View Thermal Analyzers Applications Request a Quote

Thermal analyzers typically measure heat flow, weight loss, dimension change, or mechanical properties as a function of temperature. Thermal Analysis is a branch of materials science that studies how changes in temperature affect a material’s properties. Thermal analysis techniques are important to a wide variety of industries, including polymers, composites, pharmaceuticals, foods, energy, petroleum, inorganic and organic chemicals, and many others. Understanding a material’s behavior under different temperatures is crucial for the successful design, processing, and end use of completed products.

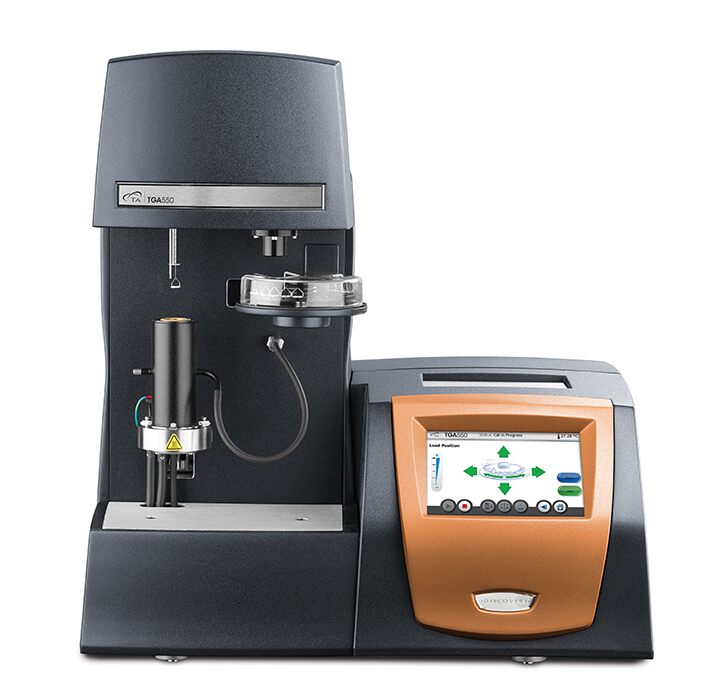

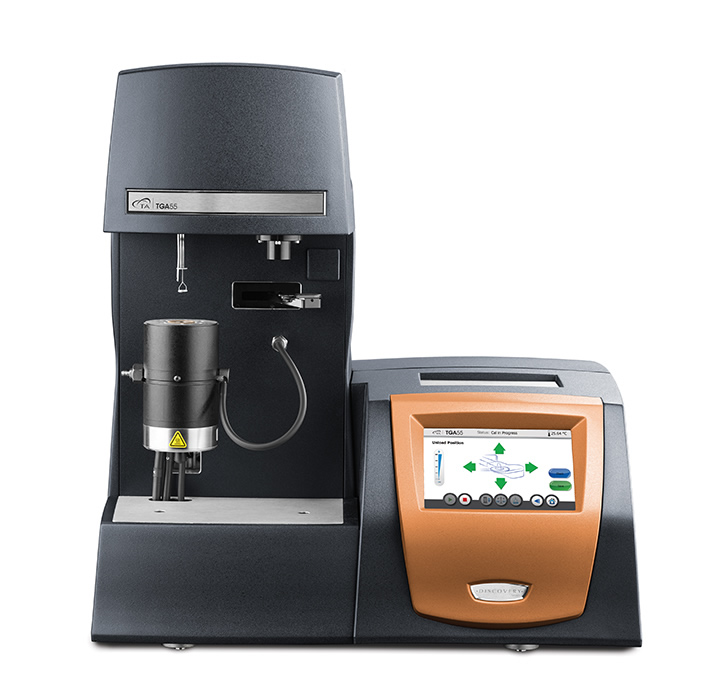

The most common thermal analyzers are Differential Scanning Calorimeters, Thermogravimetric Analyzers, Simultaneous Thermal Analyzers, High Pressure Differential Scanning Calorimeters, High Pressure Thermogravimetric Analyzers, Vapor Sorption Analyzers, Dynamic Mechanical Analyzers, and Thermomechanical Analyzers. Properties characterized include melting, crystallization, glass transitions, cross-linking, oxidation, decomposition, volatilization, hygroscopicity, coefficient of thermal expansion, and modulus. These experiments allow the user to examine structure-property relationships, end-use performance, composition, processing, stability, and molecular structure and mobility.

All TA Instruments thermal analysis instruments are manufactured to exacting standards and with the latest technology and processes for the most accurate, reliable, and reproducible data available. Multiple models are available based on testing needs, including configurations suitable for high sensitivity R&D as well as high throughput quality assurance. Available automation allows for maximum unattended laboratory productivity in all test environments. As the world leader in Thermal Analysis for over 50 years, TA Instruments brings technical expertise in thermal analysis measurements and provides a world-renowned global support network that is specialized in thermal analysis.