This product is no longer available.You may be interested in our FOX 200HT if you need a high temperature range option or check out our FOX 600 if you are looking to test larger samples. We also encourage you to Contact Us so we can discuss your application and help you determine the solution that best meets your needs.

The most intuitive solution to test materials in accordance with international standard test methods ASTM C177, ISO 8302, and EN 12667.

<< View all Thermal Diffusivity & Conductivity Meters

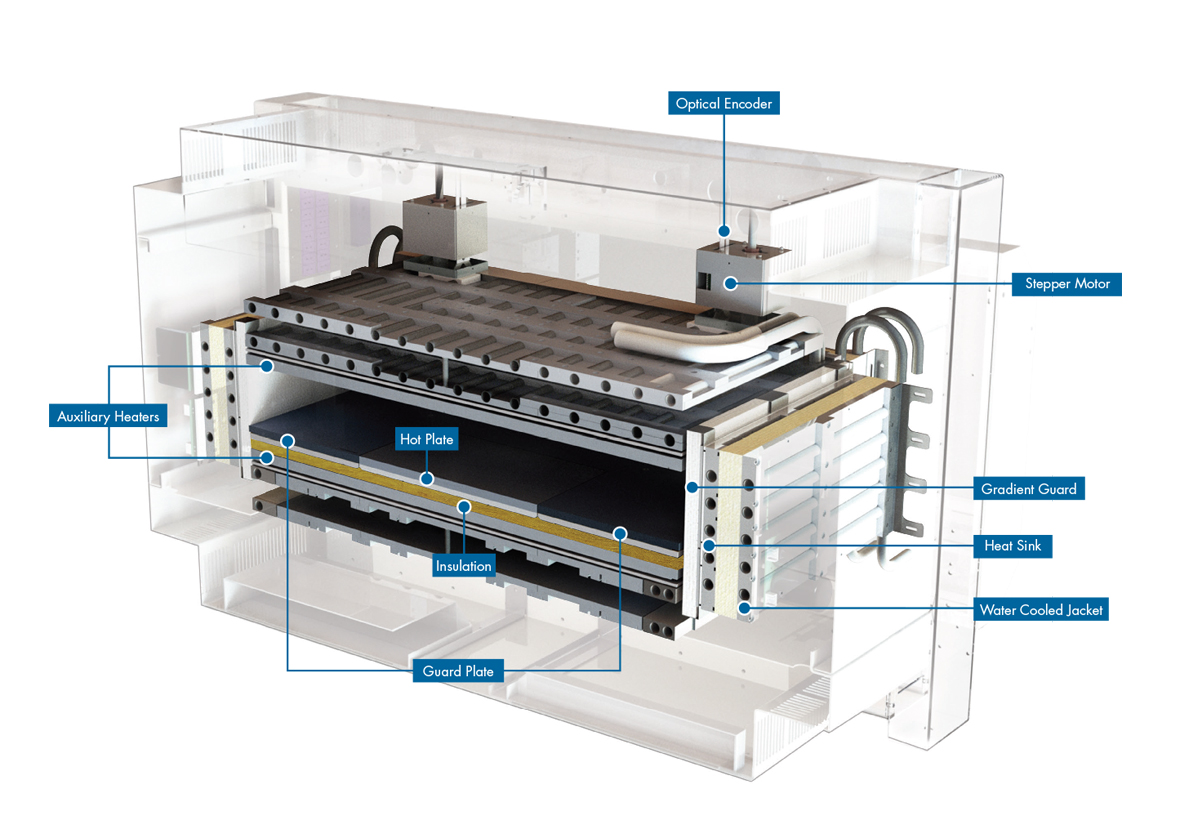

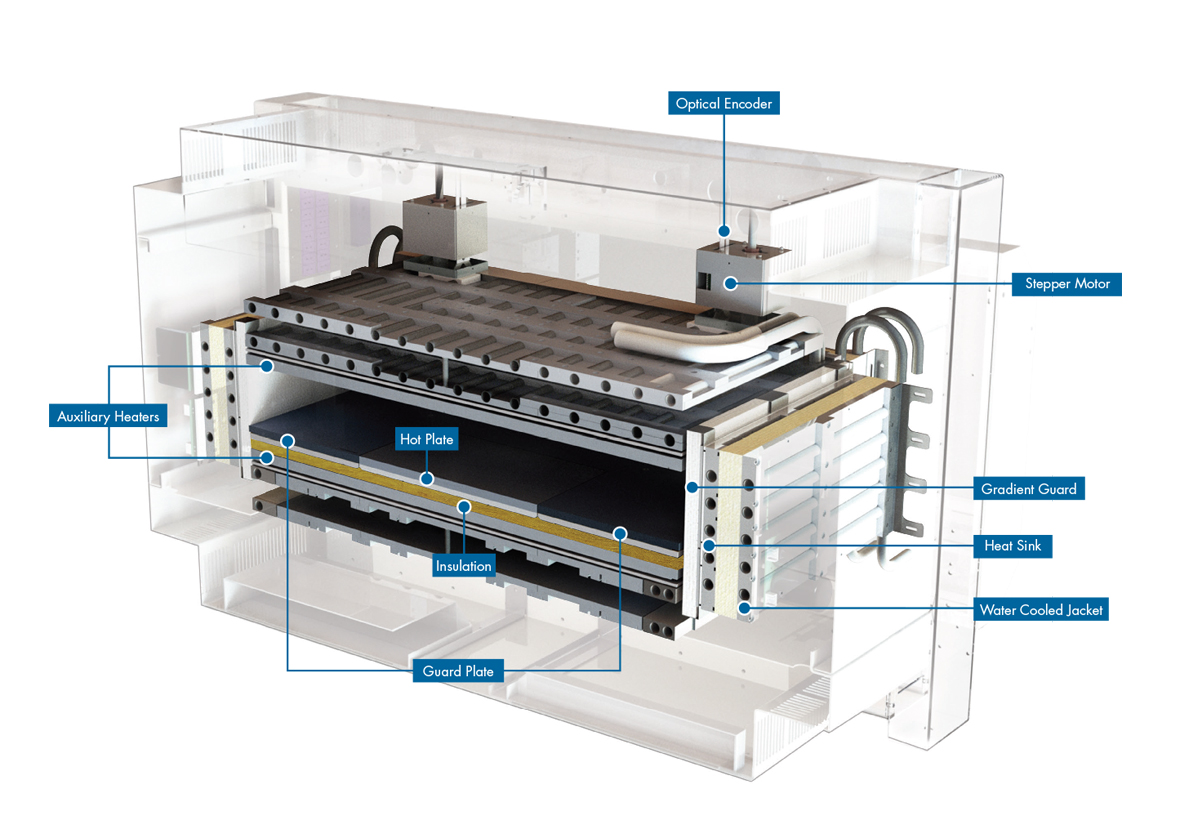

The FOX 600 GHP is especially well-suited for thermal conductivity measurements at high temperatures, exhibiting unrivaled temperature and dimensional stability. Each of its components include state-of-art technology representing the best available in today’s advanced materials and electronics.

In a Guarded Hot Plate system, a temperature difference (ΔT) is established across a sample of known thickness (L). The thermal conductivity is calculated from the temperature difference across the known thickness and the steady state power (W) per area (A) required to maintain the temperature difference. The Guarded Hot Plate uses a direct measurement of the electrical power supplied to the hot plate rather than heat flow meter signals from a Heat Flux Transducer.

Using an advanced single-sample test method, 600 GHP allows for fast cycle time yet guarantees accuracy, is easy to use, and provides stable, uniform temperature control. Using independently controlled heaters and matched thermocouples, it guarantees a homogeneity of ±0.02 °C across the entire sample. Signals are evaluated every 0.7 sec to rapidly bring the system to the selected temperatures and achieve/maintain equilibrium.

As with all FOX family instruments, the 600 GHP features optical encoders and stepper motors for independent position control and measurement at all four plate corners. This capability significantly reduces the sample preparation process, so the system can level the plates to conform to samples with non-parallel surfaces, improving thermal contact and providing a truly representative measurement of sample thickness to within 0.025 mm.

From the cutting-edge Heat Sinks to the revolutionary design of the Hot Plate, including its unique Guards, a 600 GHP is unquestionably the most advanced GHP on the market today.

FOX 600 GHP Specifications

| International Standards | ASTM C177-10, ISO 8302: 1991, EN 12667 |

| Temperature Range | 0°C – 75°C (32°F – 167°F) 25°C – 250°C (75°F – 482°F) |

| Thermal Conductivity Range | 0.0015 W/m•K to 0.35 W/m • K |

| Conductance | Up to 12 W/m2•°C |

| Test Configuration | Single-sample |

| Thickness Resolution | 0.025 mm |

| Sample Width | 610mm (24’’) square |

| Sample Thickness | up to 76mm (3’’) |

| Temperature Stability | ±0.02 °C |

| Accuracy | Better than 1% |

| Reproducibility | ±0.5% |

Single-Sample Advantages

Single-Sample Advantages

The LaserComp FOX GHP 600 employs an advanced single-sample configuration that greatly enhances accuracy, is easy to use, and eliminates the requirement to produce two identical test specimens.

Vertically Directed Heat Flow

Vertically Directed Heat Flow – Guaranteed

Our proprietary single-sample design guarantees uniform, unidirectional heat flow. A block of insulation is placed below the Hot Plate, with a temperature-controlled heater below. The auxiliary heater employs a high-output thermopile to precisely match the lower plate temperature to the Hot Plate temperature, creating a null temperature difference eliminating heat flow in the downward direction. All heat from the Hot Plate flows upward through the sample.

Superior Temperature Stability

Superior Temperature Stability and NO Lateral Heat Flow

Lateral heat flow is eliminated from the test specimen and all three plates in order to produce absolute thermal uniformity and truly one-dimensional heat flow. The Hot Plate is decoupled from the surroundings by an innovative low thermal conductivity fastening system.

Actively heated guard plates, gradient guards, and actively cooled heat sinks provide lateral temperature uniformity, and internal temperature stability over a wide temperature range, and despite changing laboratory conditions.

Uniform Temperature on both sample surfaces

Uniform Temperature on both sample surfaces

The GHP 600 provides stable, uniform temperature control to within ±0.02 °C through the use of 19 independently controlled heaters and 42 matched thermocouples. Signals are evaluated once per second to rapidly bring the system to the selected equilibrium test condition.

Optical Encoders

Optical Encoders deliver the most accurate measurement of sample thickness

Similar to the FOX Heat Flow Meters, the GHP features optical encoders and stepper motors for independent position control and measurement at all four plate corners. This gives the system the ability to level the plates to conform to samples with non-parallel surfaces, improving thermal contact and providing a truly representative measurement of sample thickness to within 25 µm.

Direct measurement of thermal conductivity

Direct measurement of thermal conductivity

In a Guarded Hot Plate system a temperature difference (ΔT) is established across a sample of known thickness (L). Hence the thermal conductivity is calculated directly from the temperature difference across the known thickness and the steady state power (W) per area (A) required to maintain the temperature difference. The Guarded Hot Plate uses a direct measurement of the electrical power supplied to the hot plate rather than heat flow meter signals from a Heat Flux Transducer.

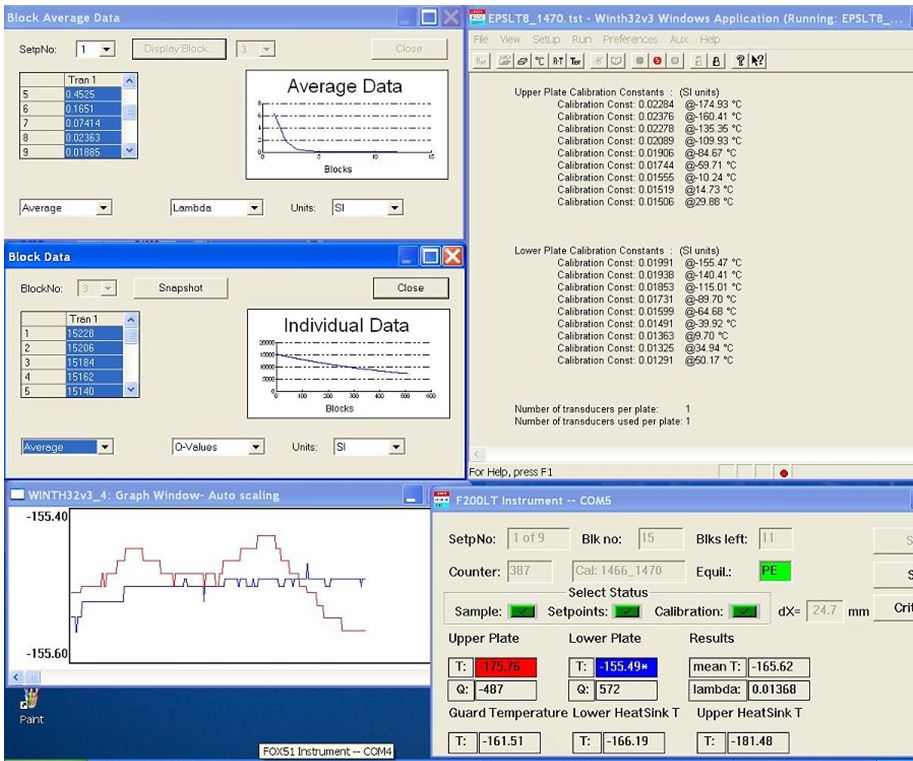

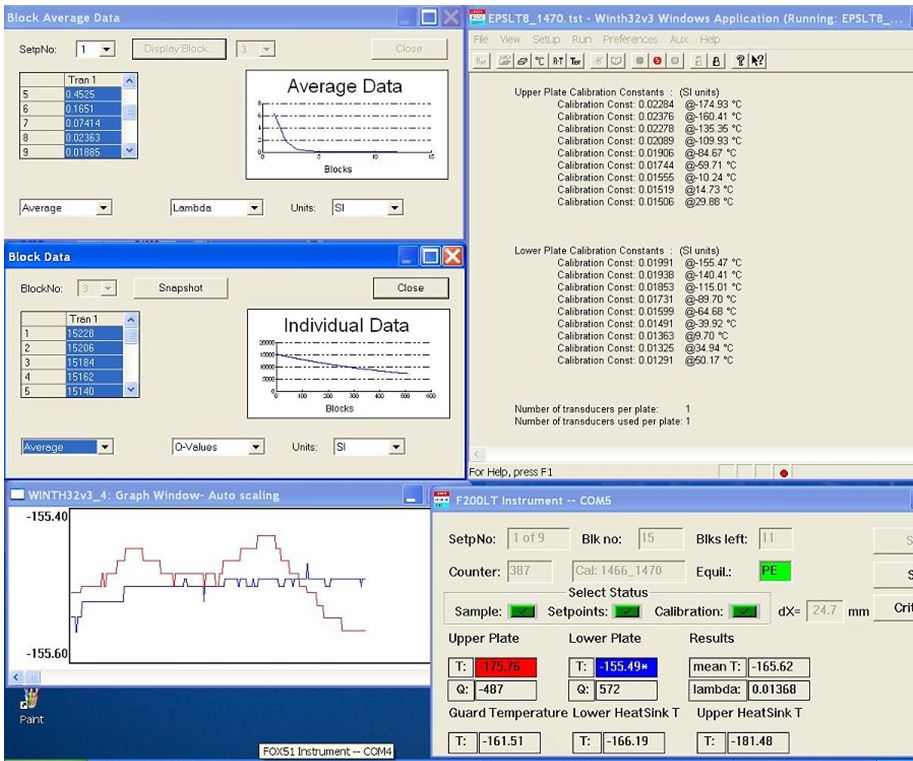

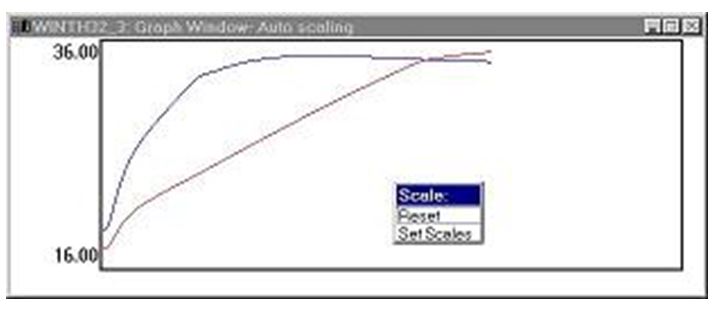

LaserComp continuously develops and improves its software providing updates free of charge.

Test results can be easily transfered to an MS Excel datasheet, including selected parameters. While it offers increased flexibility it still affords the option of running tests quickly and simply.

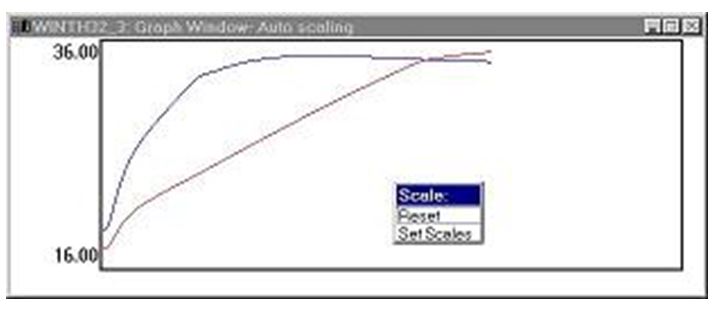

WinTherm Software package operating under Microsoft Windows enables connection of FOX instruments a computer through a standard RS232 or USB interface (optional). The computer can be used solely as a storage device for results, or WinTherm can enable you to operate the instrument entirely from the computer.

Through a series of windows all the test parameters and format of outputs can be setup and changed at any time during the test. The software provides complete control of the instrument at all times. All selected data is automatically stored on a hard disk. Once the test conditions have been set and the test started, the computer can be used to display any desired outputs in a series of windows.

Two FOX instruments can be run simultaneously on one host computer.

- Description

-

The FOX 600 GHP is especially well-suited for thermal conductivity measurements at high temperatures, exhibiting unrivaled temperature and dimensional stability. Each of its components include state-of-art technology representing the best available in today’s advanced materials and electronics.

In a Guarded Hot Plate system, a temperature difference (ΔT) is established across a sample of known thickness (L). The thermal conductivity is calculated from the temperature difference across the known thickness and the steady state power (W) per area (A) required to maintain the temperature difference. The Guarded Hot Plate uses a direct measurement of the electrical power supplied to the hot plate rather than heat flow meter signals from a Heat Flux Transducer.

Using an advanced single-sample test method, 600 GHP allows for fast cycle time yet guarantees accuracy, is easy to use, and provides stable, uniform temperature control. Using independently controlled heaters and matched thermocouples, it guarantees a homogeneity of ±0.02 °C across the entire sample. Signals are evaluated every 0.7 sec to rapidly bring the system to the selected temperatures and achieve/maintain equilibrium.

As with all FOX family instruments, the 600 GHP features optical encoders and stepper motors for independent position control and measurement at all four plate corners. This capability significantly reduces the sample preparation process, so the system can level the plates to conform to samples with non-parallel surfaces, improving thermal contact and providing a truly representative measurement of sample thickness to within 0.025 mm.

From the cutting-edge Heat Sinks to the revolutionary design of the Hot Plate, including its unique Guards, a 600 GHP is unquestionably the most advanced GHP on the market today.

- Specifications

-

FOX 600 GHP Specifications

International Standards ASTM C177-10, ISO 8302: 1991, EN 12667 Temperature Range 0°C – 75°C (32°F – 167°F)

25°C – 250°C (75°F – 482°F)Thermal Conductivity Range 0.0015 W/m•K to 0.35 W/m • K Conductance Up to 12 W/m2•°C Test Configuration Single-sample Thickness Resolution 0.025 mm Sample Width 610mm (24’’) square Sample Thickness up to 76mm (3’’) Temperature Stability ±0.02 °C Accuracy Better than 1% Reproducibility ±0.5% - Technology

-

Single-Sample Advantages

Single-Sample Advantages

The LaserComp FOX GHP 600 employs an advanced single-sample configuration that greatly enhances accuracy, is easy to use, and eliminates the requirement to produce two identical test specimens.

Vertically Directed Heat Flow

Vertically Directed Heat Flow – Guaranteed

Our proprietary single-sample design guarantees uniform, unidirectional heat flow. A block of insulation is placed below the Hot Plate, with a temperature-controlled heater below. The auxiliary heater employs a high-output thermopile to precisely match the lower plate temperature to the Hot Plate temperature, creating a null temperature difference eliminating heat flow in the downward direction. All heat from the Hot Plate flows upward through the sample.

Superior Temperature Stability

Superior Temperature Stability and NO Lateral Heat Flow

Lateral heat flow is eliminated from the test specimen and all three plates in order to produce absolute thermal uniformity and truly one-dimensional heat flow. The Hot Plate is decoupled from the surroundings by an innovative low thermal conductivity fastening system.

Actively heated guard plates, gradient guards, and actively cooled heat sinks provide lateral temperature uniformity, and internal temperature stability over a wide temperature range, and despite changing laboratory conditions.

Uniform Temperature on both sample surfaces

Uniform Temperature on both sample surfaces

The GHP 600 provides stable, uniform temperature control to within ±0.02 °C through the use of 19 independently controlled heaters and 42 matched thermocouples. Signals are evaluated once per second to rapidly bring the system to the selected equilibrium test condition.

Optical Encoders

Optical Encoders deliver the most accurate measurement of sample thickness

Similar to the FOX Heat Flow Meters, the GHP features optical encoders and stepper motors for independent position control and measurement at all four plate corners. This gives the system the ability to level the plates to conform to samples with non-parallel surfaces, improving thermal contact and providing a truly representative measurement of sample thickness to within 25 µm.

Direct measurement of thermal conductivity

Direct measurement of thermal conductivity

In a Guarded Hot Plate system a temperature difference (ΔT) is established across a sample of known thickness (L). Hence the thermal conductivity is calculated directly from the temperature difference across the known thickness and the steady state power (W) per area (A) required to maintain the temperature difference. The Guarded Hot Plate uses a direct measurement of the electrical power supplied to the hot plate rather than heat flow meter signals from a Heat Flux Transducer.

- Software

-

LaserComp continuously develops and improves its software providing updates free of charge.

Test results can be easily transfered to an MS Excel datasheet, including selected parameters. While it offers increased flexibility it still affords the option of running tests quickly and simply.

WinTherm Software package operating under Microsoft Windows enables connection of FOX instruments a computer through a standard RS232 or USB interface (optional). The computer can be used solely as a storage device for results, or WinTherm can enable you to operate the instrument entirely from the computer.

Through a series of windows all the test parameters and format of outputs can be setup and changed at any time during the test. The software provides complete control of the instrument at all times. All selected data is automatically stored on a hard disk. Once the test conditions have been set and the test started, the computer can be used to display any desired outputs in a series of windows.

Two FOX instruments can be run simultaneously on one host computer.