Patented technology for the Most Sensitive Powerful Xenon Platform

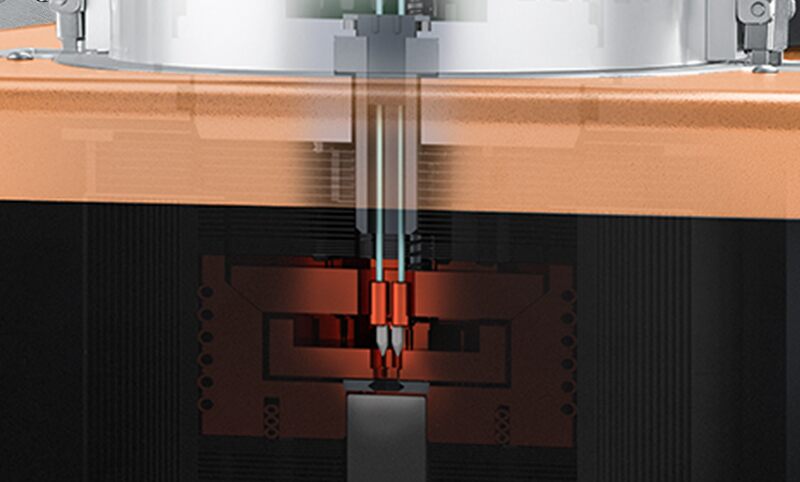

The Discovery Xenon Flash 200+ features a patented High Speed Xenon-Pulse DeliveryTM source (HSXD) and a multi-faceted Light PipeTM. Together these optics deliver a light pulse of unsurpassed power and uniform intensity to the specimen while preventing sample holder overflash. Only TA Instruments high energy Xenon design is capable of testing samples to a diameter of 25.4 mm over a temperature range from -175 °C to 900 °C. The use of large samples diminishes errors associated with inhomogeneity and permits representative measurements of poorly dispersed composites. The DXF platform is designed for research and development programs as well as production control.

DXF 200+ Features

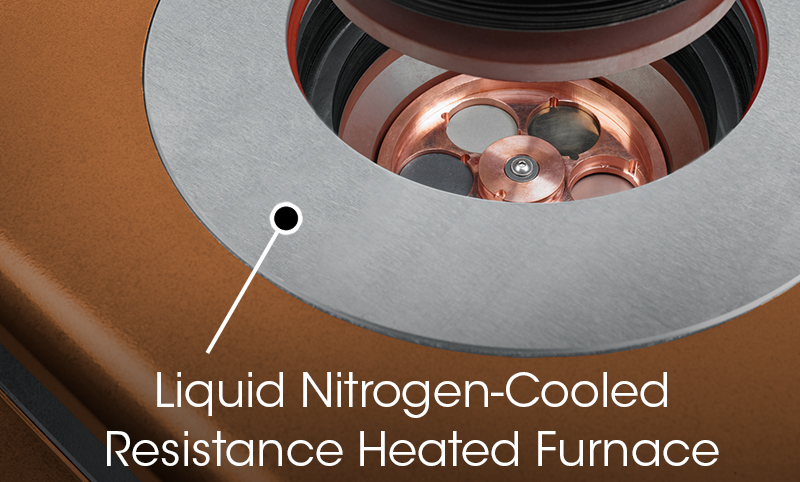

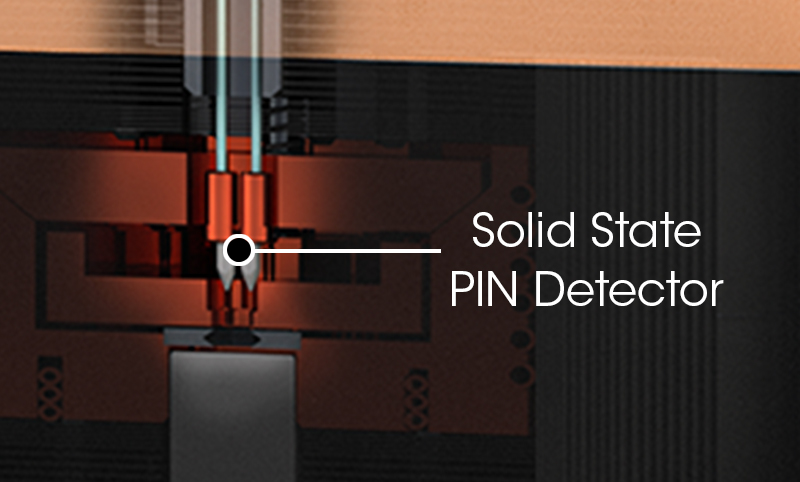

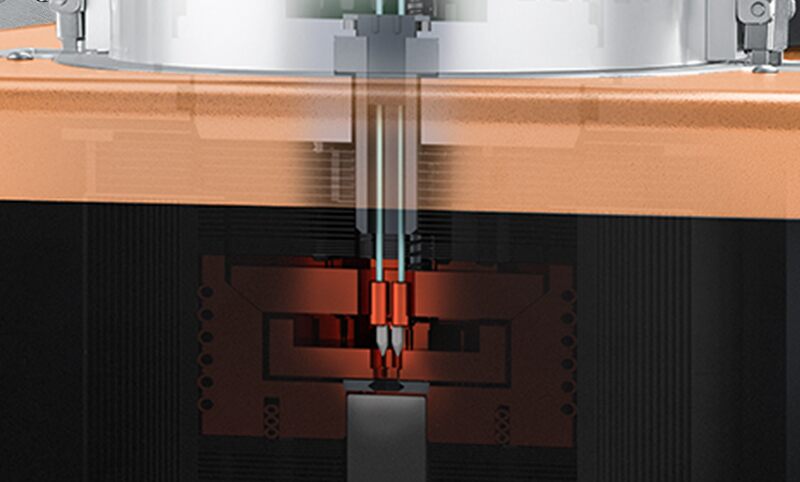

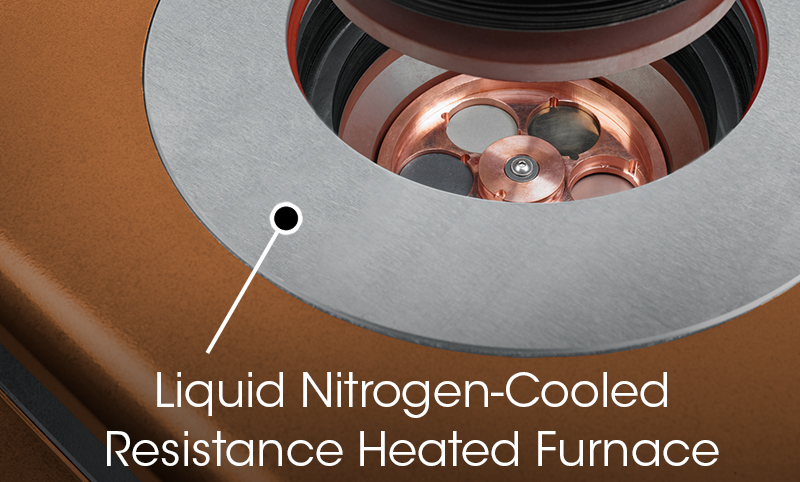

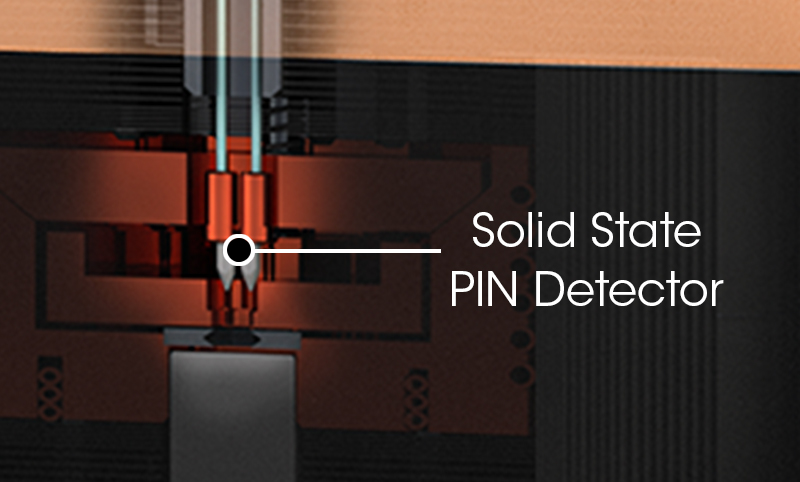

- Subambient temperature system with highly efficient liquid nitrogen cooling system and solid state PIN detectors for accurate and stable temperature control to an industry leading -175˚C.

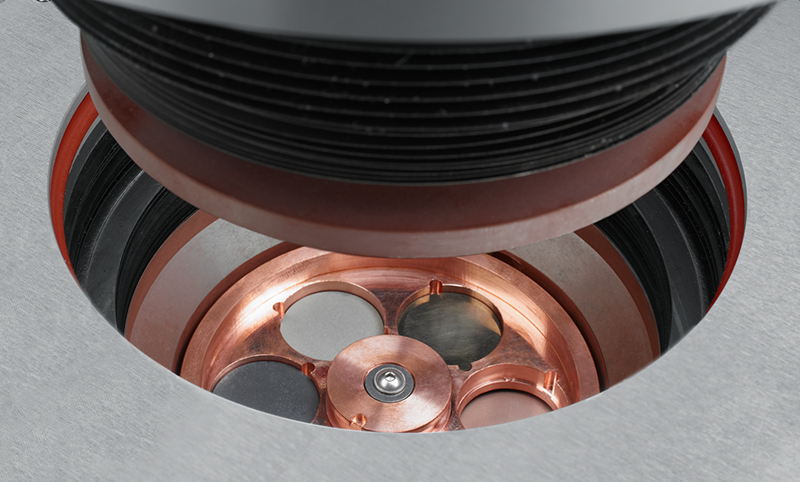

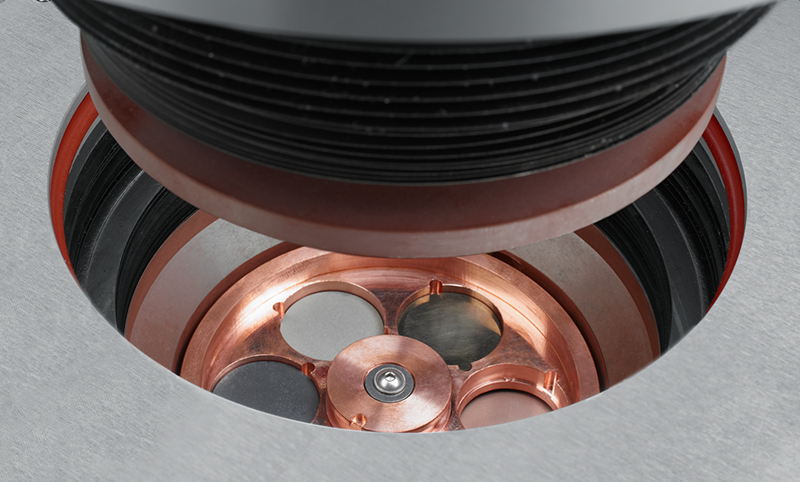

- Easily swappable autosampler trays can accommodate up to twelve samples 12.7 mm diameter or six 25.4 mm diameter samples, plus many more sizes and shapes.

- Software controlled PIN loading can be adjusted to maintain perfect contact regardless of sample thickness.

- Patented High Speed Xenon-Pulse-Delivery system provides 50% more energy than competitive designs for the highest degree of accuracy on widest range of samples regardless of thickness or thermal conductivity.

- Wide variety of sample trays accommodates multiple sample sizes (up to 25.4 mm), shapes, and special fixtures (liquids, powders, laminates, films, etc.) for maximum sample testing flexibility.

- Patented Light Pipe™ for the most effective collection and collimation of light and homogeneous delivery of radiation to the sample.

- Can test samples with maximum diameter of 25.4 mm diameter for easier sample preparation and handling, as well as improved results for inhomogeneous materials.

- Real-time pulse mapping for superior thermal diffusivity of thin and highly conductive materials.

- Designed to meet industry standard test methods including: ASTM E1461, ASTM C714, ASTM E2585, ISO 13826, ISO 22007-Part4, ISO 18755, BS ENV 1159-2, DIN 30905, and DIN EN821

Flash Source

| Type | Xenon, Benchtop |

| Pulse Energy (Variable) | Variable up to 15 Joules |

| Pulse Width | 400 µs to 600 µsec |

| Proprietary Transfer Optics | Light Pipe Beam Guide |

Furnace

| Sample Temperature Range | -175°C to 200°C |

| Atmosphere | Air, inert, vacuum (50 mtorr) |

Detection

| Thermal Diffusivity Range | 0.01 to 1000 mm2/s |

| Thermal Conductivity Range | 0.1 to 2000 W/(m*K) |

| Data Acquisition | 16 bit |

Accuracy

| Thermal Diffusivity | ±2.3% |

| Thermal Conductivity | ±4% |

Repeatability

| Thermal Diffusivity | ±2.0% |

| Thermal Conductivity | ±3.5% |

Sample

| Round | 8, 10, 12.7, 25.4 mm Diameter |

| Square | 8, 10, 12.7 mm length |

| Maximum Thickness | 10 mm |

Autosampler

| Type | Twelve-Position Carousel |

Lowest Available Temperature Limit: -175 ˚C

Lowest Available Temperature Limit: -175 ˚C

The DXF 200+ features a furnace that includes an efficient liquid nitrogen cooling system for stable and accurate temperature control from -175 ˚C to 200 ˚C. Only the DXF 200+ is capable of testing thermal management properties of materials to -175˚C making it the clear choice for scientists interested in the cryogenic range.

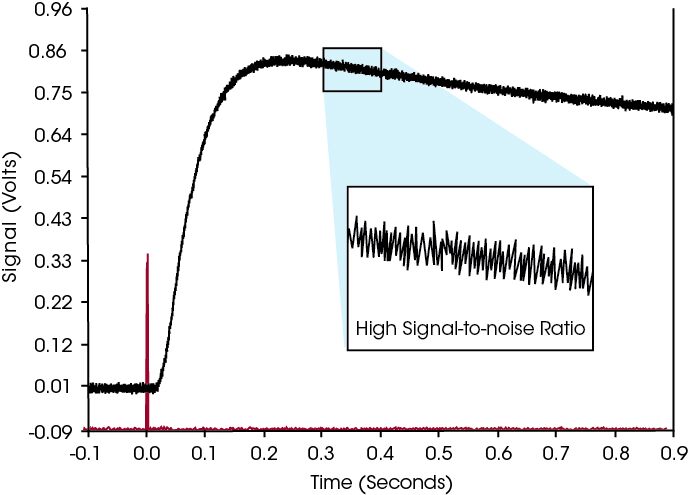

Enhanced Temperature Detection from Solid State PIN Detector

Enhanced Temperature Detection from Solid State PIN Detector

The DXF 200+ features a unique, dual PIN detector which provides optimal sensitivity and response time at temperatures below ambient. The amplitude of the signal measured at -175˚C by the PIN detector, in direct contact with the sample, is typically five times greater than the signal at the lowest detectable temperature of a traditional IR detector, which is typically 25 ˚C. This eliminates the need for signal amplification required for MCT IR detectors operating at or below room temperature. The result is an improved thermogram with greater signal-to-noise ratio, increased accuracy of specific heat capacity and thermal conductivity measurements, and a reliable data set for effortless post-test analysis.

Patented High Speed Xenon-Pulse DeliveryTM (HSXD) Source

Patented High Speed Xenon-Pulse DeliveryTM (HSXD) Source

The DXF 200+ features the proprietary High Speed Xenon-Pulse DeliveryTM (HSXD) source. With its 15 Joules of energy, the flash produced by the HSXD is the most powerful and most uniform flash of any Xenon system available on the market.

Large 25.4 mm Sample Diameter for Easy Sample Handling

Large 25.4 mm Sample Diameter for Easy Sample Handling

No other supplier can offer the ability to test up to 25.4 mm diameter samples over such a wide temperature range. Larger samples are easier to prepare and handle, guarantee more representative and reproducible data, and provide improved results for composites or inhomogeneously dispersed materials.

Real-time Pulse Mapping

Real-time Pulse Mapping

The real-time pulse mapping system accounts for the finite pulse width effect and heat losses, which is paramount for data accuracy, especially when measuring thin and highly conductive materials.

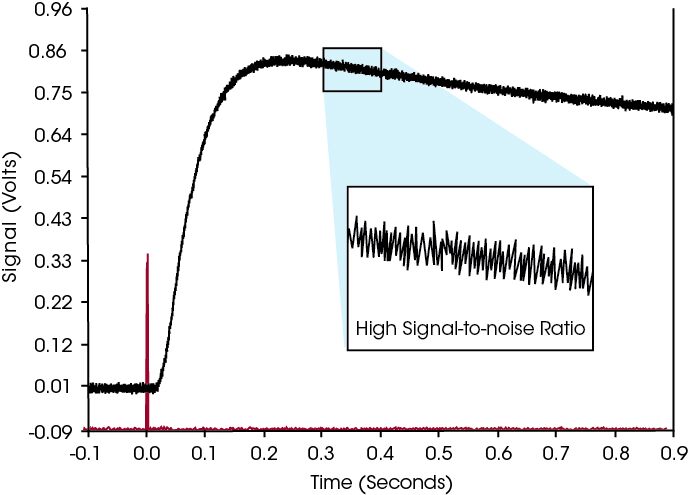

Lowest Temperature with Highest Signal-to-Noise Ratio

Lowest Temperature with Highest Signal-to-Noise Ratio

The increasing demand of new high-performance materials for the aerospace and defense industries has pushed the demand for Flash Diffusivity instrumentation with lower temperature range and better data quality. The solid state Dual PIN detector can operate down to an industryleading -175 ˚C with excellent data quality.

The figure on the upper right demonstrates the quality of the signal-to-noise ratio (SNR) of the DXF200 + at cryogenic temperatures. Even at -175 ˚C the amplitude of the directly measured signal is approximately five times greater for the solid-state PIN detector than for a traditional IR detector signal at room temperature.

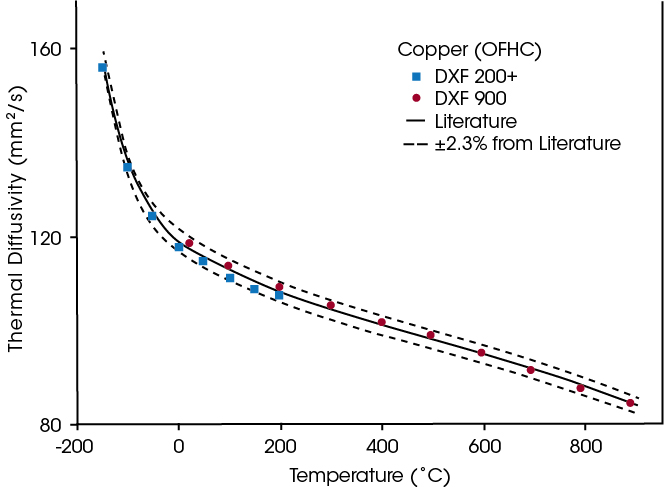

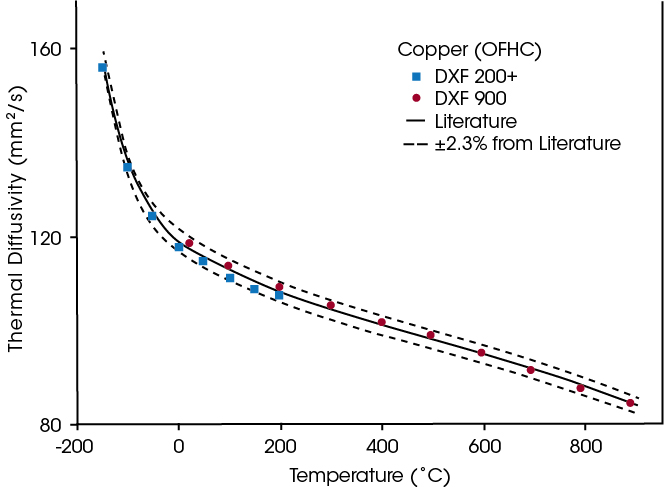

Consistent Data from -175°C to 900°C

Consistent Data from -175°C to 900°C

Often, high performance materials need to be characterized from extremely low to high temperatures. The graph on the lower right shows an oxygen-free high thermal conductivity copper (OFHC) reference material in which thermal conductivity was measured from -175 ˚C to 900 ˚C with both a DXF200 + and DXF 900.

Often, high performance materials need to be characterized from extremely low to high temperatures. The graph on the lower right shows an oxygen-free high thermal conductivity copper (OFHC) reference material in which thermal conductivity was measured from -175 ˚C to 900 ˚C with both a DXF200 + and DXF 900.

All the measurements fall within ±1.5% of the reference values. Note the agreement of the values between ambient and 200 ˚C

The Proven Software Platform for Easy, Accurate Flash Analysis Data

All Discovery Light Flash instruments include FlashLine™ software for Instrument Control and Data Analysis. The Microsoft Windows based software features an intuitive tablebased format for simple programming of experimental parameters in the instrument control interface. Real-time monitoring allows for immediate assessment of the data quality and instrument performance during each test. The Data Analysis module’s automated routines provide users with advanced analysis tools, including models for heat loss correction in both conduction and radiation.

All Discovery Light Flash instruments include FlashLine™ software for Instrument Control and Data Analysis. The Microsoft Windows based software features an intuitive tablebased format for simple programming of experimental parameters in the instrument control interface. Real-time monitoring allows for immediate assessment of the data quality and instrument performance during each test. The Data Analysis module’s automated routines provide users with advanced analysis tools, including models for heat loss correction in both conduction and radiation.

Integrated with the pulse-shape mapping measuring system, FlashLine determines the exact shape of the laser pulse versus time to make pulse shape and width correction. It also identifies the flash zero origin and enables finite pulse effect correction which is critical to guarantee accurate measurements for thin samples and high-diffusivity materials. Additionally, the TA Instrument developed “Goodness of Fit” evaluation tool allows the user to select the best results calculated by different Thermal Diffusivity models.

Software Features:

- Unlimited temperature segments with user-defined heat ramp steps

- User-selectable laser energy for each sample by temperature segment

- Data analysis of any already-completed segment during testing

- Determination of the specific heat by comparative method

- Option for automatic multiple-shots selection and averaging

- Correction for radiation component of transparent and translucent samples

- Automatic optimization of flash energy level

- Option for sample skip, and precision criterion

- Fast zoom function for X and Y segments

- Thermal diffusivity, specific heat, and thermal conductivity tables and graphs as a function of temperature

- Calculations of all models during testing and available by the completion of testing

Standard models include:

- Gembarovic for multi-dimensional heat loss correction and non-linear regression

- Goodness of Fit for the best model result selection

- Pulse gravity center to determine t0

- Pulse length and shape correction

- Two and three layers analysis

- In-plane

- Main models: Clark and Taylor, Cowan, Degiovanni, Koski, Least Squares, Logarithmic, Moment, Heckman, Azumi, and Parker

Specialty Fixtures

Laser and Xenon Light Flash instruments represent the forefront in research and development of high performance materials and the study of thermal management properties. Often, accessories with standard sizes and shapes are just not enough to test that special sample or innovative material.

In cooperation with advanced users of prestigious laboratories, TA has a range of sample holders developed specifically for the analysis of:

- Liquids

- Powders

- Pastes

- In-plane testing of thin films with high conductivity

- In-plane testing of laminates

With the ever-increasing number of new materials requiring heat transfer characterization, TA is committed to working with our customers in the development of fixtures to meet their unique testing requirements.

- Description

-

The Discovery Xenon Flash 200+ features a patented High Speed Xenon-Pulse DeliveryTM source (HSXD) and a multi-faceted Light PipeTM. Together these optics deliver a light pulse of unsurpassed power and uniform intensity to the specimen while preventing sample holder overflash. Only TA Instruments high energy Xenon design is capable of testing samples to a diameter of 25.4 mm over a temperature range from -175 °C to 900 °C. The use of large samples diminishes errors associated with inhomogeneity and permits representative measurements of poorly dispersed composites. The DXF platform is designed for research and development programs as well as production control.

- Features

-

DXF 200+ Features

- Subambient temperature system with highly efficient liquid nitrogen cooling system and solid state PIN detectors for accurate and stable temperature control to an industry leading -175˚C.

- Easily swappable autosampler trays can accommodate up to twelve samples 12.7 mm diameter or six 25.4 mm diameter samples, plus many more sizes and shapes.

- Software controlled PIN loading can be adjusted to maintain perfect contact regardless of sample thickness.

- Patented High Speed Xenon-Pulse-Delivery system provides 50% more energy than competitive designs for the highest degree of accuracy on widest range of samples regardless of thickness or thermal conductivity.

- Wide variety of sample trays accommodates multiple sample sizes (up to 25.4 mm), shapes, and special fixtures (liquids, powders, laminates, films, etc.) for maximum sample testing flexibility.

- Patented Light Pipe™ for the most effective collection and collimation of light and homogeneous delivery of radiation to the sample.

- Can test samples with maximum diameter of 25.4 mm diameter for easier sample preparation and handling, as well as improved results for inhomogeneous materials.

- Real-time pulse mapping for superior thermal diffusivity of thin and highly conductive materials.

- Designed to meet industry standard test methods including: ASTM E1461, ASTM C714, ASTM E2585, ISO 13826, ISO 22007-Part4, ISO 18755, BS ENV 1159-2, DIN 30905, and DIN EN821

- Specifications

-

Flash Source

Type Xenon, Benchtop Pulse Energy (Variable) Variable up to 15 Joules Pulse Width 400 µs to 600 µsec Proprietary Transfer Optics Light Pipe Beam Guide Furnace

Sample Temperature Range -175°C to 200°C Atmosphere Air, inert, vacuum (50 mtorr) Detection

Thermal Diffusivity Range 0.01 to 1000 mm2/s Thermal Conductivity Range 0.1 to 2000 W/(m*K) Data Acquisition 16 bit Accuracy

Thermal Diffusivity ±2.3% Thermal Conductivity ±4% Repeatability

Thermal Diffusivity ±2.0% Thermal Conductivity ±3.5% Sample

Round 8, 10, 12.7, 25.4 mm Diameter Square 8, 10, 12.7 mm length Maximum Thickness 10 mm Autosampler

Type Twelve-Position Carousel - Technology

-

Lowest Available Temperature Limit: -175 ˚C

Lowest Available Temperature Limit: -175 ˚C

The DXF 200+ features a furnace that includes an efficient liquid nitrogen cooling system for stable and accurate temperature control from -175 ˚C to 200 ˚C. Only the DXF 200+ is capable of testing thermal management properties of materials to -175˚C making it the clear choice for scientists interested in the cryogenic range.

Enhanced Temperature Detection from Solid State PIN Detector

Enhanced Temperature Detection from Solid State PIN Detector

The DXF 200+ features a unique, dual PIN detector which provides optimal sensitivity and response time at temperatures below ambient. The amplitude of the signal measured at -175˚C by the PIN detector, in direct contact with the sample, is typically five times greater than the signal at the lowest detectable temperature of a traditional IR detector, which is typically 25 ˚C. This eliminates the need for signal amplification required for MCT IR detectors operating at or below room temperature. The result is an improved thermogram with greater signal-to-noise ratio, increased accuracy of specific heat capacity and thermal conductivity measurements, and a reliable data set for effortless post-test analysis.

Patented High Speed Xenon-Pulse DeliveryTM (HSXD) Source

Patented High Speed Xenon-Pulse DeliveryTM (HSXD) Source

The DXF 200+ features the proprietary High Speed Xenon-Pulse DeliveryTM (HSXD) source. With its 15 Joules of energy, the flash produced by the HSXD is the most powerful and most uniform flash of any Xenon system available on the market.

Large 25.4 mm Sample Diameter for Easy Sample Handling

Large 25.4 mm Sample Diameter for Easy Sample Handling

No other supplier can offer the ability to test up to 25.4 mm diameter samples over such a wide temperature range. Larger samples are easier to prepare and handle, guarantee more representative and reproducible data, and provide improved results for composites or inhomogeneously dispersed materials.

Real-time Pulse Mapping

Real-time Pulse Mapping

The real-time pulse mapping system accounts for the finite pulse width effect and heat losses, which is paramount for data accuracy, especially when measuring thin and highly conductive materials.

- Performance

-

Lowest Temperature with Highest Signal-to-Noise Ratio

Lowest Temperature with Highest Signal-to-Noise Ratio

The increasing demand of new high-performance materials for the aerospace and defense industries has pushed the demand for Flash Diffusivity instrumentation with lower temperature range and better data quality. The solid state Dual PIN detector can operate down to an industryleading -175 ˚C with excellent data quality.

The figure on the upper right demonstrates the quality of the signal-to-noise ratio (SNR) of the DXF200 + at cryogenic temperatures. Even at -175 ˚C the amplitude of the directly measured signal is approximately five times greater for the solid-state PIN detector than for a traditional IR detector signal at room temperature.

Consistent Data from -175°C to 900°C

Consistent Data from -175°C to 900°C

Often, high performance materials need to be characterized from extremely low to high temperatures. The graph on the lower right shows an oxygen-free high thermal conductivity copper (OFHC) reference material in which thermal conductivity was measured from -175 ˚C to 900 ˚C with both a DXF200 + and DXF 900.

Often, high performance materials need to be characterized from extremely low to high temperatures. The graph on the lower right shows an oxygen-free high thermal conductivity copper (OFHC) reference material in which thermal conductivity was measured from -175 ˚C to 900 ˚C with both a DXF200 + and DXF 900.All the measurements fall within ±1.5% of the reference values. Note the agreement of the values between ambient and 200 ˚C

- Software

-

The Proven Software Platform for Easy, Accurate Flash Analysis Data

All Discovery Light Flash instruments include FlashLine™ software for Instrument Control and Data Analysis. The Microsoft Windows based software features an intuitive tablebased format for simple programming of experimental parameters in the instrument control interface. Real-time monitoring allows for immediate assessment of the data quality and instrument performance during each test. The Data Analysis module’s automated routines provide users with advanced analysis tools, including models for heat loss correction in both conduction and radiation.

All Discovery Light Flash instruments include FlashLine™ software for Instrument Control and Data Analysis. The Microsoft Windows based software features an intuitive tablebased format for simple programming of experimental parameters in the instrument control interface. Real-time monitoring allows for immediate assessment of the data quality and instrument performance during each test. The Data Analysis module’s automated routines provide users with advanced analysis tools, including models for heat loss correction in both conduction and radiation.Integrated with the pulse-shape mapping measuring system, FlashLine determines the exact shape of the laser pulse versus time to make pulse shape and width correction. It also identifies the flash zero origin and enables finite pulse effect correction which is critical to guarantee accurate measurements for thin samples and high-diffusivity materials. Additionally, the TA Instrument developed “Goodness of Fit” evaluation tool allows the user to select the best results calculated by different Thermal Diffusivity models.

Software Features:

- Unlimited temperature segments with user-defined heat ramp steps

- User-selectable laser energy for each sample by temperature segment

- Data analysis of any already-completed segment during testing

- Determination of the specific heat by comparative method

- Option for automatic multiple-shots selection and averaging

- Correction for radiation component of transparent and translucent samples

- Automatic optimization of flash energy level

- Option for sample skip, and precision criterion

- Fast zoom function for X and Y segments

- Thermal diffusivity, specific heat, and thermal conductivity tables and graphs as a function of temperature

- Calculations of all models during testing and available by the completion of testing

Standard models include:

- Gembarovic for multi-dimensional heat loss correction and non-linear regression

- Goodness of Fit for the best model result selection

- Pulse gravity center to determine t0

- Pulse length and shape correction

- Two and three layers analysis

- In-plane

- Main models: Clark and Taylor, Cowan, Degiovanni, Koski, Least Squares, Logarithmic, Moment, Heckman, Azumi, and Parker

- Sample Holders

-

Specialty Fixtures

Laser and Xenon Light Flash instruments represent the forefront in research and development of high performance materials and the study of thermal management properties. Often, accessories with standard sizes and shapes are just not enough to test that special sample or innovative material.

In cooperation with advanced users of prestigious laboratories, TA has a range of sample holders developed specifically for the analysis of:

- Liquids

- Powders

- Pastes

- In-plane testing of thin films with high conductivity

- In-plane testing of laminates

With the ever-increasing number of new materials requiring heat transfer characterization, TA is committed to working with our customers in the development of fixtures to meet their unique testing requirements.

- Video

-