View ElectroForce Applications Request a Quote

Mechanical testing includes a wide variety of testing techniques that aim to either characterize a material’s mechanical properties or determine a structure’s response to a specific force. Mechanical testing is a standard and crucial part of the design and manufacture of any product. From medical implants to airplane wings, all materials can be verified as safe and efficient for their application through mechanical testing.

Common mechanical test techniques include:

- Fatigue

- Dynamic Mechanical Characterization (DMA)

- Tension/Compression

- Bending

- Multi-axial

- Torsion

- Shear

- Creep

- Stress Relaxation

- Pulsatile

- Failure Testing

- Accelerated Life Testing

Material designers and product manufacturers frequently use these techniques in tandem, and therefore need versatile instruments uniquely suited to their specific tests. Mechanical testing instruments come in various shapes, sizes, and capability ranges.

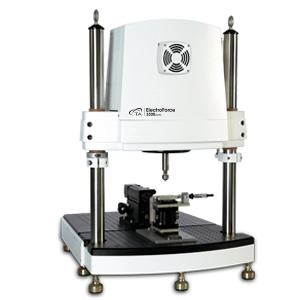

TA Instruments ElectroForce offers a complete line of mechanical test instruments to match any testing need from early material selection to final product evaluation. ElectroForce load frames, test benches, high force DMAs, fatigue, and cardiovascular instruments are globally recognized as industry leaders in mechanical testing. Our patented frictionless ElectroForce motor technology is uniquely designed for ultra-durable and high-precision testing. ElectroForce instruments meet ASTM standards and offer exceptional force capacity, speed, precision, and accuracy. When you choose ElectroForce, you choose world leading instrumentation and a team of experts to engineer a tailored test solution for your needs.