Sealed for Accuracy, Delivered with Precision

The TGA Smart-Seal Pan from TA Instruments was developed to enable thermogravimetric analysis (TGA) of atmosphere-sensitive samples without the need to install the TGA instrument in a glovebox.

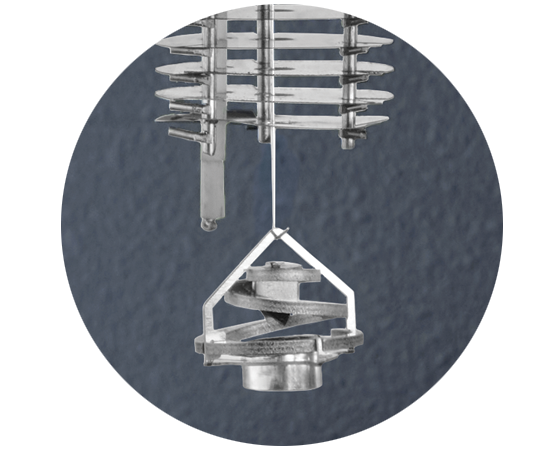

The new pans offer a hermetic seal that protects the samples from contamination. The pan seal is automatically opened in the closed TGA furnace, ensuring inert conditions throughout the process. A temperature-activated actuator made of a nitinol shape memory alloy operates a cutter at 55 °C opening the pan seal.

The innovative TGA Smart-Seal Pan simplifies sample handling and reduces costs compared to installing the TGA in a glovebox.

Description

The innovative TGA Smart-Seal Pan from TA Instruments is an effective and user-friendly solution for analyzing atmosphere-sensitive sample materials in a standard thermogravimetric analyzer. Thermogravimetric Analysis (TGA) measures the mass change of a material as it is exposed to controlled temperature changes, providing scientists insights into thermal stability, composition, and decomposition characteristics.

In applications with advanced materials such as batteries and pharmaceuticals, researchers work with samples that are sensitive to atmospheric conditions. Traditionally, this has been solved by preparing the materials in pans sealed with a lid which is pierced open shortly before loading into the TGA. However, newer performance materials are often extremely atmosphere sensitive. Even the brief atmosphere contact between opening the pan seal and loading into the TGA furnace will affect the data quality or pose a risk to the user. Up to this time, a common way to analyze such materials has been to install the TGA in a glove box. This is an expensive and space-consuming solution that goes along with significant disadvantages for the usability and serviceability of the TGA.

The new TGA Smart-Seal Pan from TA Instruments offers an innovative solution for TGA analysis of highly sensitive samples without installing the TGA instrument in a glove box. The hermetically sealed pans help ensure inert sample handling by maintaining a controlled environment throughout the sample loading into a Discovery TGA instrument. The TGA Smart-Seal Pan opens automatically inside the closed and purged TGA furnace once the temperature reaches approximately 55°C. TGA Smart-Seal Pans offer uncompromising TGA data quality while simplifying operation and reducing costs compared to installing the TGA in a glove box.

Features and Benefits:

- Enhanced Sample Protection: The hermetic seal protects sensitive samples from atmospheric contamination.

- Cost Efficiency: Significant cost and space savings compared to glovebox installation of TGA.

- Ease of Use: Straightforward sample encapsulation and handling comparable to standard TGA test.

- Evolved Gas Analysis – EGA: Standard EGA connection without the complex gas sampling setups often used for glovebox installed TGAs, enabling easy analysis of decomposition gases.

Technology

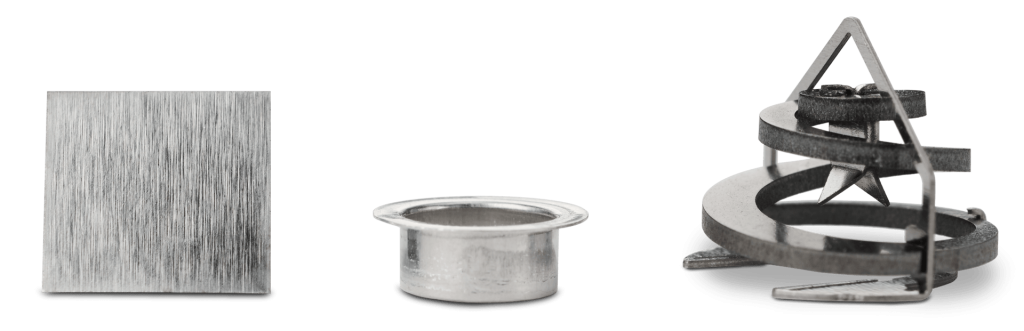

The TGA Smart-Seal Pan consists of an aluminum TGA sample pan, an aluminum foil lid, and a bail assembly with temperature-activated cutter which can be used for TGA analysis up to 600 °C with atmosphere sensitive samples. The sample is filled into the sample pan under a protective atmosphere, usually in a glovebox. The pan is sealed with an aluminum foil lid. This sealing helps ensure protection of the sample from the atmosphere during the subsequent transfer to the TGA installed under normal ambient conditions.

After the sealed TGA Smart-Seal Pan has been loaded from the autosampler to the TGA, the furnace is closed and purged with inert gas. Once purged, the heating program of the TGA begins. The innovation of the TGA Smart-Seal Pan is its autonomous, temperature-activated opening mechanism. In the bail assembly, a shape memory alloy activates the cutter around 55 °C, which opens the aluminum foil on the crucible. This opens the seal of the pan automatically without user interaction in the closed and purged TGA furnace and the TGA analysis can be carried out as usual.

Application

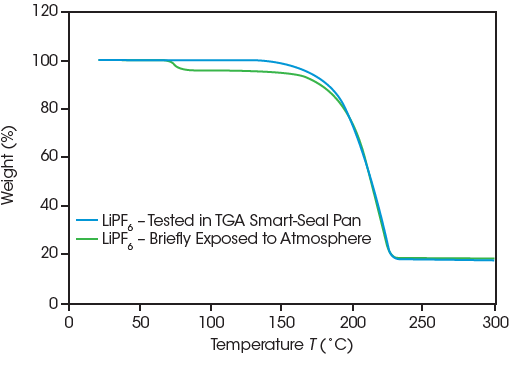

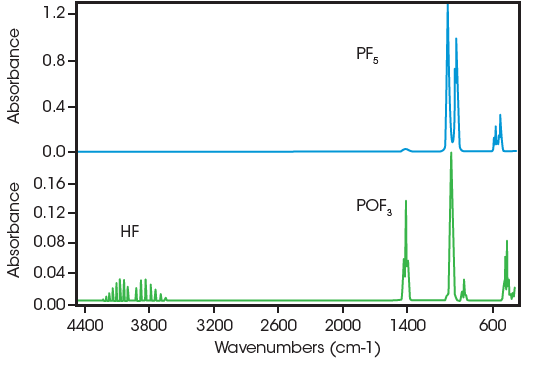

Lithium hexafluorophosphate (LiPF6) is a highly water sensitive battery electrolyte component. Under dry conditions, the sample decomposes in a single step to phosphorous pentafluoride (PF5) between 150 – 250 °C. Under wet conditions, it will produce hydrogen fluoride (HF) and phosphoryl fluoride (POF3). The TGA data is impacted with the appearance of a second weight loss step under 100 °C, which is associated with some HF and POF3 evolution.

The TGA data below shows a comparison between a LiPF6 sample sealed in a TGA Smart-Seal Pan in a glovebox and a LiPF6 sample exposed to water vapor in a manner similar to a typical TGA sealed pan during loading. A Discovery 5500 TGA installed in an ambient laboratory was used. No indication of weight loss was detected below 100 °C in the sample run in the TGA Smart-Seal Pan. FTIR data also shown indicate no detected POF3 evolved from the sample in the TGA Smart-Seal Pan, as opposed to the sample exposed briefly to ambient humidity. The data clearly show that the LiPF6 run in the TGA Smart-Seal Pan remained dry during the experiment’s execution.

Fig. 1: LiPF6 TGA data showing expected single weight loss step when using a TGA Smart-Seal Pan (blue) and a 2-step weight loss indicating humidity contamination for a sample only briefly exposed to atmosphere (green).

Fig. 2: FTIR analysis of evolved gas from LiPF6 TGA shows only PF5 for test with TGA Smart-Seal Pan (blue) while the sample briefly exposed to atmosphere leads to HF and POF3 decomposition products indicating humidity contamination (green).

To explore the full application, please click here.