Overview

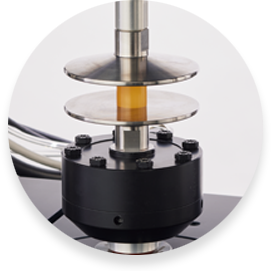

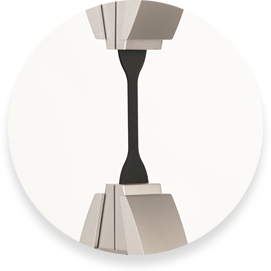

TA Instruments ElectroForce titanium tension/compression fatigue grips are low-mass grips that can be used in a variety of applications including engineered materials, biomaterials, and tissue testing.

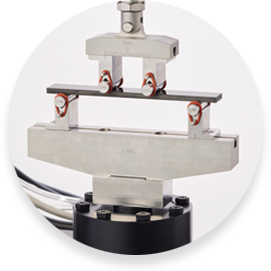

In this mode, the sample is clamped at the top and bottom and placed in tension or tested ‘through zero’ for fatigue loading with reversing stress. Multiple tension clamps are available including a self-aligning and versatile wedge grip and a submersible vise grip with changeable faces.

Key Features

- Titanium construction

- Can be used in both submersible and non-submersible applications

- Corrosion resistant design

- 10-32 UNF mounting thread

- 450 N force capacity

- Total estimated weight: 79 grams each

- Clamp design with hex drive nuts for locking

- Interchangeable grip faces

- Knurled flat, V-cut grip faces available

- For use on a variety of ElectroForce test systems

- Operating range: -150 °C to 350 °C