Products | ElectroForce Mechanical Test Instruments | ElectroForce™ Apex 1 Instrument

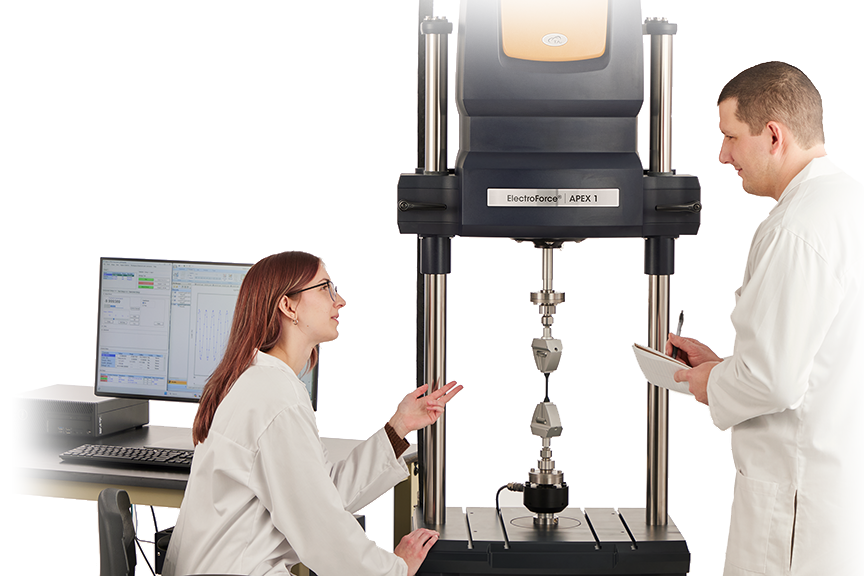

ElectroForce™ Apex 1 Instrument

The TA Instruments ElectroForce Apex 1 Mechanical Testing Instrument empowers scientists, engineers, and technicians to assess mechanical properties efficiently and reliably through monotonic tests, fatigue studies, and other material characterization methods, all with minimal training required.

Watch Demo

Mechanical testing is a standard practice among top laboratories and manufacturers to support material selection, design decisions, component evaluation, and product performance validation. The ElectroForce Apex 1 Instrument is engineered to deliver precise results with ease and reliability.

Take Your Testing to New Heights

The ElectroForce Apex 1 Mechanical Testing Instrument enables customers across diverse industries to measure a wide range of mechanical properties easily and efficiently. Its enhanced stroke length and user-friendly design supports precise tensile and fatigue testing of high performance and lightweight polymers and composites.

- Versatility – increased motor stroke range (100mm) expands testing of more materials across diverse industries, offering greater insights from one instrument

- Dynamic performance – completes fatigue testing for complex materials up to 30% faster, resulting in faster product development and validation

- Streamlined workflow – automated controls and fewer process steps reduce operator errors and ensure precision, enabling safe and confident testing

Achieve Precision with Simplified Testing

ElectroForce Apex 1 Instrument features:

- Enhanced test setup and safety: Integrated motor brake, crosshead lock sensing, and setup mode reduces training and ensures sample and system protection.

- Dependable testing: Automated control system tuning and data acquisition enables confident characterization of materials, while minimizing the need to manage instrument operations.

- User-friendly features: SmartSwap™ Technology simplifies sensor and configuration, while the System Status Indicator provides quick visual feedback on instrument status.

- Exceptional accuracy: High-precision displacement sensor exceeds ASTM E2309 Class A standards with 1 nanometer resolution.

- Flexible testing: Available in 3 configurations (axial tabletop, axial floor standing, and axial torsional floor standing) and offers a broad range of accessories for real-world testing.

Ensure Product Performance and Durability

Material strength and durability testing is increasingly important for accelerating the development of products in demanding applications from airplanes to construction materials. Leading labs and manufacturers commonly use monotonic and fatigue testing to inform material selection and design, followed by component and product performance assessments.

Employing monotonic and fatigue testing on the ElectroForce Apex 1 Instrument early in development can reduce costs, by identifying and eliminating weaknesses in material selection and design, before the validation or post-launch phase.

| Mechanical Properties | Material Characteristic Measured |

| Elastic (Young’s) modulus | Stiffness |

| Yield strength | Maximum stress before permanently deforming |

| Ultimate strength | Maximum stress supported by material |

| Elongation at break | Length change at breaking point |

| Fatigue life | Durability under repeated loading |

| Creep compliance | Deformation over time at constant load |

| Stress relaxation | Decrease in stress over time |

| Fracture toughness | Amount of stress to fracture |

| Fatigue crack growth | Amount cracks grow under repeated loading |

Broaden the Scope of Your Material Analysis

The ElectroForce Apex 1 linear motor technology enables versatile testing across a wide range of forces, frequencies, and displacements, from < 1Hz to > 100Hz and microns to 100mm.

Purpose-built for mechanical testing, its advanced design ensures precise execution of experiments, delivering faster results and accelerating development programs. The friction-free motor, combined with high accuracy displacement sensor technology, helps ensure accurate motion control, preserving even subtle material characteristics without distortion.

This innovative system empowers researchers to perform reliable and efficient testing with maximum precision.

Expedite Testing with Reduced Steps

The ElectroForce Apex 1 Instrument, powered by our next-generation TuneIQ technology, reduces or eliminates the need to carefully select and change control modes during setup and test execution.

Simply install your sample and start testing — no complex control mode adjustments required.

- Simplified test set-up process reduces operator training time and errors, increasing operator confidence

- Constant sample monitoring protects your sample and the instrument

- Sample break detection immediately stops the motor when a sample fracture is detected, preventing damage to the sample surface

Evaluate Samples in Real-Life Conditions

Accurate mechanical testing often needs to simulate real-life conditions to best measure material properties. ElectroForce Apex 1 Instrument accessories empower users to measure sample behavior under a wide variety of conditions and end-use environments.

Environmental

Ovens and baths simulate a wide temperature range, including conditions to simulate the human body for biomaterials and medical device research.

Clamps

Grips for tension, or tension and compression, are commonly used to simulate sample conditions, in addition to compression platens and bend fixtures.

Sensors

Optional sensors measure sample behavior under many conditions, including low force, submersible testing, and direct strain measurement.

Accelerate Operator Training and Proficiency

The ElectroForce Apex 1 Instrument helps minimize training needs with its intuitive operation and user-friendly design. Operators quickly build confidence thanks to features that expedite test processes and reduce the risk of errors.

- Guided test-specific workflows streamline inputs and reduce setup complexity.

- Automated data acquisition setup ensures reliable and accurate data recording.

- Next-generation TuneIQ automates control modes and reduces the tuning process.

- Test parameter traceability enables tracking from setup to the final TRIOS software data file.

- Integrated software and data analysis automatically displays the most relevant data, enabling insightful conclusions.

How the ElectroForce Apex 1 Supports Inkbit’s Innovation

Learn how leading material analysis technology is advancing innovation at InkBit, a 3D printing company, from Chief Technology Officer & Co-Founder Javier Ramos. He shares how the new ElectroForce Apex 1 Mechanical Testing Instrument has helped them cut costs and run tests more efficiently.

Resources

- Product Video: ElectroForce Apex 1: The Next Generation in Advanced Mechanical Testing

- Product Demonstration: ElectroForce Apex 1: Mechanical Testing Instrument Product Demonstration

- Application Note: Flexural Fatigue Behavior of Woven Fiberglass Composites at Elevated Temperature

- Application Note: Tensile and Fatigue Properties of Additively Manufactured Polyamides

- Application Note: Mechanical Testing as a Methodology for Resin Selection

- Tech Tip: Performing Tensile and Fatigue Tests on the ElectroForce Apex 1

- Product Brief: ElectroForce™ Apex 1 Mechanical Testing Instrument

- Sample Data: ElectroForce™ Apex 1 Mechanical Testing Instrument