Environmental Systems & Probes

Mechanical Cooling System

Mechanical Cooling System

Mechanical Cooling System

Take advantage of the convenient Mechanical Cooling Accessory, the MCA 70, for unattended TMA and Modulated TMATM (MTMATM) operation over a broad temperature range. The MCA 70 is ideal for cyclic heating/cooling experiments that are increasingly being used by manufacturers to test materials under conditions of actual use.

Temperature Cycle Testing (TCT) determines the ability of parts to withstand extremely low and high temperatures and cyclical exposures to these extremes. A mechanical failure resulting from cyclical thermomechanical loading is known as a fatigue, so temperature cycling primarily accelerates fatigue failures. The MCA 70 makes it easier than ever to study a materials’ response to extreme changes in temperature.

MCA 70 Features and Benefits:

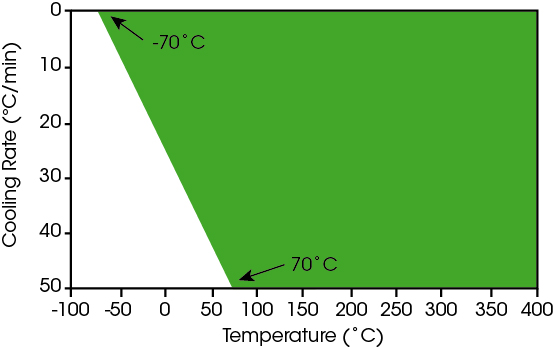

- Two-stage refrigeration system that provides a temperature range of -70°C to 400°C

- Sealed system eliminates the need for liquid nitrogen cooling

- Enables cycling, Modulated TMA, controlled, and ballistic cooling experiments

- Safe,convenient, and continuous cooling operation for your laboratory needs

|

Controlled Rate |

To Lower Temperature |

|

50℃/min |

70℃ |

|

20℃/min |

-15℃ |

|

10℃/min |

-40℃ |

|

5℃/min |

-55℃ |

|

2℃/min |

-65℃ |

* MCA 70 Controlled Cooling Rates, from 400oC (upper limit)

* Performance may vary slightly, depending on laboratory conditions

Cooling rate and temperature performance envelope of the MCA 70

* Obtained under an inert nitrogen atmosphere

* Performance may vary slightly, depending on laboratory conditions

Expansion Test Fixtures

Expansion

Expansion measurements determine a material’s coefficient of thermal expansion (CTE), glass transition temperature (Tg), and compression modulus. A flat-tipped standard expansion probe is placed on the sample (a small static force may be applied), and the sample is subjected to a temperature program. Probe movement records sample expansion or contraction. This test is used with most solid samples. The larger surface area of the macro-expansion probe facilitates analysis of soft or irregular samples, powders, and films, and the dilatometer fixture allows the determination of volumetric coefficient of thermal expansion.

Expansion |

Macro Expansion |

Volumetric |

Penetration Test Fixtures

Penetration

Penetration measurements use an extended tip probe to focus the drive force on a small area of the sample surface. This provides precise measurement of glass transition (Tg), softening, and melting behavior. It is valuable for characterizing coatings without their removal from a substrate. The probe operates like the expansion probe, but under a larger applied stress.The hemispherical probe is an alternate penetration probe for softening point measurements in solids.

Penetration |

Hemispherical |

Tension Test Fixtures

Tension

Tension

Tensile studies of the stress/strain properties of films and fibers are performed using a film/fiber probe assembly. An alignment fixture permits secure and reproducible sample positioning in the clamps.Application of a fixed force is used to generate stress/strain and modulus information.Additional measurements include shrinkage force,Tg, softening temperatures, cure, and cross-link density. Dynamic tests (e.g. Dynamic TMA, Modulated TMA™) in tension can be performed to determine viscoelastic parameters (e.g., E’, E”, tan delta), and to separate overlapping transitions.

3-Point Bending Test Fixtures

3-Point Bending

3-Point Bending

In this bending deformation (also known as flexure), the sample is supported at both ends on a two-point quartz anvil atop the stage. A fixed static force is applied vertically to the sample at its center via a wedge-shaped quartz probe. This test is considered to represent “pure” deformation, since clamping effects are eliminated. It is primarily used to determine bending properties of stiff materials (e.g., composites) and for distortion temperature measurements. Dynamic measurements are also available with the TMA 450EM, where a special low-friction metallic anvil replaces the quartz version.