and enables finite pulse effect correction which is critical to guarantee accurate measurements for thin samples and high-diffusivity materials. Additionally, the TA Instrument developed “Goodness of Fit” evaluation tool allows the user to select the best results calculated by different Thermal Diffusivity models.

Software Features:

- Unlimited temperature segments with user-defined heat ramp steps

- User-selectable laser energy for each sample by temperature segment

- Data analysis of any already-completed segment during testing

- Determination of the specific heat by comparative method

- Option for automatic multiple-shots selection and averaging

- Correction for radiation component of transparent and translucent samples

- Automatic optimization of flash energy level

- Option for sample skip, and precision criterion

- Fast zoom function for X and Y segments

- Thermal diffusivity, specific heat, and thermal conductivity tables and graphs as a function of temperature

- Calculations of all models during testing and available by the completion of testing

Standard models include:

- Gembarovic for multi-dimensional heat loss correction and non-linear regression

- Goodness of Fit for the best model result selection

- Pulse gravity center to determine t0

- Pulse length and shape correction

- Two and three layers analysis

- In-plane

- Main models: Clark and Taylor, Cowan, Degiovanni, Koski, Least Squares, Logarithmic, Moment, Heckman, Azumi, and Parker

- Description

-

The Discovery Laser Flash DLF 2800 is an advanced freestanding instrument for the measurement of thermal diffusivity and specific heat capacity of materials from room temperature to 2800°C. The distinctive design incorporates a proprietary laser, laser optics, detector, and furnace technologies, and along with the unique six-position sample carousel, ensures unprecedented measurement accuracy and sample throughput. With the ability to operate in a variety of atmospheric conditions, including inert gas or under vacuum, the DLF 2800 can characterize a wide variety of materials, including polymers, ceramics, carbons, graphite, composites, glasses, metals, and alloys.

- Features

-

DLF 2800 Features

- Powerful laser provides 40% more energy than any competitive design for the most accurate testing to the highest temperatures and widest range of samples, regardless of thickness and thermal conductivity

- Proprietary fiber optic wand delivers 99% homogeneous beam at the sample for increased measurement accuracy

- Unique six-position carousel for unmatched throughput and accurate heat capacity measurements

- Flexible carousel design configurable with a variety of sample holders, adapters and special fixtures over the widest testing range

- Advanced furnace for uncompromised temperature performance from RT to 2800°C, and measurements in inert gas or vacuum

- High sensitivity IR detector for optimum signal-to-noise ratio, delivering the highest accuracy over the entire temperature range

- Real-time pulse mapping for unmatched accuracy of thermal diffusivity measurements for testing of thin and highly conductive materials

- Meets a variety of industry standard test methods including: ASTM E1461, ASTM C714, ASTM E2585, ISO 13826, ISO 22007-Part4, ISO 18755, BS ENV 1159-2, DIN 30905

*US Patent #6.375.349.81

- Specifications

-

Laser Source

Type Class 1Nd: Glass, Floor-standing Pulse Energy (Variable) Up to 35 Joules Pulse Width 300 µs to 400 µsec Proprietary Transfer Optics Fiber Optic Wand Furnace

Temperature Range RT to 2800°C Atmosphere Inert, vacuum (50 mtorr) Detection

Thermal Diffusivity Range 0.01 to 1000 mm2/s Thermal Conductivity Range 0.1 to 2000 W/(m*K) Accuracy

Thermal Diffusivity ±2.3% Thermal Conductivity ±4% Repeatability

Thermal Diffusivity ±2.0% Thermal Conductivity ±3.5% Sample

Round 8, 10, & 12.7 mm Diameter Square 8 & 10 mm length Maximum Thickness 10 mm Autosampler

Type Six-Position Carousel - Technology

-

High Power Laser and Advanced Optics

High Power Laser and Advanced Optics

The DLF 2800 features the industry’s most powerful and robust laser light source and most efficient delivery system. The proprietary Class 1 Neodymium-Phosphate Glass laser and fiber optic power wand system, with built-in alignment, ensure effective generation and delivery of laser energy to the sample.

- Proprietary laser designed and manufactured by TA

- 40% more light pulse energy delivered to the sample surface than the closest competitive system

- 99% homogenized laser energy profile ensures unmatched measurement accuracy

- Noise-free design – The separation of the laser and furnace modules eliminates the effect of electromagnetic interference, and ensures long-term optical alignment stability

Dual-Pyrometer Temperature Reading

Dual-Pyrometer Temperature Reading

The DLF 2800 incorporates a proprietary dual-pyrometer design guaranteeing unrivaled high temperature precision and accuracy. This unique feature also enables uninterrupted sample testing from room temperature to 2800°C. Above 900°C, a two-color pyrometer provides a second temperature reading, eliminating the possibility of uncertainty due to changes in the emissivity of the sample, degradation of the optical windows, or the alignment conditions of optical paths.

2800 °C Furnace

2800°C Furnace

The DLF 2800 is configured with a graphite furnace with a maximum temperature of 2800°C. The intelligent design of the furnace sets it apart from competitive light flash analysis instruments in every aspect of temperature performance. The furnace employs high quality heating elements, a muffle tube, and multiple baffles along its length preventing thermal disturbances. The result is a furnace designed to provide the most stable and uniform heating for reliable control of the sample at 2800°C. When operating the DLF 2800, every sample in the carousel absolutely reaches and maintains the programmed temperature from ambient up to 2800°C throughout the testing time. Sample testing can be conducted in static or dynamic atmospheres, including vacuum or inert gas purge. The DLF 2800 provides the most reproducible thermal diffusivity measurements available from RT to 2800°C.

Precision IR Detector and Optics

Precision IR Detector and Optics

The DLF 2800 includes a high sensitivity liquid nitrogen cooled Indium Antimonide (InSb) IR detector with an optimum signal-to-noise ratio over the entire temperature range. A built-in liquid nitrogen dewar provides unattended 24-hour operation for uninterrupted extended experiments. Additionally, the optics in the detector path ensure uniform and accurate measurement of the sample thermogram. The IR detection area covers more than 90% of the sample surface, and representative data is collected without contributions from extraneous radiation, including edge effects such as flash-through caused by imperfect sample preparation.

Flexible High Productivity Sample Carousel

Flexible High Productivity Sample Carousel

The DLF 2800 is the only high temperature flash system on the market that comes standard with a carousel enabling simultaneous testing of up to six samples in a single experiment to 2800°C. This multi-sampling capability significantly increases throughput, and avoids unnecessary downtime between experiments. Additionally, it delivers the most accurate heat capacity (Cp) measurements; Measurements of heat capacity by the flash method rely on comparing a sample and reference tested under identical conditions. With the multi-sample carousel, the sample and reference can be measured sequentially under identical thermal and environmental conditions leading to faster and more accurate results.

The carousel accepts samples up to 12.7 mm diameter and 10 mm thick, 50% thicker than any competitive high-temperature light flash instrument. Optional trays and adapters can accommodate a variety of sample dimensions and shapes, including round and square. Specialty sample holders are available for liquids, powders, pastes, laminates, and in-plane testing of thin films.

- Performance

-

Unmatched Accuracy and Repeatability

Unmatched Accuracy and Repeatability

Accuracy, which defines how close a set of measured data are to the true value, is paramount in understanding how well an instrument performs under known conditions. The figure to the right shows results of a graphite sample tested to 2800°C compared to the reference value. The data shows the accuracy is better than ±3% across the entire temperature range.

- Software

-

The Proven Software Platform for Easy, Accurate Flash Analysis Data

All Discovery Light Flash instruments include FlashLine™ software for Instrument Control and Data Analysis. The Microsoft Windows based software features an intuitive tablebased format for simple programming of experimental parameters in the instrument control interface. Real-time monitoring allows for immediate assessment of the data quality and instrument performance during each test. The Data Analysis module’s automated routines provide users with advanced analysis tools, including models for heat loss correction in both conduction and radiation. Integrated with the pulse-shape mapping measuring system, FlashLine determines the exact shape of the laser pulse versus time to make pulse shape and width correction. It also identifies the flash zero origin and enables finite pulse effect correction which is critical to guarantee accurate measurements for thin samples and high-diffusivity materials. Additionally, the TA Instrument developed “Goodness of Fit” evaluation tool allows the user to select the best results calculated by different Thermal Diffusivity models.

Software Features:

- Unlimited temperature segments with user-defined heat ramp steps

- User-selectable laser energy for each sample by temperature segment

- Data analysis of any already-completed segment during testing

- Determination of the specific heat by comparative method

- Option for automatic multiple-shots selection and averaging

- Correction for radiation component of transparent and translucent samples

- Automatic optimization of flash energy level

- Option for sample skip, and precision criterion

- Fast zoom function for X and Y segments

- Thermal diffusivity, specific heat, and thermal conductivity tables and graphs as a function of temperature

- Calculations of all models during testing and available by the completion of testing

Standard models include:

- Gembarovic for multi-dimensional heat loss correction and non-linear regression

- Goodness of Fit for the best model result selection

- Pulse gravity center to determine t0

- Pulse length and shape correction

- Two and three layers analysis

- In-plane

- Main models: Clark and Taylor, Cowan, Degiovanni, Koski, Least Squares, Logarithmic, Moment, Heckman, Azumi, and Parker