View TestBench & Planar Biaxial Test Brochure ElectroForce Accessories Request a Quote

TestBench instruments are used to perform tests similar to Load Frames since they also reveal important stiffness, strength, and durability characteristics of test samples, often pushing samples to failure to determine yield strength, ultimate strength and fatigue life. Test samples range from materials to subcomponents to complete components/products. Loading is applied by linear motors with a variety of loading profiles. These profiles can be a single push or pull-to-failure such as a classic ‘tensile test’, repetitive loading for fatigue, or creep/stress-relaxation measurements. Environmental effects can be evaluated by testing in fluid submersion. Occasionally, more complex modes such as axial-torsion or planar biaxial loading are used to characterize samples in various states of stress and strain, including evaluating material anisotropy.

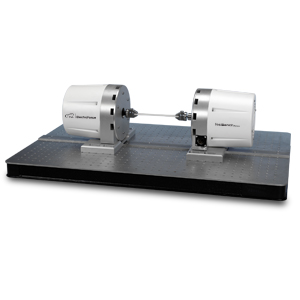

A versatile breadboard-based instrument such as the TestBench series offers a highly configurable, flexible, and open test space to accommodate a range of sample sizes and geometries. It leverages one or more linear motors as the primary loading mechanism(s), and force and displacement sensors for measuring the sample’s mechanical response. These can be flexibility oriented in virtually any position on a breadboard baseplate to act on one sample in multiple directions, or to load multiple specimens independently but side-by-side. The components are integrated to a test controller and software user interface which allows users to program a variety of tests, ranging from a simple ramp-to-failure, fatigue sine waves, and complex real-world simulation profiles.

The ElectroForce TestBench and Planar Biaxial instruments feature 200 N or 400N electrodynamic linear motors, combining rare-earth magnets and specifically designed electromagnetic topologies that are optimized for material testing and deliver best-in-class displacements and force over a wide range of frequencies. Operating without contact bearings, these motors provide friction-free linear guidance that delivers the ultimate in reliability backed by a 10-year motor warranty and precise control that is only possible with a no-friction motor design. The TestBench series is available in multiple configurations for maximum versatility and enables users to reposition the components based on a specific test need.

Common Testing Standards

- ISO 1099 – Metallic materials — Fatigue testing — Axial force-controlled method

- ISO 6475 – Implants for Surgery: Metallic Bone Screws

- ISO 6892 – Metallic materials — Tensile testing

- ISO 14801 – Dentistry — Implants — Dynamic loading test for endosseous dental implants

- ASTM D4482 – Test Method for Rubber Property—Extension Cycling Fatigue

- ASTM F382 – Bone plate testing – Standard Specification and Test Method for Metallic Bone Plates

- ASTM F384 – Fracture fixation device testing – Standard Specifications and Test Methods for Metallic Angled Orthopedic Fracture Fixation Devices

- ASTM F543 – Standard Specification and Test Methods for Metallic Medical Bone Screws

- ASTM F564 – Bone staple testing – Standard Specification and Test Methods for Metallic Bone Staples

- ASTM F1781 – Finger component testing – Standard Specification for Elastomeric Flexible Hinge Finger Total Joint Implants

- ASTM F2118 – Standard Test Method for Constant Amplitude of Force Controlled Fatigue Testing of Acrylic Bone Cement Materials

- ASTM F3014 – Standard Test Method for Penetration Testing of Needles Used in Surgical Sutures

ElectroForce TestBench & Planar Biaxial Test Instruments

Webinars

- Coming soon!