Materials Testing

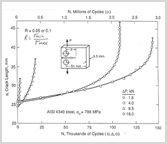

TA ElectroForce test instruments perform a broad range of materials testing tasks. With a product line ranging in capacity from the 22 N Model 3100 system to the 15 kN Model 3550 system. The ElectroForce materials testing product line provides many options for automotive and aerospace material materials testing requirements. These requirements range from simple static tests used to acquire tensile, compressive or bending data, to more complex fatigue and fracture materials testing applications.

TA ElectroForce test instruments perform a broad range of materials testing tasks. With a product line ranging in capacity from the 22 N Model 3100 system to the 15 kN Model 3550 system. The ElectroForce materials testing product line provides many options for automotive and aerospace material materials testing requirements. These requirements range from simple static tests used to acquire tensile, compressive or bending data, to more complex fatigue and fracture materials testing applications.

TA Electroforce low-force systems lend themselves well to the testing of fibers, foils, films, wire, and other automotive and aerospace specimens that require precision control at very low forces or small displacements. The higher force Model 3500 systems provide materials testing capabilities for performing static, fatigue, and fracture mechanics tests on larger specimens and higher strength structural materials without the infrastructure needed with more traditional testing systems.

A multi-purpose TA Electroforce test system using clean servoelectric technology, makes it an excellent choice for the characterization of engineered materials. Proprietary TA Electroforce linear motor technologies provide excellent performance for material tests which require stability such as creep or stress relaxation tests, as well as the bandwidth and precision for fatigue and other dynamic testing applications.