Interfacial Exchange Cell

The Interfacial Exchange Cell expands TA Instruments’ patented offerings for interfacial rheology by providing the ability to directly manipulate the composition of the lower liquid layer (subphase) during rheological measurements. This unique capability enables the characterization of the interfacial response to a modified subphase composition, opening possibilities for quantifying the effects of changes in pH, salt, or drug concentration, or the introduction of new proteins, surfactants, or other active ingredients

Technology

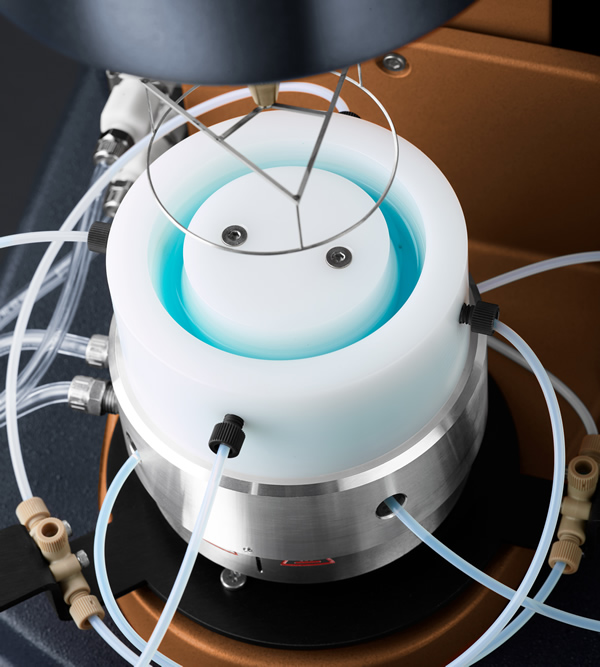

The Interfacial Exchange Cell consists of three key components – the Double Wall Ring geometry, an exchange cell trough with inlet and outlet ports, and a computer-controlled syringe pump. The cell design, based on computational fluid dynamic simulations by Schroyren et. al. (1), is optimized to maximize compositional uniformity while maintaining a constant interfacial height and minimize the stress at the interface from pumping fluid into the cell.

(1) Schroyen et. al., Rheologica Acta, Volume 56, Issue 1, pp1-10

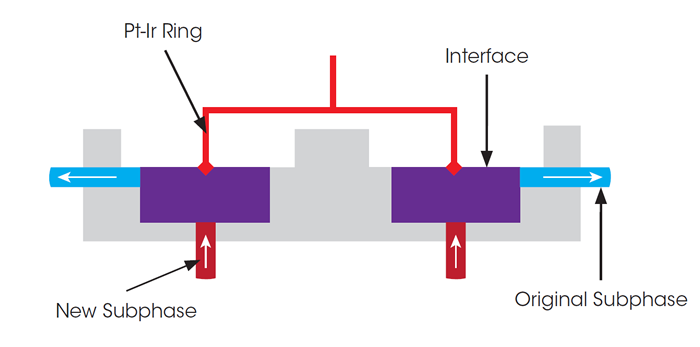

Exchange Cell Trough

Exchange Cell Trough

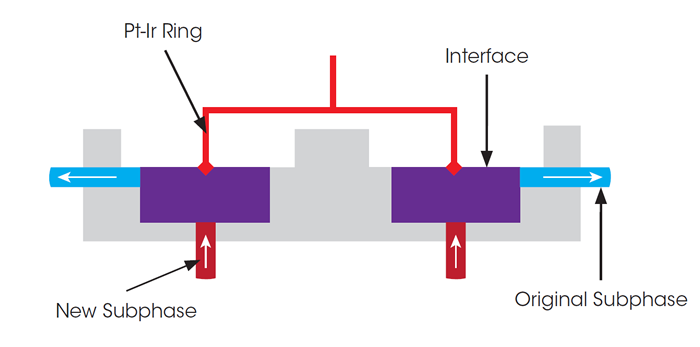

The specially-designed double wall interfacial trough (2) features strategically placed fluid inlet and outlet ports to exchange the subphase during a rheological measurement. During the experiment, the new subphase is introduced through four ports located at the bottom of the cell while the same volume is simultaneously removed through four ports located just below the fluid/fluid interface. This concurrent exchange and the balanced trough design ensures uniform infusion and withdrawal guaranteeing a constant subphase volume and interface location throughout the test.

(2) U.S. Patent # 7,926,326

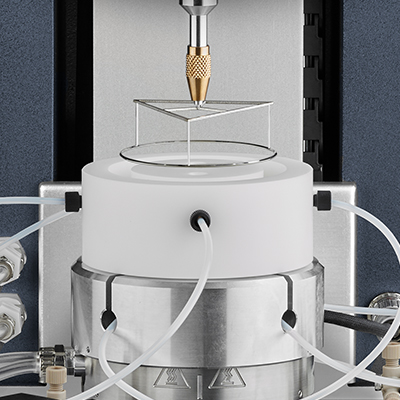

Double Wall Ring

Double Wall Ring

Double Wall Ring

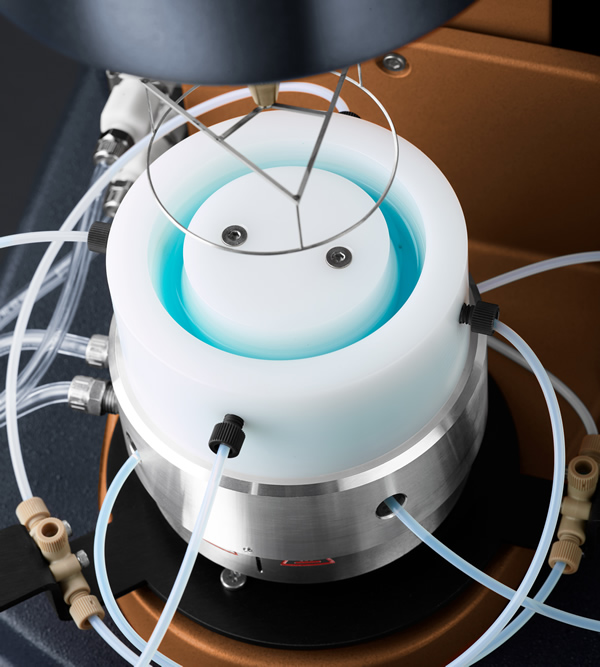

The Interfacial Exchange Cell uses the ultra-low inertia Double Wall Ring (DWR) as the measuring geometry. Featuring a large diameter and a diamond shaped cross-section to “pin” the interface to the ring, the DWR is the preferred platform for sensitive, quantitative interfacial rheology data.

Syringe Pump

Syringe Pump

The subphase exchange is precisely executed by a simultaneous infuse/withdraw syringe pump that is directly controlled and programmed through TRIOS software. A pair of syringes at each side allow for a complete and uniform exchange of the subphase volume while maintaining a constant interfacial height. At a representative 6 mL/min flow rate, the subphase volume inside the cell can be completely exchanged within 8 minutes.

Applications

Applications

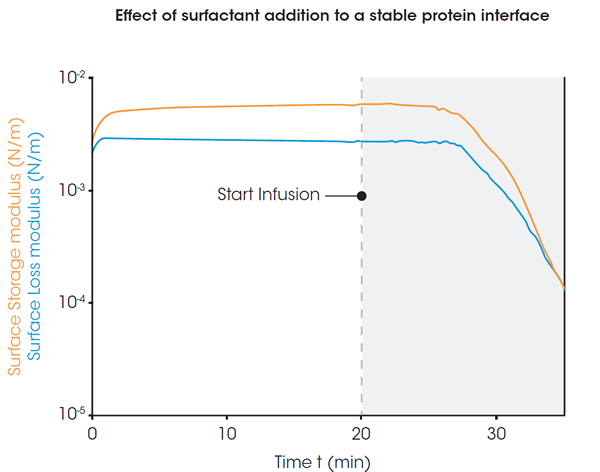

Controlled Infusion of Soap Solution

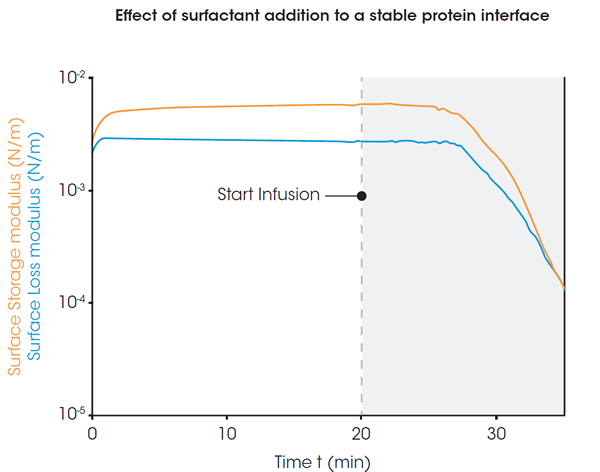

The interfacial strength of a protein network adsorbed at an oil/water interface can be affected by factors such as the pH, salt concentration, and presence of surfactants. In this example, a strong and stable network of bovine serum albumin was formed at the interface between a phosphate-buffered saline solution and dodecane.

Next, the buffer solution in the subphase was exchanged with a very dilute soap solution. Within minutes after the infusion of the soap solution, the interfacial moduli drop several orders of magnitude, reflecting a dramatic destruction of the protein interface. The introduction of the surfactant lowers the surface tension and displaces protein molecules from the interface. Over time, the continued accumulation of surfactant at the interface brings about the catastrophic destruction of the original protein interface through an orogenic displacement or phase separation processes

Resources

“A versatile subphase exchange cell for interfacial shear rheology”, B. Schroyen, D. Z. Gunes, J. Vermant, Rheologica Acta, 2017, Volume 56 (1), pp 1-10

Webinar: Interfacial Rheology by Prof. Gerry Fuller, Stanford University

- Description

-

Interfacial Exchange Cell

The Interfacial Exchange Cell expands TA Instruments’ patented offerings for interfacial rheology by providing the ability to directly manipulate the composition of the lower liquid layer (subphase) during rheological measurements. This unique capability enables the characterization of the interfacial response to a modified subphase composition, opening possibilities for quantifying the effects of changes in pH, salt, or drug concentration, or the introduction of new proteins, surfactants, or other active ingredients

- Technology

-

Technology

The Interfacial Exchange Cell consists of three key components – the Double Wall Ring geometry, an exchange cell trough with inlet and outlet ports, and a computer-controlled syringe pump. The cell design, based on computational fluid dynamic simulations by Schroyren et. al. (1), is optimized to maximize compositional uniformity while maintaining a constant interfacial height and minimize the stress at the interface from pumping fluid into the cell.

(1) Schroyen et. al., Rheologica Acta, Volume 56, Issue 1, pp1-10

Exchange Cell Trough

Exchange Cell Trough

The specially-designed double wall interfacial trough (2) features strategically placed fluid inlet and outlet ports to exchange the subphase during a rheological measurement. During the experiment, the new subphase is introduced through four ports located at the bottom of the cell while the same volume is simultaneously removed through four ports located just below the fluid/fluid interface. This concurrent exchange and the balanced trough design ensures uniform infusion and withdrawal guaranteeing a constant subphase volume and interface location throughout the test.

(2) U.S. Patent # 7,926,326

Double Wall Ring

Double Wall Ring

Double Wall RingThe Interfacial Exchange Cell uses the ultra-low inertia Double Wall Ring (DWR) as the measuring geometry. Featuring a large diameter and a diamond shaped cross-section to “pin” the interface to the ring, the DWR is the preferred platform for sensitive, quantitative interfacial rheology data.

Syringe Pump

Syringe Pump

The subphase exchange is precisely executed by a simultaneous infuse/withdraw syringe pump that is directly controlled and programmed through TRIOS software. A pair of syringes at each side allow for a complete and uniform exchange of the subphase volume while maintaining a constant interfacial height. At a representative 6 mL/min flow rate, the subphase volume inside the cell can be completely exchanged within 8 minutes.

- Applications

-

Applications

ApplicationsControlled Infusion of Soap Solution

The interfacial strength of a protein network adsorbed at an oil/water interface can be affected by factors such as the pH, salt concentration, and presence of surfactants. In this example, a strong and stable network of bovine serum albumin was formed at the interface between a phosphate-buffered saline solution and dodecane.

Next, the buffer solution in the subphase was exchanged with a very dilute soap solution. Within minutes after the infusion of the soap solution, the interfacial moduli drop several orders of magnitude, reflecting a dramatic destruction of the protein interface. The introduction of the surfactant lowers the surface tension and displaces protein molecules from the interface. Over time, the continued accumulation of surfactant at the interface brings about the catastrophic destruction of the original protein interface through an orogenic displacement or phase separation processes

- Resources

-

Resources

“A versatile subphase exchange cell for interfacial shear rheology”, B. Schroyen, D. Z. Gunes, J. Vermant, Rheologica Acta, 2017, Volume 56 (1), pp 1-10

Webinar: Interfacial Rheology by Prof. Gerry Fuller, Stanford University