An accurate, easy-to-use instrument for measuring thermal conductivity

The FOX 314 Heat Flow Meter is an accurate, easy-to-use instrument for measuring thermal conductivity according to ASTM C518 and ISO 8301. Operating in standalone or PC-controlled configurations, the FOX Heat Flow Meter provides rapid, accurate results. The instrument features proprietary thin film heat flux transducers, digital thickness measurements and responsive temperature control. The FOX 314 is a versatile instrument and is especially well-suited to measuring slices of cellular plastics.

- Conforms to ASTM C518 and ISO 8301

- Easy-to-use, rapid results

- Stand-alone or PC-based operation

- Solid state cooling/heating

- Thickness measurement to 0.025 mm

- Two Thin-Film Heat Flux Transducers

- Suitable for R&D and QC testing

- WinTherm software extends flexibility

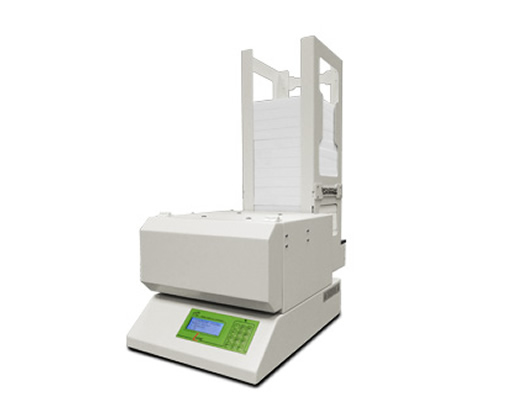

- Available Autosampler for unattended high-throughput productivity

Statistics Sheet for FOX314

FOX 314 models in their different configurations comply with ASTM C518, ISO 8301, ASTM 1784, EN 12664, and JIS A 1412 Standards.

| Maximum Sample Thickness | 102mm (4″) |

| SampleSize | 305 x 305mm (12 sq. in.) |

| Temperature Range | -20 °C to 75 °C |

| Temperature Control Accuracy | ±0.01 °C |

| Accuracy | ±1% |

| Reproducibility | ±0.5% |

| Thermal Conductivity Range | 0.005 to 0.35 W/m K

(0.035 to 2.4 BTU in/hr ft2 °F) up to 2.5 W/m K |

| Heat Flux Transducers Area | 100 x 100mm (4 sq. in.) |

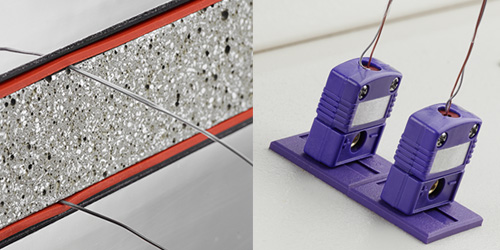

| Available Options | Autosampler

External Thermocouple Kit |

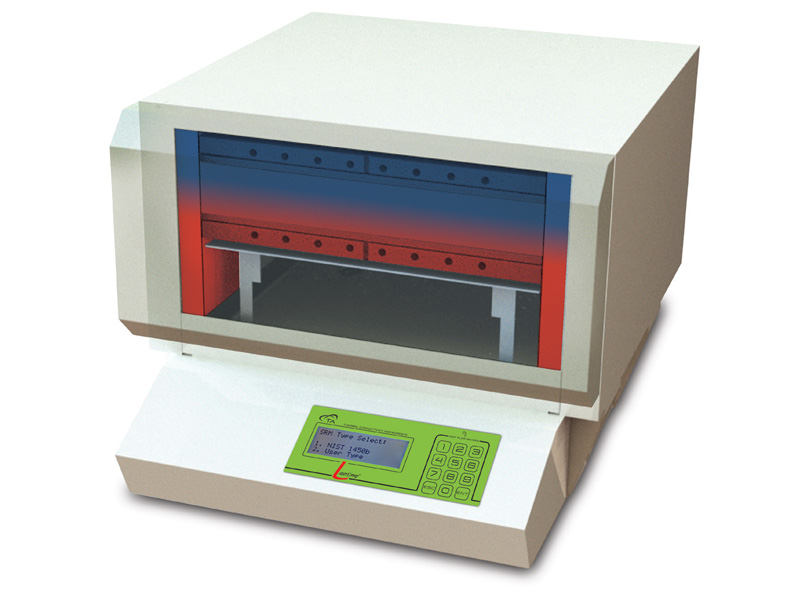

Measurement Technique

Measurement Technique

Samples are placed between two plates in the test stack and a temperature gradient is established over the thickness of the material. The plates may be positioned either to a user-defined thickness, or using AutoThickness, in which the instrument automatically moves to establish contact with the sample. In-situ sample thickness is measured with four optical encoders, one at each corner of the plate, providing stable measurements to within 0.025 mm.

Advanced Heat Flux Measurement

Advanced Heat Flux Measurement

At the heart of the measurement is the LaserComp Heat Flux Transducer, designed and manufactured specifically and exclusively for thermal conductivity measurements. The Heat Flux Transducer integrates over the entire active area (100 x 100mm/ 4 sq. in.) to provide a truly representative measurement of the total heat flow. Overall transducer thickness is less than 1 mm, precluding heat flow distortion. A type E thermocouple is bonded in the center of each transducer and both are sealed to ensure consistent precision over the life of the instrument. Because each thermocouple is positioned within 0.1 mm of the sample surface, they provide truly representative readings of the sample’s surface temperature (± .01 °C resolution) and heat flux. The same thermocouples are also used for plate temperature control.

Using the External Thermocouple Option, thermocouples can be attached directly to the sample surfaces for enhanced single-run accuracy for with higher thermal conductivity samples. Auxiliary outlets on the instrument are provided for the thermocouples with this option.

Precision Temperature Control

Precision Temperature Control

The FOX series Heat Flow Meters achieve accurate, stable thermal equilibrium quickly through a combination of intimate sample temperature measurement, low mass solid state elements and advanced temperature control electronics.

Plate temperature control is based on the same responsive thermocouples in close sample contact as are used for the sample heat flux measurement. An advanced temperature control algorithm monitors the plate temperatures 20 times per second and rapidly brings the system to the selected equilibrium test condition. Plate temperature is controlled to within 0.01 °C by a digital signal processor. A multistage PID algorithm ensures temperature control which is responsive, stable, and prevents set-point overshoot. To achieve this, heater power output from the solid state elements is adjusted every 0.5 s.

Both the top and bottom plates can be heated or cooled, allowing for testing with heat flow up or down. The low thermal mass design of the plates combined with the power of the DSP and power output board enable extremely fast attainment of set-points.

Complete Thermal Conductivity Solution

Complete Thermal Conductivity Solution

The FOX series Heat Flow Meters can be operated as either stand-alone instruments, or coupled to a PC for test set-up and data storage. The WinTherm software package is a user-friendly tool for setting experimental parameters, viewing real-time test results, storing, and analyzing data. In either operational mode, the instrument electronics detect equilibrium according to defined conditions, automatically proceeding to the next programmed measurement temperature after a final value is collected. Specific heat measurements are also available, with data collection and calculation guided by the WinTherm software.

Automatic Sample Feeder

Automatic Sample Feeder

The Automatic Sample Feeder (ASF) is mounted to the back of the instrument and is controlled directly by the WinTherm Instrument Control Software. The ASF automatically loads and unloads up to 20 standard size samples (stack height 500 mm). Additional samples can be added while a test is in progress.

External Thermocouple Kit

External Thermocouple Kit

Thermocouples are attached directly to the sample surfaces, eliminating the impact of interface resistance, and improving the measurement accuracy for higher thermal conductivity samples (up to 2.5 W/m K). External thermocouples are placed in contact with the sample or placed in grooves machined in rigid specimens. Instruments configured for this option feature auxiliary outlets for the external thermocouples.

Linear Gradient Guard

Linear Gradient Guard

The FOX 304 is a specialized configuration of the FOX 314 that includes a Linear Gradient Guard. This provides an active thermal guarding system on all four sides of the plates, precluding distortions in results due to edge heat loss or gain when testing thick samples. This minimizes dependence of calibration factor on thickness, decreases the time to thermal equilibrium, and improves accuracy of tests for very thick samples.