Controlled Sample Heating Rate

In Hi-Res TGA, the heating rate is controlled by the decomposition rate of the sample. The Discovery TGA 5500 and 550 designs are ideal for these measurements with rapid response furnaces for precise temperature control, and sensitive thermobalances designed to quickly detect small weight changes.

Benefits of Hi-Res TGA include:

- Separation of broad and overlapping weight losses

- Increased productivity with better resolution

- Rapid survey over wide temperature range with excellent resolution

- Simple method set up

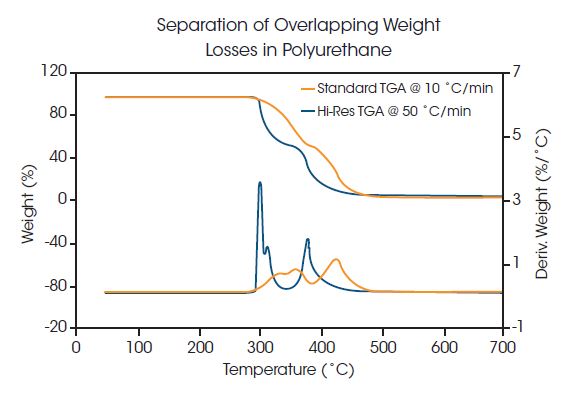

The figure to the right shows the Hi-Res TGA results for a polyurethane material by standard and Hi-Res TGA. The superior resolution provided by the Hi-Res technique is clearly evident in both the TGA weight loss and the first derivative (DTG) signals. The latter signal is especially useful in defining the onset and the end-set of the individual weight loss segments, as well as indicating subtle events that provide a “fingerprint” of the sample.

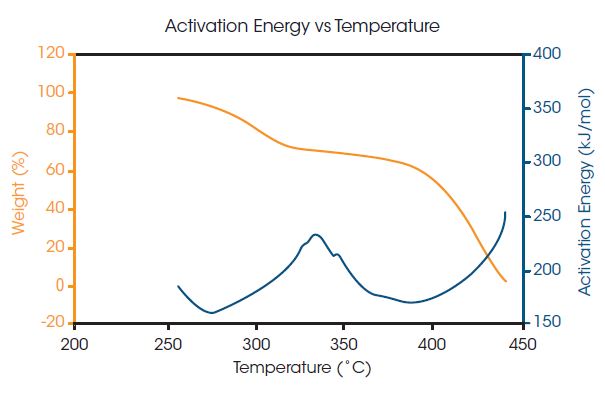

Produce Model-Free Kinetic Data

TA’s patented MTGA* is another TA Instruments innovation that offers advantages for material decomposition studies. Developed from the proprietary heater control technology utilized by Hi-Res TGA and MDSC, MTGA produces model-free kinetic data. Activation energy can be calculated real-time and studied as a function of time, temperature, and conversion.

Benefits of MTGA include:

- Increased productivity for studying kinetics

- Model-free kinetic data

- Can be combined with Hi-Res for better separation of overlapping weight losses

- Direct measurement of activation energy

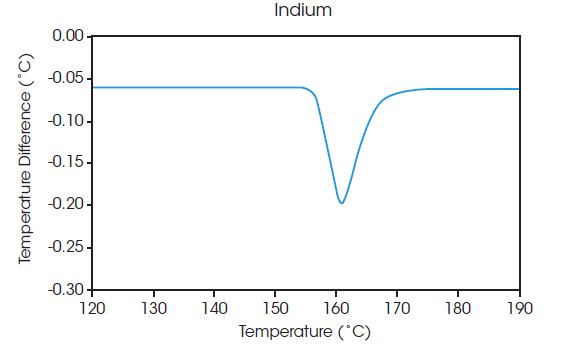

Qualitative Measurement of Endothermic and Exothermic Reactions

The DTA signal is a qualitative measurement of endothermic and exothermic reactions occurring in the TGA. This signal can also be used for temperature calibration by using melting point standards.