The measurement system consists of the sample tube, bearings, and pushrod. Two moveable sample bearings (cutting edges) ensure reliable and frictionless positioning of the sample within the tube. Given the very high temperatures under investigation, considerable care must be taken to prevent chemical or physical interaction between the sample and measurement system. For this reason, several material types are used based on the temperature range of interest and the reactivity of the sample.

Measurement Systems Table

| fused silica | -160°C to 1100°C |

| sapphire | 20°C to 1750°C |

| Al2O3 | 20°C to 1750°C |

| tungsten | 20°C to 2000°C |

| graphite | 20°C to 2400°C |

Container made of fused silica, AL2O3, sapphire, and graphite for the measurement of pastes, liquids, etc. A special evaluation software corrects the volume difference between the container and the sample as well as the dead volume.

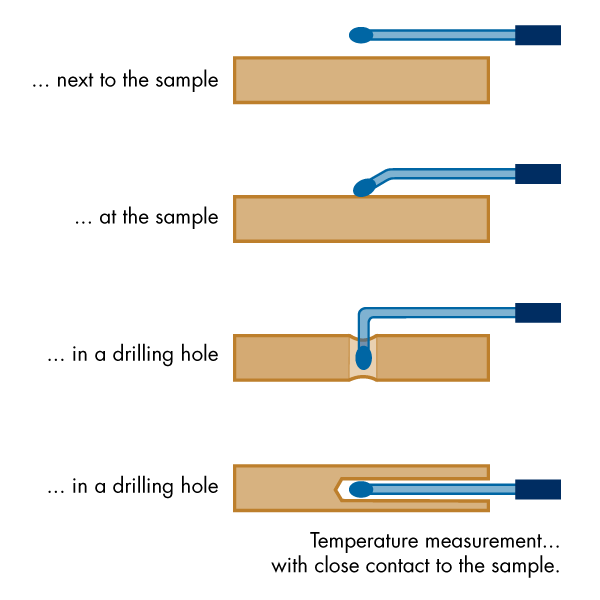

The exact measurement of temperature is critical to any dilatometric experiment. The thermocouple must be in close proximity to the sample and must be located at a representative place. However, metallic contact must be avoided, as thermocouple elements may alloy with many metals and diffuse into the test specimen. TA Instruments dilatometers utilize high quality thermocouples appropriate to the temperature range of interest and offer flexibility in thermocouple positioning to allow the most accurate measurement for each experiment.

Thermocouples and Pyrometers

| Fe-CuNi (type J) | -200°C to 900°C |

| NiCr-Ni (type K) | -200°C to 1100°C |

| PtRh10-Pt (type S) | 20°C to 1500°C |

| PtRh30-PtRh6 (type B) | 120°C to 1750°C |

| WRe26-WRe5 (type C) | 20°C to 2050°C |

| two-color pyrometer | 900°C to 2400°C |

| spectral pyrometer | 350°C to 2000°C |