Characterize viscoelasticity of materials under flow

Orthogonal Superposition (OSP) provides direct measurements of viscoelasticity under simultaneous shear, for complete characterization of materials throughout all stages of use. This new dimension in rheological testing bridges the gap between oscillation and flow, measuring a material’s viscoelastic behavior under the same shear conditions experienced during critical processes such as mixing, extrusion, dispensing, pouring, pumping or spreading.

The rheology of complex fluids (emulsions, suspensions, gels, pastes and more) is traditionally characterized using either oscillation, or steady shear. Steady shear measures non-Newtonian viscosity over a range of shear rates or stresses, ensuring the sample will flow during processing, dispensing and end use. Oscillatory rheology provides a more information-rich measurement, characterizing the quiescent material’s viscoelastic response, directly resulting from its microstructure.

With OSP, G’, G” and Tan Delta are directly quantified under the same conditions relevant to performance in the field. Measurements of viscoelasticity during flow provide an inside look at shear-induced changes in microstructure, resulting in performance at key stages of use. OSP also offers 2D-SAOS (small amplitude oscillatory shear, in rotational and axial mode) for characterizing anisotropy, or particle orientation under shear. These testing capabilities deliver new insights into the relationship between structure and performance, providing a missing piece in characterizing complex rheological behavior

Features and Benefits

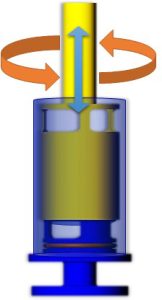

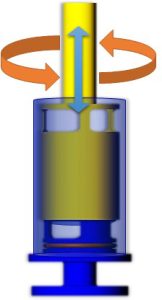

- Directly measure G’, G” and Tan Delta while under shear with precisely controlled axial oscillation from the DHR’s patented magnetic bearing

- Measure changes in shear-sensitive microstructure of complex fluids with the enhanced force sensitivity of the SmartSwap™ OSP Load Cell

- Ensure data accuracy in both rotational and axial measurements, avoiding pumping and surface tension effects, with the specially designed OSP geometry

- Monitor temperature-dependent changes and replicate real-world processing conditions with optional temperature control through the Environmental Test Chamber (-10 °C to 150 °C)

- Easily program OSP and 2D-SAOS experiments and quickly analyze data using powerful TRIOS software

Technology

- Sinusoidal axial deformation is precisely controlled using the DHR’s patented magnetic bearing

- The Smart Swap OSP load cell provides the enhanced force sensitivity necessary for axial oscillatory measurements of liquids

- OSP cup and rotor geometries are optimized for accuracy in both rotational and axial measurements

- Optional temperature control (-10 °C to 150 °C) is available using the Environmental Test Chamber (ETC)

OSP: Characterizing Rheology of Lotion During Use

Steady-shear rheology provides valuable measurements of shear-thinning materials, like lotion and other personal care products. Yet, viscosity measurements lack insight into properties such as consistency and texture, important to the consumer experience. Complete rheological characterization of lotion requires oscillatory measurements of viscoelasticity.

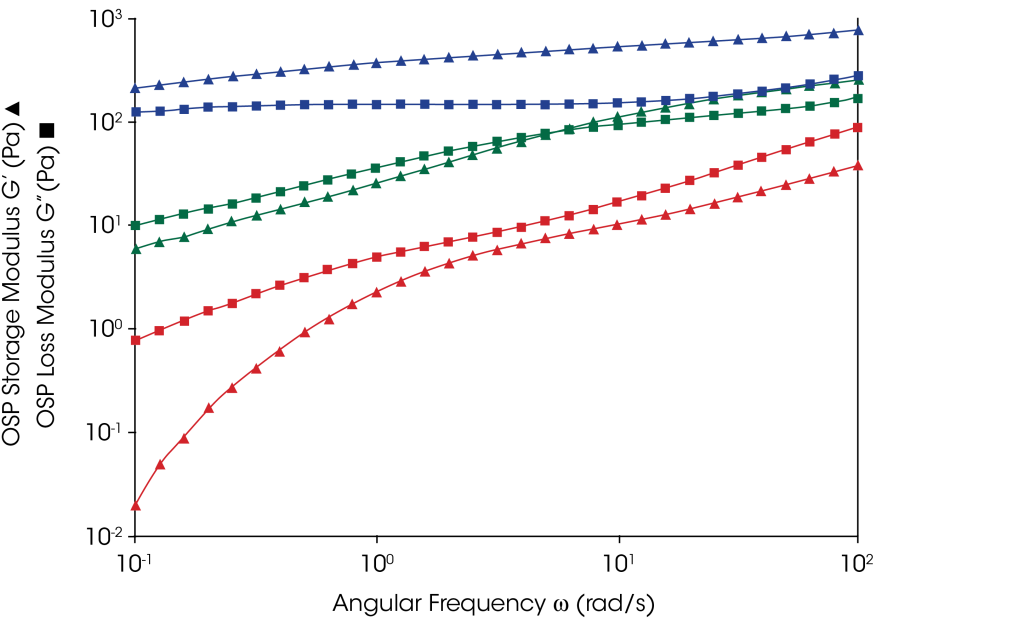

The figure above shows oscillatory frequency sweeps on the lotion, orthogonal to simultaneous shear. The viscoelastic response at each rate reflects the shear-induced change in the emulsion microstructure and the resulting behavior at each stage of use:

– At Rest: The lotion behaves as a “soft solid”; G’ is greater than G”, indicating it does not readily flow. This is beneficial for shelf stability, and easy handling by the consumer.

– Dispensing: At shear rates experienced during pumping or squeezing from a tube, the lotion shows a decrease in G’, indicating less elastic structure. At high frequencies, G’ is greater than G”, reflecting an elasticity that prevents drips during dispensing.

– Spreading: Under higher shear, G’ is greatly decreased and lower than G”, especially at low frequencies. In this state, the lotion is easy to spread, and readily absorbed by the skin.

OSP measurements of lotion go beyond the traditional flow curve, characterizing the rheological behavior most relevant to its performance during use.

- Description

-

Orthogonal Superposition (OSP) provides direct measurements of viscoelasticity under simultaneous shear, for complete characterization of materials throughout all stages of use. This new dimension in rheological testing bridges the gap between oscillation and flow, measuring a material’s viscoelastic behavior under the same shear conditions experienced during critical processes such as mixing, extrusion, dispensing, pouring, pumping or spreading.

The rheology of complex fluids (emulsions, suspensions, gels, pastes and more) is traditionally characterized using either oscillation, or steady shear. Steady shear measures non-Newtonian viscosity over a range of shear rates or stresses, ensuring the sample will flow during processing, dispensing and end use. Oscillatory rheology provides a more information-rich measurement, characterizing the quiescent material’s viscoelastic response, directly resulting from its microstructure.

With OSP, G’, G” and Tan Delta are directly quantified under the same conditions relevant to performance in the field. Measurements of viscoelasticity during flow provide an inside look at shear-induced changes in microstructure, resulting in performance at key stages of use. OSP also offers 2D-SAOS (small amplitude oscillatory shear, in rotational and axial mode) for characterizing anisotropy, or particle orientation under shear. These testing capabilities deliver new insights into the relationship between structure and performance, providing a missing piece in characterizing complex rheological behavior

- Features

-

Features and Benefits

- Directly measure G’, G” and Tan Delta while under shear with precisely controlled axial oscillation from the DHR’s patented magnetic bearing

- Measure changes in shear-sensitive microstructure of complex fluids with the enhanced force sensitivity of the SmartSwap™ OSP Load Cell

- Ensure data accuracy in both rotational and axial measurements, avoiding pumping and surface tension effects, with the specially designed OSP geometry

- Monitor temperature-dependent changes and replicate real-world processing conditions with optional temperature control through the Environmental Test Chamber (-10 °C to 150 °C)

- Easily program OSP and 2D-SAOS experiments and quickly analyze data using powerful TRIOS software

- Technology

-

Technology

- Sinusoidal axial deformation is precisely controlled using the DHR’s patented magnetic bearing

- The Smart Swap OSP load cell provides the enhanced force sensitivity necessary for axial oscillatory measurements of liquids

- OSP cup and rotor geometries are optimized for accuracy in both rotational and axial measurements

- Optional temperature control (-10 °C to 150 °C) is available using the Environmental Test Chamber (ETC)

- Applications

-

OSP: Characterizing Rheology of Lotion During Use

Steady-shear rheology provides valuable measurements of shear-thinning materials, like lotion and other personal care products. Yet, viscosity measurements lack insight into properties such as consistency and texture, important to the consumer experience. Complete rheological characterization of lotion requires oscillatory measurements of viscoelasticity.

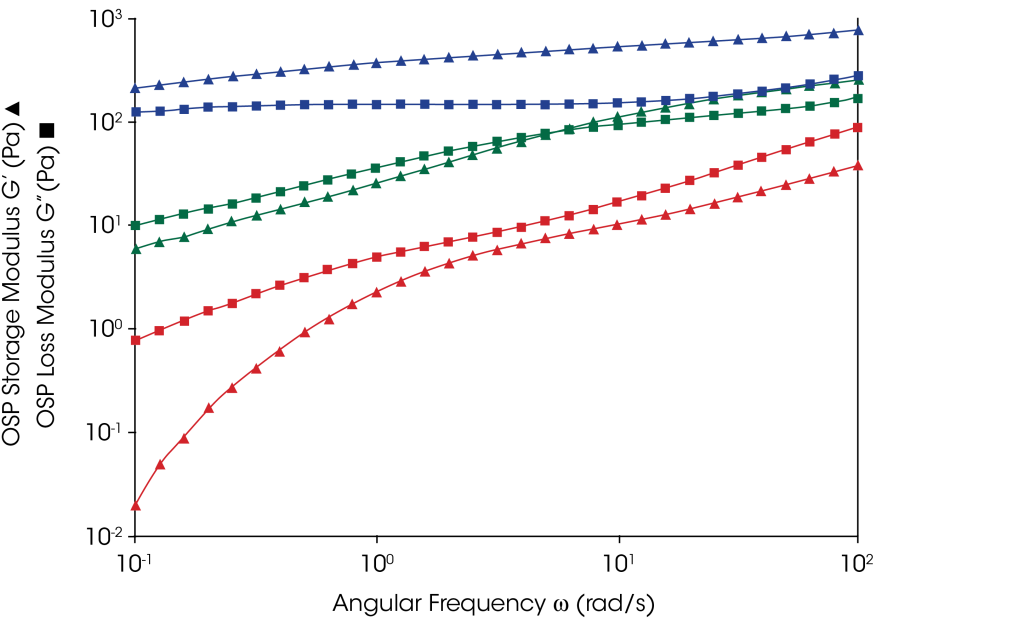

The figure above shows oscillatory frequency sweeps on the lotion, orthogonal to simultaneous shear. The viscoelastic response at each rate reflects the shear-induced change in the emulsion microstructure and the resulting behavior at each stage of use:

– At Rest: The lotion behaves as a “soft solid”; G’ is greater than G”, indicating it does not readily flow. This is beneficial for shelf stability, and easy handling by the consumer.

– Dispensing: At shear rates experienced during pumping or squeezing from a tube, the lotion shows a decrease in G’, indicating less elastic structure. At high frequencies, G’ is greater than G”, reflecting an elasticity that prevents drips during dispensing.

– Spreading: Under higher shear, G’ is greatly decreased and lower than G”, especially at low frequencies. In this state, the lotion is easy to spread, and readily absorbed by the skin.

OSP measurements of lotion go beyond the traditional flow curve, characterizing the rheological behavior most relevant to its performance during use.

- Video

-