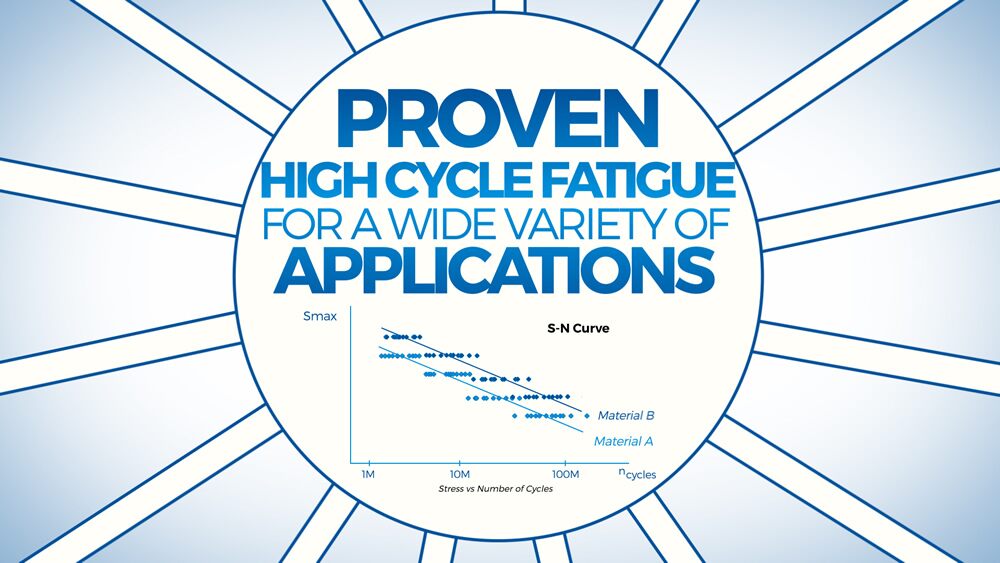

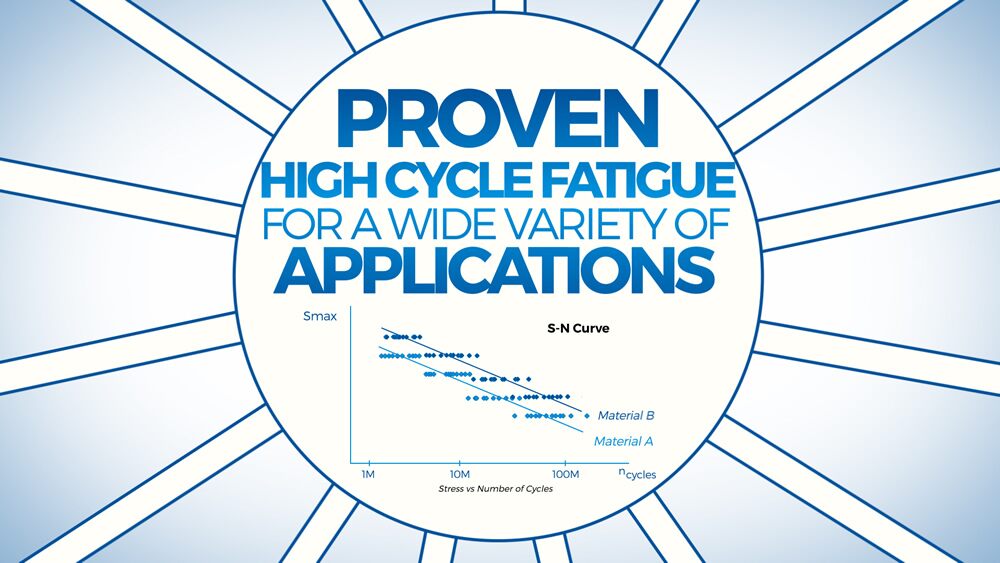

Accelerating high cycle fatigue and durability studies by combining 16 samples of simultaneous loading with industry-leading dynamic performance and instrument reliability.

Sales Promotions

Key Features

- Simultaneous axial fatigue of 16 specimens

- Unparalleled durability and dynamic performance with the patented ElectroForce linear motor technology

- Accelerated testing frequencies up to 100 Hz with unparalleled displacement amplitudes

- Nanometer resolution and 5 micron accuracy displacement sensor

- Independent force measurement for each specimen for real-time independent specimen failure detection

- Individual precision adjustment and locking mechanisms for each specimen

- Auto-fill fluid bath for convenience and stable temperature control from ambient to 45 °C

- Integrated overtravel stop for reliable specimen protection

- Complete visibility of all 16 specimen for easy optical measurements

Multi-Specimen Technology

16-Specimen Capacity

16-Specimen Capacity

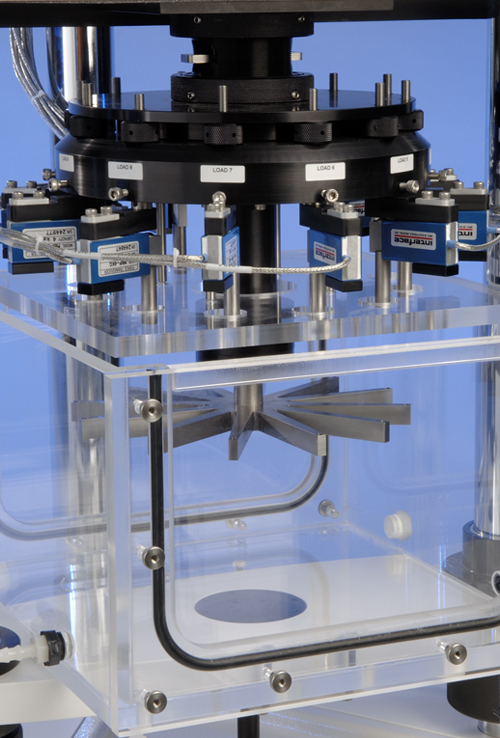

Multiple test specimen sites with up to 100 mm height and 38 mm spacing between specimens are driven by a lower spider connected to the upper linear motor. This design effectively transmits the upper motor’s motion to each specimen. Testing can be run using the standard sine waveform or users can define their own motion profiles up to 100 Hz.

High Performance Linear Motor

High Performance Linear Motor

With the highest dynamic capabilities and proven reliability, the ElectroForce linear motor delivers precise and controlled motion to all 16 specimens. Its reliability from frictionless moving magnet design is perfectly suited for the millions to billions of test cycles of demanding accelerated fatigue test programs. This reliability is backed up by the industry’s only 10-year motor warranty.

Independent Force Measurements

Independent Force Measurements

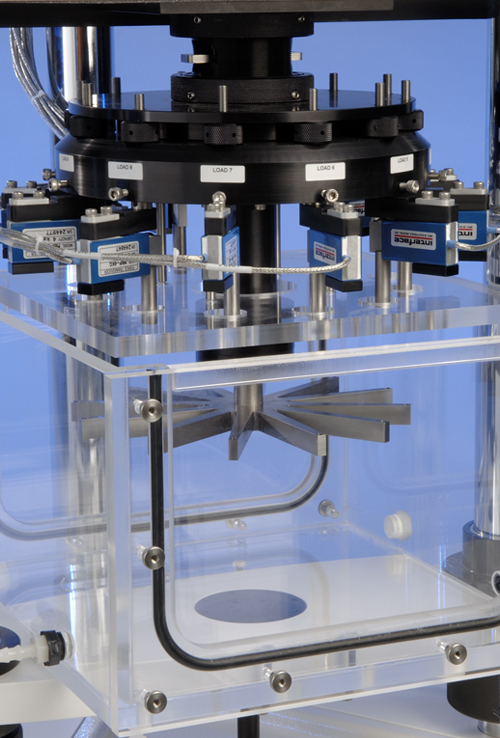

Force sensors are individually connected above each of the 16 specimens. These are monitored by the WinTest test control and acquisition software which records the cycle count of each specimen failure.

Precision Specimen Preload Adjustments

Precision Specimen Preload Adjustments

Each specimen station includes a thumbscrew for adjusting the mean position of the upper specimen attachment point. With 20 mm of travel, precise guidance, and fine threads, users can accurately position each specimen to apply specific mean preloads prior to dynamic testing.

Tool-free Specimen Preload Clamps

Tool-free Specimen Preload Clamps

This novel clamping mechanism allows users to securely clamp each specimen at an adjusted preload. It eliminates the need for external tools and minimizes both vertical and lateral motion during locking.

Mechanical Overtravel Stop

Mechanical Overtravel Stop

This mechanism physically prevents motion beyond desired levels within the full 25 mm range of travel, eliminating unintentional specimen overload and giving the user peace of mind.

Temperature Controlled Fluid Bath

Temperature Controlled Fluid Bath

The temperature-controlled fluid bath enables dynamic testing within fluid environments up to 45 °C. Positioned below the multi-specimen assembly, the bath allows users to lower mounted specimen into fluid prior to test initiation.

Auto-Fill Bath

Auto-Fill Bath

Designed to avoid the inconvenience and temperature variations caused by the user periodically manually refilling the bath during long-term fatigue tests. Upon fluid loss, a float valve releases fluid into the rear auxiliary bath and slowly gravity fed into the main bath preventing temperature fluctuations which may adversely affect temperature-sensitive specimens.

Accessible and Viewable Samples

Accessible and Viewable Samples

Each of the 16 specimens are positioned to avoid obstruction by the columns of the test frame. This makes both test setup and optical monitoring easy and free from this obstruction.

Convenient Specimen Fixture Mounting

Convenient Specimen Fixture Mounting

Each site includes an upper and lower threaded connection for user-designed fixturing. Detailed drawings, including these attachment points, are provided to the user upon purchase.

3300 Series III Load Frame

3300 Series III Load Frame

The MSF16 configuration is built upon the industry leading 3300 Series III instrument and load frame. MSF16 users enjoy multiple user conveniences such as electric lifts, tool-free locks and system status indicator lights. When desired, the MSF 16 accessory can be removed to leverage the single-specimen test capabilities of the stand alone 3,000 N and 25 mm ElectroForce 3330 instrument.

Motor Technology

Reliable testing

Reliable testing

- 10-year ElectroForce® motor warranty

- ElectroForce motor designed, developed and manufactured by TA Electroforce to exacting standards

- Frictionless design ensures optimal control and long-life for a variety of durability testing applications

High-fidelity, responsive control

High-fidelity, responsive control

- Accurate control and high-resolution performance provides more precise material properties

- Very low motor moving-mass provides industry leading frequency response

Clean, electromagnetic technology

Clean, electromagnetic technology

- Standard ElectroForce® systems can be used in clean rooms or incubators for exceptional versatility

- Efficient electromagnetic power conversion is well-suited for a variety of test environments

Energy-efficient technology

Energy-efficient technology

- Efficient power utilization reduces operating costs

- Lab-friendly instruments and easy installation allows testing to start immediately

- No expensive infrastructure or contamination – saves upfront costs and operating expense

Software Technology

Easy-to-use, flexible software

Easy-to-use, flexible software

- Test setup and status window to guide users

- Customizable windows and views

- Intuitive and configurable test setup

- Multiple test monitoring sources

Direct control over your data

Direct control over your data

- Customizable and flexible data collection

- Control of data acquisition before and during the test

- Data is stored even if test stops unexpectedly

Real-time test parameter control

Real-time test parameter control

- Adjust waveforms in real-time

- No need to stop test to reconfigure major test parameters

Security and history tracking

Security and history tracking

- User login for added security

- Secure workspace with audit trail traceability

- File system security to protect test files

3330 MSF16 with 40 N Force Sensors

3330 MSF16 with 40 N Force Sensors

3,000 N Electrodynamic Motor with 25 mm travel and 40 N Force Sensors.

The 40 N force sensors offer lower levels of force measurement but tolerate less fixture mass than the 100 N configuration. Recommended for specimen fixture masses less than 20 grams.

3330 MSF16 with 100 N Force Sensors

3330 MSF16 with 100 N Force Sensors

3330 MSF16 with 100 N Force Sensors

3,000 N Electrodynamic Motor with 25 mm travel and 100 N Force Sensors.

The 100 N force sensors accommodate more force and more specimen fixture mass than the 40 N sensor configuration with slight trade-off of minimum force measurement. Recommended for specimen fixture masses less than 75 grams.

| Specifications | 3330 MSF16 with 40 N Sensors | 3330 MSF16 with 100 N Sensors |

| Number of Samples | 16 | 16 |

| Force Range (per sample) | 0.2 – 40 N | 0.5 – 100 N |

| Displacement Range | 0.005 – 25 mm | 0.005 – 25 mm |

| Maximum Test Frequency | 0.00001 to 100 Hz | 0.00001 to 100 Hz |

| Fluid Bath Temperature Range | Ambient to 45 °C | Ambient to 45 °C |

| Instrument Dimensions (HxWxD) | 1283 x 686 x 555 mm (50.5 x 27 x 22 in) | 1283 x 686 x 555 mm (50.5 x 27 x 22 in) |

| Instrument Weight | 190 kg (419 lbs) | 190 kg (419 lbs) |

The MSF16 excels at accelerated fatigue and durability studies including, but not limited to, ASTM F3211, F3374, F2942 and D430

- Description

-

TA Instrument’s Multi-Specimen Fatigue Instruments are designed to accelerate fatigue studies for a variety of materials, subcomponents and complete devices. With the capability of simultaneously testing up to 16 specimens at up to 100 Hz, users can generate S/N curves faster and with higher statistical confidence levels than ever before. In this system, proven and refined technologies come together to quickly and confidently deliver results.

Key Features

- Simultaneous axial fatigue of 16 specimens

- Unparalleled durability and dynamic performance with the patented ElectroForce linear motor technology

- Accelerated testing frequencies up to 100 Hz with unparalleled displacement amplitudes

- Nanometer resolution and 5 micron accuracy displacement sensor

- Independent force measurement for each specimen for real-time independent specimen failure detection

- Individual precision adjustment and locking mechanisms for each specimen

- Auto-fill fluid bath for convenience and stable temperature control from ambient to 45 °C

- Integrated overtravel stop for reliable specimen protection

- Complete visibility of all 16 specimen for easy optical measurements

- Technology

-

Multi-Specimen Technology

16-Specimen Capacity

16-Specimen Capacity

Multiple test specimen sites with up to 100 mm height and 38 mm spacing between specimens are driven by a lower spider connected to the upper linear motor. This design effectively transmits the upper motor’s motion to each specimen. Testing can be run using the standard sine waveform or users can define their own motion profiles up to 100 Hz.

High Performance Linear Motor

High Performance Linear Motor

With the highest dynamic capabilities and proven reliability, the ElectroForce linear motor delivers precise and controlled motion to all 16 specimens. Its reliability from frictionless moving magnet design is perfectly suited for the millions to billions of test cycles of demanding accelerated fatigue test programs. This reliability is backed up by the industry’s only 10-year motor warranty.

Independent Force Measurements

Independent Force Measurements

Force sensors are individually connected above each of the 16 specimens. These are monitored by the WinTest test control and acquisition software which records the cycle count of each specimen failure.

Precision Specimen Preload Adjustments

Precision Specimen Preload Adjustments

Each specimen station includes a thumbscrew for adjusting the mean position of the upper specimen attachment point. With 20 mm of travel, precise guidance, and fine threads, users can accurately position each specimen to apply specific mean preloads prior to dynamic testing.

Tool-free Specimen Preload Clamps

Tool-free Specimen Preload Clamps

This novel clamping mechanism allows users to securely clamp each specimen at an adjusted preload. It eliminates the need for external tools and minimizes both vertical and lateral motion during locking.

Mechanical Overtravel Stop

Mechanical Overtravel Stop

This mechanism physically prevents motion beyond desired levels within the full 25 mm range of travel, eliminating unintentional specimen overload and giving the user peace of mind.

Temperature Controlled Fluid Bath

Temperature Controlled Fluid Bath

The temperature-controlled fluid bath enables dynamic testing within fluid environments up to 45 °C. Positioned below the multi-specimen assembly, the bath allows users to lower mounted specimen into fluid prior to test initiation.

Auto-Fill Bath

Auto-Fill Bath

Designed to avoid the inconvenience and temperature variations caused by the user periodically manually refilling the bath during long-term fatigue tests. Upon fluid loss, a float valve releases fluid into the rear auxiliary bath and slowly gravity fed into the main bath preventing temperature fluctuations which may adversely affect temperature-sensitive specimens.

Accessible and Viewable Samples

Accessible and Viewable Samples

Each of the 16 specimens are positioned to avoid obstruction by the columns of the test frame. This makes both test setup and optical monitoring easy and free from this obstruction.

Convenient Specimen Fixture Mounting

Convenient Specimen Fixture Mounting

Each site includes an upper and lower threaded connection for user-designed fixturing. Detailed drawings, including these attachment points, are provided to the user upon purchase.

3300 Series III Load Frame

3300 Series III Load Frame

The MSF16 configuration is built upon the industry leading 3300 Series III instrument and load frame. MSF16 users enjoy multiple user conveniences such as electric lifts, tool-free locks and system status indicator lights. When desired, the MSF 16 accessory can be removed to leverage the single-specimen test capabilities of the stand alone 3,000 N and 25 mm ElectroForce 3330 instrument.

Motor Technology

Reliable testing

Reliable testing

- 10-year ElectroForce® motor warranty

- ElectroForce motor designed, developed and manufactured by TA Electroforce to exacting standards

- Frictionless design ensures optimal control and long-life for a variety of durability testing applications

High-fidelity, responsive control

High-fidelity, responsive control

- Accurate control and high-resolution performance provides more precise material properties

- Very low motor moving-mass provides industry leading frequency response

Clean, electromagnetic technology

Clean, electromagnetic technology

- Standard ElectroForce® systems can be used in clean rooms or incubators for exceptional versatility

- Efficient electromagnetic power conversion is well-suited for a variety of test environments

Energy-efficient technology

Energy-efficient technology

- Efficient power utilization reduces operating costs

- Lab-friendly instruments and easy installation allows testing to start immediately

- No expensive infrastructure or contamination – saves upfront costs and operating expense

Software Technology

Easy-to-use, flexible software

Easy-to-use, flexible software

- Test setup and status window to guide users

- Customizable windows and views

- Intuitive and configurable test setup

- Multiple test monitoring sources

Direct control over your data

Direct control over your data

- Customizable and flexible data collection

- Control of data acquisition before and during the test

- Data is stored even if test stops unexpectedly

Real-time test parameter control

Real-time test parameter control

- Adjust waveforms in real-time

- No need to stop test to reconfigure major test parameters

Security and history tracking

Security and history tracking

- User login for added security

- Secure workspace with audit trail traceability

- File system security to protect test files

- Configurations

-

3330 MSF16 with 40 N Force Sensors

3330 MSF16 with 40 N Force Sensors

3,000 N Electrodynamic Motor with 25 mm travel and 40 N Force Sensors.

The 40 N force sensors offer lower levels of force measurement but tolerate less fixture mass than the 100 N configuration. Recommended for specimen fixture masses less than 20 grams.

3330 MSF16 with 100 N Force Sensors

3330 MSF16 with 100 N Force Sensors

3330 MSF16 with 100 N Force Sensors3,000 N Electrodynamic Motor with 25 mm travel and 100 N Force Sensors.

The 100 N force sensors accommodate more force and more specimen fixture mass than the 40 N sensor configuration with slight trade-off of minimum force measurement. Recommended for specimen fixture masses less than 75 grams.

- Specs.

-

Specifications 3330 MSF16 with 40 N Sensors 3330 MSF16 with 100 N Sensors Number of Samples 16 16 Force Range (per sample) 0.2 – 40 N 0.5 – 100 N Displacement Range 0.005 – 25 mm 0.005 – 25 mm Maximum Test Frequency 0.00001 to 100 Hz 0.00001 to 100 Hz Fluid Bath Temperature Range Ambient to 45 °C Ambient to 45 °C Instrument Dimensions (HxWxD) 1283 x 686 x 555 mm (50.5 x 27 x 22 in) 1283 x 686 x 555 mm (50.5 x 27 x 22 in) Instrument Weight 190 kg (419 lbs) 190 kg (419 lbs) - Applications

-

The MSF16 excels at accelerated fatigue and durability studies including, but not limited to, ASTM F3211, F3374, F2942 and D430

- Resources

- Video

-