Immobilization cell

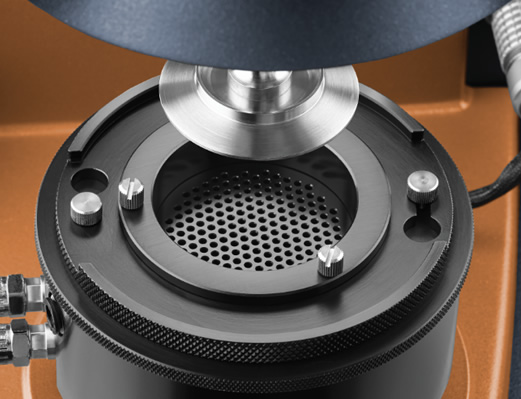

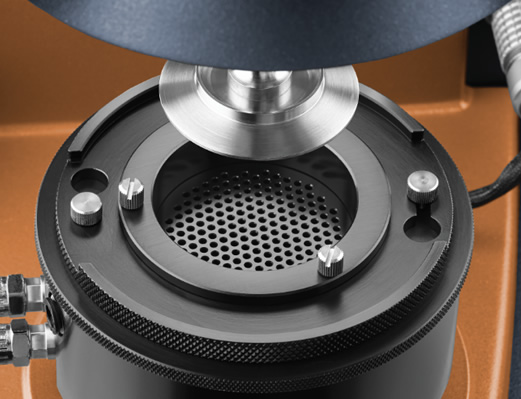

The new Immobilization Cell Accessory for the Discovery Hybrid Rheometer permits the characterization of drying, retention, and immobilization kinetics of paints, coatings and slurries. Solvent is dewatered from the sample through a paper substrate affixed to a perforated lower plate under controlled temperature and vacuum. Rheological changes in the sample during this immobilization process are simultaneously quantified through an oscillatory time sweep test with controlled axial force. Solid state Peltier heating and cooling provides faster, more stable temperature control, and is easier to use than competitive designs that rely on liquid-based temperature control. The DHR Immobilization Cell is a Smart Swap™ system that is extremely easy to install, use, and clean.

Technology

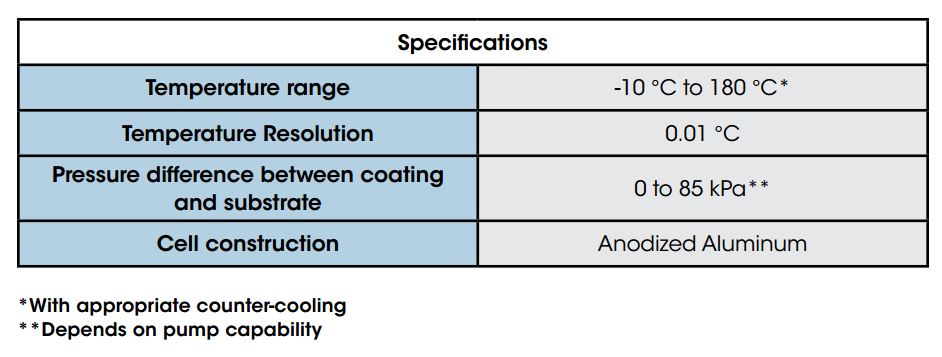

The Immobilization Cell accessory consists of a temperature-controlled jacket, a perforated platform and substrate clamping ring. Peltier temperature control provides stable, responsive control without a refrigerated circulator. A manifold to control the vacuum and collect waste is connected to the cell. The system is used in conjunction with an upper 50 mm parallel plate geometry.

Features and Benefits

- Smart Swap™ technology for quick installation

- Peltier temperature control

- Easy sample cleaning

- Replaceable sieve

- Software-controlled vacuum trigger

- Controlled-stress, -strain, and -rate operation

Characterization of Paint drying

Characterization of Paint drying

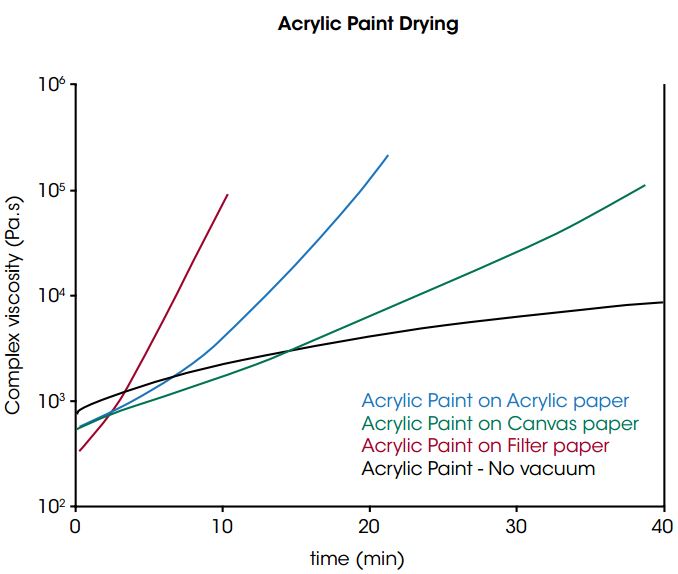

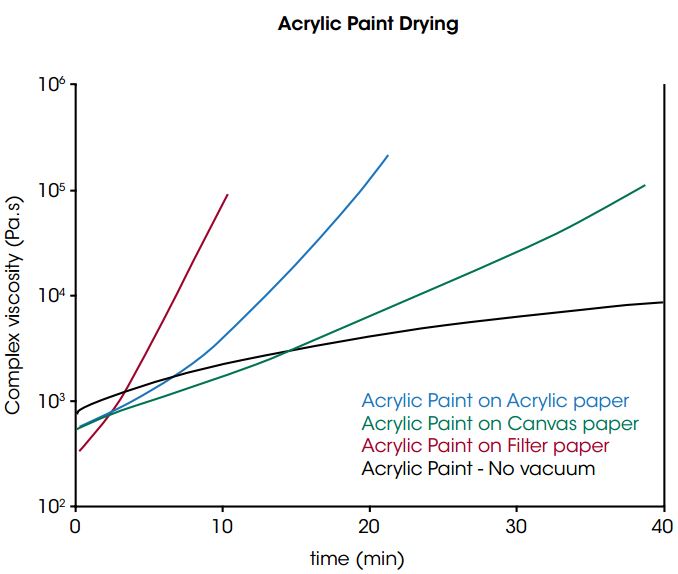

The drying characteristics of an acrylic paint formulation coated onto various paper substrates are illustrated in the figure to the right. With no vacuum applied the acrylic paint dries slowly, as indicated by the gradual increase in complex viscosity. When full vacuum is applied there is an initial decrease in the complex viscosity followed by continuous drying and an associated increase in viscosity. The rate at which drying or settling occurs depends on the particulate properties of the paint, the porosity and density of the substrate, and more.

- Description

-

Immobilization cell

The new Immobilization Cell Accessory for the Discovery Hybrid Rheometer permits the characterization of drying, retention, and immobilization kinetics of paints, coatings and slurries. Solvent is dewatered from the sample through a paper substrate affixed to a perforated lower plate under controlled temperature and vacuum. Rheological changes in the sample during this immobilization process are simultaneously quantified through an oscillatory time sweep test with controlled axial force. Solid state Peltier heating and cooling provides faster, more stable temperature control, and is easier to use than competitive designs that rely on liquid-based temperature control. The DHR Immobilization Cell is a Smart Swap™ system that is extremely easy to install, use, and clean.

- Technology

-

Technology

The Immobilization Cell accessory consists of a temperature-controlled jacket, a perforated platform and substrate clamping ring. Peltier temperature control provides stable, responsive control without a refrigerated circulator. A manifold to control the vacuum and collect waste is connected to the cell. The system is used in conjunction with an upper 50 mm parallel plate geometry.

- Features

-

Features and Benefits

- Smart Swap™ technology for quick installation

- Peltier temperature control

- Easy sample cleaning

- Replaceable sieve

- Software-controlled vacuum trigger

- Controlled-stress, -strain, and -rate operation

- Applications

-

Characterization of Paint drying

Characterization of Paint drying

The drying characteristics of an acrylic paint formulation coated onto various paper substrates are illustrated in the figure to the right. With no vacuum applied the acrylic paint dries slowly, as indicated by the gradual increase in complex viscosity. When full vacuum is applied there is an initial decrease in the complex viscosity followed by continuous drying and an associated increase in viscosity. The rate at which drying or settling occurs depends on the particulate properties of the paint, the porosity and density of the substrate, and more.